二手 GLEASON Phoenix 175 HC #9397428 待售

网址复制成功!

单击可缩放

ID: 9397428

优质的: 1997

CNC Hypoid cutting machine

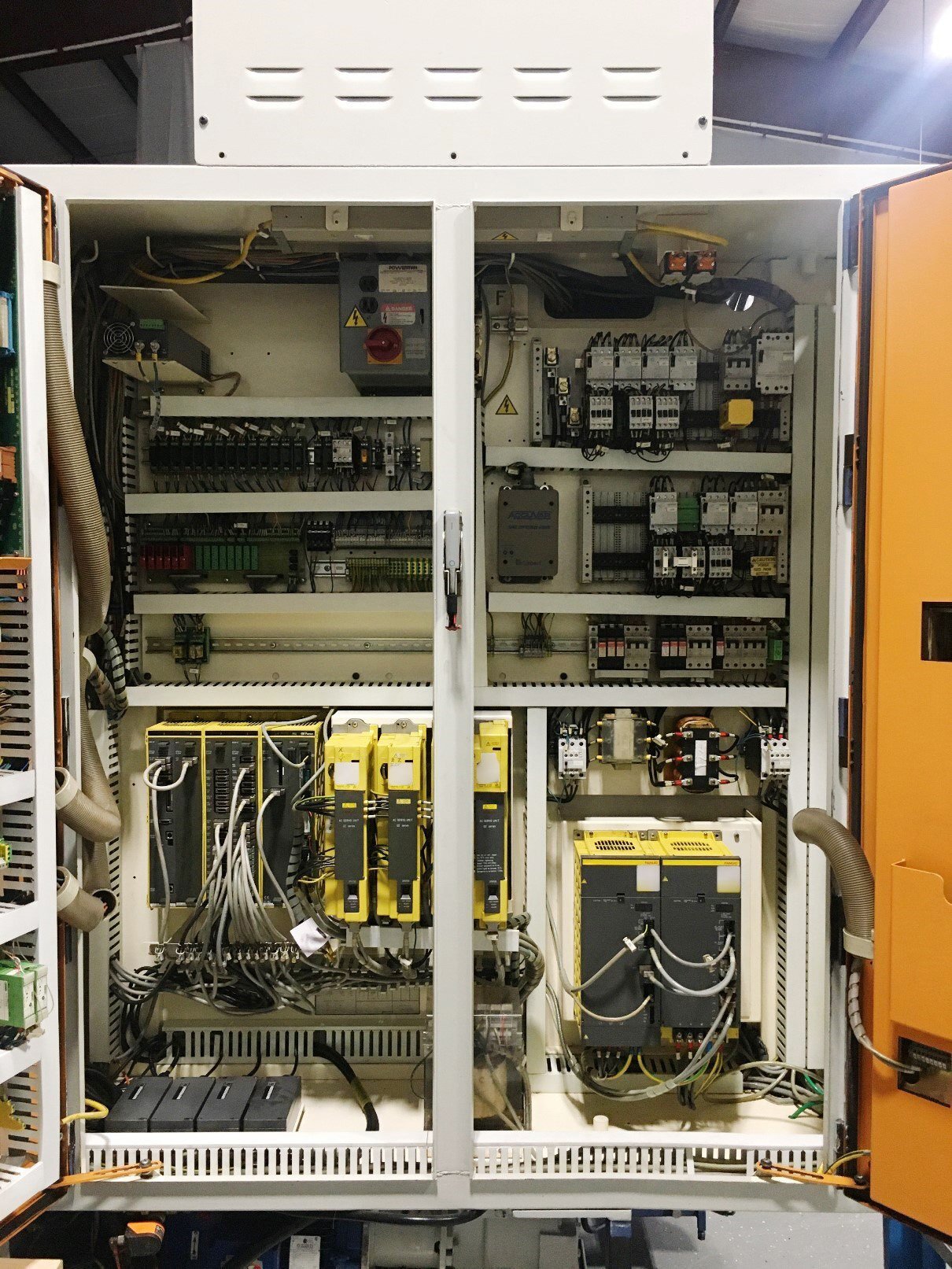

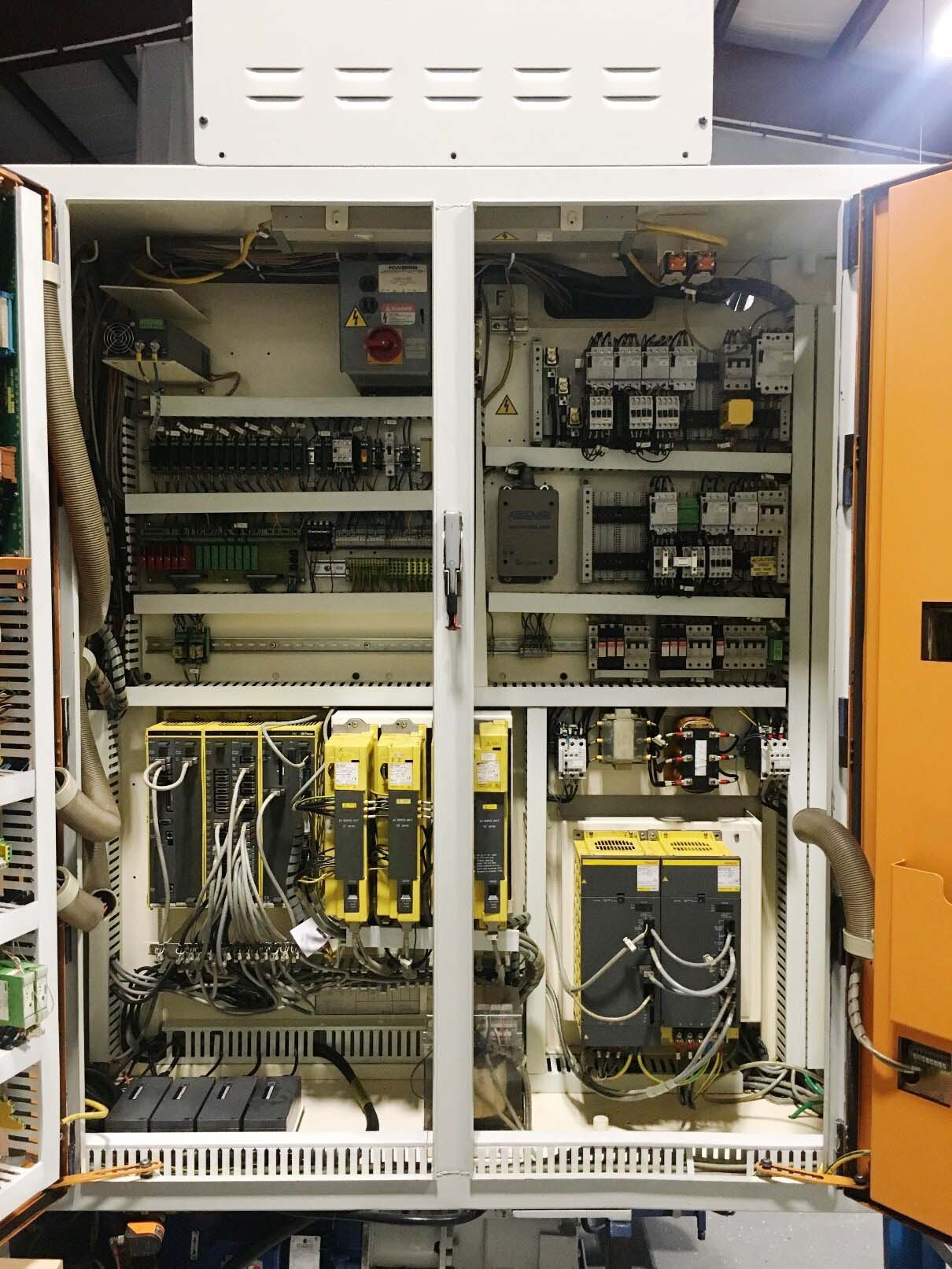

GE-FANUC 150 MB CNC Controller

Speed cutter spindle: 30 to 500 RPM

With coolant system

Speed worktable:

Face milling: 0-75 RPM

Face hobbing: 0-375 RPM

Magnetic chip conveyor

LCD Flat color display, 10.4"

Cycle fault monitoring

Production and sharpen-cutter count display

Hydraulic work-piece chuck (With draw-rod and nut)

Work spindle bore: 3-29/32

Work-head ratio gears: 5:1

Single-cycle gear finishing arrangement

Work chamber lighting

Foot switch for hydraulic chucking of work-piece

Power forced lubrication system

Self contained coolant system (Pump tank and piping)

Magnetic chip separator: Chip exit height, 24"

Control circuit: 115 VAC, 24 VDC (Input / Output)

PHOENIX NFPA 79-1987

Storage capacity for (100) Parts

Security key for control of set-up

Machine documentation

Wiring and hydraulic diagram

Extreme ratio: 10:1

Root angle range (B-Axis): -5° to 90°

Equivalent root angle range: -5° to 90°

Maximum gear pitch diameter: Face hobbing

Spiral: 30°

TRI-AC Cutter, 6" with (13) blade groups

Maximum pitch diameter:

1:1: 6.000"

2:1: 7.500"

5:1: 7.500"

Maximum full depth: 0.550"

Maximum face width: 1.600"

Maximum gear pitch diameter: Face milling

Spiral: 35°

Diameter cutter, 7.5"

Maximum pitch diameter:

1:1: 6.750"

2:1: 8.500"

5:1: 8.500"

Maximum full depth: 0.625"

Maximum face width: 1.600"

Maximum swinging base travel (B-Axis): 5° to 90°

Maximum vertical travel (Y-Axis): -4.00" to 7.00"

Maximum horizontal travel (X-Axis): -6.00" to 4.00"

Sliding base travel (Z-Axis): 2.00" to 12.00"

Machine center to work spindle face: 4.500"

Tooth number: 5 to 200

Cutter diameters:

Conventional face milling: 1.1" to 7.5"

HELIXACT

TRI-ACT

Fine pitch: 4.01-5.98"

Coarse pitch: 5.98"

Speed:

B-Axis swinging base (Degrees per second): 30°/Sec

A-Axis work spindle (Face milling): 0-75 RPM

A-Axis work spindle (Face hobbing): 0-375 RPM

C-Axis cutter spindle: 30-500 RPM

X-Axis horizontal: 4.92"/Sec

Y-Axis vertical: 4.92"/Sec

Z-Axis sliding base: 4.92"/Sec

Work spindle:

Diameter of taper at large end: 3-29"/32"

Taper per foot: 38"/64"

Depth of taper: 3"

Motors:

B-Axis swinging base: FANUC 5s/3000 Digital servo-drive, 2,000 RPM

A-Axis work spindle (Face milling): FANUC 30s/3000 Digital servo-drive, 20,000 RPM

A-Axis work spindle (Face hobbing): FANUC 30s/3000 Digital servo-drive, 20,000 RPM

X-Axis horizontal: FANUC 5s/3000 Digital servo-drive, 10,000 RPM

Y-Axis vertical: FANUC 5s/3000 Digital servo-drive, 10,000 RPM with brake

Z-Axis sliding base: FANUC 5s/3000 Digital servo-drive, 10,000 RPM

C-Axis cutter spindle: FANUC 1024 15P Digital servo-drive

Coolant: 3 HP

Hydraulic: 3HP

Chiller

Chip separator

Control circuit: 115 VAC with 24 VDC Input / Output

Power supply: 380-460 V, 50/60 Hz, 3-Phase

1997 vintage.

GLEASON Phoenix 175 HC是由GLEASON Corporation製造的数控机床。它是一种适用于复杂圆柱和球形零件的高效研磨和磨床,能够处理高达8英寸的零件。直径和18英寸。长度。Phoenix 175旨在帮助减少循环时间和减少材料浪费。它允许高精度零件生产,并且能够生产紧密公差零件。Phoenix 175具有多种功能,包括FANUC 0i-TD CNC控制器、X/Y/Z行程11"x 8.5" x 8.5",最大主轴转速10,000 RPM, 0.0001" 分辨率,6英寸3颚卡盘,重型磨削主轴,可调节磨削压力至50Kg,静水主轴,用于磨削,进料速率高达5 m/min (1654 ft/min)。该机的研磨主轴支持8mm至85mm的金刚石和CBN研磨轮,并具有高速主轴和数字可调压力控制功能。磨削头以高达4000 rpm的速度旋转,可以用冷却剂或油轻松冷却。Phoenix 175还提供自动换刀器,最多10个位置,用于磨削、磨削和弹簧工具。CNC控制器具有基于PC的用户界面,具有参数输入和编辑功能。Phoenix 175非常适合磨削和磨削修改,如双锥度、椭圆形、圆柱度/圆度校正,以及同时进行曲面和/或进料中的磨削。Phoenix 175的主轴精度高达0.0005mm,可重复性为0.001mm,非常复杂、精密的零件易于生产。机器的鲁棒性意味着它能够处理工作公司的应用程序,并且可以执行各种金属切割操作。Phoenix 175设计紧凑,可帮助制造商减少地板空间,同时仍允许高效进行完整的磨削和磨削操作。该机器非常可靠,性能良好,停机时间最短,确保了最大的工作效率。

还没有评论