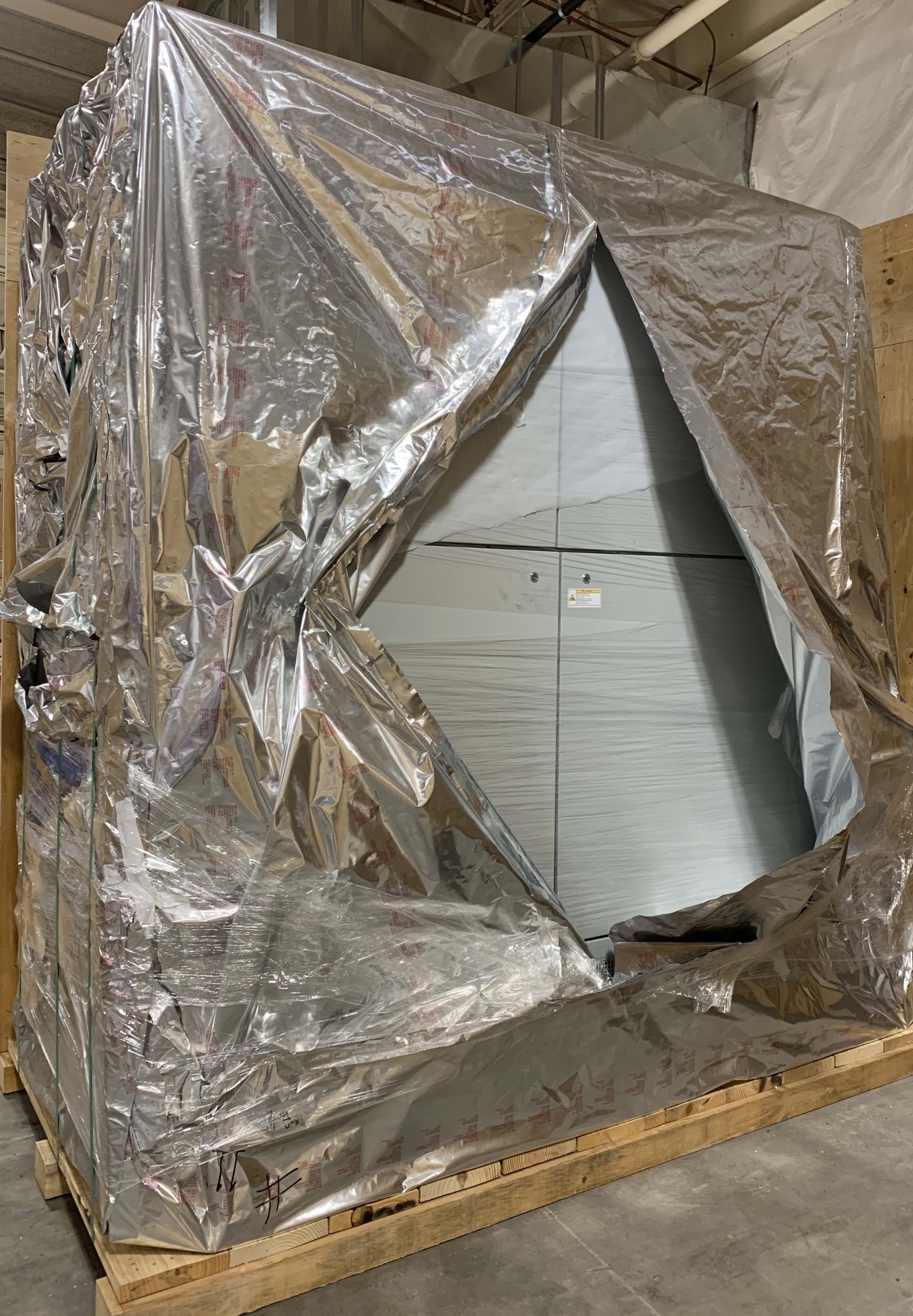

二手 CENTROTHERM E1550 HT 260-4 #9260101 待售

网址复制成功!

单击可缩放

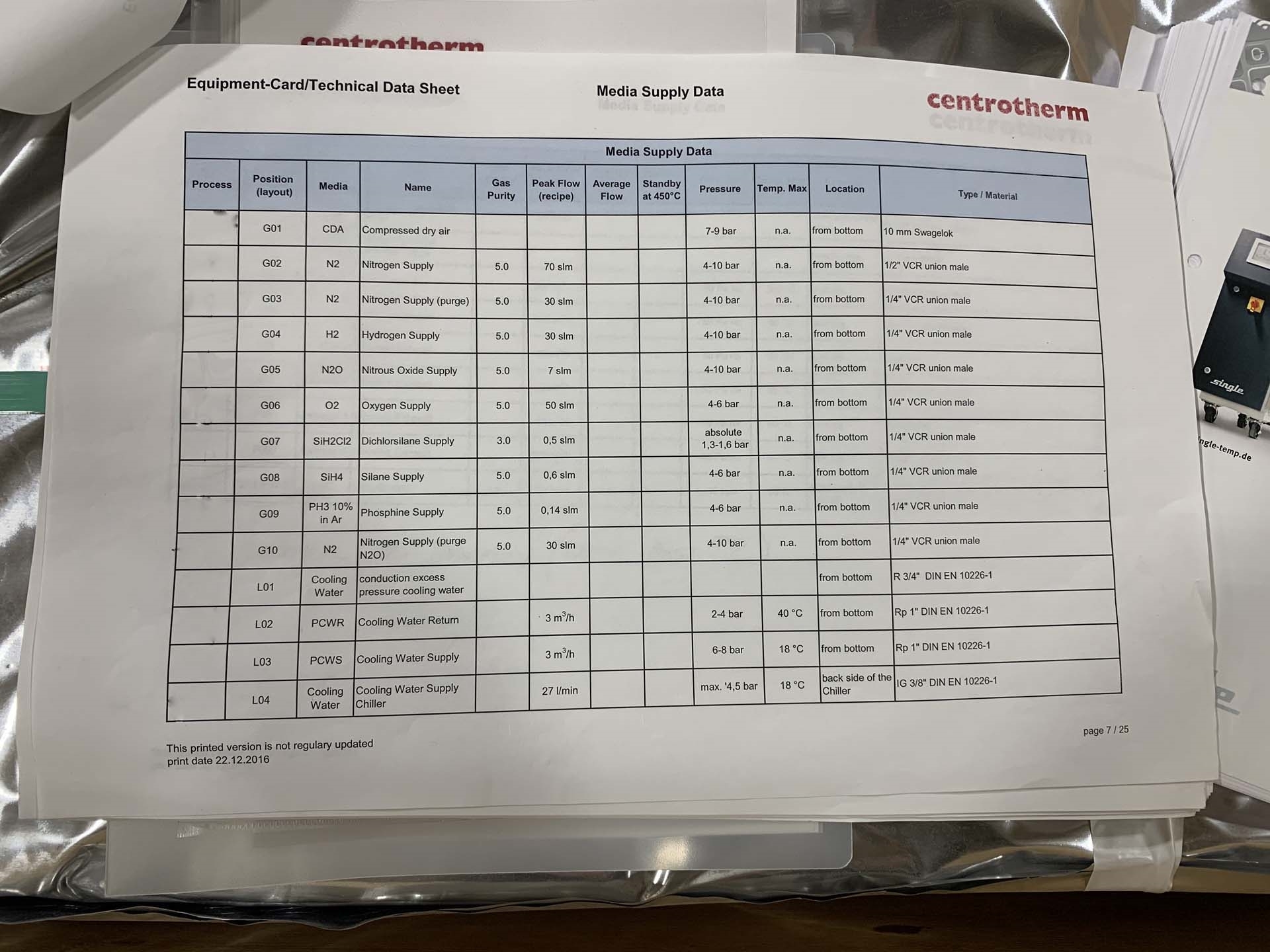

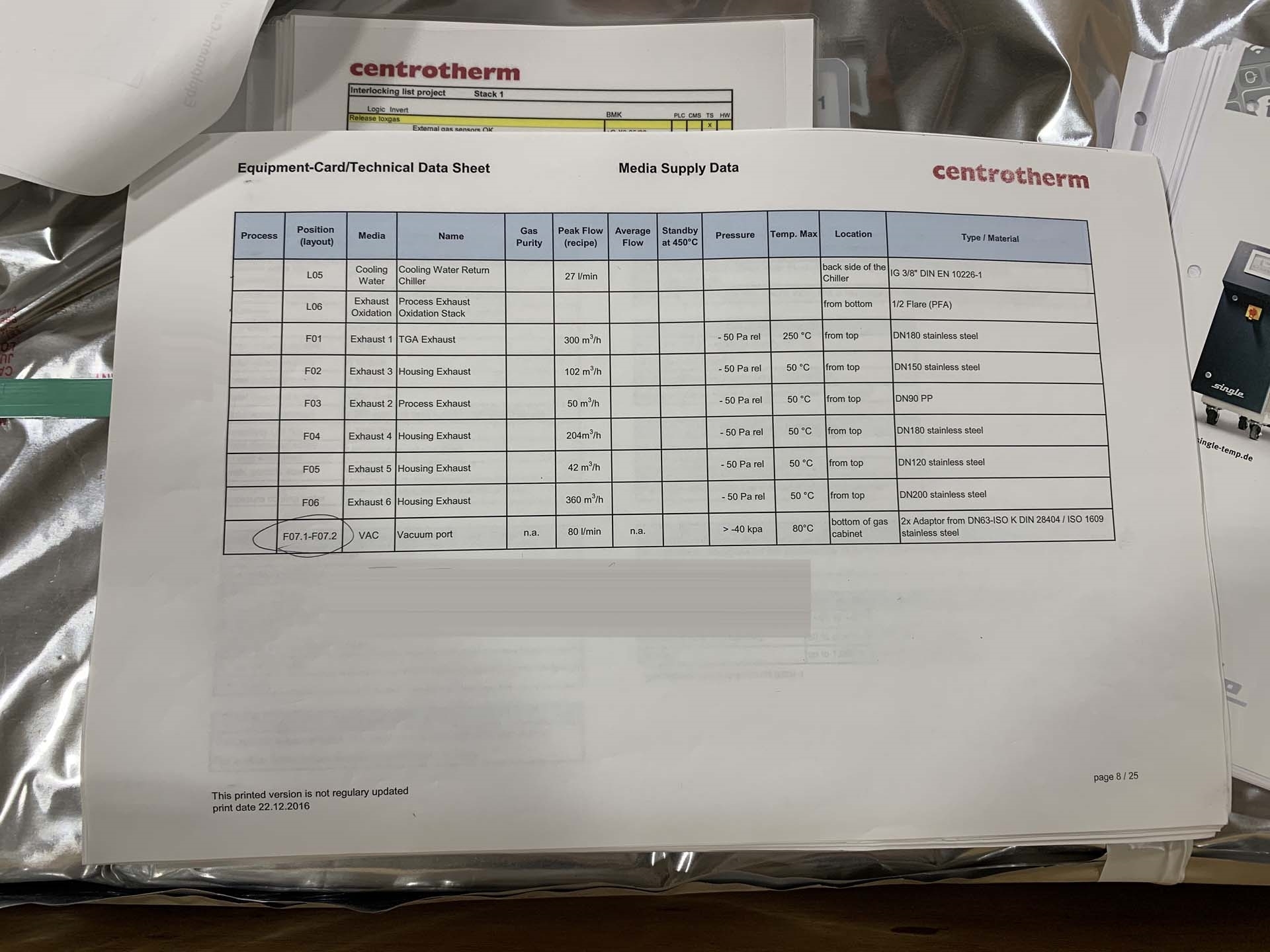

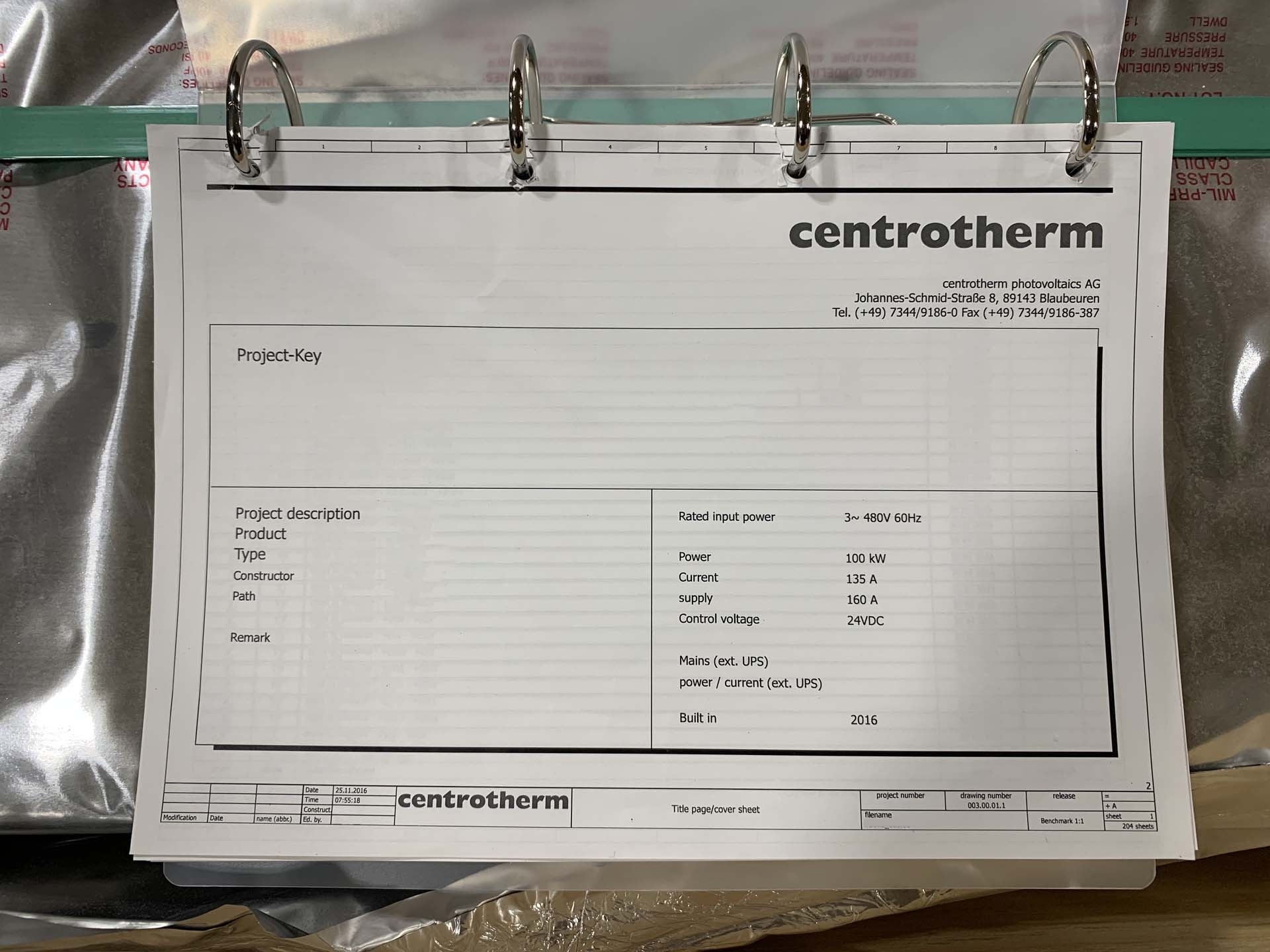

ID: 9260101

晶圆大小: 6"

优质的: 2016

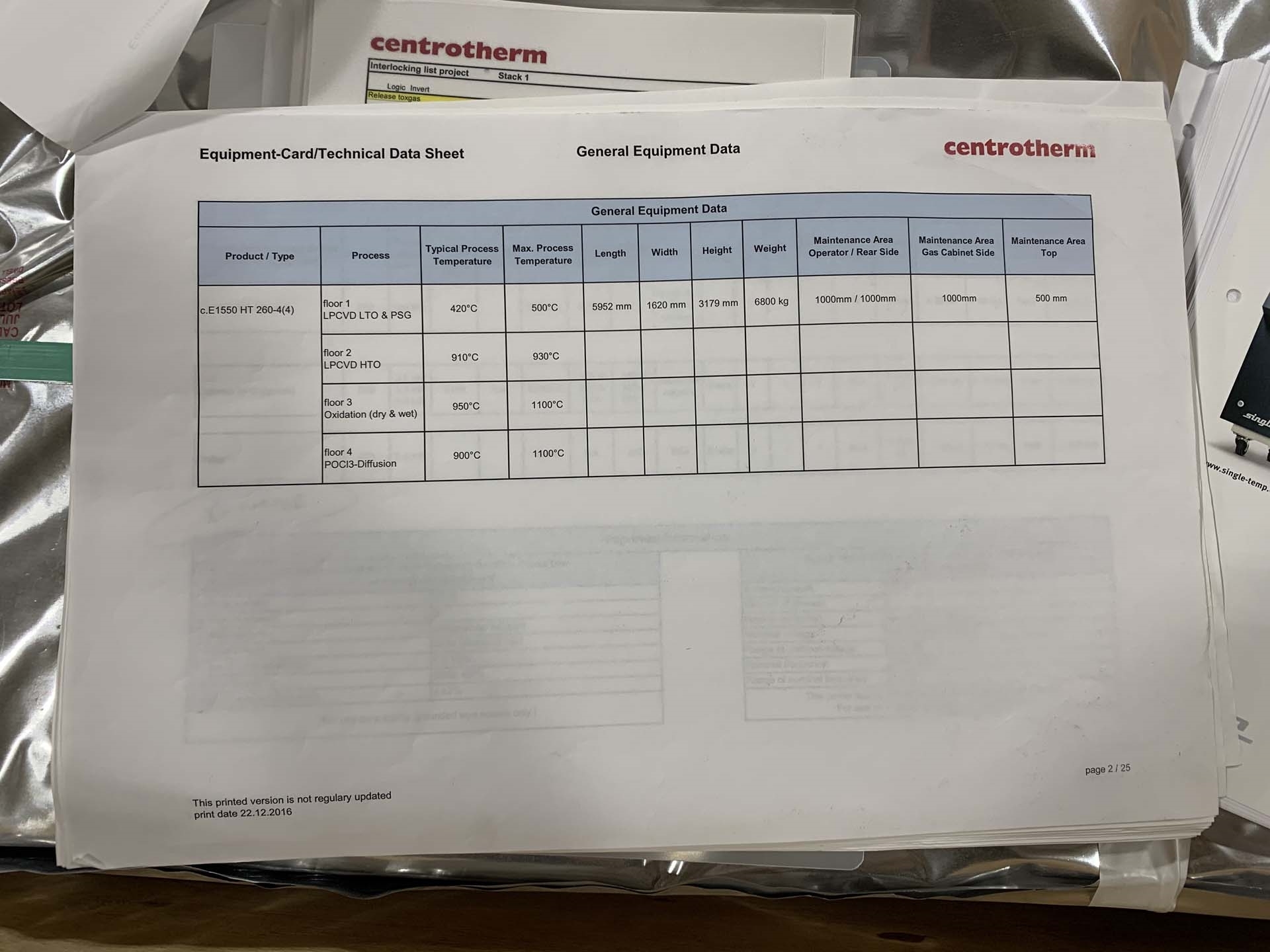

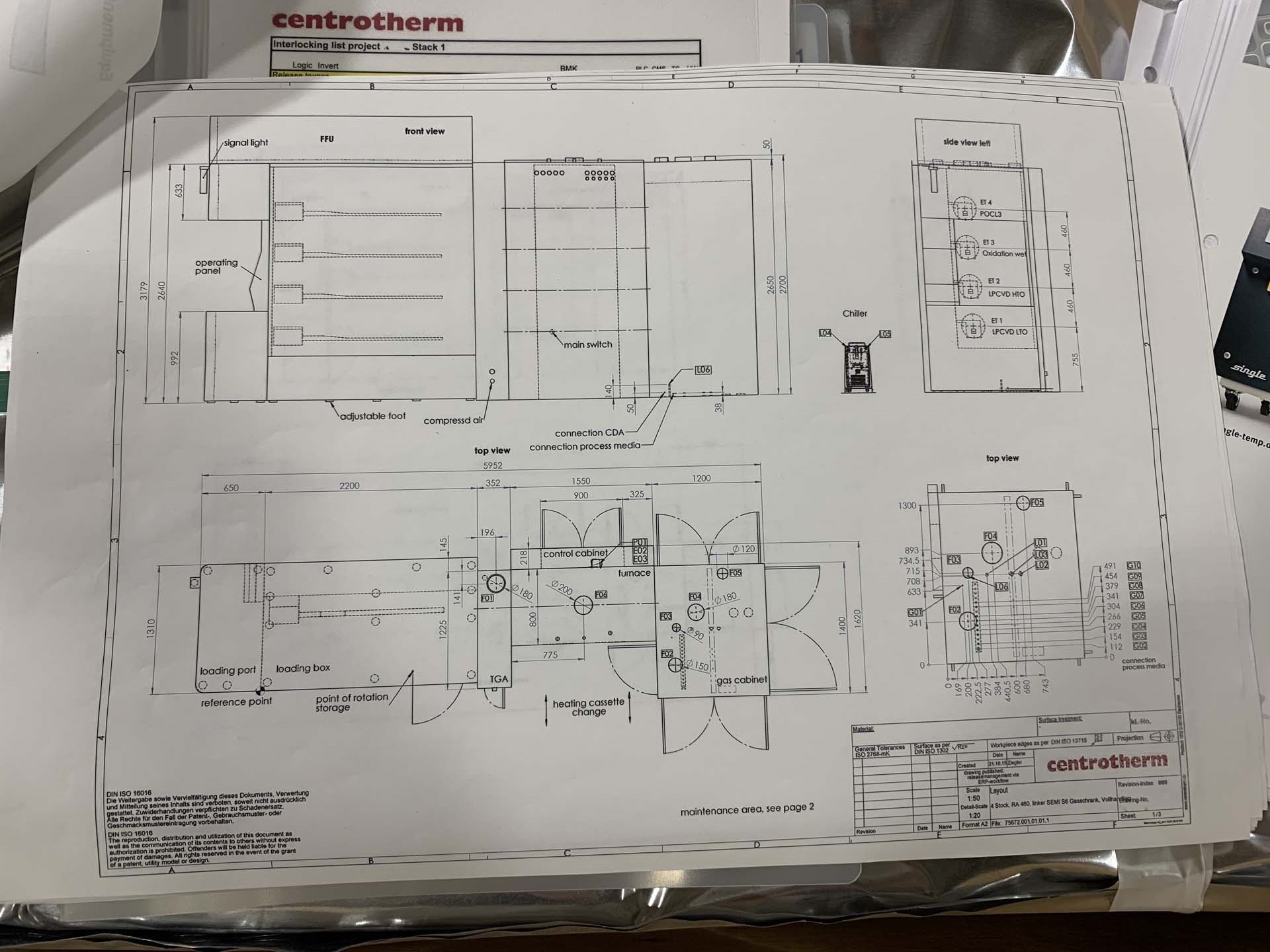

Horizontal furnace, 6"

(4) Stacks

(4) Tubes configuration:

LPCVD LTO-PSG

LPCVD HTO

POCl3 Diffusion

Wet oxidation

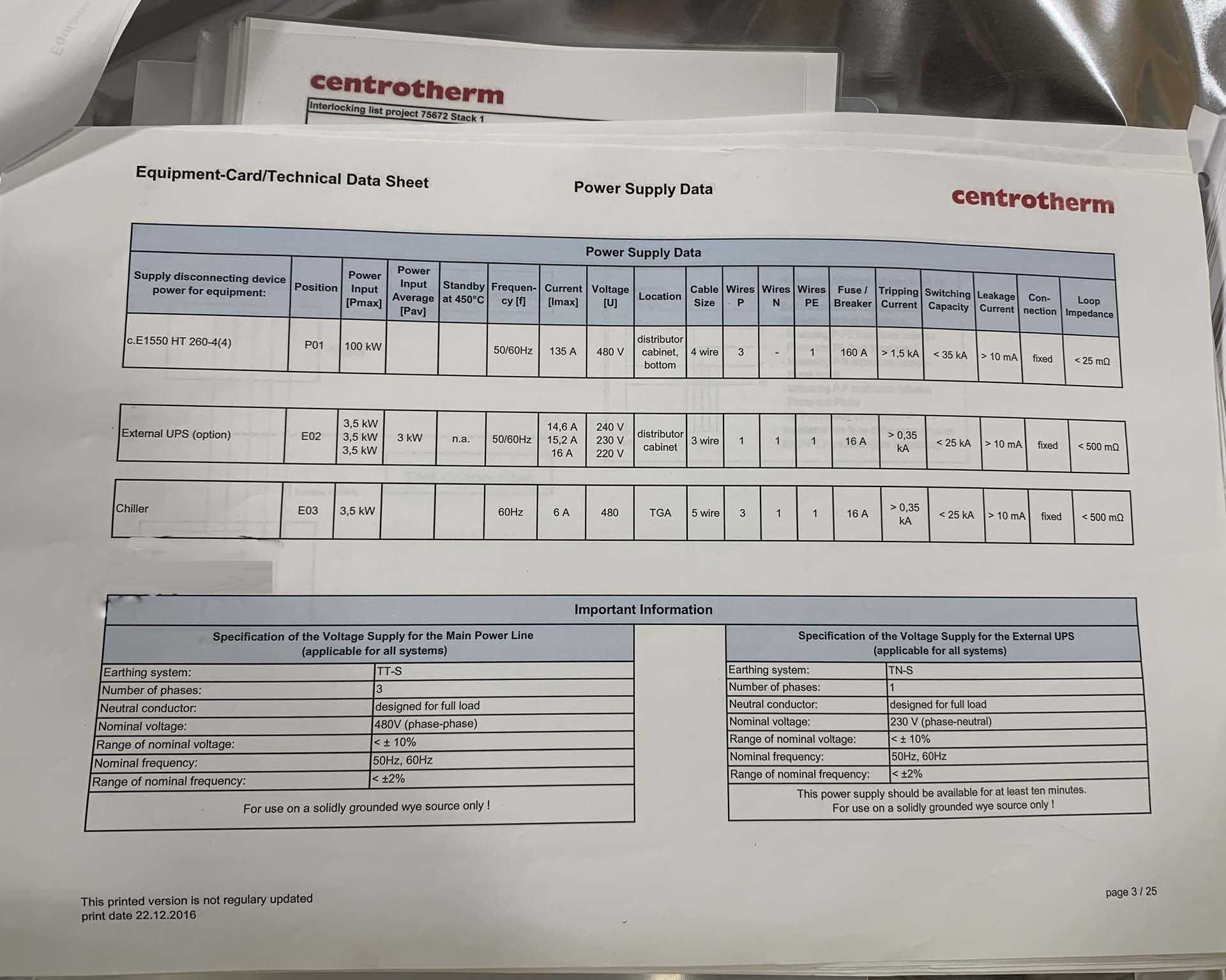

Heating element: 100-600°C

Flat length: 600 mm

Diameter: 260 mm

(5) Heating zones

Heating element: 400°C-1050°C

Flat length: 600 mm

Diameter: 260 mm

(5) Heating zones

(2) Heating elements: 600-1300°C

Flat length: 600 mm

Diameter: 260 mm

(5) Heating zones

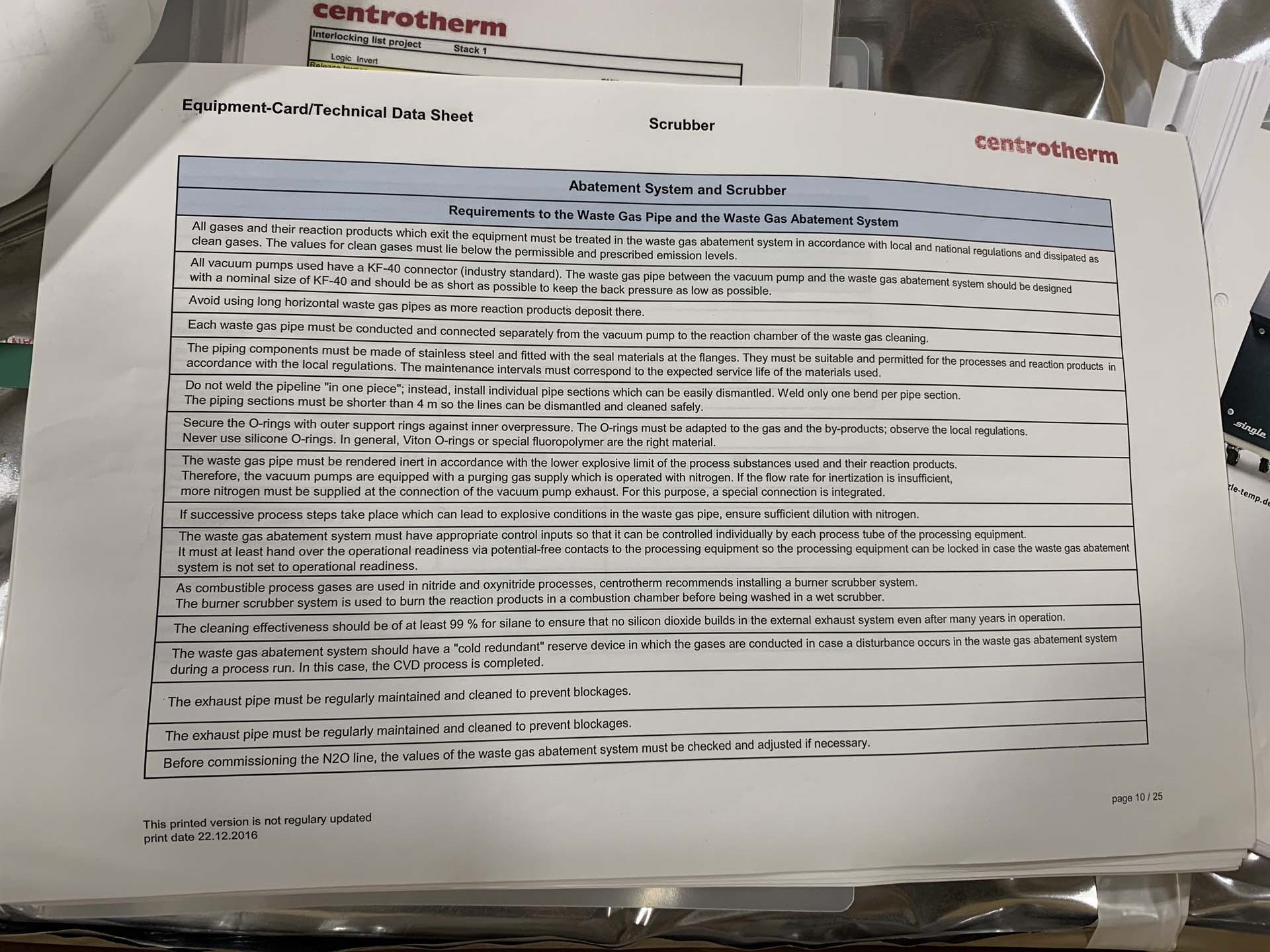

Furnace cooling system: Integrated gas system for DCS: HTO / TEOS process

(3) Standard cooling systems:

Tube closed cycle water cooling system

CENTROTHERM Machine Interface (CMI)

Graphical user interface

(4) Furnace control systems (Field bus: CAN)

(4) Temperature measurements

(4) REG 97 Temperature controllers

Fuzzy enhanced PID control

(4) Cascade temperature controls

(4) Profiling elements

For (5) zone heating elements: Type R

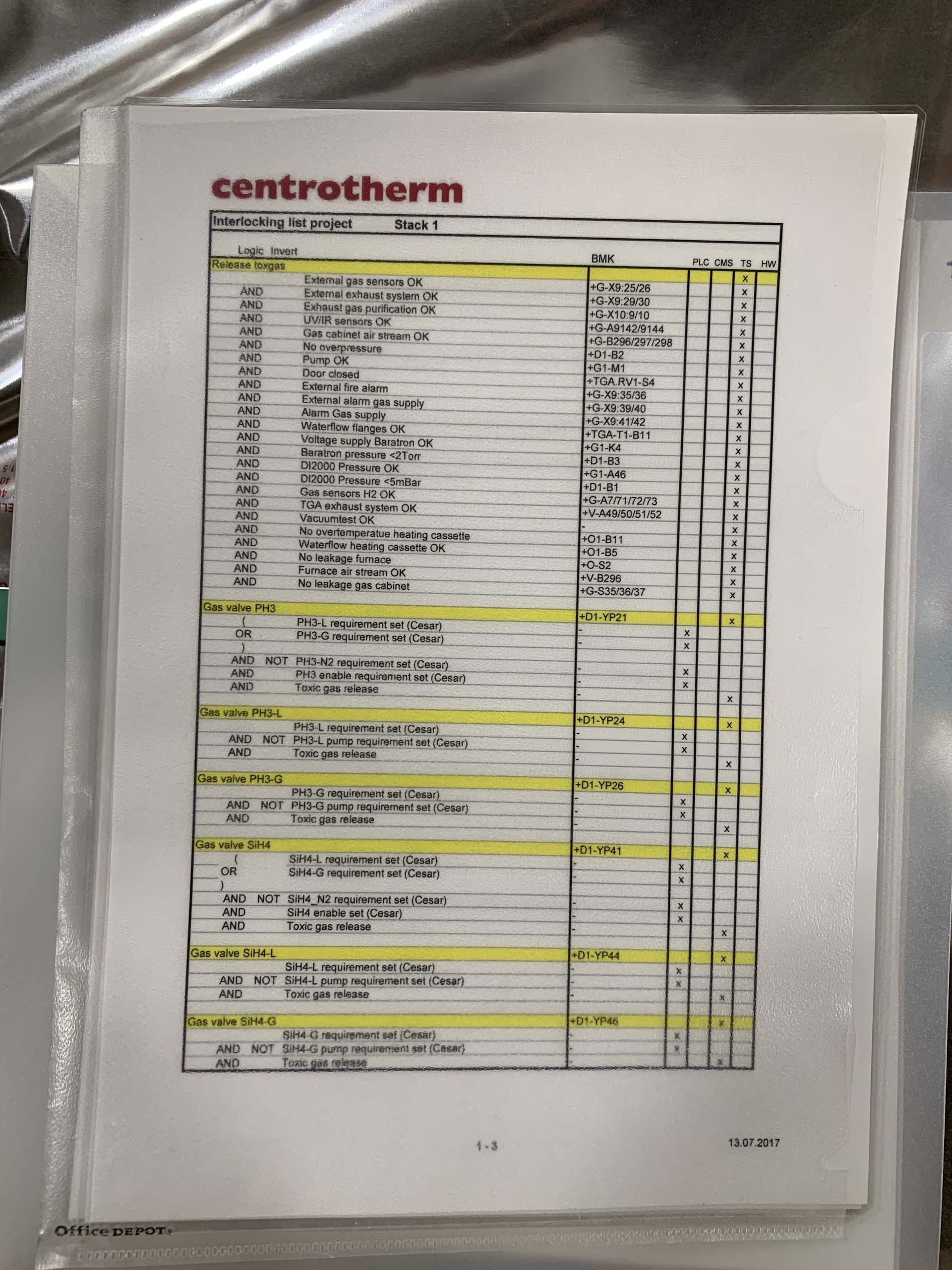

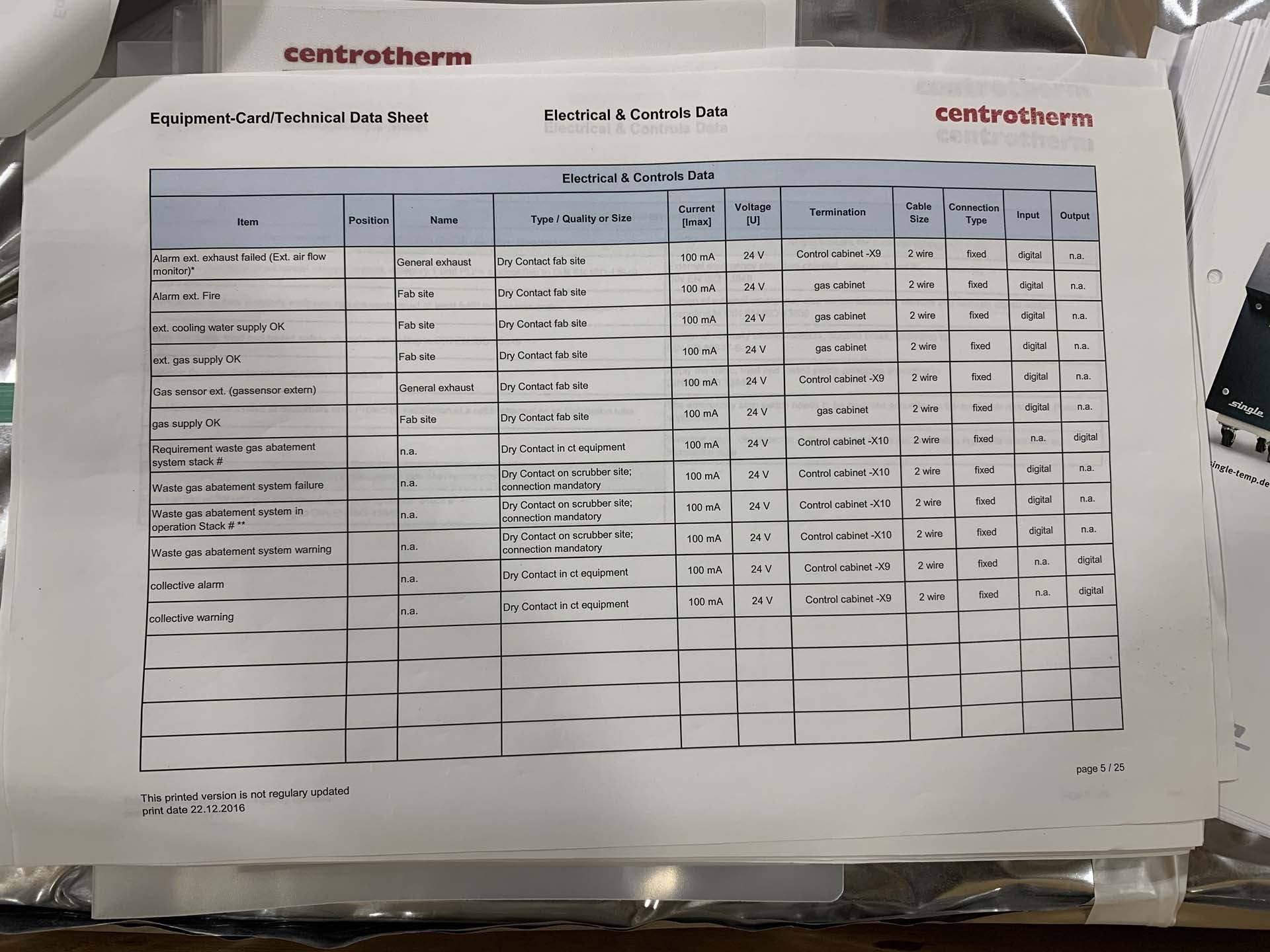

Security system CMS

Independent for up to (4) tubes

Automatic pressure tightness system for closed tube systems

Scavenger

(2) Tube closures

Closed tube for soft landing system

Vacuum door for soft landing system

(4) Tube loading systems:

For soft landing process boat

Gas system cabinet GVS

With main gas lines for N2, O2, H2, SiH4, SiH2Cl2, PH3, N2O

Gas / Vacuum system: LPCVD: LTO-PSG

Gas lines: N2, SiH4 (Rear), PH3 (10% in Ar) (Front, rear), O2 (Front, rear) without vacuum pump

Gas / Vacuum system: LPCVD: HTO

Gas lines: N2, SiH2Cl2 (front, rear), N2O (front, rear), without vacuum pump

Gas system: POCL3 Diffusion

Gas lines: N2, N2 (POCl3), O2, O2 (High)

Gas system: Wet oxidation (Hydrox - ext. torch, DCE – TransLC)

Gas lines: N2, O2, H2, N2O, N2 (DCE), O2 (DCE)

Laminar flow system:

For vertical flow

Process boat lift

Without storage and controlling computer, 6"

Process boat storage

Storage positions plus one manual loading storage, 6"

Loading port

Process boat transfer system

Flat aligner

Power supply: UPS10

No auxiliary equipment

2016 vintage.

CENTROTHERM E1550 HT 260-4扩散炉是为各种散装晶体生长过程而设计的专业级设备。它是需要高温才能大规模生长的材料的理想选择,例如砷化的、硅和氮化物。这种四区炉可以达到高达1300 °C的温度,设计用于气体输送或直接接触加热。炉的中央部分由链条驱动的旋转炉膛组成,容纳了四个加热区。每一种都可以独立控制,以便在整个材料体积中精确控制温度。这四个加热区可以以气体或电加热元件作为能源来操作。气体输送设备由一个三向阀组成,用于控制燃料气体流入每个加热区的流量。此外,CENTROTHERM E1550具有吸热气体喷射系统,可快速冷却.该炉包括一个两级循环空气单元,每个区域分别装有堆栈风扇。风扇提供散装冷却以及热空气循环,甚至可以在整个材料体积中加热。附加的安全功能如在线紧急停止按钮、可听和视觉警报以及火焰监测热电偶进一步提高了机器的安全性。E1550 HT 260-4扩散炉还带有气体和电气连接,以及详细的操作说明。为了获得最佳性能和效率,我们建议您将其与CENTROTHERM配套的支持附件套件配对,包括耐火材料、管道和其他辅助设备。这些配件可以更精确地控制炉子的烧制参数,并确保你的工作质量最高。总之,CENTROTHERM E1550 HT 260-4扩散炉是各种块状晶体生长过程的理想选择。其先进的功能和全面的安全系统使其成为任何需要高温和精确控制的应用程序的首选设备。

还没有评论