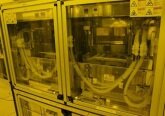

二手 DNS / DAINIPPON SK-2000 #9277248 待售

网址复制成功!

单击可缩放

ID: 9277248

晶圆大小: 8"

(4) Coater / (4) Developer systems, 8"

Resist temperature system

Resist Pump

Wafer shape: SNNF

Wafer cassette: 8" PP MIRAIAL

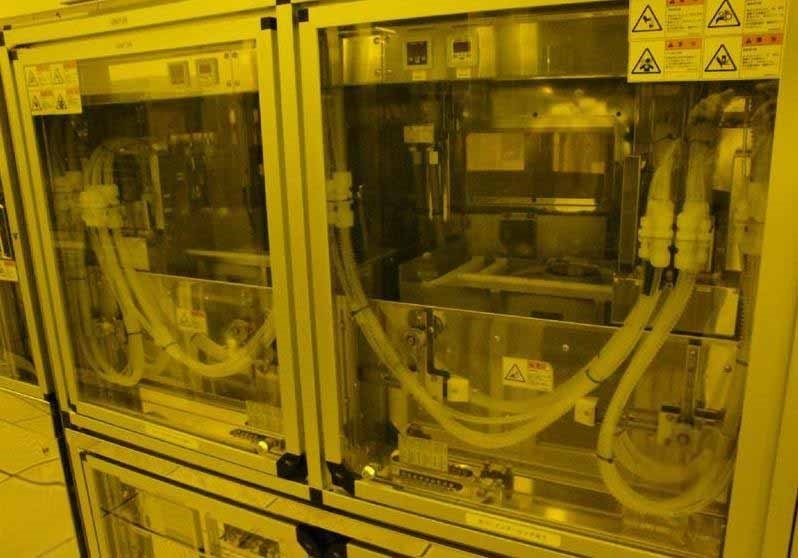

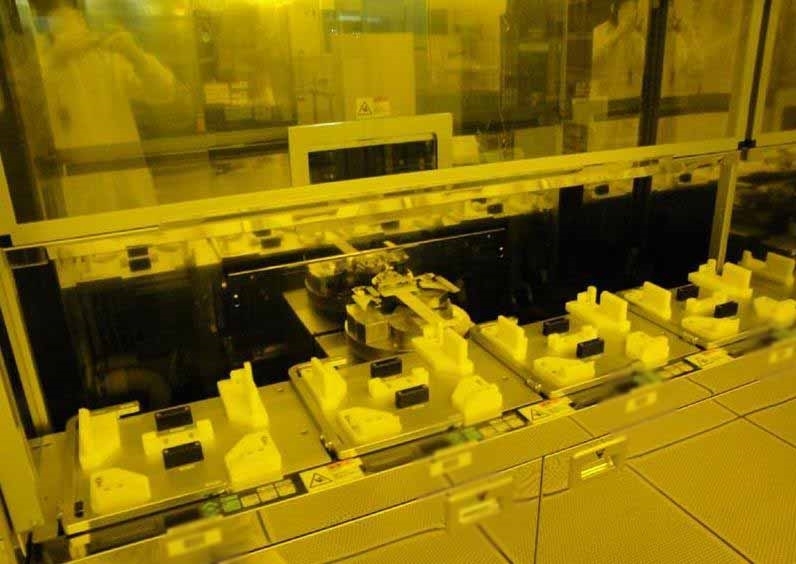

(2) Process blocks

(2) Coater heads

(2) Barc coater heads

(4) Develop heads

(2) Adhesion chambers

(10) Cooling plates

(12) Rapid hot plates

(3) Hot plates

(1) EEW

(1) EEFT

(1) IFB

(1) Source bottle cabinet

(1) Chemical box (HMDS/Solvent/NMDW)

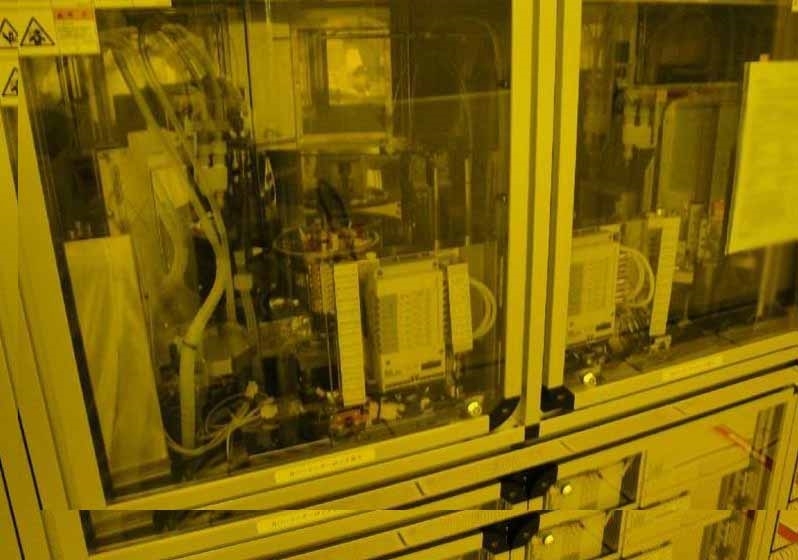

(1) Controller cabinet

(1) Power box

(1) Handling unit controller

(1) Carrier station

(6) Nozzle

Cup:

Top cup material: PP

Middle cup material: PP

Bottom cup material: PPS

Spin chuck:

Material: Peek

Back rinse flow meter with flow sensor

Mist nozzle flow meter with flow sensor

Edge cleaner flow meter with sensor

With VPS+ option

Solvent solution supply

Drain central

Barc

Nozzle slit scan nozzle

Develop solution supply Central supply

Developer Cup PVC

Spin chuck PEEK

Develop nozzle flow meter with sensor

Develop nozzle wash meter with sensor

Rinse nozzle flow meter with sensor

Back rinse flow meter with sensor

Develop temperature System

Control for 1 line x 2

Drain central

Adhesion

Method vapor prime by N2 bubbling

Hot plate 60-150 deg by 0.1 deg pitch

HMDS solution supply central supply

Hot plate

Method proximity bake with ceramic ball

Hot plate 50-180 deg by 0.1 deg pitch

Cooling plate

Rapid hot plate.

DNS/DAINIPPON SK-2000是一种数字光刻设备,它使用激光器和新颖的光学系统来提高曝光图样的准确性,并有助于确保在特征尺寸小至几百纳米的基板上精确地复制特征。DNS SK2000利用脉冲激光束,在基板上聚焦到5 um的光斑大小,安装在x-y检流计扫描仪上。脉冲宽度可在2到12n之间编程,能量可在50mJ到1J之间编程。激光安装在连接到精密x-y检流计扫描仪的垂直扫描仪上。激光和扫描仪同步,在基板上创建精确的曝光模式.然后由用户界面定义曝光模式,允许在基板上绘制曝光模式。DAINIPPON SK 2000还利用了一个专有的光学单元,它结合了曝光模式和底物的薄膜厚度。这样可以在特征尺寸小至几百纳米的基板上实现精确的曝光模式。此外,还可以针对特定基板优化曝光模式,从而提高精度和精度。除了激光和光学系统外,DNS/DAINIPPON SK 2000还配备了温度控制装置,允许在曝光过程中使用温度敏感的基板。这样可以提高暴露材料的电阻率和耐热性。DNS SK-2000除了精确度和精确度外,还提供多种可使用的曝光模式。它设计用于各种工艺,包括光刻、沉积技术,如化学气相沉积和干蚀刻。其广泛的曝光模式允许提高吞吐量和缩短处理时间。DNS SK 2000是一款先进的光刻机。它利用了几种独特的功能,包括脉冲激光、先进的光学工具、精密扫描仪和温度控制单元。这些特性能够精确和精确地再现基板上的曝光模式,其特性尺寸小至几百纳米。此外,它提供的各种曝光模式可提高吞吐量和缩短处理时间。这使得DNS/DAINIPPON SK2000光刻、沉积技术和干蚀刻等广泛应用的理想选择。

还没有评论