二手 DAGE 2400 PC #58694 待售

网址复制成功!

单击可缩放

ID: 58694

Shear / Pull Tester

Power Requirements: 110-120 VAC @ 5 A, 220-240 VAC @ 3.15 A

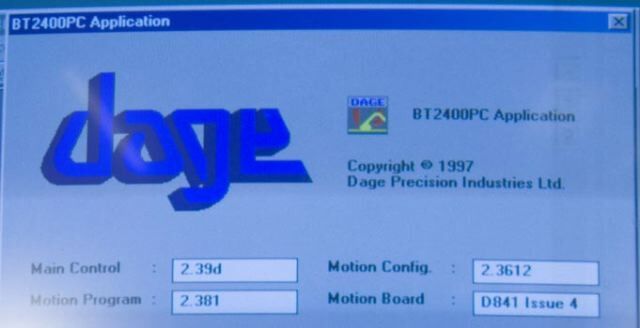

Dage BT2400PC Application 1997

Windows 98

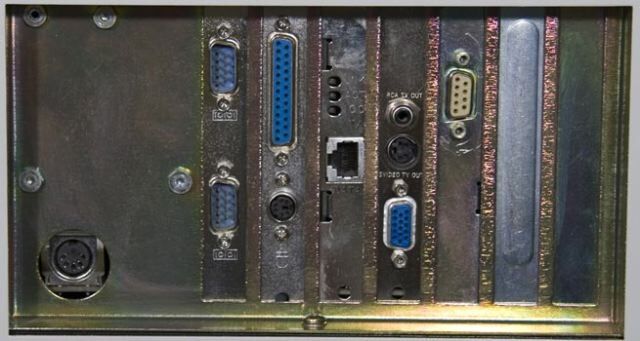

Fully configured tower style machine control computer

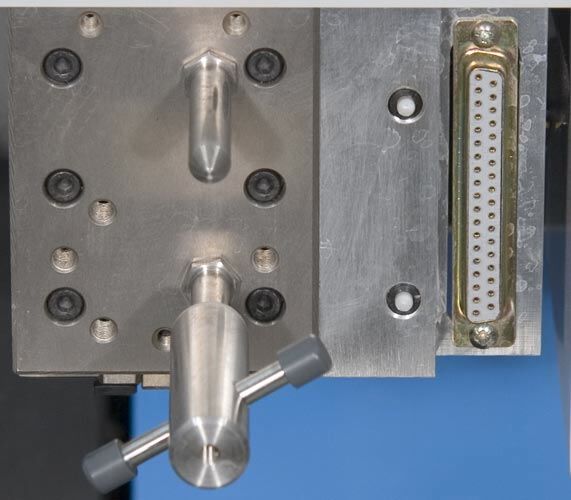

Supplied with a manually adjustable X-axis table.

This unit is a multi-function, semi-automatic test facility, offering extremely versatile destructive and non-destructive testing (NDT) or ball-bonds, and wire pull

Features:

Pentium motherboard installed versus standard EPROM board configuration

Windows 95 software interfaced to system hardware by motion control card

PC Monitor used versus typical LED-type display

Automatic Calibration and Linearity Checks

Advanced Load Cartridge Design

Mouse-driven operation for machine set-up, control and analysis operations

Floppy and hard drives include for introduction and storage of test configurations and results

Comprehensive range of analysis screens and test result files allow data analysis directly on the PC2400T. Information can be printed using standard Windows print options.

Results are automatically stored on the hard disk in CSV text file format and can be exported to floppy disk, RS232 port or directly to a factory mainframe via a network.

Quick release design ensures that change-over time between test functions is minimized

Applications include:

Ball shear

Aluminum wedge shear

Low force die shear

The system caters for these types of bond test using up to 5 kg force

Die shear using up to 100 kg force

Wire-pull testing using up to 10 kg force

Software/Configuration Versions:

Main Control: 2.39d

Motion Config: 2.3612

Motion Program: 2.381

Motion Board: D841 Issue 4

Cartridge included (Choice of one):

Model Number: 2400PC-BS5KG Ball Shear Cartridge for 5k grams

Model Number: 2400PC-WP100 Wire-Pull Cartridge for 100 grams

Specifications:

Z Axis Travel: 2.87"

Work Holder:

X Axis Travel: 1.0" manual adjustment, 0.9" motorized adjustment

Y Axis Travel: 0.9"

Maximum Test Force:

Z Axis: 10 kg

Y Axis: 100 kg

Minimum Detectable Load (From Software Version 2.20):

5% of currently selected test load range

(For destructive testing - 5% of the threshold parameter slider setting)

Work Area (Swing Round Tool): 8.5" minimum

Keypad: 4 x 4 matrix

Joystick: Self centering

Illumination: 20W Halogen lamp

Vacuum Base: 20" Hg minimum (supply to machine)

Sound Level:

Continuous A-weighted sound pressure at the workstation < 70 dB(A)

Die Shear Testing Specifications:

Measurement Accuracy: +/-0.5% of load cell rating

Test Mode: Destructive or Non-Destructive

Shear Mode: Automatic

Shear Direction: Y axis, front to back

Shear Tool (Standard): Tungsten carbide

Landing Speed (Programmable): 0 to 0.039" / s

Landing Force: 3g to 10g (depending on landing speed)

Shear Height:

Range: 0 to 0.019"

Resolution: 0.00025 mm

Accuracy (At Start of Test): +/-0.00025 mm

Accuracy (Though Test): +/-0.0005 mm

Shear Speed (Programmable Range): Cartridge dependent

Y Axis Travel During Shear Test: Cartridge dependent

Ball Shear Testing Specifications:

Measurement Accuracy: ±0.5% of load cell rating

Test Mode: Destructive or Non-Destructive

Shear Mode: Automatic

Shear Direction: Y axis, front to back

Shear Tool (Standard): Tungsten carbide

Landing Speed (Programmable): 0 to 0.039" / s

Landing Force: 3g to 10g (depending on landing speed)

Shear Height:

Range: 0 to 0.5 mm (0.019")

Resolution: 0.001 mm

Accuracy (At Start of Test): ±0.00025 mm

Accuracy (Through Test): ±0.0005 mm

Shear Speed (Programmable Range): Cartridge dependent

Y Axis Travel During Shear Test: Cartridge dependent

Pull Testing Specifications:

Measurement Accuracy: ±0.5% of load cell rating

Test Mode: Destructive or Non-Destructive

Pull Mode: Manual, Step back, or Autohook

Pull Direction: Z axis, vertical

Z Axis Stroke: 73 mm

Pull Tool (Standard): Hook or tweezer

Pull Speed (Programmable):

Range (up to 1kg rating): up to 5.0 mm/s

NDT Overshoot: 0.5% FSD.

DAGE 2400 PC是一种在半导体工业中广泛使用的精密球楔接合器。它能够进行精细的螺距和金属丝楔形粘结,以及精确的热压焊接。该设备能够生产各种粘结尺寸,最大导线尺寸为0.0025英寸(25 μ米)。它与铜和金键线兼容,允许使用任一材料。系统的电子设置可以轻松调整,允许用户自定义键合时间和电流设置等参数。DAGE 2400PC还配备了Anti-Tilt Unit,以减少在粘合过程中导线失真的机会。这台机器是为各种基材而设计的.它配备了接触位置传感器,以确保在线键过程中元件的最佳对准。为进一步提高精度,该工具配备了CCD摄像头,可用于精确测量粘结并检查其可靠性和质量。对于运营商来说,2400 PC功能主要通过触摸屏显示。这允许用户轻松访问各种选项,包括调整程序设置、查看绑定参数和有关组件的信息以及操作绑定器。2400PC还包括一个警报资产,它可以在发生绑定错误时向用户发出警报。这样就可以采取纠正措施,防止进一步中断操作。还包括自动卡盘模型,该模型可自动提取、定位和弹出元件。这样可以缩短循环时间,提高粘合器的整体输出。DAGE 2400 PC是一款可靠、通用、精确的粘合器。它可以用于各种各样的任务,并且能够产生可靠和一致的结果。其易用性和定制设置的能力使其成为半导体生产的绝佳选择。

还没有评论