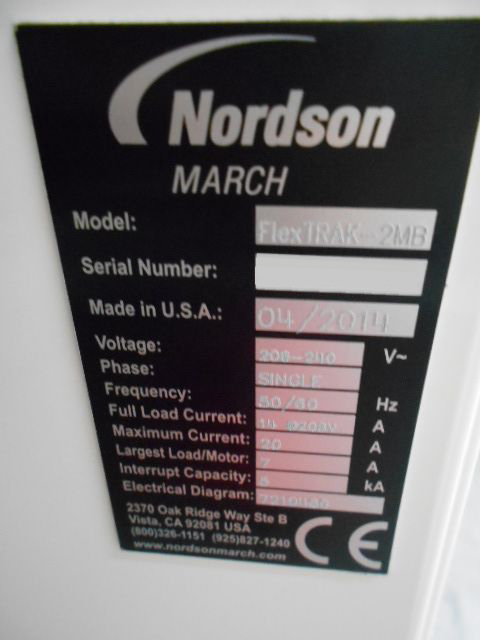

二手 MARCH FLEXTRAK-2MB #9185980 待售

网址复制成功!

单击可缩放

ID: 9185980

优质的: 2014

Plasma cleaners

Multiple inline plasma modules

Uniform plasma treatment

Dual lane boat handling

Ideal for pre-flip-chip underfill

(3) Axes symmetrical plasma chamber

(2) Boats/plasma cycles

Chamber maximum volume: 5.5 liters (338 in³)

Plasma processes:

Pre-flip chip underfill

Pre-die attach

Pre-wire bond

Pre-mold steps

Plasma contamination removal & cleaning:

Fluorine & other halogens

Metals & metal oxides

Organic compounds

Electrodes:

Variable electrode configurations:

Power-ground

Ground-power

Power-power

Working area: 305W x 305D mm (12W x 12D in.)

RF Power:

Standard wattage: 600 W

Frequency: 13.56 MHz

Gas control:

Flow volumes: 10, 25, 50, 100, 250 or 500 sccm

(4) MFCs

Control & interface:

Software control: EPC with PC-Based touch screen interface

Remote interface: SMEMA, SECS/GEM

Vacuum pump:

Standard dry pump: 16 cfm

Optional wet pump: 19.5 cfm

Optional purged dry pump: 16 cfm

N2 Purged pump flow: (2) slm

Process gas fitting size & type: 6.35 mm (0.25 in.) OD SWAGELOK Tube

Process gas purity: Lab or electronic grade

Process gas pressure: 0.69 bar (10 psig) min. to 1.03 bar (15 psig) max

Purge gas fitting size & type: 6.35 mm (0.25 in.) OD SWAGELOK Tube

Purge gas purity: Lab or electronic grade N2/CDA

Purge gas pressure: 2 bar (30 psig) min to 6.9 bar (100 psig) max

Pneumatic valves fitting size & type: 6.35 mm (0.25 in.) OD SWAGELOK Tube

Pneumatic gas purity:

CDA

Oil free

Dewpoint: ≤7°C (45°F)

Particulate size: <5μm

Pneumatic gas pressure: 3.45 bar (50 psig) min to 6.89 bar (100 psig) max

Exhaust: 25.4 mm (1 in.) OD Pipe flange

SEMI: E10, S2/S8 (EH&S/Ergonomics)

Gas generators: Nitrogen, hydrogen (requires additional non-optional hardware)

Chiller

Scrubber

Power supply: 220 VAC, 15A, 50/60 Hz, 1-Phase, 12 AWG, 3-Wire

CE Marked

2014 vintage.

MARCH FLEXTRAK-2MB是一种蚀刻器/asher,设计用于半导体行业内的洁净室生产环境。它能够以5微米的分辨率将光刻胶图像再现到半导体晶片或其他基板上。与其他可用的蚀刻解决方桉相比,这种最先进的蚀刻器/蚀刻器具有许多独特的优势。MARCH FLEXTRAK 2MB具有14英寸的大工作区域,允许广泛的光刻加工操作。它支持随机和均匀阵列,包括线形、矩形、圆和椭圆。这样可以确保图像的制作具有很高的准确性和精确度。FLEXTRAK-2MB配备了先进的可编程逻辑电路,便于修改其蚀刻参数。这意味着蚀刻过程可以根据给定应用程序的特定要求进行调整。通过调整蚀刻时间、分辨率、功率等参数,可以实现卓越的重复性、均匀性和图像质量。FLEXTRAK 2MB提供了许多安全功能。为确保操作过程中的最大安全,该装置配备了紧急停止能力、用于处理晶片的自动编子系统以及用于监视的背光安全玻璃。蚀刻器/asher还具有独特的冷却系统,可保护细腻晶片的表面不会过热。MARCH FLEXTRAK-2MB提供了广泛的应用程序编程选项,使光刻蚀刻过程易于自动化。用户可以利用各种专有软件程序来提高吞吐量和流程质量,同时还可以利用MARCH FLEXTRAK 2MB的高级功能。最后,FLEXTRAK-2MB设计的功耗低,有助于减少对环境的影响。这使得它非常适合研究和生产环境,在这些环境中,能效是优先考虑的。总之,FLEXTRAK 2MB是任何需要高分辨率、精确度和重复性的蚀刻操作的理想选择。凭借其先进的功能和低功耗,它是洁净室生产、研究或其他行业应用的理想选择。

还没有评论