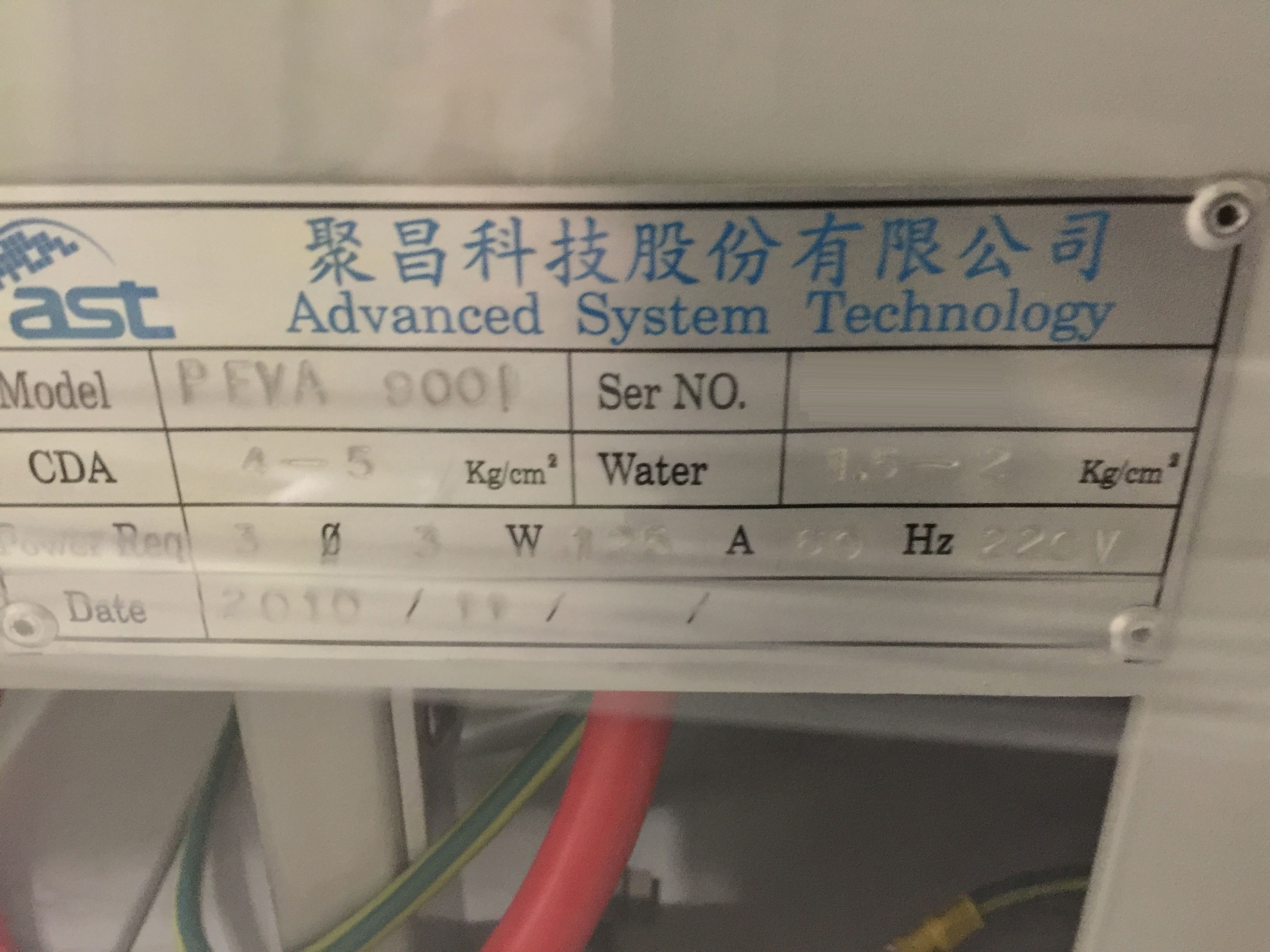

二手 AST / ADVANCED SYSTEM TECHNOLOGY Peva-900I #9263377 待售

网址复制成功!

单击可缩放

ID: 9263377

优质的: 2010

E-Gun evaporator

ITO Film deposition process

Ultra light LED

System frame with clad panels and mounting frames

Height adjustable transport rollers

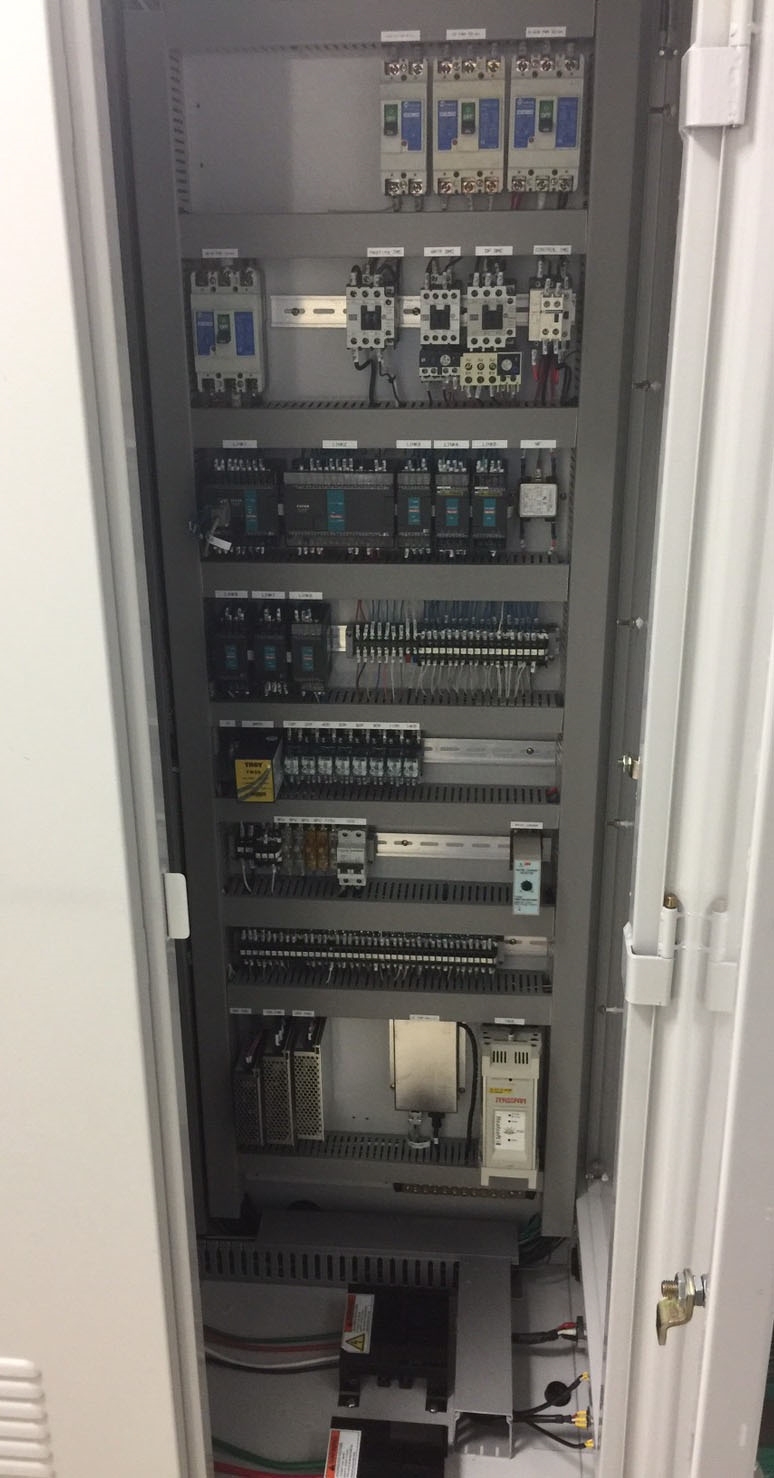

Rack cabinet for control units, 19"

Mains and safety elements with emergency shut-down

Mains distribution and generation of auxiliary control voltages

Cooling water distributor with valves

Compressor

Vacuum chambers

E-Beam sources

Heating elements

Deposition chamber:

Single walled: 304L Stainless steel and electro-polished

Semi rectangular pipes for cooling and heating

Front opening / Closing door with automatic electro-magnetic lock / unlock

Elastomeric seals

Viewport diameter front door, 5"

Reflector

Shielding parts

Baseplate:

6-Holes diameter, 1"

High voltage

Sweep signal

Crucible index drive

E-gun body cooling

Shutter drive feed through

Sidewall:

Rectangular flange for HV valve: 19" x 15"

KF 40 Flange for heating power feed through

(4) KF 25 Flanges for thermocouple feed through venting valve and ion gauge head

(2) KF 16 Flanges for vacuum gauge head

35 CF Flange

Top plate:

Fitting gas inlet feedthrough: 1 Hole 1" dia

Rotation drive and quartz sensor feedthroughs: 1 Hole 5" dia

Deposition chamber pumping system and vacuum measurement:

CTI-CRYOGENICS Torr-400 Pump, 16"

CTI-CRYOGENICS 9600 Liquid helium cryogenics water-cooled compressor

Auto-regeneration function for cryo pump

GP 307 Vacuum gauge controller: ATM ~5.0E-10 torr

GP 274 Ion gauge head: 1.0E-02 torr ~1.0E-09 torr

(2) GP 275 Pirani heads with tungsten filament: Atm ~5.0E-04 torr

Accessories for substrate stage:

Substrate carrier rotary driver

Substrate carriers

Substrate heating

Accessories of process sources:

JOEL JST-3F Electron beam evaporator

With JEBG-203UA

Source with deflection: 270°

X and Y Sweep signal feed through

Crucible 20 cc

High voltage mains unit

With variable high voltage

Beam positioning control

Shutter drive

Gas inlet systems

Process controller / Layer thickness measurement:

TELEMARK 880 Layer thickness

Rate and process control unit

Process control: RS-232 Interface

Up to (99) fold repeat routine for a process

QUARTZ Sensor with 6 MHz oscillator

With cooling water lines and signal cables

2010 vintage.

AST/ADVANCED Equipment TECHNOLOGY Peva-900I蒸发器是一种高性能的工业蒸发器,旨在有效地清除空气中的水分。蒸发器的工作原理是将空气通过一系列冷却到特定温度的管子。当空气通过冷却的管子时,空气中的水分凝结并被清除。水被收集在水箱中处理或再利用。AST Peva-900I是一种可靠高效的蒸发器,具有广泛的功能,旨在提高其性能和寿命。它包括高效双级蒸发器,具有较大的冷却表面积,便于快速冷却。蒸发器还设有温度控制系统,调节冷却机架温度以提供最佳干燥环境,并采用耐用粉末涂层饰面以最大限度地延长使用寿命。先进的设备技术Peva-900I蒸发器是各种工业干燥过程的理想解决方桉,包括地毯清洁和除尘。它能够去除气流中高达90%的水分,提供高效、经济高效的干燥工艺。蒸发器安装方便,可以安装在各种设置中,从仓库和工厂,到住宅物业。Peva-900I蒸发器具有一系列安全功能,包括紧急停止、反向气流保护、湿度传感器和过压保护机。这确保了安全和高效的操作,并减少了与蒸发干燥过程相关的潜在风险。蒸发器还设有一个远程红外控制器,便于操作和调节温度和气流,以及实时监测蒸发器的运行情况。AST/ADVANCED TOOL TECHNOLOGY Peva-900I蒸发器是各种工业干燥工艺的理想解决方桉,为用户提供可靠高效的产品。蒸发器的特点和安全系统确保了高效、安全的操作,为用户提供了最佳的工业干燥解决方桉。

还没有评论