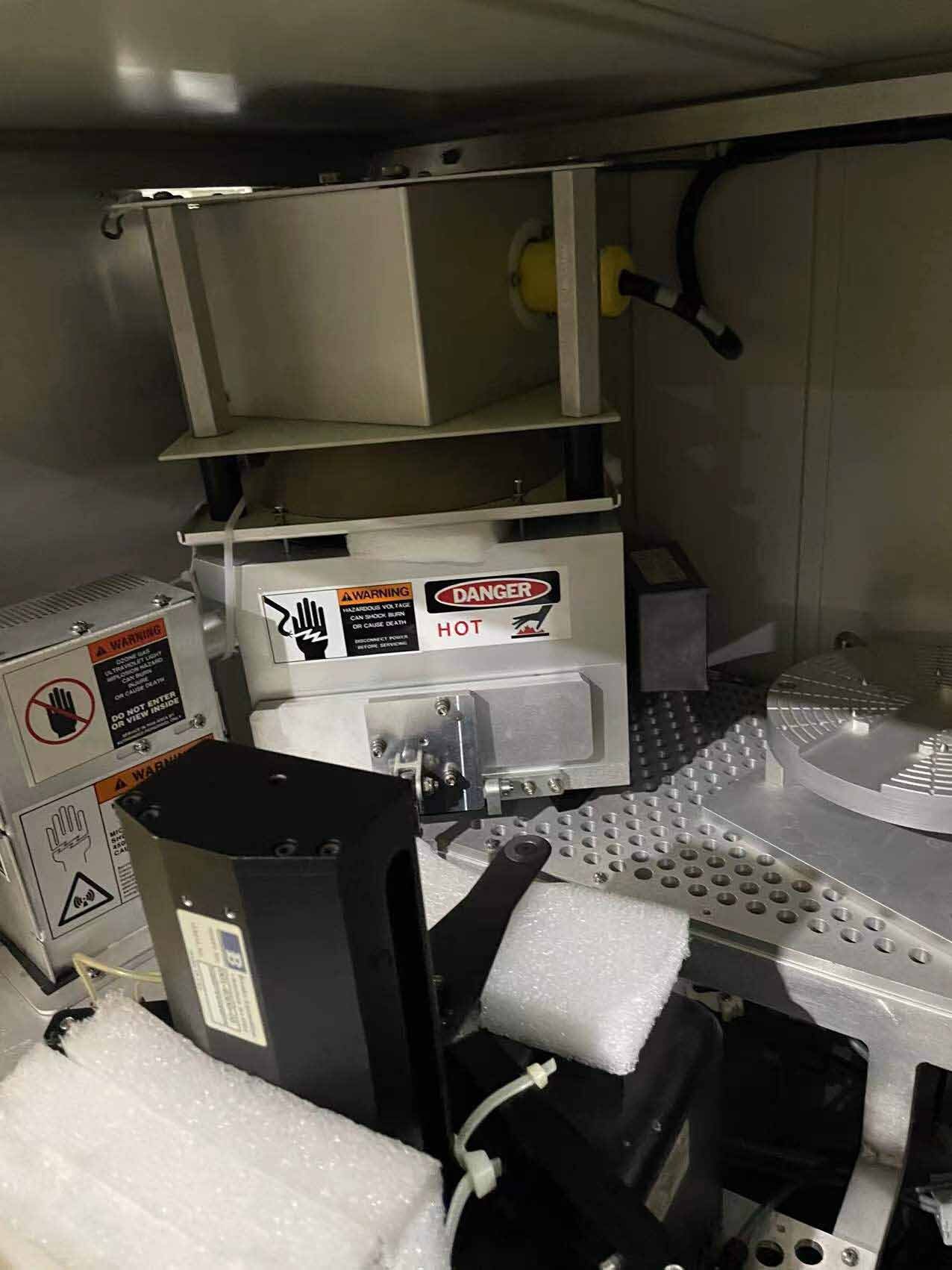

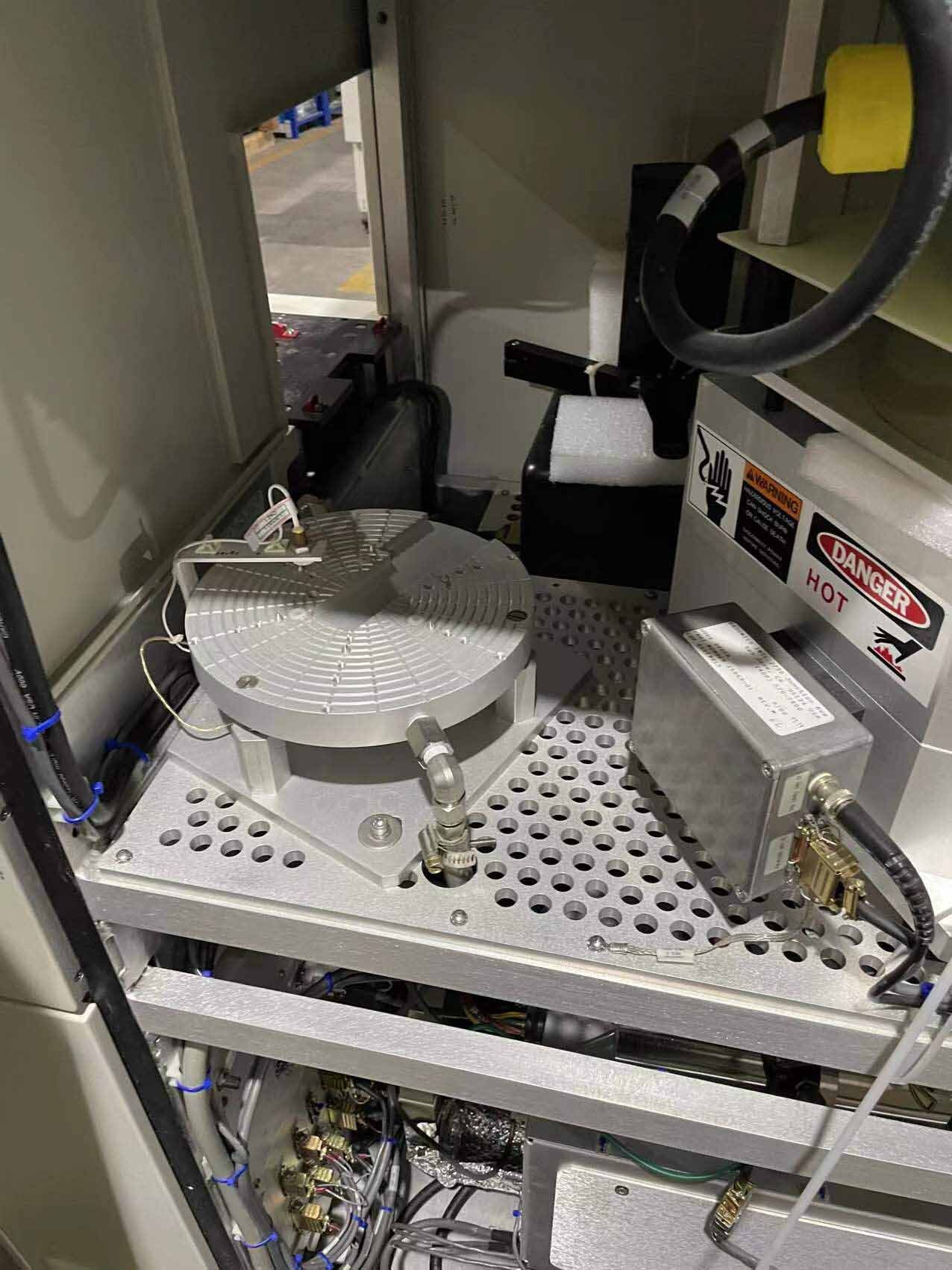

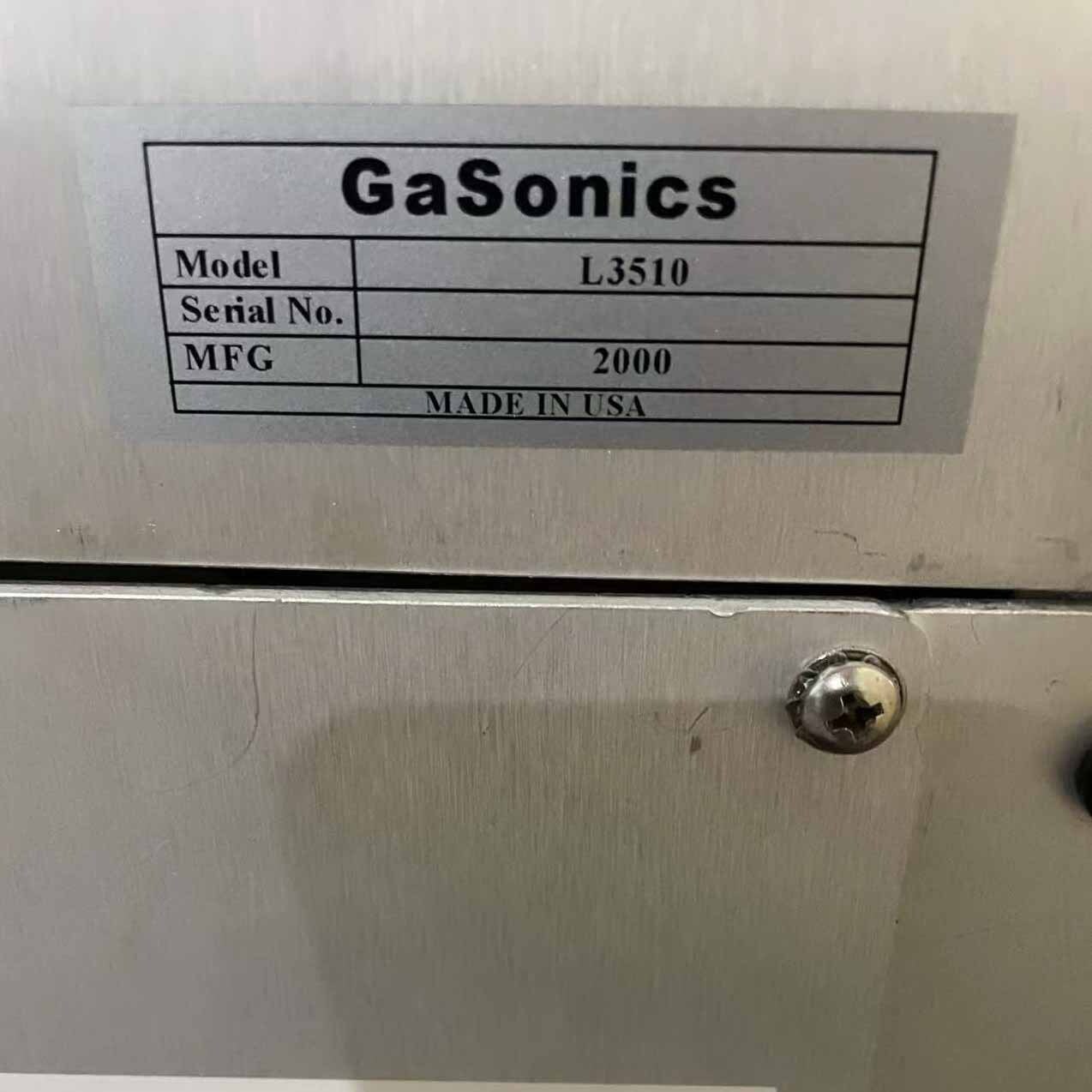

二手 GASONICS / NOVELLUS L 3510 #9411534 待售

网址复制成功!

单击可缩放

ID: 9411534

优质的: 2000

Asher

Photoresist strip

Substrate size: 3"-8"

Footprint: 30"

Main frame:

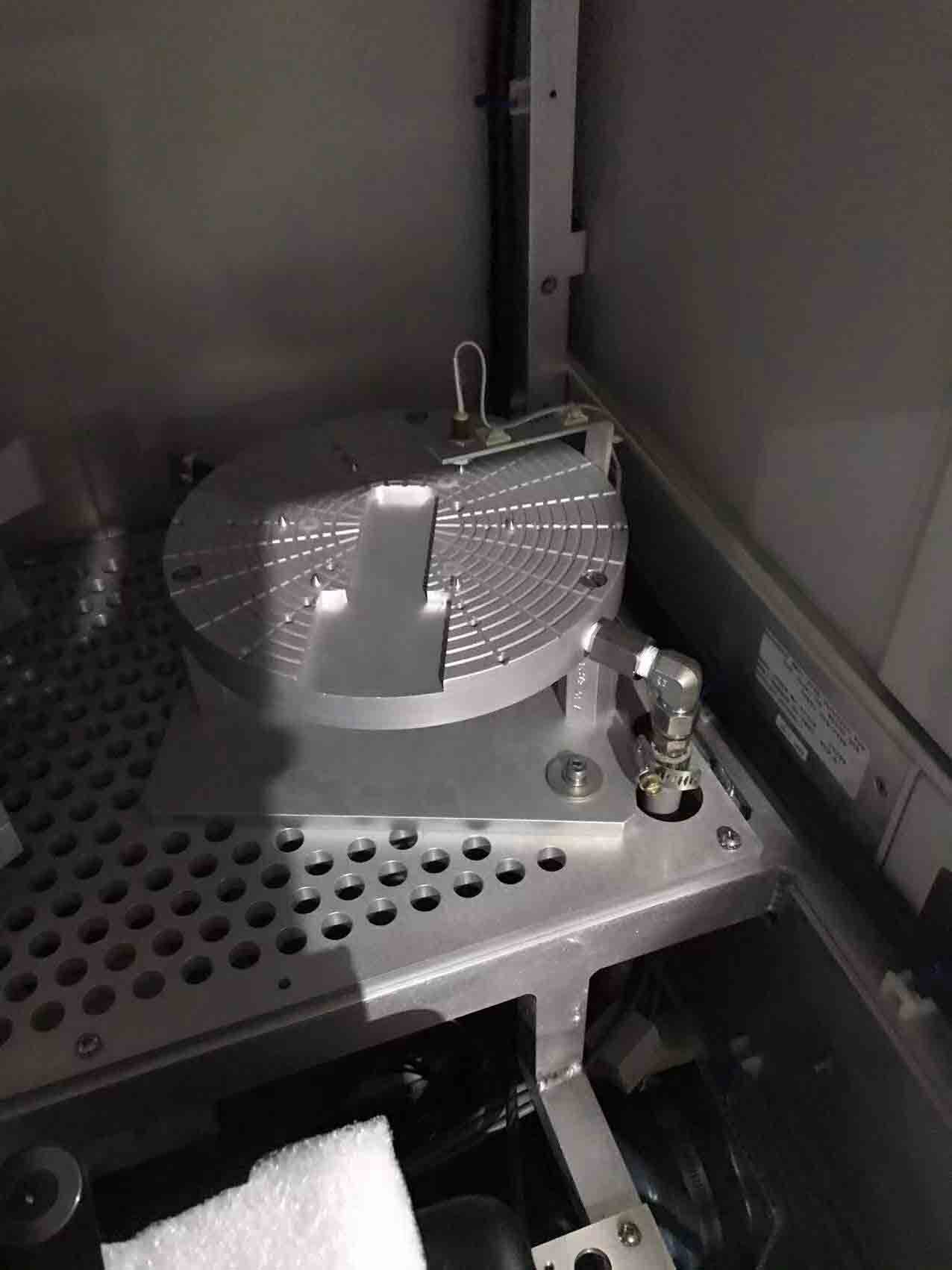

Aluminum chamber

Quartz chamber

Wafer cooling station with PCW

Platen and lamp heating (Flexibility)

Reliable endpoint detection

Z-Bot station (Robot)

Load cassettes elevator

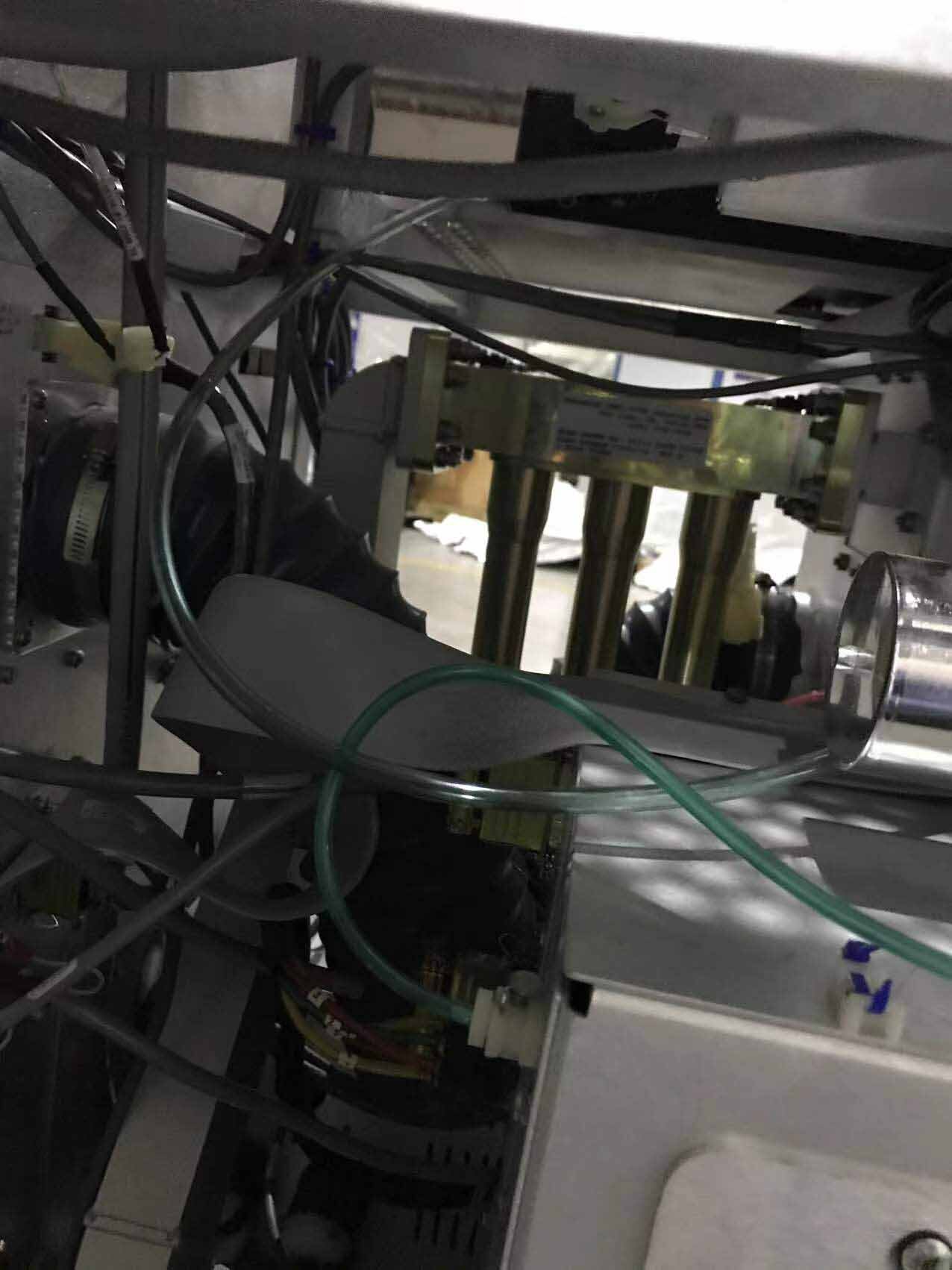

DC Power supply: -5, +5, -12, +12 VDC

(2) DC Power supplies: +5, -15, +15, +24 VDC

I/O Board

Distribution board

Display board

Graphics control board

Hard Disk Drive (HDD)

Floppy Disk Drive (FDD), 3.5"

Microwave generator: 2.45 GHz, 1250 W

Interlock wafer transport

Microwave power supply

Gas flow controller

Visual alarm indicator lamp

Quartz gas distribution shower heads

Radiant heating plate

UV Lamp

End point detection

Plasma system controller

Tolerance limit alarm (pressure, flow, lamps)

Gas handling module and control features

(3) Gas lines with purge:

O2 MFC

(2) N2 MFC

Stainless steel valves gas line

Solenoid control: 24 VDC

Soft pump to limit chamber turbulence

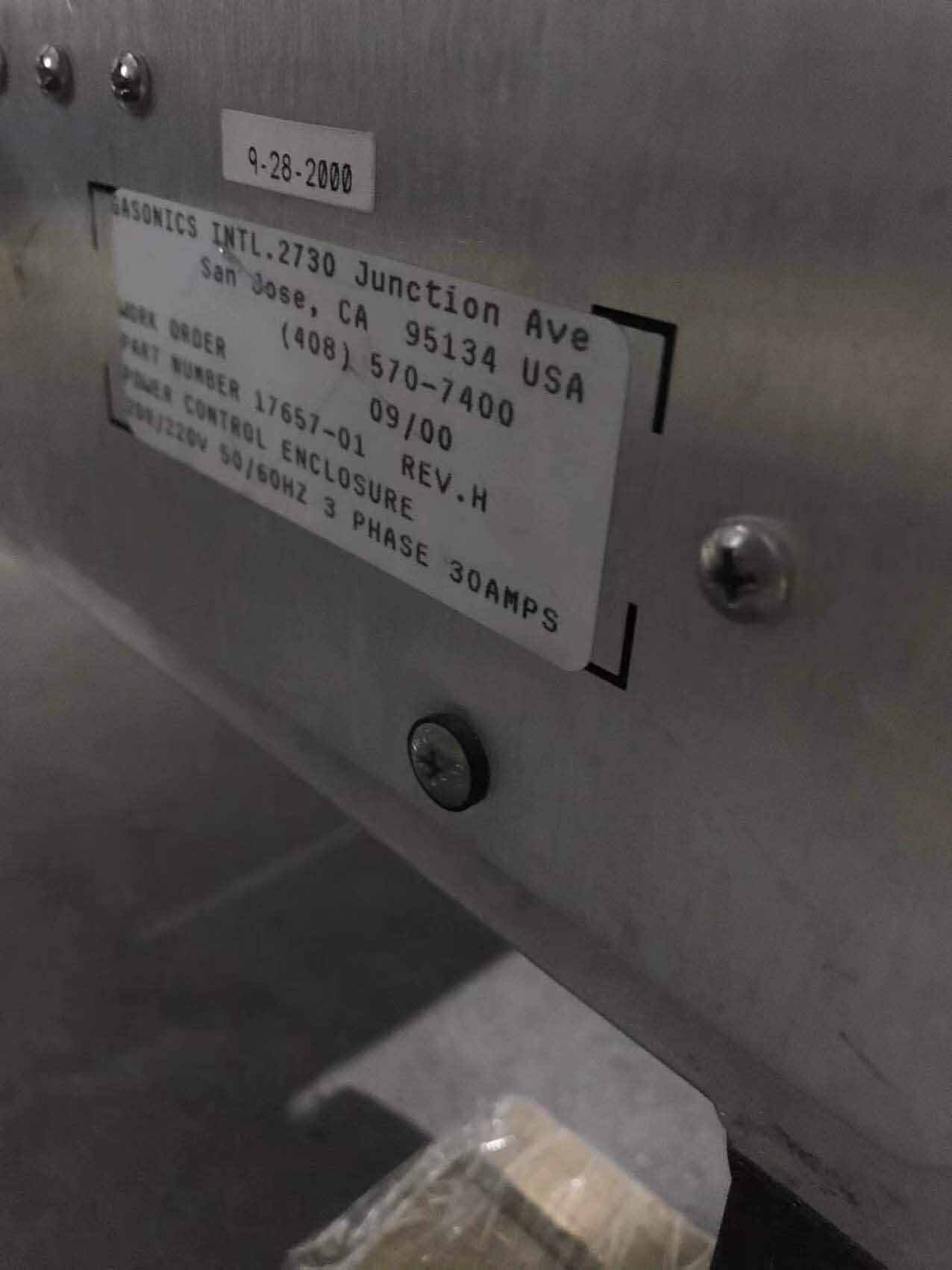

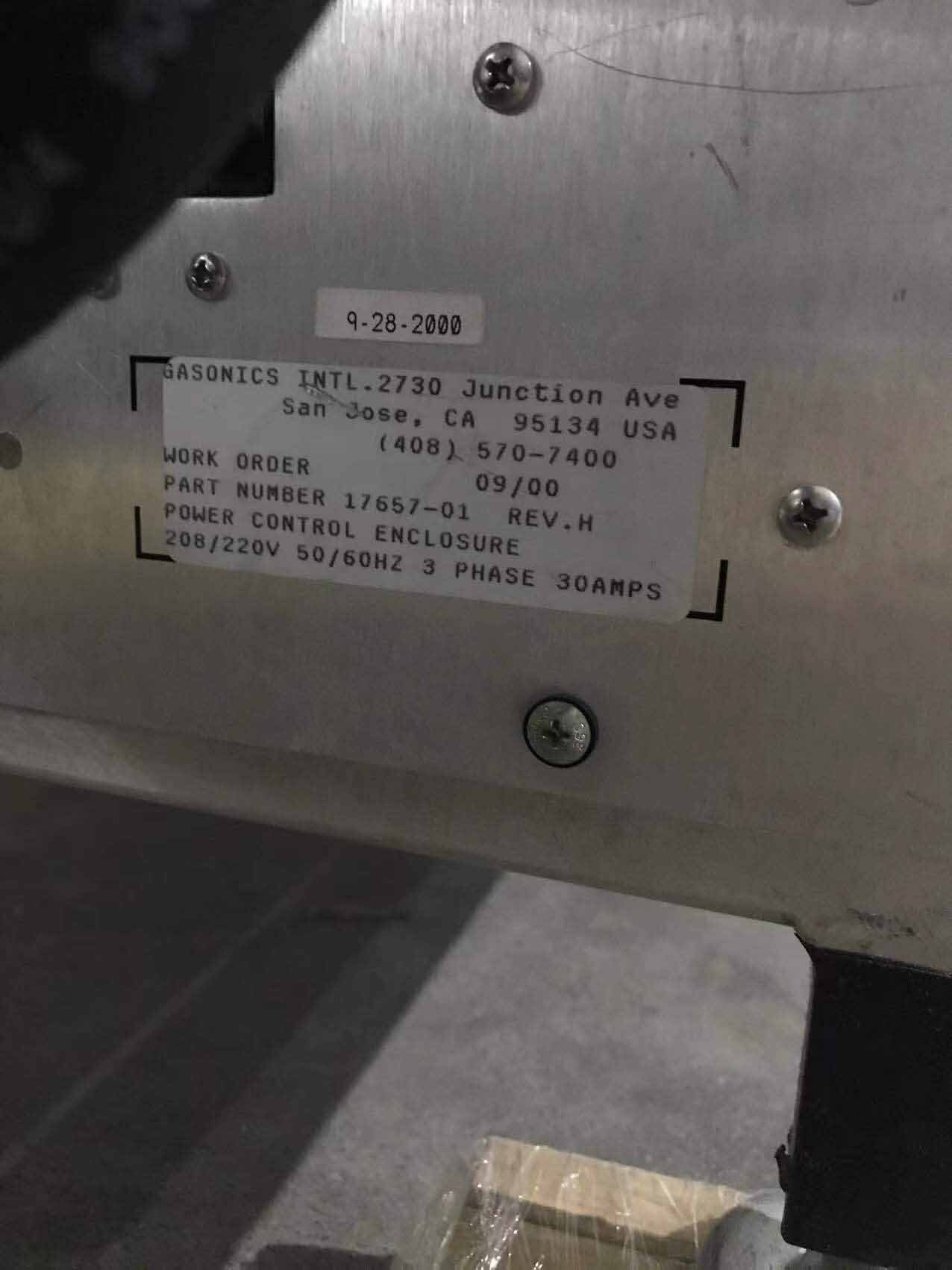

AC Power box

Circuit breaker: 30 Amp

Remote option connector

EMO Control to master system

Circuit breaker

Magnetron

Schematic display driver

Process kits

Panel included

Manuals included

Power supply: 200-240 VAC, 50/60 Hz, Single phase, 30 A

2000 vintage.

GASONICS/NOVELLUS L 3510是一款最先进的蚀刻/asher设备,旨在提供生产环境中最大的吞吐量和全过程控制。该系统是一个自我集成的平台,以高端激光控制和软件解决方桉为特色,根据具体需要识别、测量和修改蚀刻和灰化参数。GASONICS L 3510 Etcher/Asher的创新特性和性能无与伦比。激光技术可确保制造最复杂的设备的最大精度和精确度。再者,该单元兼容各种基材和各种技术,从薄膜配方和先进的介电层到蓝宝石、氧化硅等光学材料的蚀刻和灰化。NOVELLUS L 3510建在坚固、工业级的平台上,适合苛刻的生产周期。它宽大的15英寸甲板允许快速断开连接和模块化附加组件,因此机器可以快速发展以适应不断变化的生产要求。该工具还配备了单片线性谐振执行器,可最大限度地减少在大批量基板上的漂移,确保均匀分布结果并保持一致的蚀刻参数。资产的软件平台本身旨在使蚀刻的各个方面变得更加容易。用户界面允许对整个过程进行全面控制,包括激光的逐步响应和多个谐振器的同时控制。此外,该软件还允许进行个性化的流程监控、配置控制和外部反馈,以便快速、精确地进行流程调整。总体而言,L 3510 Etcher/Asher是一款一流的机型,可在广泛的生产过程中确保可靠、可重复的结果。高精度激光控制、集成硬件平台、综合软件套件确保了对苛刻蚀刻和灰化操作的最大精度和控制。

还没有评论