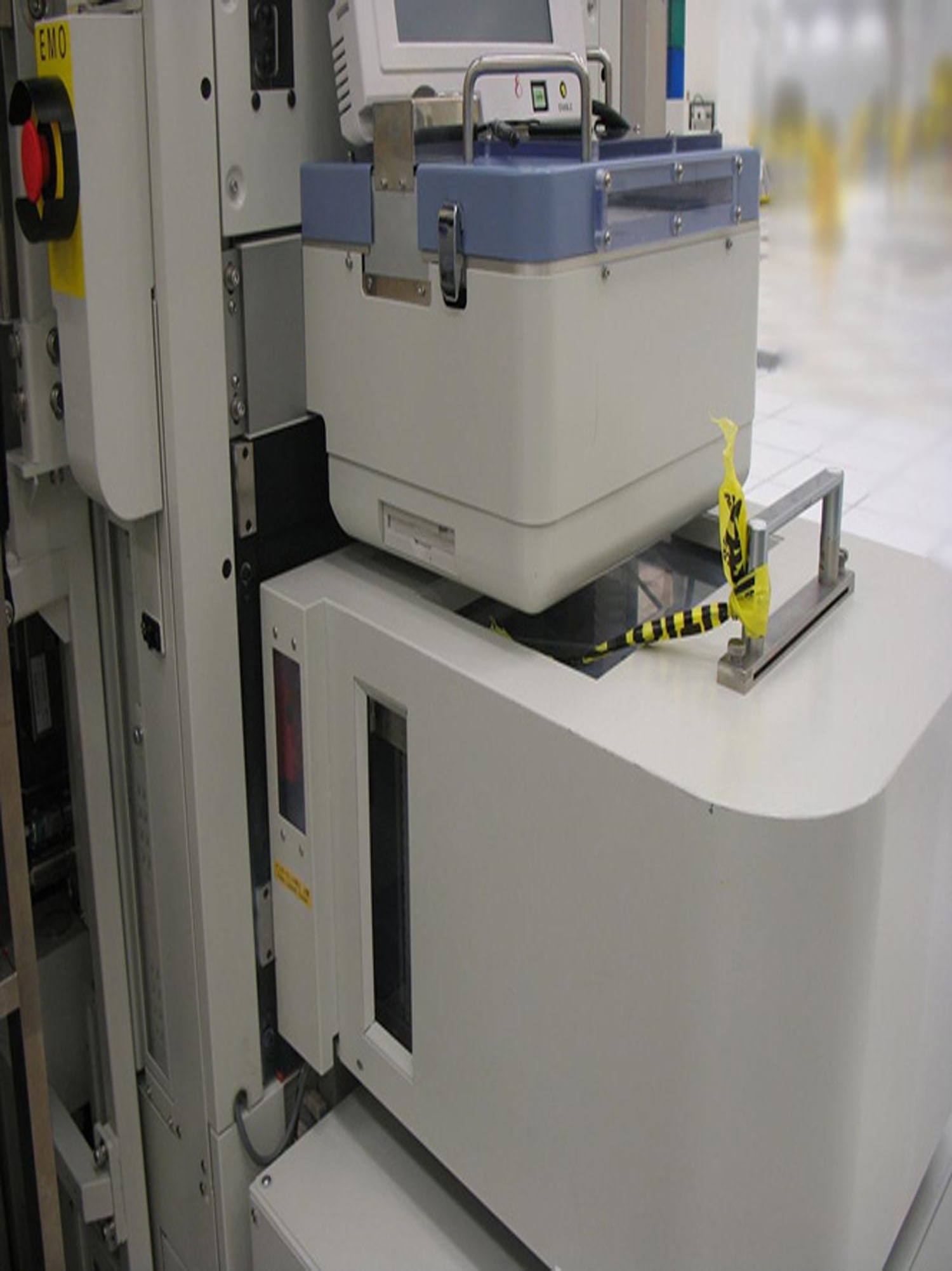

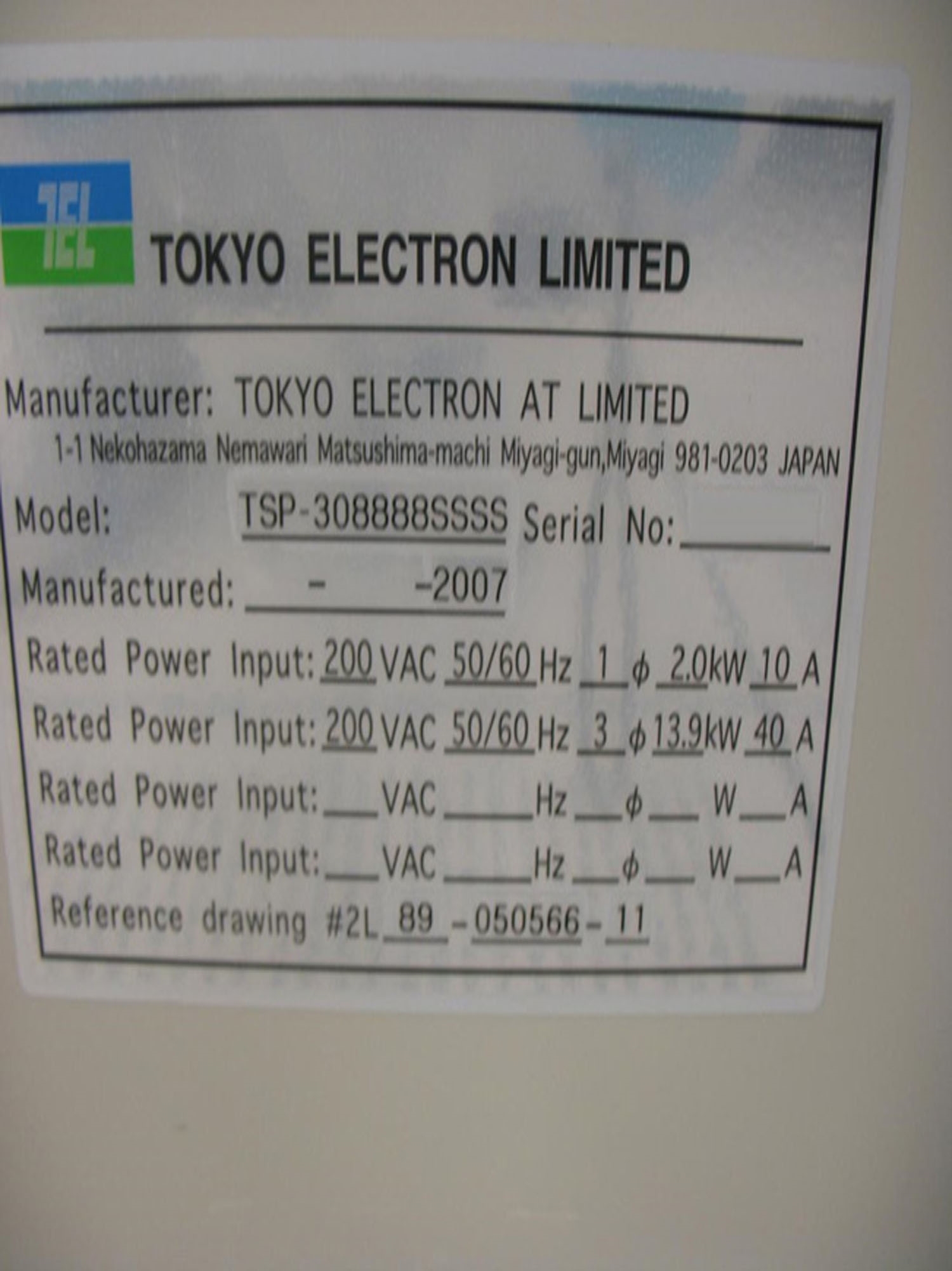

二手 TEL / TOKYO ELECTRON Telius SP 308QS #9213296 待售

网址复制成功!

单击可缩放

ID: 9213296

Deep trench silicon etchers

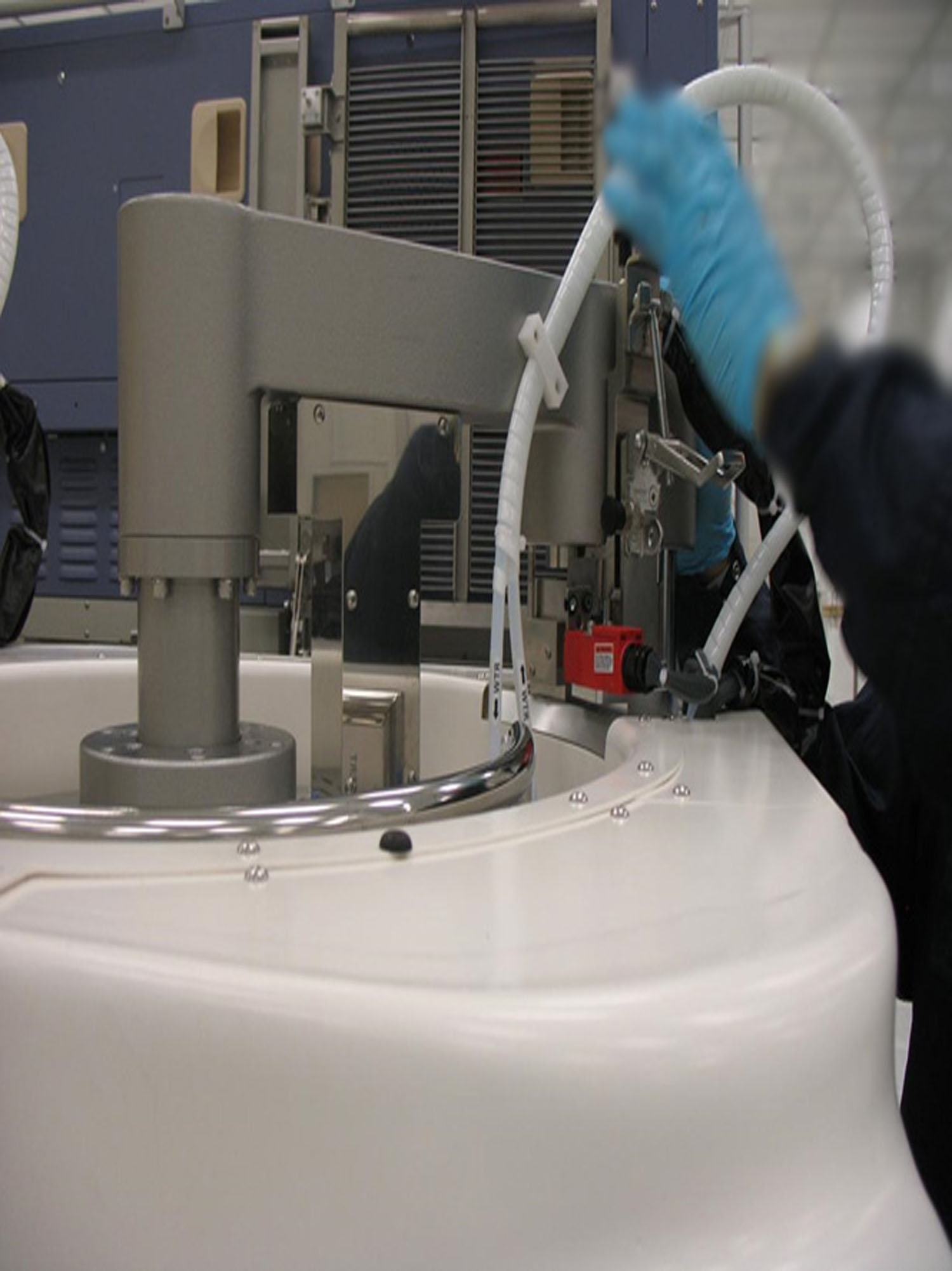

12" FOUP

(4) Chambers (SCCM)

(5) Loader ports

Load locker modules

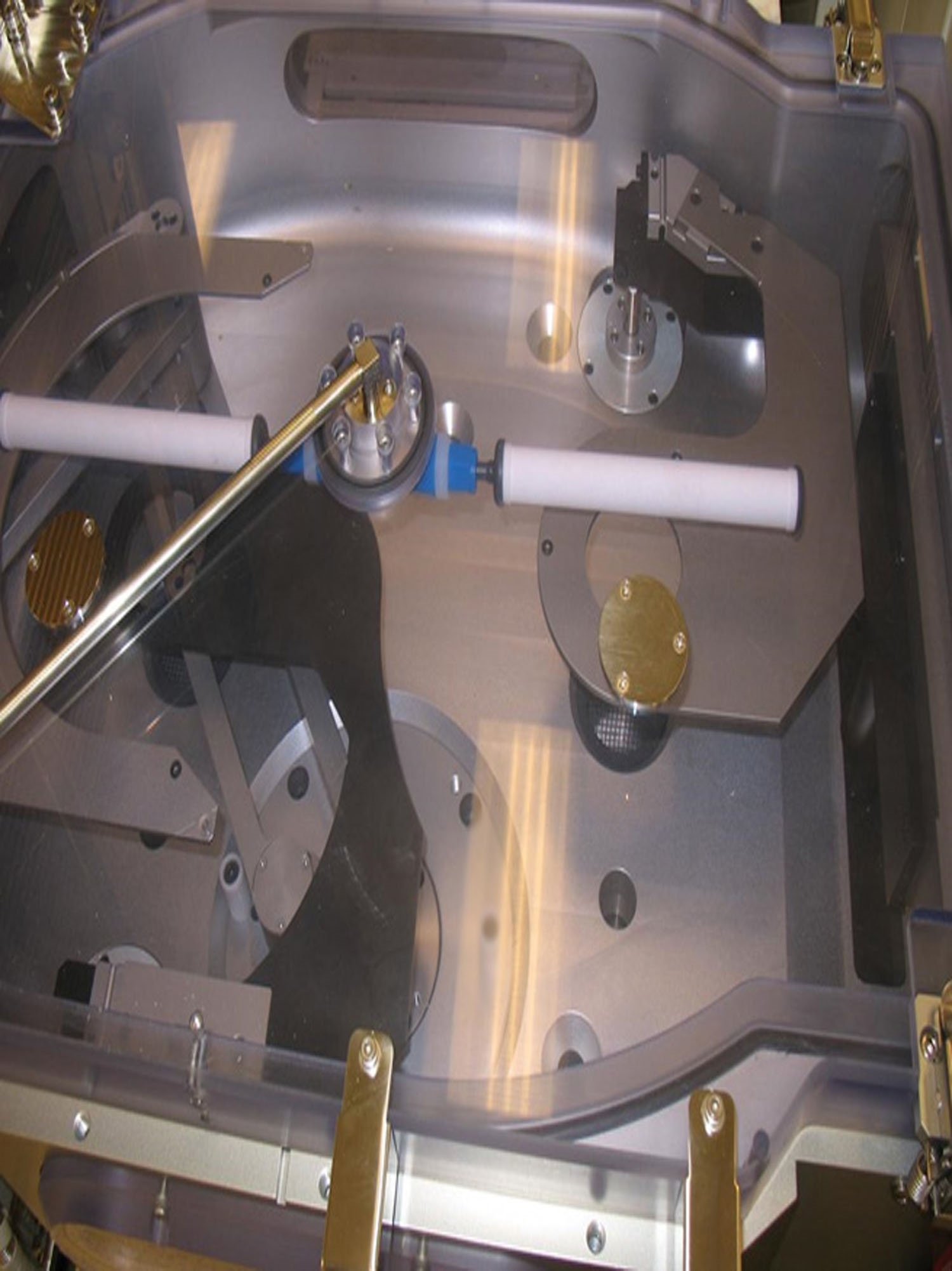

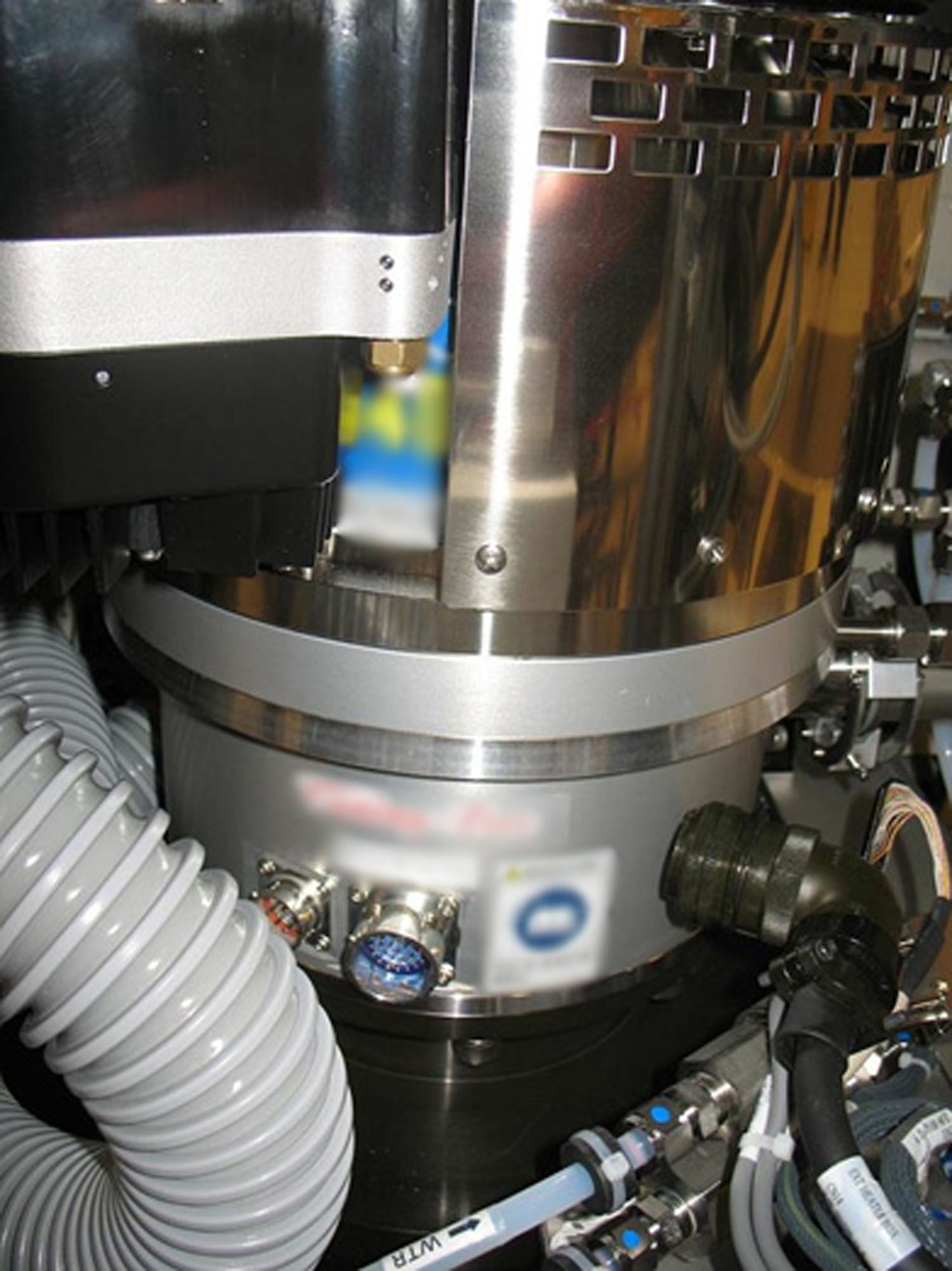

GEW3040 and NOVA50A 40MHz and 3.2MHz dual frequency source

ESD Chuck

Temperature control

RF Application method

Process: 80um deep 90nm wide via silicon etch

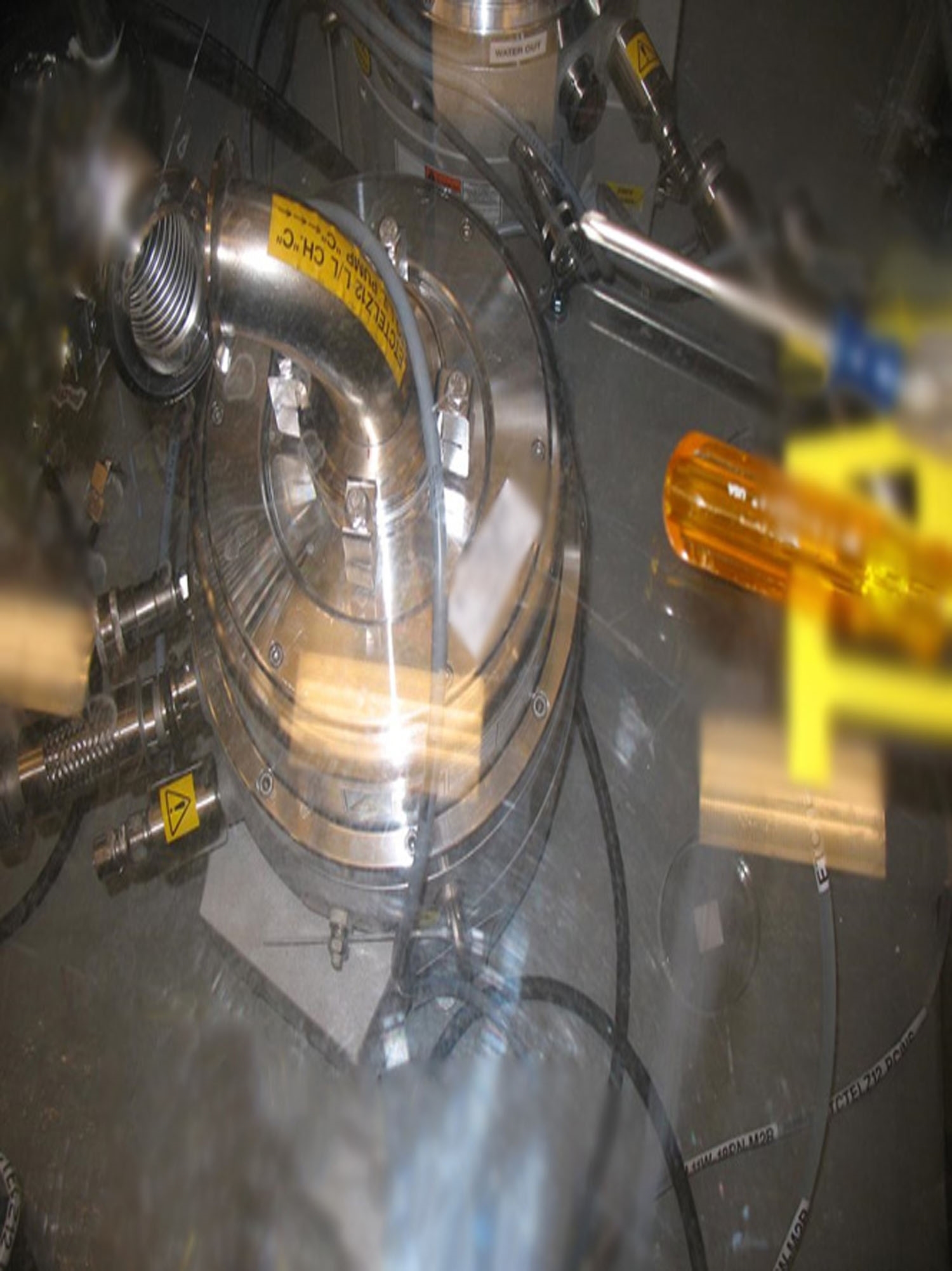

Chamber:

Aluminum alloy chamber

Material: Aluminum alloy (A6061)

Surface finishing: Hard sulfuric acid anodizing

RF Application method: Apply upper RF to lower electrode

Discharge method: SCCM Type

Temperature control:

Upper electrode: Temperature control by heater and cooling water

Lower electrode: Temperature control by circulating coolant

Side wall: Temperature control by heater

Upper electrode:

Quartz cover or aluminum alloy (A6061) with hard sulfuric acid anodizing

Shield ring

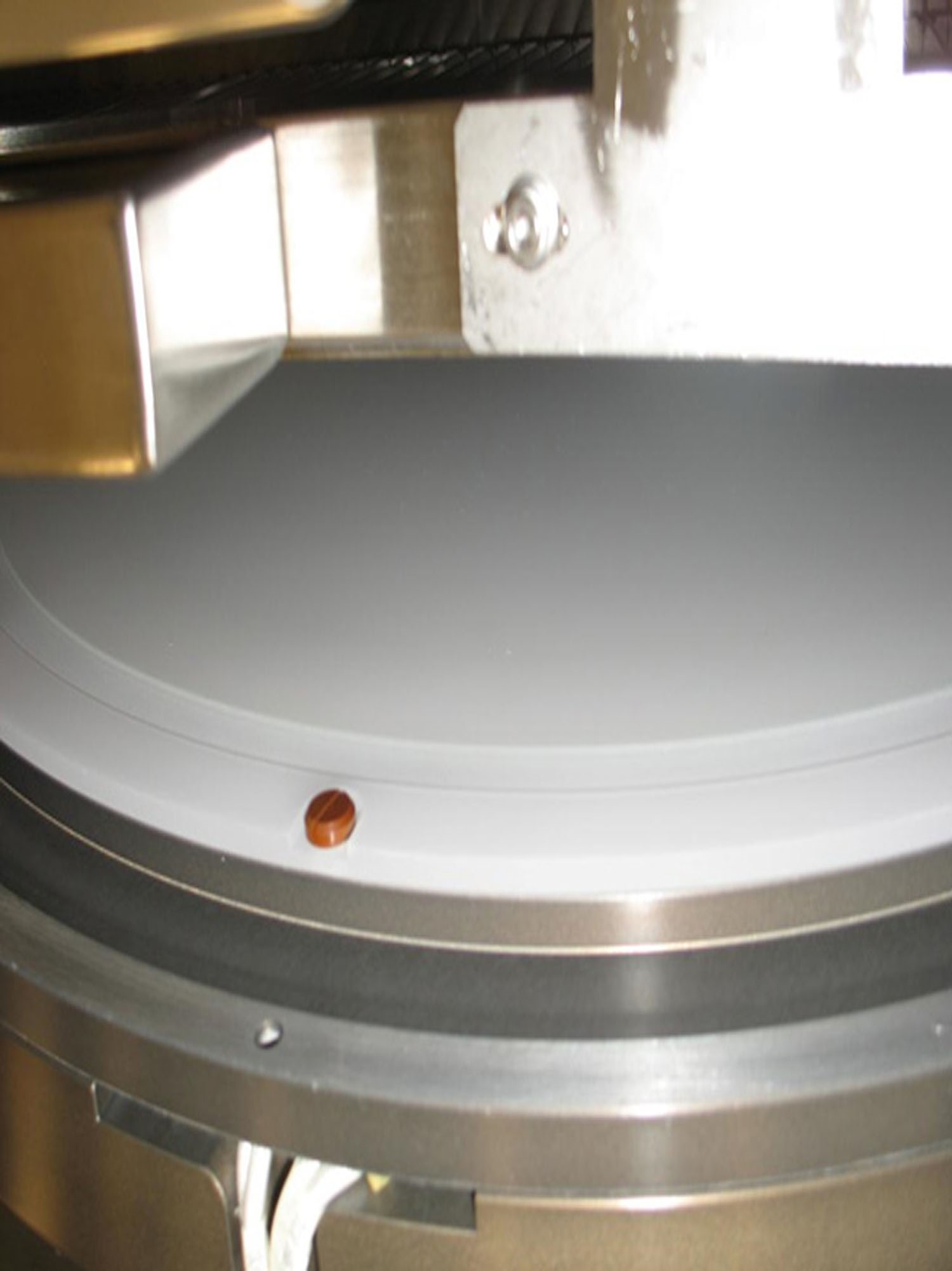

Lower electrode:

Ceramics electro static chuck

Thermometer

Wafer holding method: Electrostatic chuck(φ300) mechanism

Lifter: Resin

Focus ring: Qz

Exhaust plate: Aluminum alloy with hard sulfuric acid anodizing

Insulation ring: Quartz cover or aluminum alloy (A6061) with hard sulfuric acid anodizing

Distance between electrodes: 30~35 mm

Magnet:

Intensity: 170G (center)

Rotation: 20± 1rpm

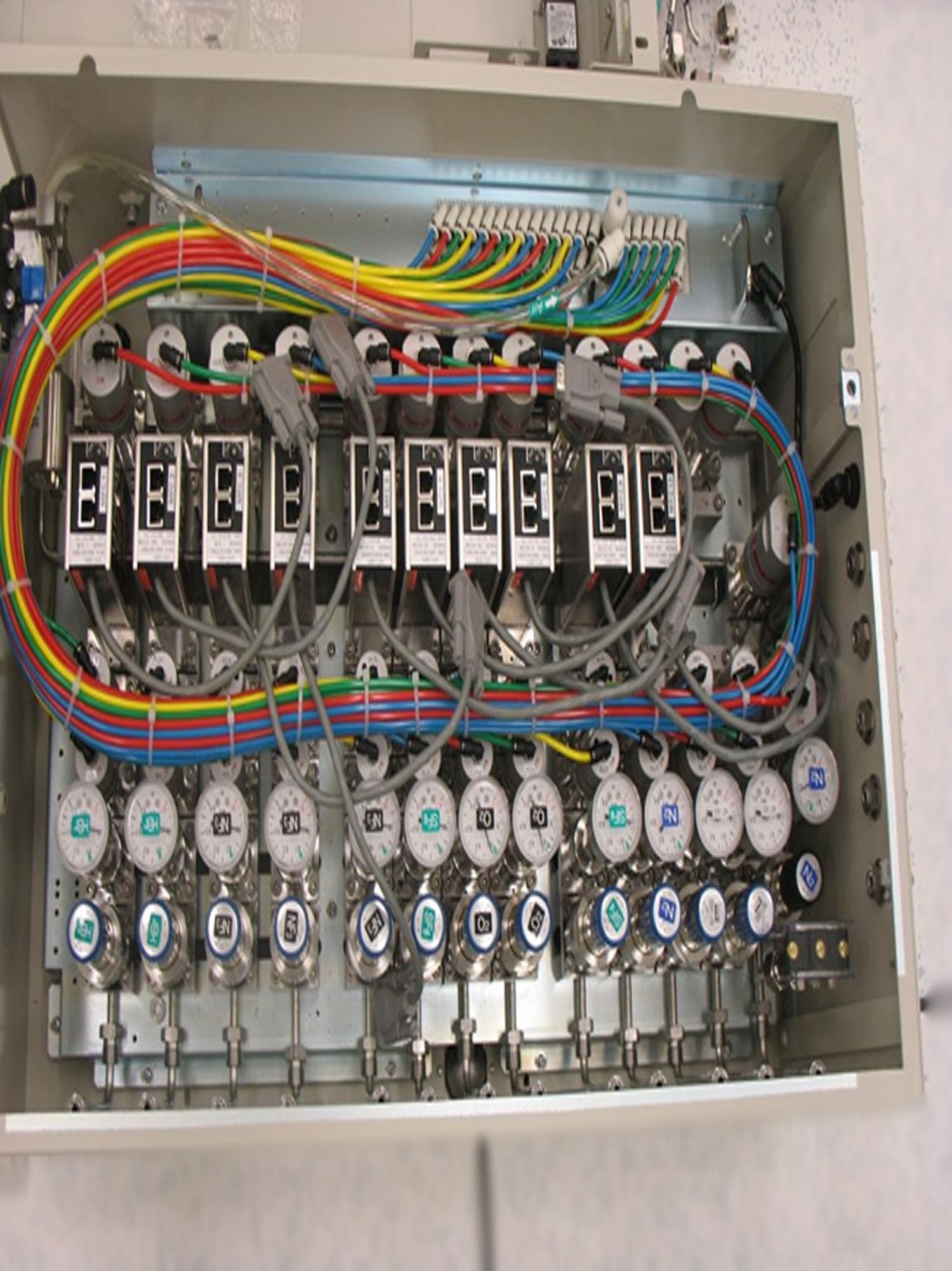

Pressure monitor: (3) Types

He B.P unit: Cooling gas for wafer back

Pressure switch: PCV (STEC)

Number of line: (2) Lines

Control range of pressure:

(Center / Edge): 0~7980Pa(0~60Torr)

He monitor: Leakage monitor

Detection of valve open / close: Valve ON/OFF sensor

End point detection: SE2000

Confirmation of luminescence

Window: Orifice (Quartz)

Deposition shield: Removable depo-shield

Material: Quartz

Shutter:

Plate: Aluminium alloy with hard sulfuric anodizing

Drive: Air cylinder

Final valve: Diaphragm type mega-one (Fujikin)

Manifold: Aluminium alloy with hard sulfuric anodizing

O-ring for chamber: Chemratz

Specifications for performance:

Ultimate vacuum: 0.0133 Pa (7.5*10-2 mTorr) or less

Leak back: 0.133 Pa/min (1 mTorr/min) or less

2007 vintage.

TEL/TOKYO ELECTRON TELIUS SP 308QS是一款高精度的蚀刻器/asher,设计用于实现精确的薄膜厚度控制和快速的基板处理。该机利用多种先进技术,在提供卓越吞吐量速度的同时,达到高质量的效果。TEL Telius SP 308QS具有直观的图形用户界面,使蚀刻过程简单明了。蚀刻室的设计考虑了灵活性和人体工程学,适合各种蚀刻应用。它拥有先进的四激光干涉测量设备,用于精确控制薄膜厚度。该系统能够测量和测量从0.2 nm到70 mm的薄膜厚度。它还具有自动i-LINE模式,用于高精度蚀刻和简单的一键操作。该单元附带一个图形模式编辑器,您可以根据高级应用程序要求轻松编辑蚀刻模式。蚀刻过程在热控超高真空蚀刻室中进行。该真空室能够达到高达10-7 Torr的真空水平。它具有自动优化功能,可用于自动调整蚀刻条件,以实现更高的蚀刻速率和更低的蚀刻选择性。自动优化功能还可用于微调蚀刻条件,以实现更精确的工艺控制。TOKYO ELECTRON TELIUS SP 308QS配备了先进的流程监控和数据记录功能,能够进行流程产量分析。它具有高精度的离子监控器,可确保一致且可重复的蚀刻过程。蚀刻器还具有先进的图形处理器单元,在吞吐量过程中允许更高的性能,同时还提供高质量的数据输出。Telius SP 308QS是一款高度先进的蚀刻机,可提供可靠、可重复的蚀刻结果,并具有显着的吞吐量速度。其创新的设计和先进的技术使其成为各种蚀刻应用的理想解决方桉。

还没有评论