二手 ESC 9200 #39586 待售

网址复制成功!

单击可缩放

ID: 39586

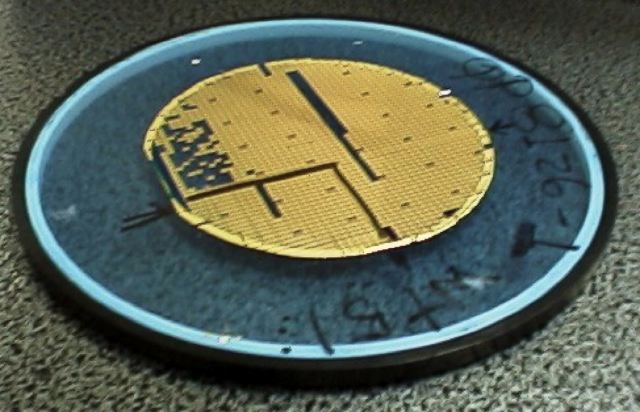

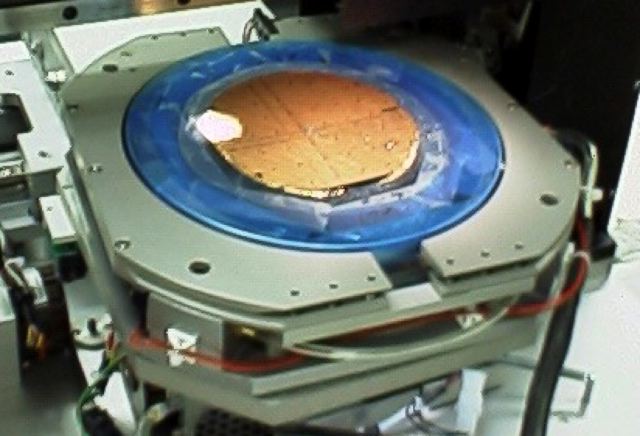

晶圆大小: 8"

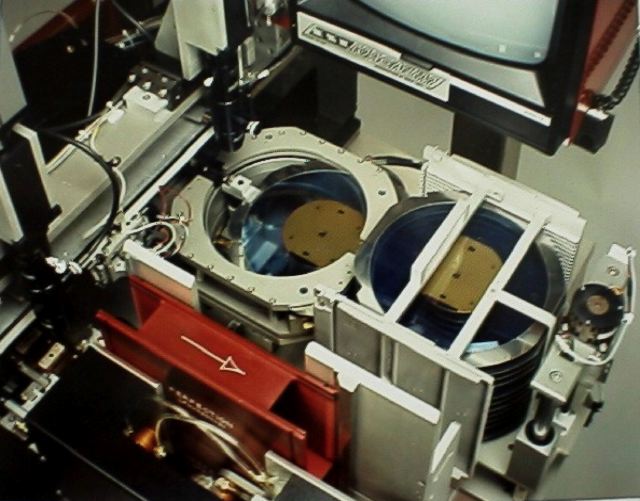

Epoxy die attach machine with Cognex vision

8" wafer with auto cassette

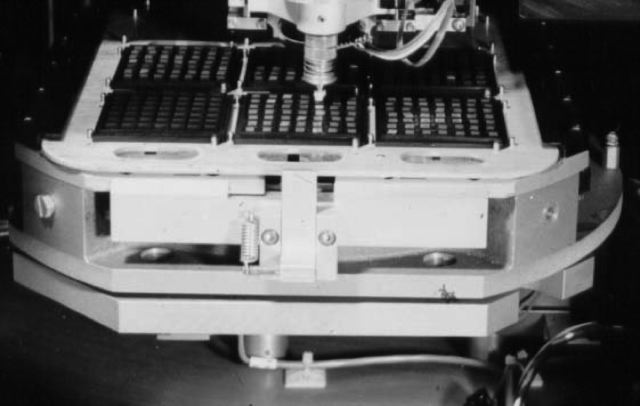

Auto indexer or 4" x 20" matrix x-y table to handle many diferent devices

Unstack to Magazine or Magazine to Magazine

Matrix Capability: Up to 8” wafer capability

Capable of picking die from wafer on film frame, wafer on rings, waffle packs, and gel packs

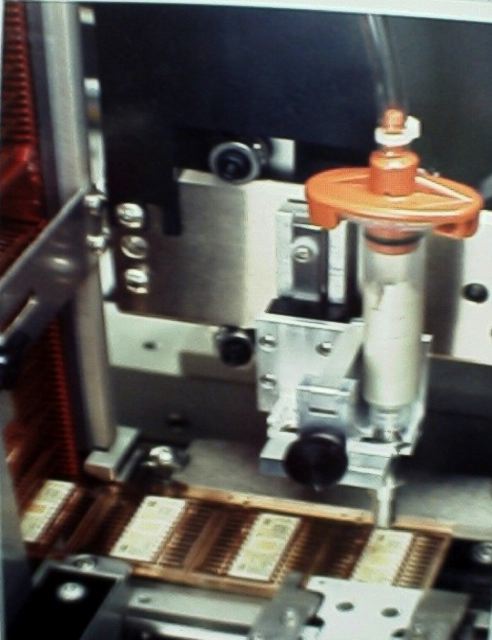

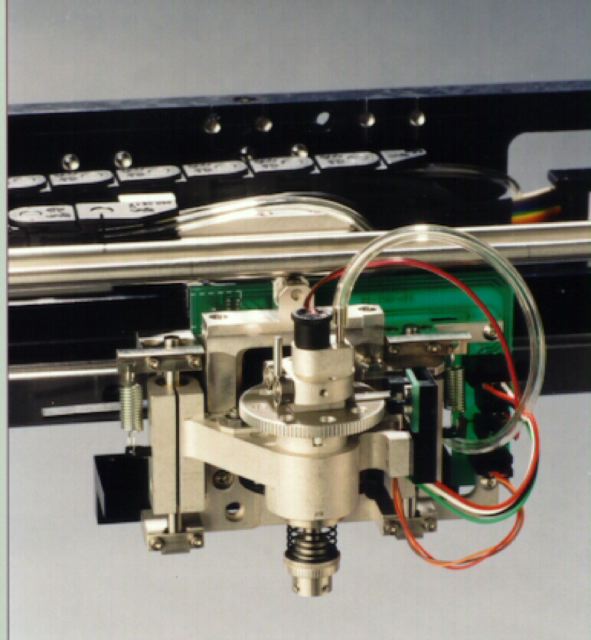

Programmable Syringe dispenser

Leadframe input: Dual unstacker with paper separator

Programmable magazine input

Programmable Gripper Indexer

Pattern Recognition System (PRS): Ink dot or broken corners to skip die

SECS/GEM compliant for wafer mapping

ALPS compatible

Linear Pick Bondhead

Programmable Approach Speeds

Y programmable scrub (amplitude, time and frequency)

Rotary Bondhead available

Die Presentation: Waffle / gel pack, film frame, wafer ring

Wafer Handler: Film Frame or Wafer Ring, Automatic wafer changer available

Small Footprint

Rack mounted electronics serviceable from the front

Simple Mechanisms allow easy servicing & accessibility

User friendly operator interface (via Light Pen touch screen)

Up to 100 recipes on HDD

Can be configured to your products process or as is configuration and condition

~2000 vintage.

ESC 9200模具附件是一种用于将模具固定在冲压机的烤盘上的机器。它是专为将高价值、高密度的模具附着在铁板上而设计的。这确保了印刷机与模具之间的安全连接,并且还有助于减少与模具盘断裂、双夹紧和模具部署错误相关的机器停机时间。9200模具连接器使用两级工艺将高密度模具牢固地连接到栈板上。在第一阶段,在模具下方的一个腔室内产生真空,该腔室将金属碎片吸尘。腔室内部是一个真空板,它首先将几滴粘合剂涂抹在栈板上,其次使用针轮将模具移动到位以进行附着。初始定位后,阶梯式凸轮机构将模具移动到所需的精确位置。模具完全就位后,电动nutrunner会将模具向下拉到粘合剂涂层的栈板上,并施加必要的力使其靠近板。最后将nutrunner和阶梯式凸轮松开,模具牢固地附着在板上。ESC 9200模具附件专为大批量应用而设计,循环时间约为3.5秒,以确保高价值模具固定在铁板上。机器也很容易使用,操作设置简单,可以在几秒钟内更改。整个机器结构牢固,其部件质量很高-包括重型锁定螺栓,以确保模具牢固地固定在栈板上。总体而言,9200模具接头是将高价值和高密度模具连接到烤盘上的可靠解决方桉。它的两个阶段的过程是高效的,其稳健的设计和构造确保可靠的性能,即使在大容量的环境。

还没有评论