二手 TEL / TOKYO ELECTRON Indy-B-L #293637434 待售

网址复制成功!

单击可缩放

ID: 293637434

晶圆大小: 12"

优质的: 2007

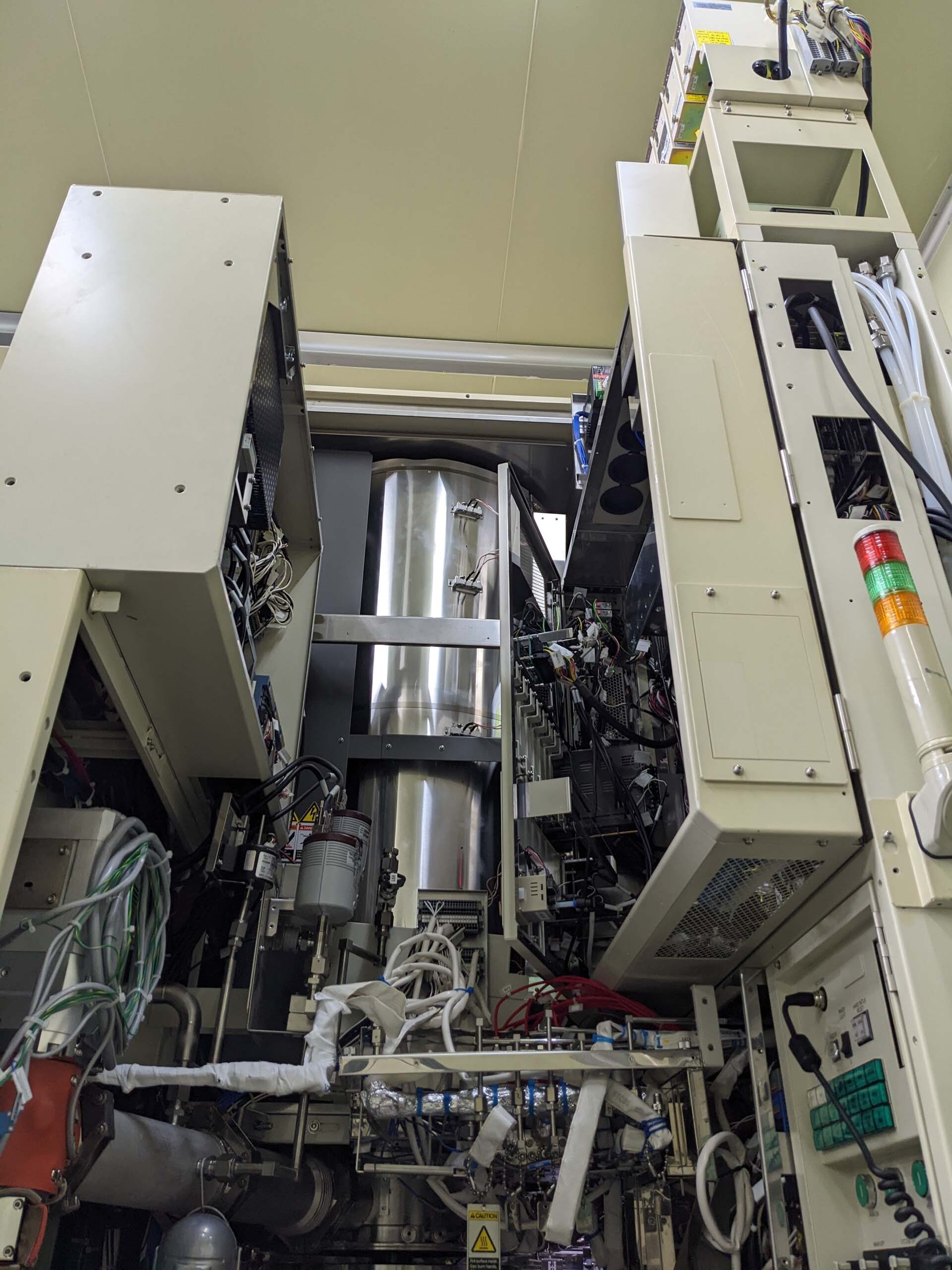

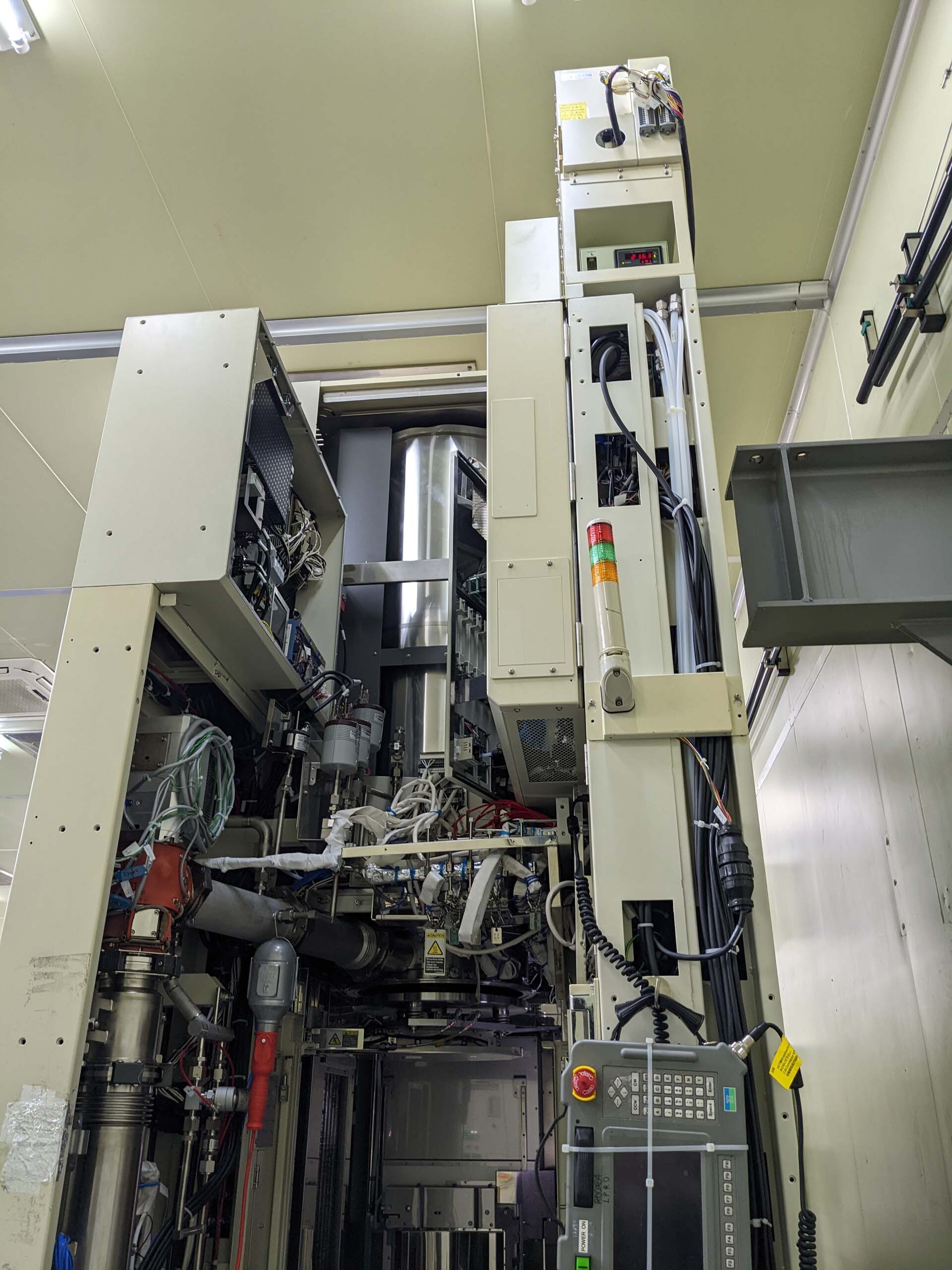

LPCVD Furnace, 12"

Wafer type: Si semi STD Notch

(100) Production wafers

Maximum operating temperature: 500-1000

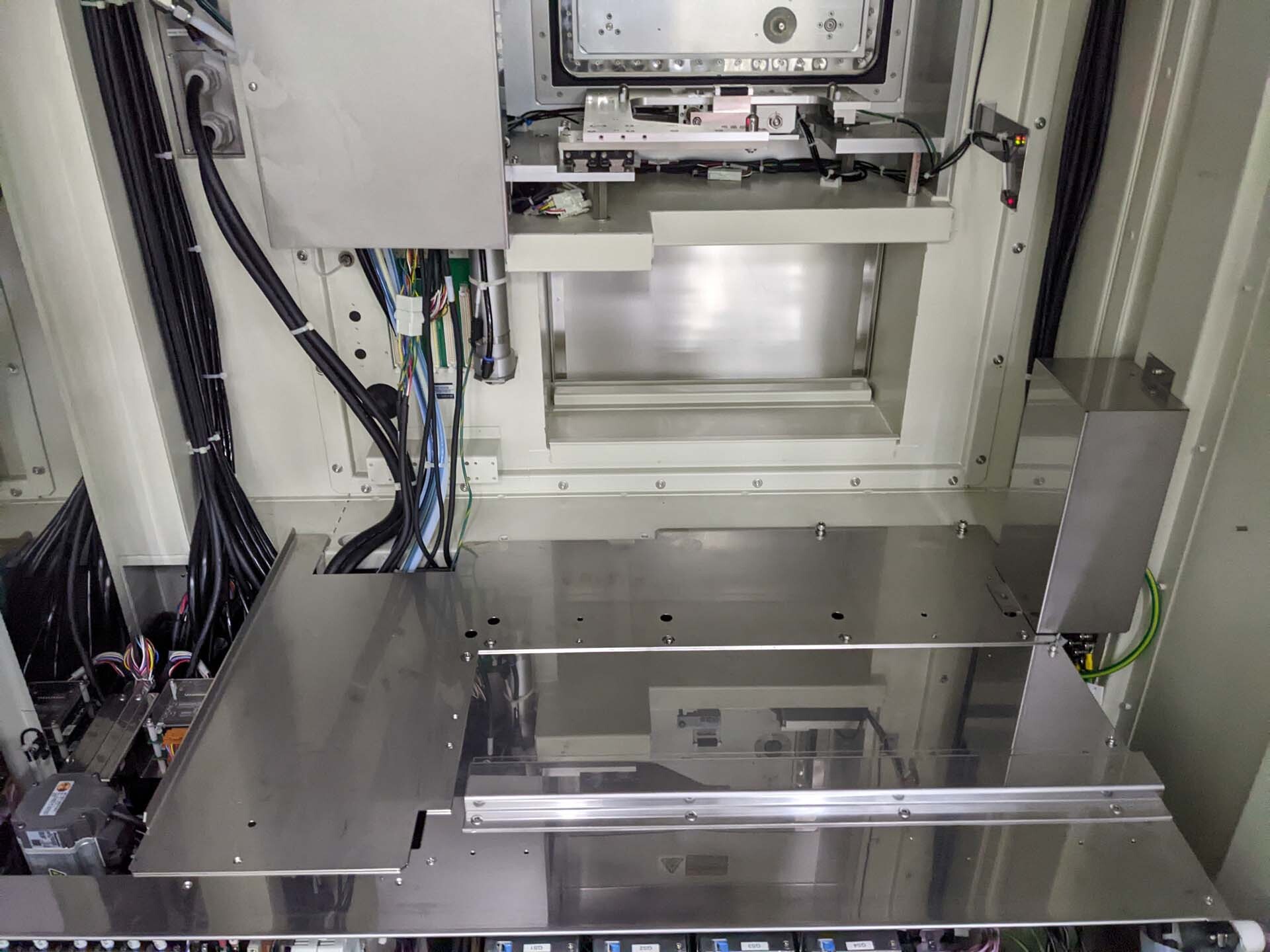

N2 Load lock

Boat type handling position

O2 Density control for N2 Load lock

N2 Boat shower wafer cooling

560A Furnace temperature controller

VMM-56-002 Heater

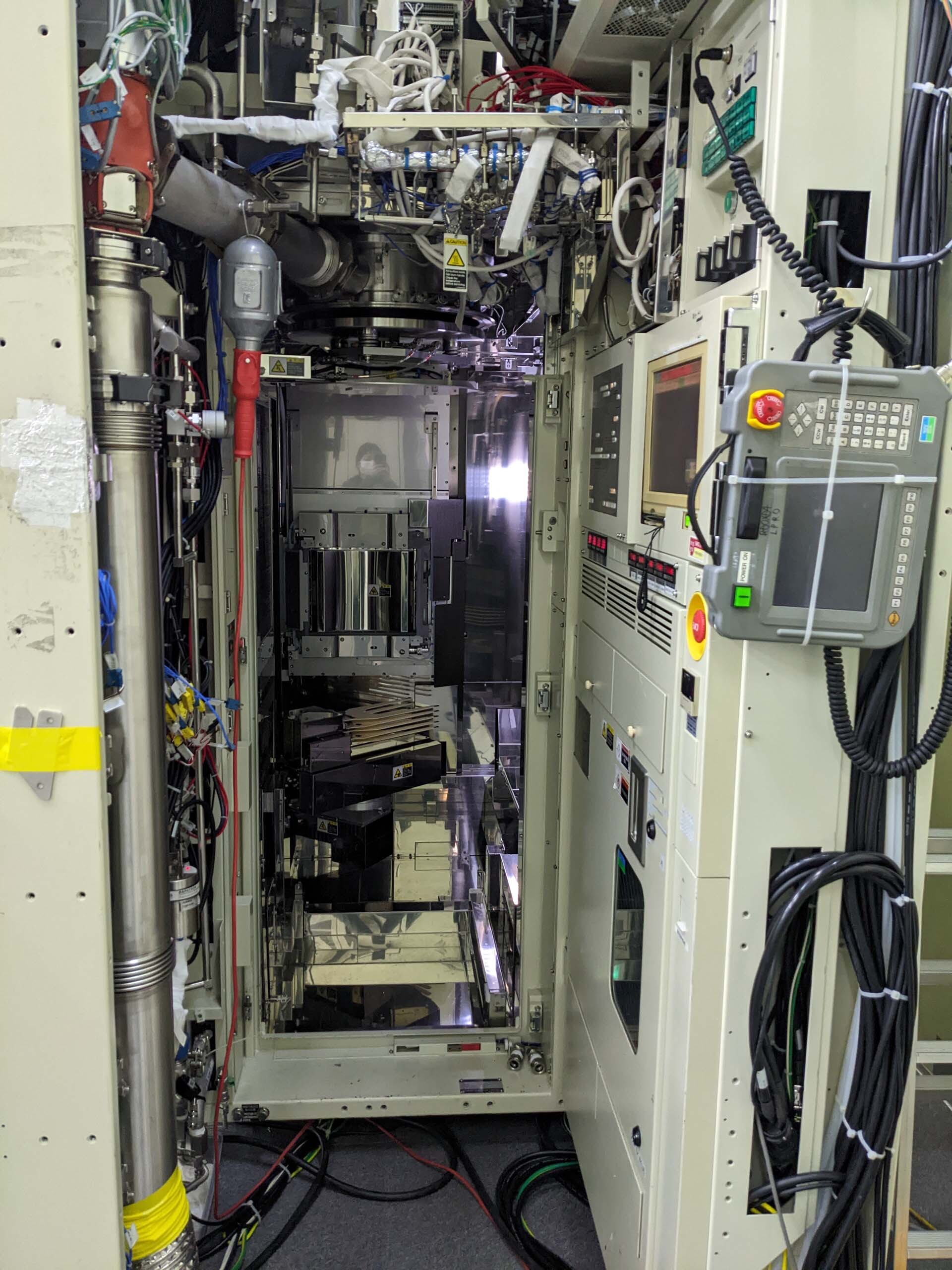

Wafer / Carrier handling:

(25) Carrier type: FOUP

ENTEGRIS A300

Carrier stage capacity: 16

Pin pad A, B

Fork material: Al203 and peek

With type: 1+4 Edge grip

With auto teaching

Furnace facilities:

Furnace exhaust connection point: Top connection

Cooling water connection point: Bottom connection

Gas specification:

IGS 1.5" W-seal rail-mount

FUJIKIN IGS

Tubing bend bend (Less than 90°)

HORIBA STEC

Incoming gas connection point: Bottom connection

Gas vent connection point: Bottom connection

Gas unit exhaust connection point: Bottom connection

Process gas exhaust connection point: Bottom connection

Exhaust specification:

MKS Vacuum gauge-press controller

MKS Vacuum gauge-press monitor

MKS Vacuum gauge-pump monitor

CKD-VEC Main valve

Condenser

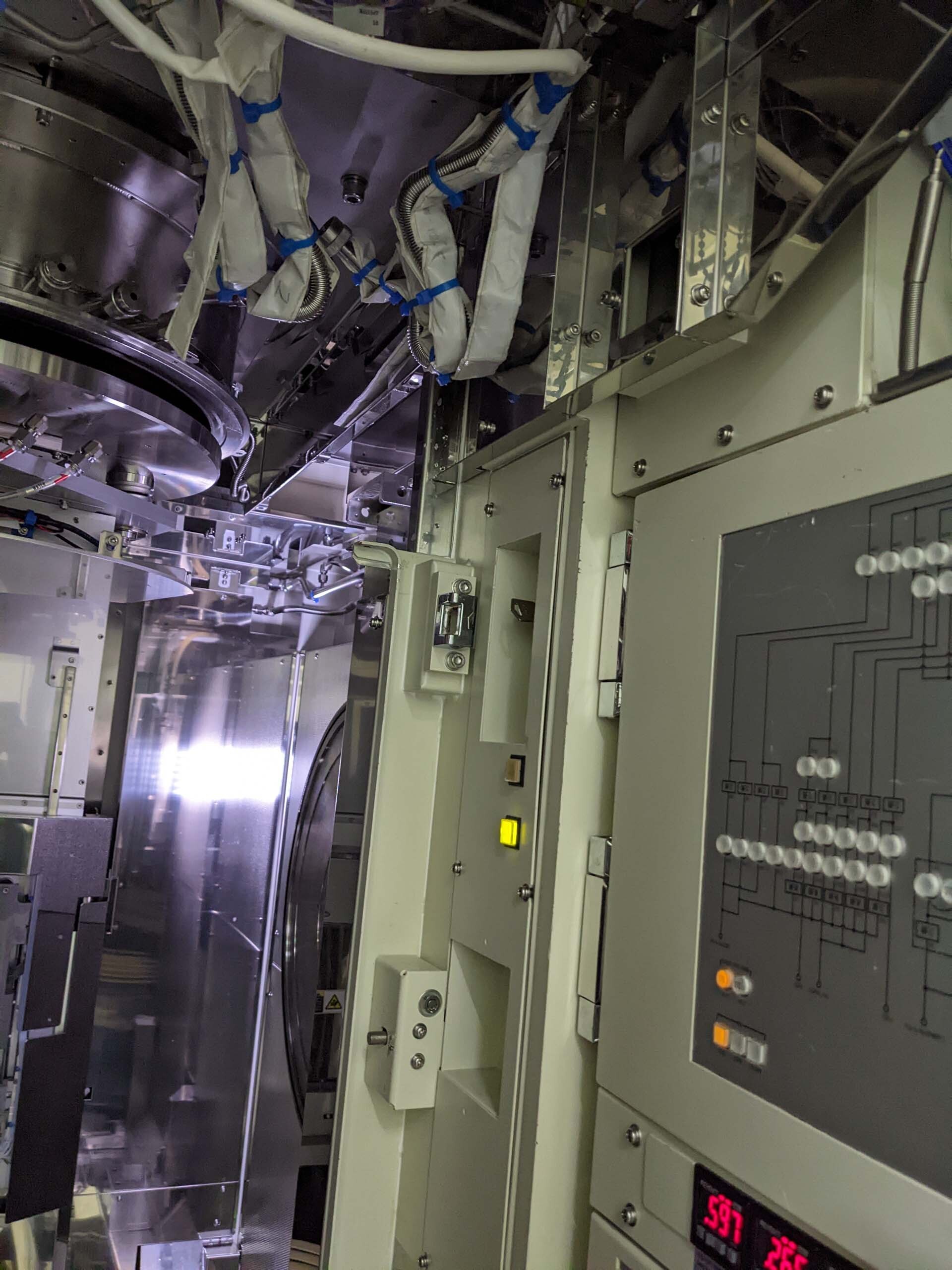

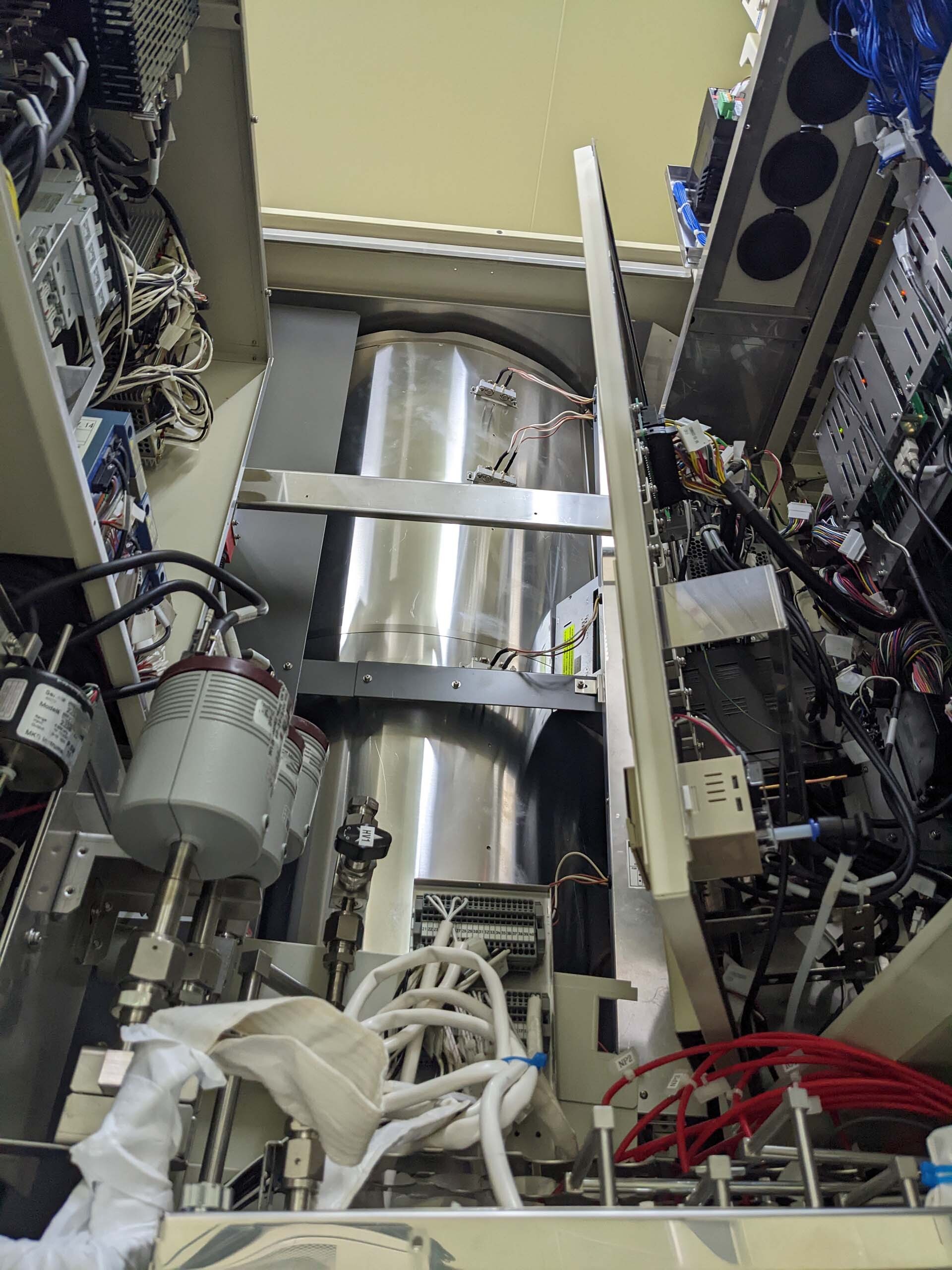

Reactor specification:

Tube material: Quartz (outter), quartz (inner)

Inner tube type (LP): Straight

Inner T/C: Outer tube inferior (wall type)

Tube sealing: O Ring

Soft backfill injector

Boat type: (117) Slots, pitch, 8 mm

Boat rotation

Pedestal type: Quartz

No shutter purge type

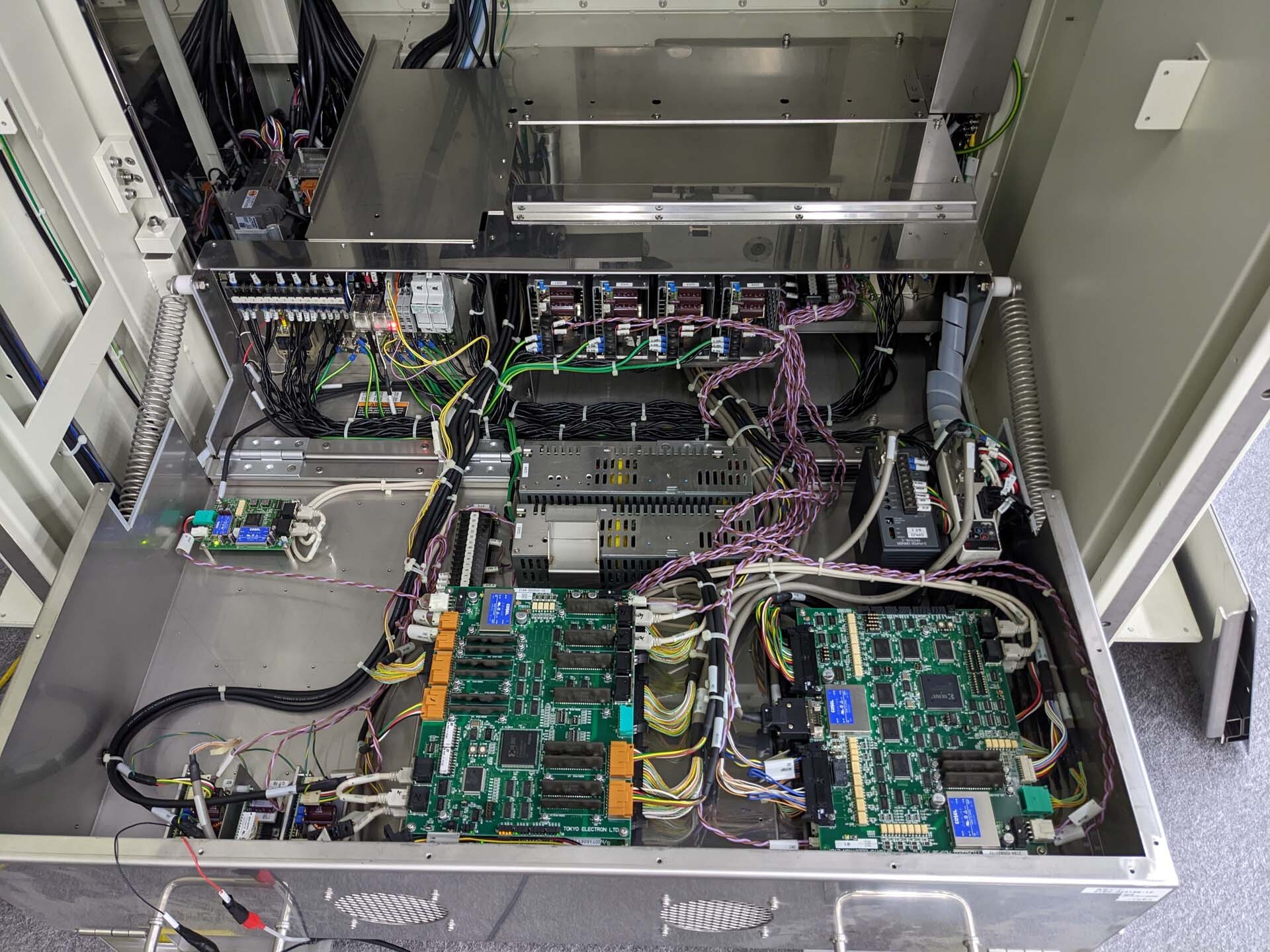

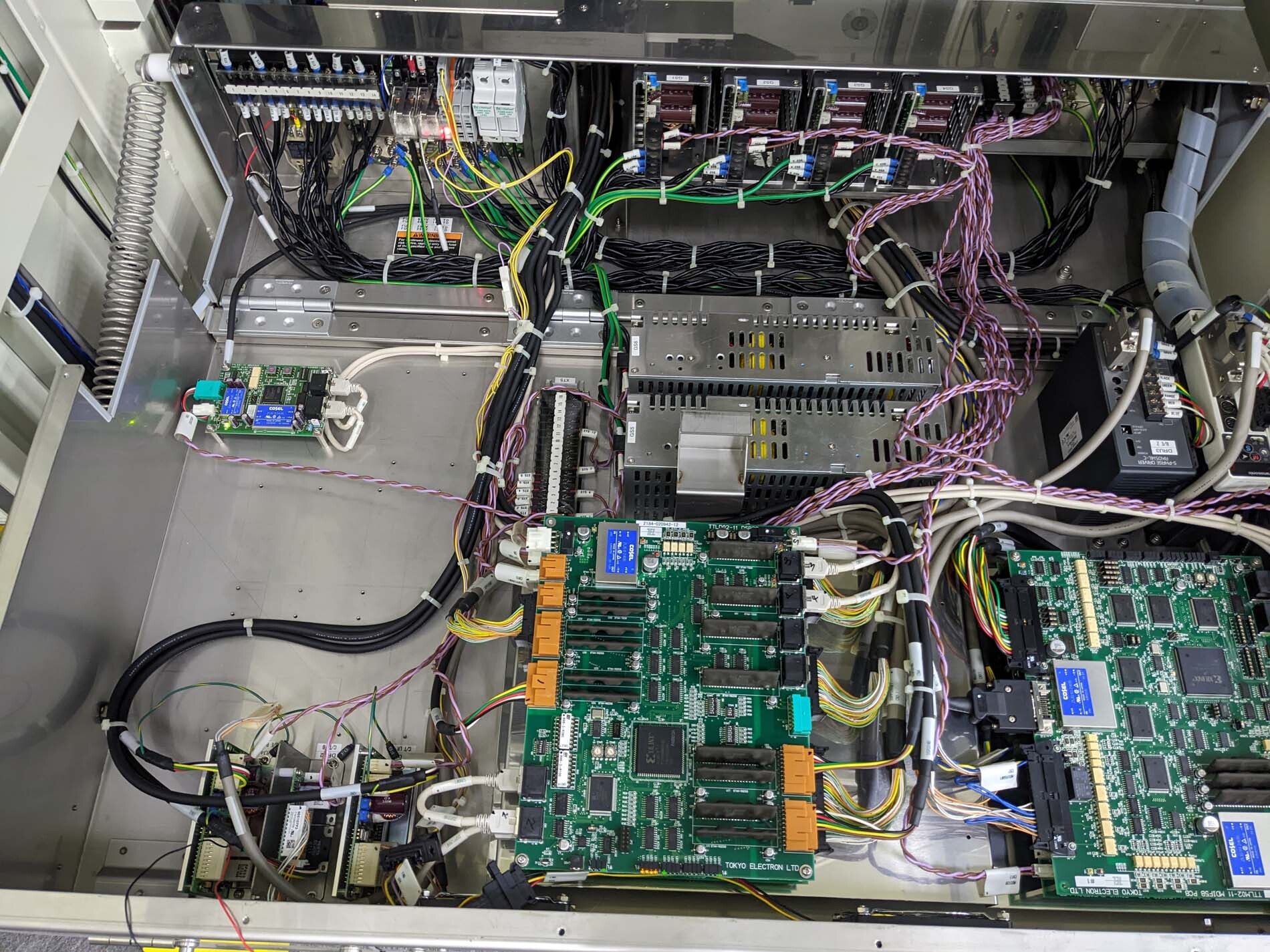

Interface specification:

Host communication: Comply with GJG

Equipment host I/F Connection: Gas box top HSMS

Ingenio

OHT Capability

Load port operation: Upper

PIO I/F Location: FNC Top

HOKUYO DMS-HB1-Z PIO

RF Carrier ID Reader writer type

CIDRW L/P: Read and write

ASYST ATR 9100 CIDRW

TEL CIDRW

User interface

Signal tower model: Customized

Signal tower colors (From the top): Red / Green / Yellow

Signal tower location: Front

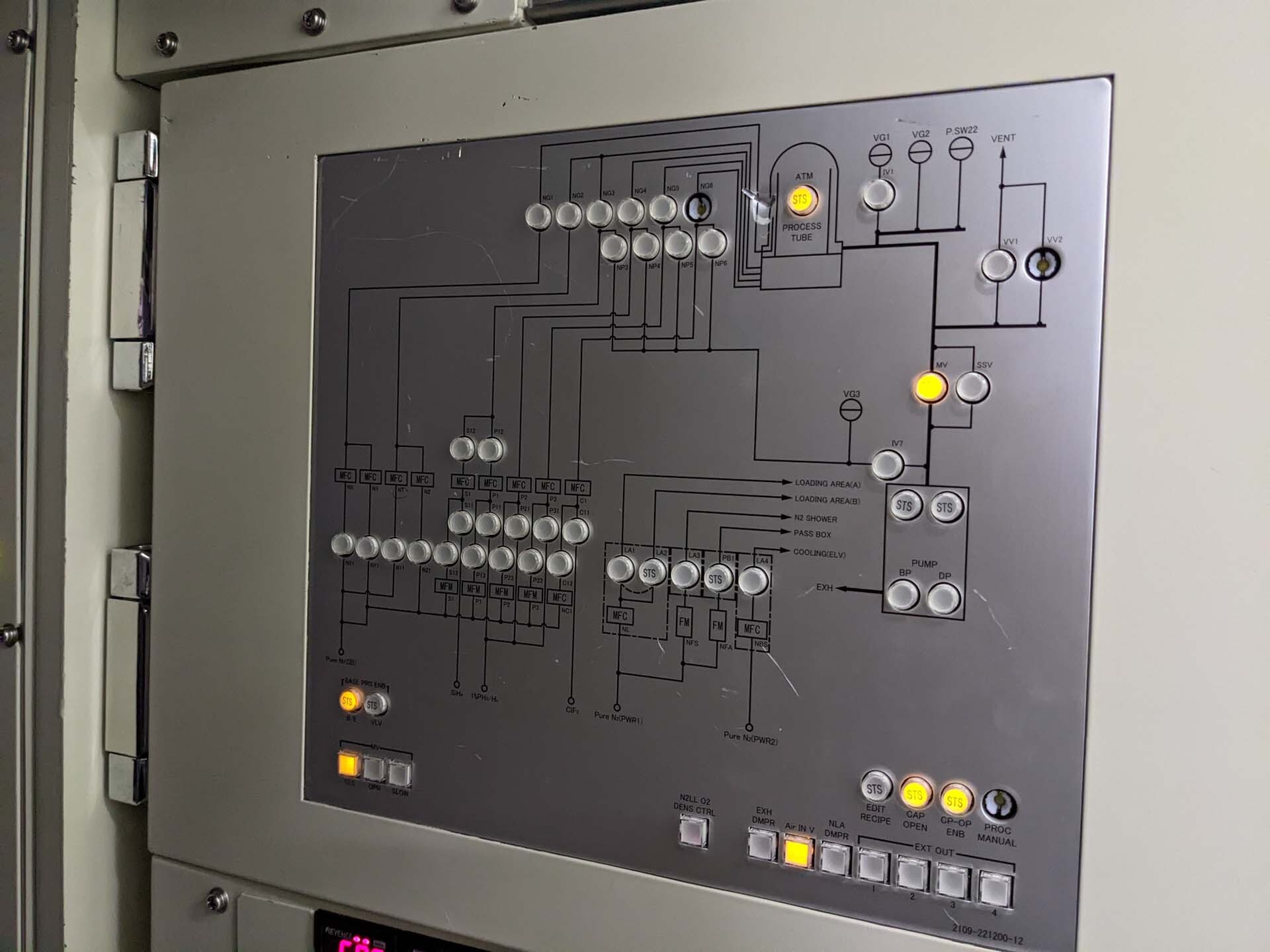

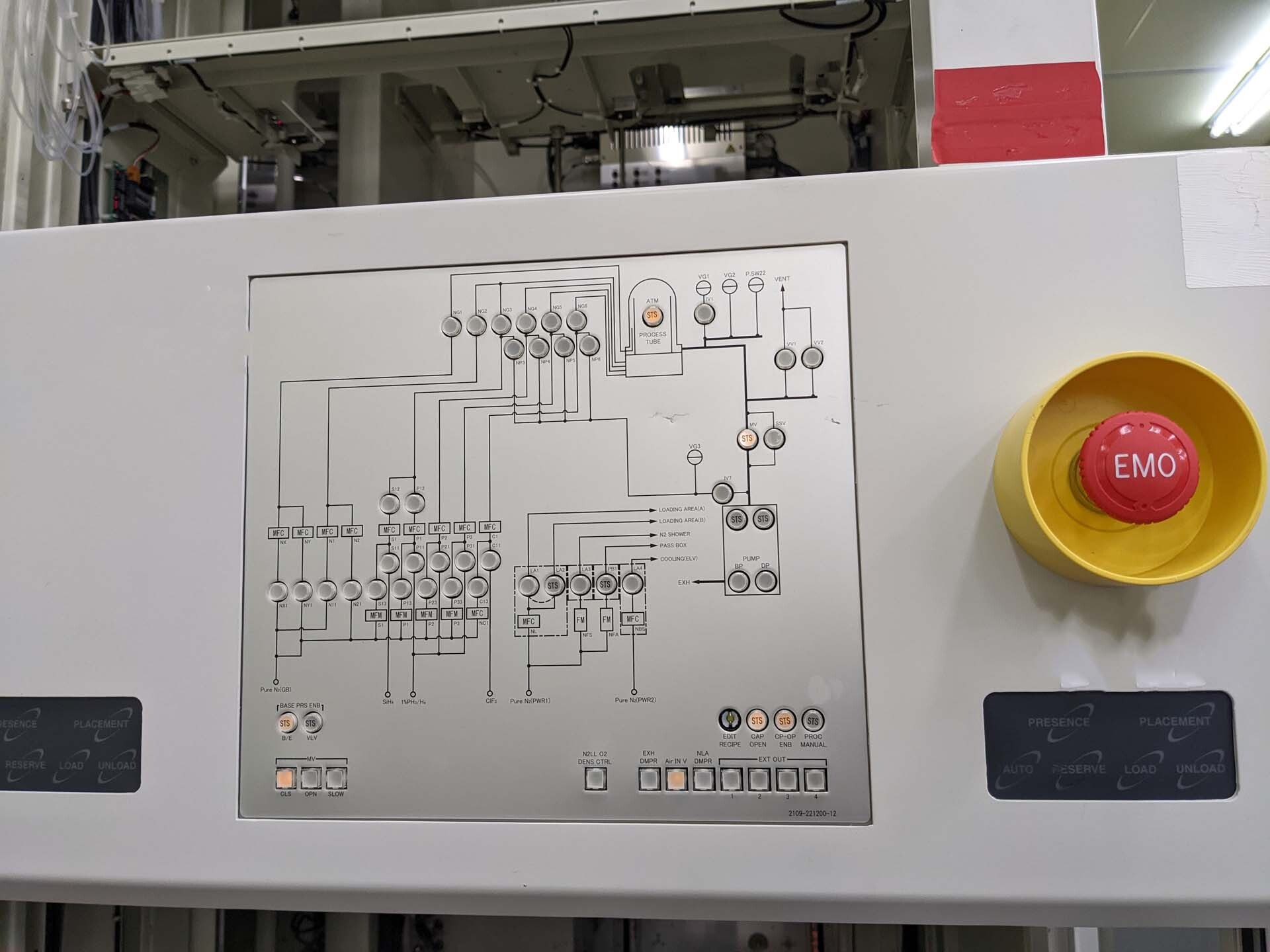

Front operation panel

MMI and gas flow chart: Gas box and front operation panel installed

Indicator type: Superset

Operator switch: Operator access / orange

Pressure display unit (Gas inlet / vacuum): Mpa / Pa

Cabinet exhaust pressure display unit: Pa

Gas leak detector:

Gas1 / SiH4

Gas2 / PH3

Gas3 / ClF3

Cable length:

FNC-Power box: 20 meter

Power box -refill system: 30 meter

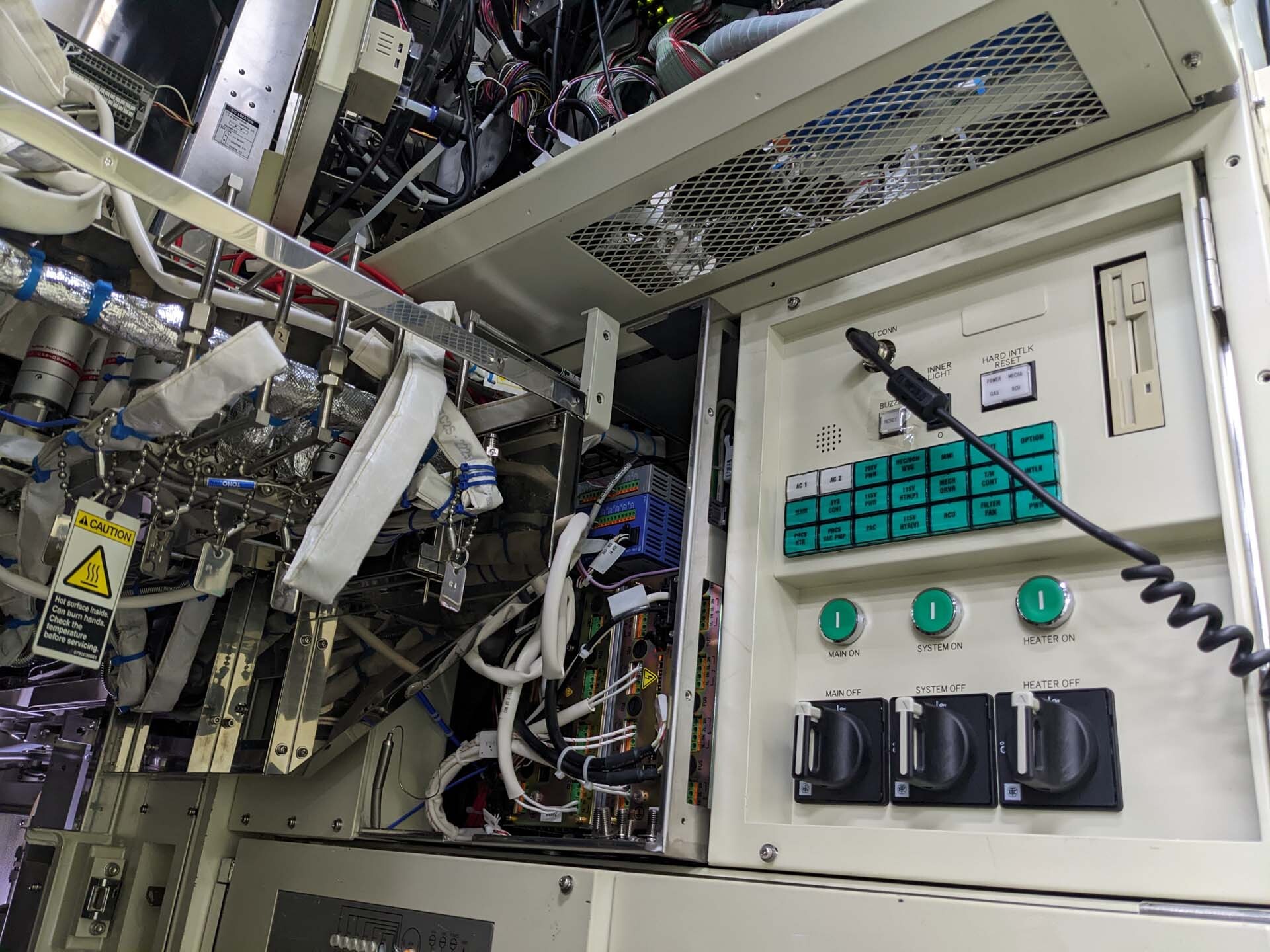

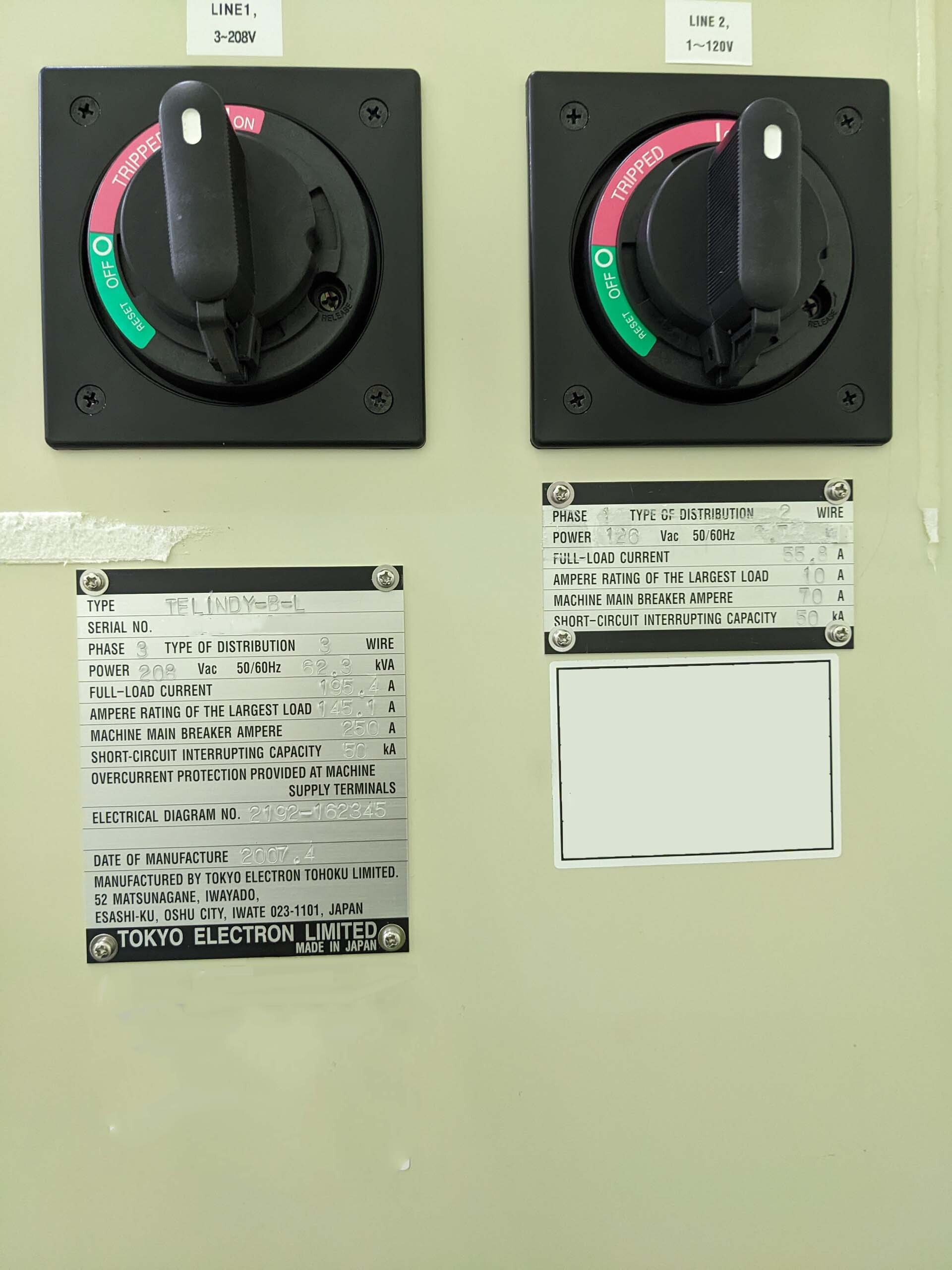

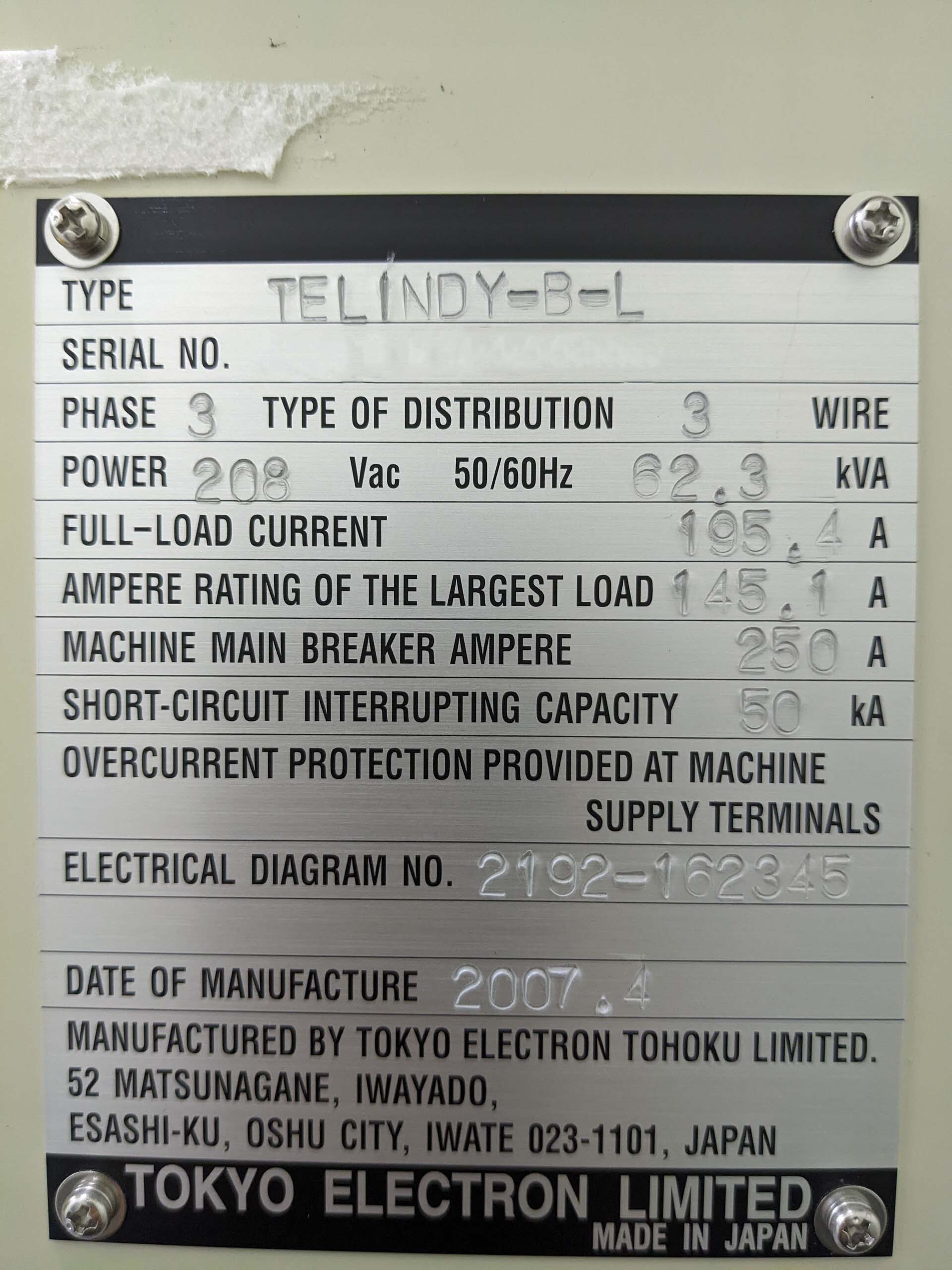

Power specification:

Voltage: 208 VAC, 3 Phase

Phase connection type: Star connection

Voltage single-phase: 120 VAC

Single-phase connection type: Grounded

Frequency: 60 Hz

Power cable input entrance location: Power box top

2007 vintage.

TEL/TOKYO ELECTRON Indy-B-L是一款为半导体和复合材料行业设计的蚀刻器/asher。它是一种先进、可靠、精密的蚀刻/灰化设备,用于制造最优质的材料。TEL INDY B L蚀刻器具有可编程阶段系统,可以执行各种功能,如预清洁、脱气、灰泥、蚀刻和蚀刻/愈合。预清洁阶段用于去除基板上的污染物,而脱气阶段则去除不需要的气体分子。灰化过程会去除表面原子,而蚀刻过程会从基板中去除细腻而坚硬的层。蚀刻/愈合阶段用于减少基板上的残余应力。该蚀刻器利用先进的基于AI的智能冷却装置(SCS)来保持最佳温度以进行精确蚀刻。TOKYO ELECTRON INDY B-L提供广泛的专门蚀刻能力,包括深蚀刻、后蚀刻统一和低温蚀刻。该机还提供小至10纳米零件的精确表面修改,使其非常适合MEM和LSI设备等高端应用。蚀刻器也是完全自动化的,可以通过其简单的触控面板界面操作。TOKYO ELECTRON INDY B L还提供全面的安全功能,以确保其操作员和周围环境的保护。它配备了一个高度精密的内置真空泄漏检测工具(VLDS)来识别任何潜在的泄漏。它还设有标准化气体供应资产,只有在安全条件允许的情况下,才通过模型供应气体。最后,创新环保冷却设备(KIECS)通过在操作暂停期间自动减少气体消耗来节约能源。总体而言,Indy-B-L是一款精密的蚀刻器/asher,专为半导体和复合材料行业的高端应用而设计。它具有高级功能,如SCS、VLDS、SGSS和KIECS,并提供到纳米级的精密蚀刻。它的安全特性确保了最佳的安全条件和复杂的触摸面板界面,使其易于操作。

还没有评论