二手 JST V350 #9070711 待售

网址复制成功!

单击可缩放

ID: 9070711

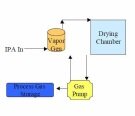

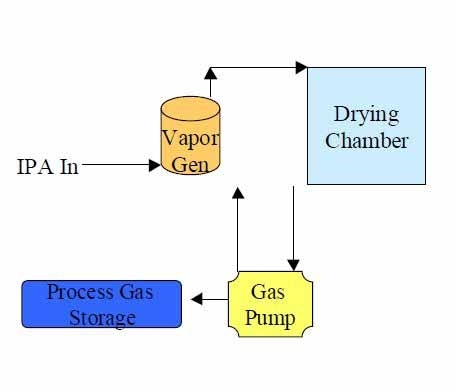

Hot N2 dryers

Hot nitrogen

PLC Controlled

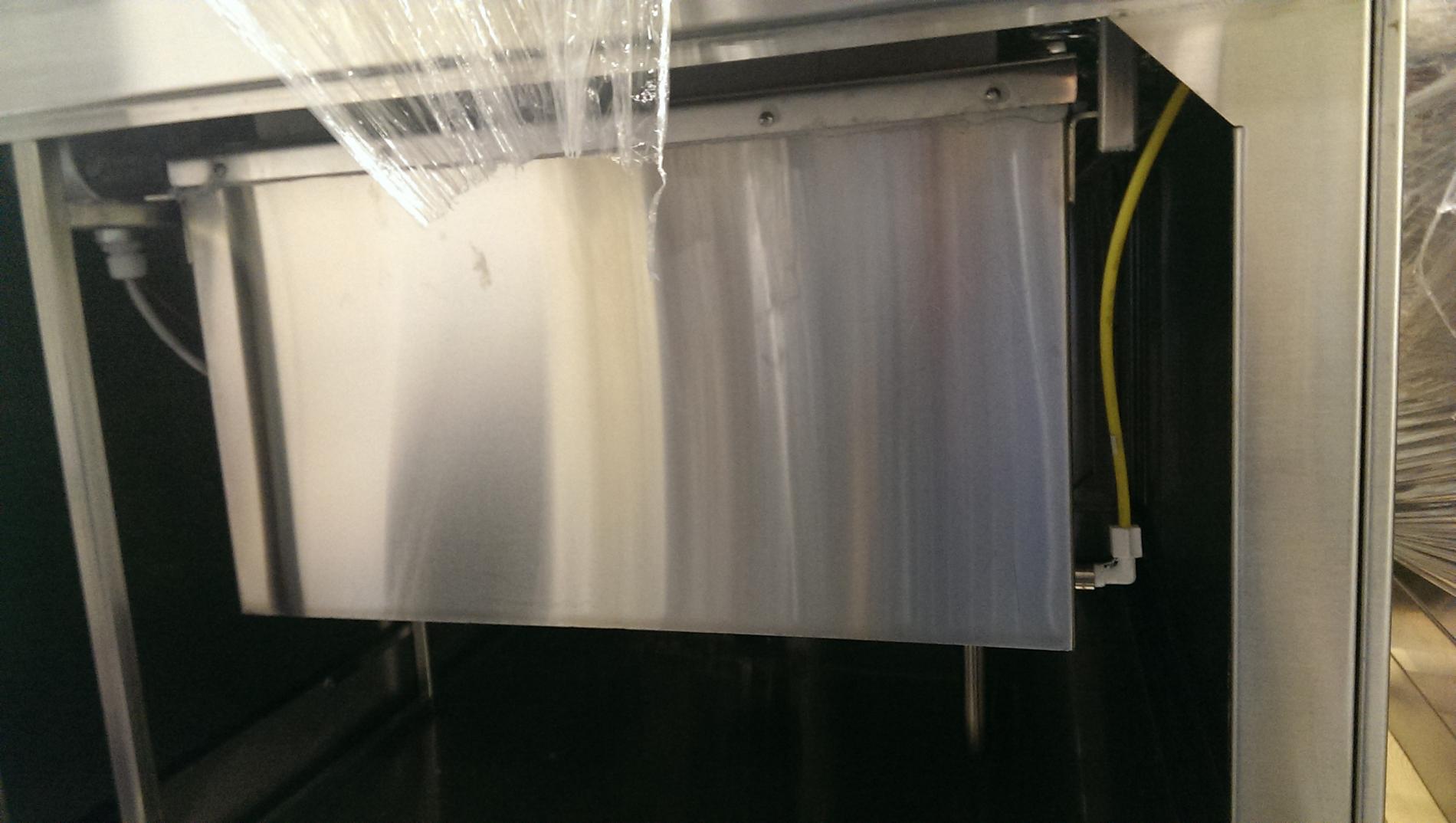

Stainless steel construction

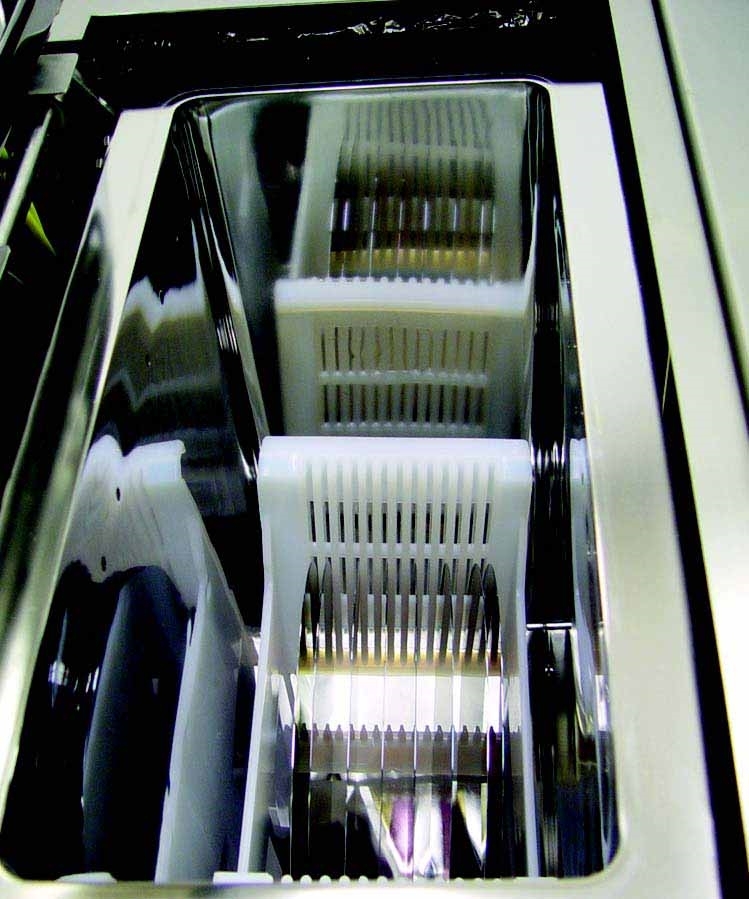

Cassettes:

(3) 200 mm

300 mm

Drying applications:

Silicon wafer

Glass substrates

Disc drives

Optics

Options:

Charcoal filter

Bulk chemical dispense

Safety:

Sealed vessel with closed loop process

Load / Unload: No vapor present

Low emissions: <1 lb per day

Indirect heating: IPA

CO2 Fire suppression system

Automated lid with safety interlocks

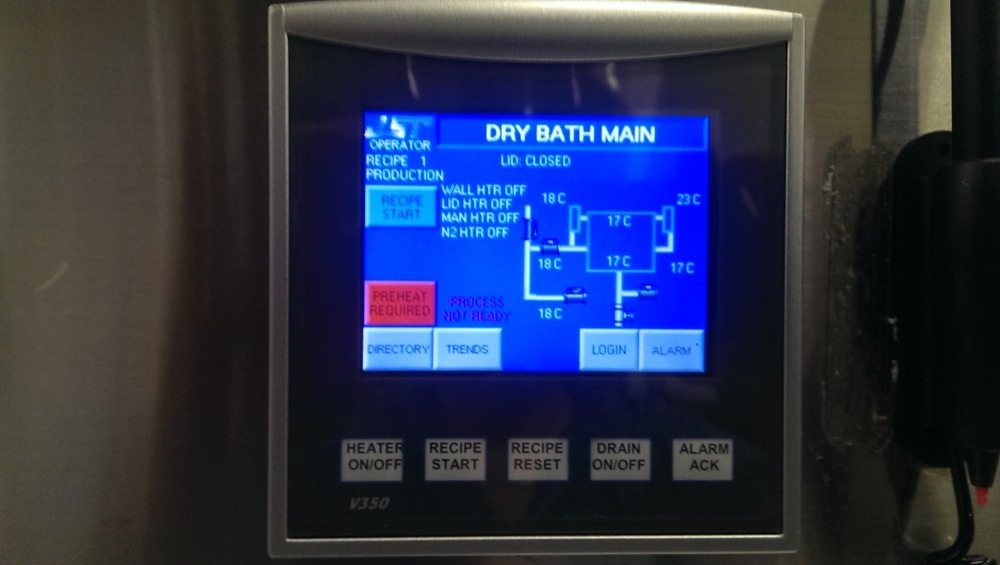

Controls:

Industrial grade PLC

Modular design for quick replacements & minimal down time

Interactive touch screen interface

Alarm indicator screens for easy troubleshooting

Design: Multi-level menu

Flexible process adjustment

Visual process flow during recipe operation

Multi level security structure

Independent CO2 fire controller interlocked to master PLC control

Wafers in quartz

Cassette / Glass panels: Up to 550 mm x 650 mm

Dry cycle: 10 Minutes

IPA: 60 cc per Cycle

Proven process:

Particle neutral drying size: 0.16m

Facility requirements:

CDA: 80 psi, <10 cfh

Argon / Nitrogen: 20 psig @ 2 cfm

Per cycle: < 1.5 cft

Exhaust: ~ 80 scfm, 4” Collar

Electrical: 208 VAC, 3 Phase, 5 wire, 30 A.

JST V350是由JST Manufacturing, Inc.制造的环境室,可用于多种应用。该腔室设计用于高性能和可靠性,非常适合需要精确环境条件的应用。V350是一个完全绝缘的独立单元与左侧入口门。它具有不锈钢结构和环氧涂层钢内部。这提供了非凡的耐用性和强度,确保腔室在其最佳性能。腔室具有标准的湿度控制,相对湿度在0-100%之间。该机组还具有可调节的温度控制,范围从环境到150 °C。温度控制以0.1°C为增量可调节。JST V350还有一个内置计时器,允许用户将腔室设置为在预设时间和预设温度之间运行。此功能为测试和研究增加了便利和效率。该室还有一系列可供定制的配件。这包括一个侧面接入端口、货架和其他门锁。这些配件是为了满足任何测试或研究计划的需要而设计的。V350是任何需要精确控制环境和温度条件的实验室的重要组成部分。该设备的特点和附件使其成为那些寻求准确可靠的工具来满足其环境测试需求的人的理想选择。

还没有评论