二手 ASM Advance 300 VT #9206104 待售

网址复制成功!

单击可缩放

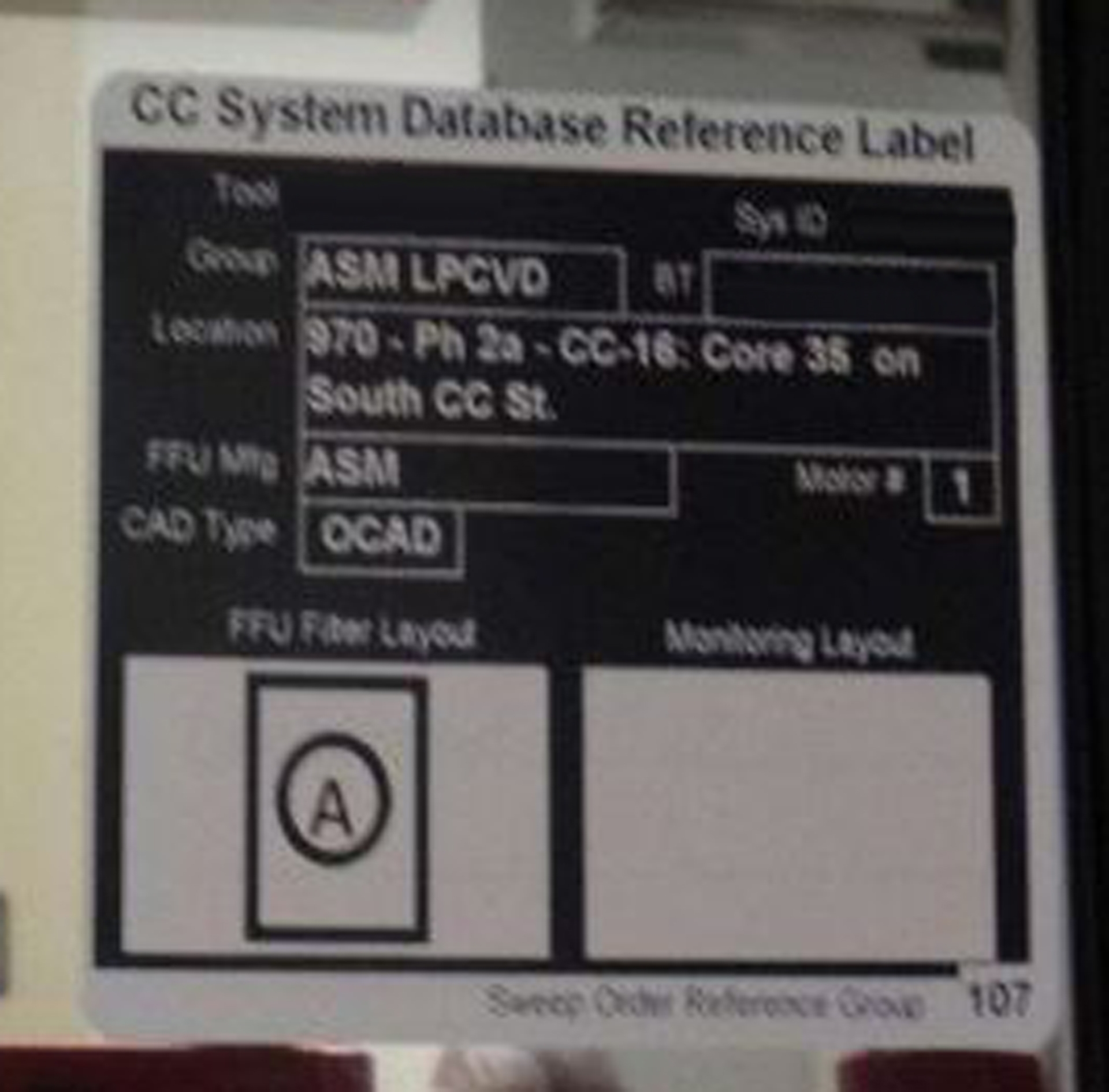

ID: 9206104

Vertical LPCVD furnace

Process: Oxide

CIM

Hardware configuration:

Main system:

Main body (Carrier stage)

Utility box

Handler system:

Wafer handing robot

Boat elevator

Cassette loader

Configuration:

Safety specification: ASM Standard

System layout type: U/Box type (I)

System hand: LL

N2 Load lock

Heater type: Temp wire

Torch heater

Process gasses:

Process gas 1 / N2 (30SLM)

Process gas 2 / O2 (20SLM)

Process gas 3 / HCL

Process gas 4 / N2O

Process gas 5 / H2O

Gas distribution system:

Basic style: Conventional gas system

Tubing material: Stainless steel

Tubing finish: Electro-polished

Manual & air-operated valve: Nupro

MFC Unit

Wafer / Cassette handling:

SEMI STD-Notch, 8"

Cassette type: Entergris / 704-503T2

Cassette number of wafers: 25

Cassette storage: 16

Fork type / Material

Fork variable pitch

Boat / Pedestal: 2 Boat

(150) Production wafers

Boat rotation not installed

System control:

System controller: IBM 486 OS2

Torch controller: H2O Separate element Pre burner

Signal tower colors: G / A / B

General pressure display unit: Pressure PSI

Cabinet exhaust display unit: H20

ASM Furnace temp controller:

Host communication

Host communication: User host computer

User host computer I/F: SECS I / II (RS232)

Information transfer protocol: GEM

Equipment host I/F connection: U/BOX Top

Group controller: HIA

Facility electrical equipment power input (2 Lines):

Voltage: 208 VAC, 3 Phase

Voltage: 120 VAC, 1 Phase

UPS Input / Output voltage: 120V / 100V

1997 vintage.

ASM Advance 300 VT是为金属处理提供可靠、高精度气氛而设计的下一代扩散炉。它配备了广泛的配件,使其能够执行包括硬化、回火、退火、涂层和渗碳在内的一系列工艺。该炉采用重型不锈钢制造,具有坚固耐用的寿命和可靠性设计。它配有一个单独的扩散室,以确保最高的准确度。还包括易于使用的触摸屏控件,允许精确的温度和大气控制。在100公升的活动性容积下,Advance 300 VT可以加热到1 350°C(2 460°F),并且可以调整到任何温度在25°C(77°F)和1 350°C(2 460°F)之间。它还具有强大的加热元件和水冷系统,确保快速、受控的热循环。在配件方面,ASM Advance 300 VT配备了许多可以根据您的需求量身定制的功能。它配有一系列的坩埚处理配置,包括方形和圆形版本。还包括可切换的氧探针,这些探针在运行过程中检测气体中的氧浓度,并可进行相应调整。其他可选配件包括不锈钢过滤器单元、温度传感器、冷却剂流量计、用于硬化、回火、退火的多柱托盘、用于柚子的专用高温计以及用于处理非氧化材料的真空系统。Advance 300 VT是一种以其精度和性能为价值的强大扩散炉。配饰种类繁多,是金属处理的绝佳工具。它非常适合各种专业和工业应用,并提供可靠的结果和长期的性能。

还没有评论