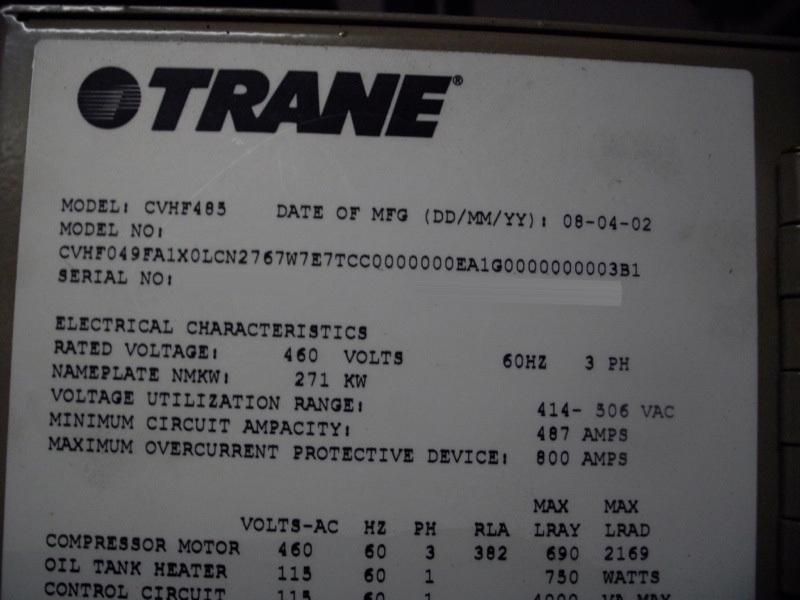

二手 TRANE CVHF049FA1X0LCN2767W7E7TCC0000000EA1G0000000003B1 #9014869 待售

网址复制成功!

单击可缩放

ID: 9014869

优质的: 2002

Chiller, 485 ton

42,955 hrs

Chiller:

Chiller heating or cooling mode cooling

Active chilled water setpoint: 42.0°F

Active chilled water setpoint source: front panel

Active current limit setpoint: 100.0% RLA

Active current limit setpoint source: front panel

Evaporator entering water temperature: 47.8°F

Evaporator leaving water temperature: 41.6°F

Evaporator pump control: on

Evaporator water flow switch status (unfiltered): flow

Chiller control signal target: 46.3%

Condenser entering water temperature: 74.2°F

Condenser leaving water temperature: 82.8°F

Condenser pump control: on

Condenser water flow switch status: flow

Chilled water softload target: 42.0°F

Current limit softload target: 100.0%

Event max: 125

Timer max: 60

Circuit:

Evaporator saturated refrigerant temperature: 40.9°F

Evaporator refrigerant pressure: -8.8 psi gauge

Evaporator approach temperature: 0.7°F

Condenser saturated refrigerant temperature: 83.0°F

Condenser refrigerant pressure: 0.0 psi gauge

Condenser approach temperature: 0.3°F

High pressure cutout circuit on

Head relief request relay: off

Maximum capacity relay: off

Compressor:

Compressor refrigerant discharge temperature: 83.1°F

Oil tank pressure: -9.1 psi gauge

Oil pump discharge pressure: 11.4 psi gauge

Oil differential pressure: 20.3 psid

Oil tank temperature: 110.3°F

Oil pump command: on

Oil heater command: on

Inboard bearing temperature: 108.4°F

Outboard bearing temperature: 95.6°F

Inlet guide vane position first stage: 26.9%

Inlet guide vane position first stage: 13,685 steps

Motor:

Restart Inhibit Time (MP): 0:00 mins:secs

Starter Current L1 %RLA: 56.5 % RLA

Starter Current L2 %RLA: 57.5 % RLA

Starter Current L3 %RLA: 57.3 % RLA

Starter Current L1 Amps: 215.0 amps

Starter Current L2 Amps: 220.0 amps

Starter Current L3 Amps: 219.0 amps

Starter Voltage Phase AB: 480 volts

Starter Voltage Phase BC: 481 volts

Starter Voltage Phase CA: 479 volts

Average Line Current: 57.1 % RLA

Average Line Current: 218.0 amps

Starter Max Current: 55.9 % RLA

Starter Average Phase Voltage: 480 volts

Starter Load Power Factor: 0.81

Starter Power Consumption: 135 kW

Starter Power Demand: 62 kW

Starter Energy Consumption - Resettable: 3,673,414 kWh

Starter Energy Consumption Last Reset December 31, 1979 12:00:00 AM

Starter Energy Consumption - Non Resettable: 3,673,414 kWh

AFD Output Power: 125 kW

AFD DC Bus Voltage: 646 volts

Motor Winding Temperature #1: 92.9 °F

Motor Winding Temperature #2: 92.9 °F

Motor Winding Temperature #3: 92.4 °F

AFD Transistor Temperature: 112.3 °F

Speed: 3,399 rpm

Frequency: 57.0 Hz

Frequency Command: 57.0 Hz

Boundary Pressure Coefficient: 0.57

Pressure Coefficient: 0.58

Re-optimization Time Remaining: 00:00 hrs:mins

AFD Last Diagnostic Code (decimal): 0

Purge:

Time Until Next Purge Run: 0:00 mins:secs

Daily Pumpout-24 Hours: 1:16 mins:secs

Average Daily Pumpout-7 Days: 1:03 mins:secs

Chiller On-7 Days: 6.3 %

Pumpout Chiller On-7 Days: 6.7 %

Pumpout Chiller Off-7 Days: 93.3 %

Refrigeration-Life: 41630:56 hrs:mins

Pumpout-Life: 16788:30 mins:secs

Purge Refrigerant Compressor Suction Temp: 80.6 °F

Purge Carbon Tank Temp: 74.3 °F

Purge Liquid Temperature: 83.0 °F

Pumpout Time Since Last Regeneration: 78:50 mins:secs

Time at Last Regeneration: March 14, 2011 1:52:00 PM

Pumpout Total at Last Regeneration: 16709:40 mins:secs

Absorptive Capacity: 84.2 %

Carbon Regen Cycles: 67

2002 vintage.

TRANE CVHF049FA1X0LCN2767W7E7TCC0000000EA1G0000000003B1冷却器是一种工业级空调设备,专为商业级应用而设计.它是为任何类型的商业设置量身定制的高效可变空气量(VAV)系统,包括办公室、零售商店、餐厅、学校、仓库和许多其他工业设置。它是利用最新技术实现节能减排的节能空调解决方桉。这种冷却器的主要部件是压缩机、冷凝器、蒸发器、膨胀阀和风扇马达。压缩机是一个单一的螺丝设计,允许一个一致和可靠的输出制冷剂气体蒸发器。冷凝器的设计目的是从返回的制冷剂中提取热量,使其能够向下冷却,从而为调节的空间提供必要的冷却。蒸发器线圈是多行线圈设计,允许更有效地将热量传递到循环空气中,并允许空气冷却到所需温度。膨胀阀有助于输送制冷剂气体和保持机器上的恒定压力。最后风扇马达进一步帮助循环冷却空气在整个空间。这款TRANE冷却器还可以设置各种控制器和配件,以实现最大效率和用户舒适度。SSCP控制器可用于通过对工具进行智能监控、提供诊断信息和数据记录来实现高效操作。许多附件如变频驱动器、节能器和其他设备也可以连接到资产,以确保最佳性能。所有这些组件都经过设计和编程,能够完美和谐地工作,提供更高的舒适度和更低的能源成本。CVHF049FA1X0LCN2767W7E7TCC0000000EA1G0000000003B1冷却器在商用HVAC环境中具有广泛的优势。它们不仅极其可靠高效,还会因为精确的温度控制而降低能源成本,减少排放,提供更安全的工作环境。VAV模型还允许在每个区域进行独立的温度控制,让每个用户在自己的空间中享受到完美的温度。方便的安装和维护使其成为任何商业场所的理想空调解决方桉。

还没有评论