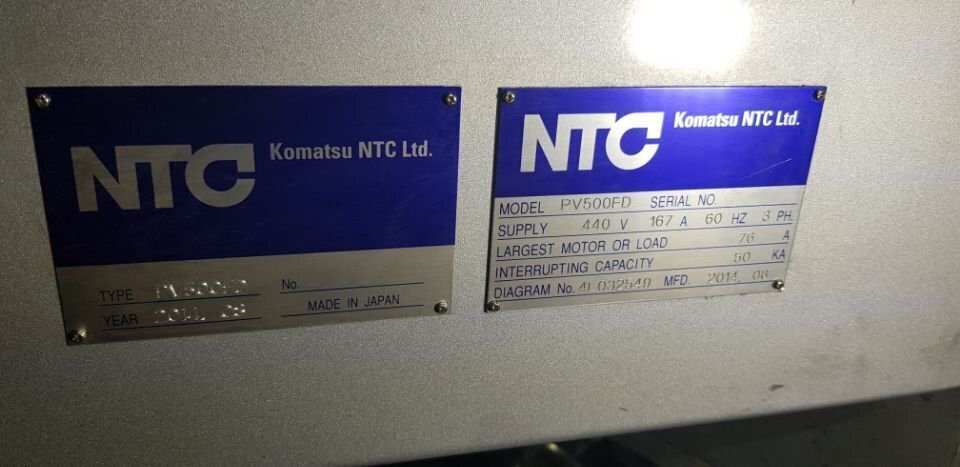

二手 NTC / KOMATSU PV500FD #9216984 待售

网址复制成功!

单击可缩放

ID: 9216984

优质的: 2014

Diamond wire saw

Wire running method:

Coolant (Diamond wire): Acceleration / Deceleration 3 sec, (2) cycles/min

Slurry:

Two way / One way (Wire speed: 900 m/min / Slower)

One-way (Wire speed: Faster than 900 m/min)

Acceleration / Deceleration: 3 sec, (2) cycles/min

Wire speed (Maximum):

1200 m/min Coolant (Diamond wire)

1000 m/min (Slurry)

Cutting method (Feed): Downward cut

Cutting feed speed (Feed): 0.1 - 2.5 mm/min

Rapid feed / Rapid return speed (Feed): 50 - 500 mm/min

Wire storage capacity: 100 km

Core wire diameter: Φ 0.12 mm

Abrasive grain diameter: 10/20 µm

Wire diameter: Φ 0.15 mm

Wire tension: 25 N

Noise level: 80 dB (A) / Less

Compressed air (Dry air):

Air pressure: 0.4 - 0.6 MPa

Air capacity: 600 NL/min

Pipe size: Rc1/2 / Greater

Cooling water:

Cooling water temperature: 11 ± 1°C

Cooling water pressure: 0.35 - 0.40 MPa

Cooling water flow rate:

250 L/min (Supply to heat exchanger)

10 L/min (Cooling main spindles)

Cutting fluid:

Slurry:

Use slurry: 170 mPas / Below

SC1000 (Viscosity 100 - 150 mPa.s)

Coolant (Diamond wire):

Stock solution

Water-dilution: SUNDASH Series (Nicca chemical)

Mist exhaust: Recommended exhaust capacity 3 - 5 m³/min

Piping and primary power cable inlet: Overhead

Automatic coolant change unit:

Supply: 40 A

Discharge: 40 A

Feed unit:

Stroke: 355 mm

Cutting feed speed: 0.1 - 2.5 mm/min

Rapid feed speed: 50 - 500 mm/min

Motor output:

0.75 kW With brake (AC Servomotor)

With 1-25 reduction gear

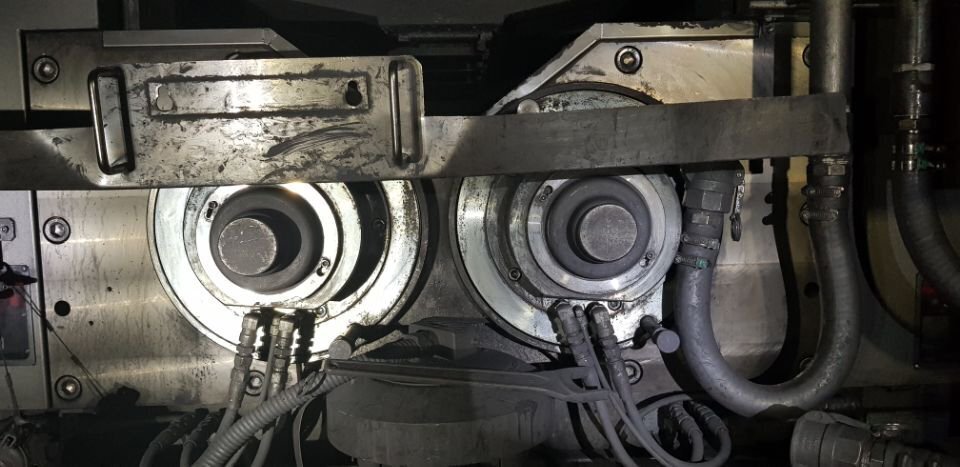

Main roller:

Groove outer diameter (Usable range): Φ240 - Φ230

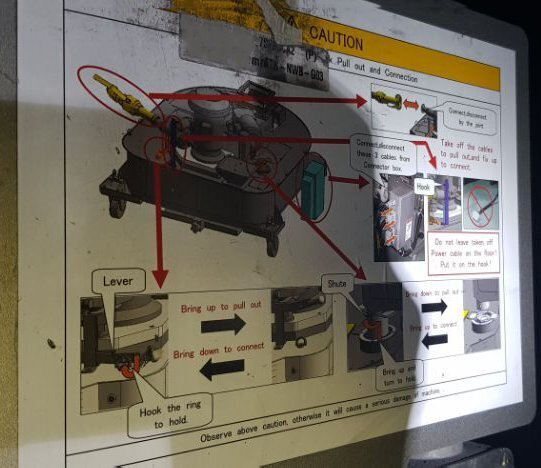

(2) Main spindlers:

Motor output: 60 kW (AC Servomotor)

Rated motor torque: 500 Nm

(2) Reel spindlers / Traverse:

Motor output: 16 kW (AC Servomotor)

(2) Dancer rollers:

Wire tension: 10 to 25 N

Motor output: 5.5 kW With brake (AC Servomotor)

(6) Guide rollers:

Roller groove diameter: 100 mm

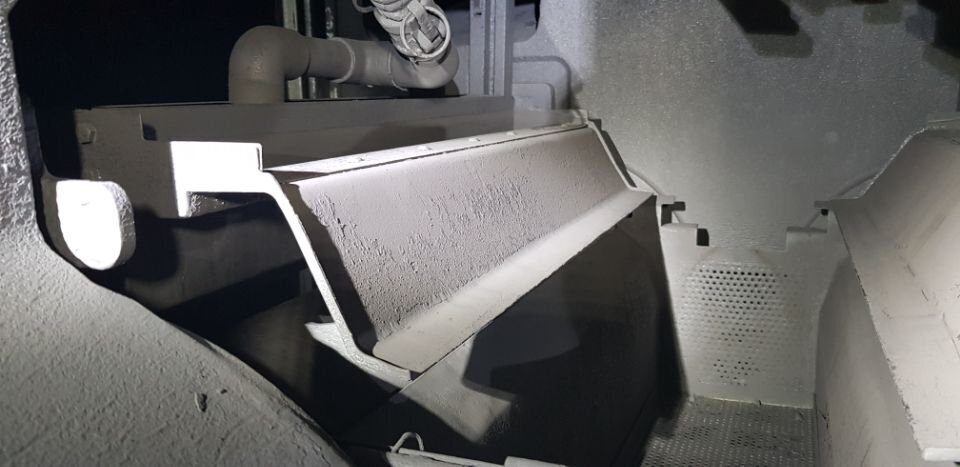

Coolant tank unit:

Tank capacity: 400 L

Coolant supply pump output: 7.5 kW

Agitator motor: 0.75 kW

Fluid level detection: Float type

Heat exchanger:

Method: Cooling water control, (2) paths

Heat exchanger duty: 90 kW (77400 k cal)

Lubrication:

Grease:

Main spindles

Reel spindles

Feed ball screw

Traverses

Hydraulic unit: Tank capacity 1.4 L

Control power source: 100 VAC, 24 VDC

Electric power capacity:

Machine: 74 kVA (Maximum: 125 kVA)

Primary power source: 380 VAC, 50 Hz / 440 VAC, 60 Hz, 3-Phase, 3-Wire

Voltage fluctuation: ±10%

Frequency fluctuation: ±1 Hz

2014 vintage.

NTC/KOMATSU PV500FD是一种综合性晶体生长、锯切和切片设备,专为高效生产材料而设计,包括集成电路的硅。它配备了脉冲加热化学气相沉积(CVD)合成系统、高精度线锯切片单元等先进部件。这使得它非常适合在各种材料、应用和规格中进行高质量的散装晶体生长。CVD合成机包括一个高温脉冲加热的感应炉,容量可达250毫米。它能够达到高达2000 °C的高温。也可用于复合半导体生长和金刚石膜的化学气相沉积。该炉具有自动倾斜和从属系统的特点,可精确设置和提高温度均匀性。高精度金刚石线锯切片工具用于单晶切片。它配备了变速直驱伺服电机、自动进给和跟踪速度控制。其分体式切割序列和自动切片选项提高了收率。刚性结构的倒车线锯最多可装载六个插槽,也可用于多次锯切操作。NTC PV500FD能够使用精密金刚石刀片执行多级切片。切片功能具有调整刀片尺寸、切削速度、切削方向和切片轮廓的能力。它还能够存储多达50种不同的切片食谱。KOMATSU PV500FD资产还配备了机器人操作的多箱,在切片后进行分类和分类的模型。设备可以根据用户的要求进行定制,并可以连续或批量模式操作。该系统旨在最大限度地减少功耗并降低成本。它具有供暖机节能回收回火装置和提高能效的主动温度控制功能。它还包括用于检测工具中异常状况的监视器。PV500FD是高效生产各种应用所需材料(包括集成电路用硅)的综合资产。配备脉冲加热CVD合成模型、高精度金刚石线锯切片设备、切割切片机器人、切片后分选件的多箱分选系统。该设备设计为以最高效率运行,以最大程度地减少功耗并降低成本。

还没有评论