二手 MAZAK Integrex 200-IVS #9316531 待售

网址复制成功!

单击可缩放

ID: 9316531

优质的: 2011

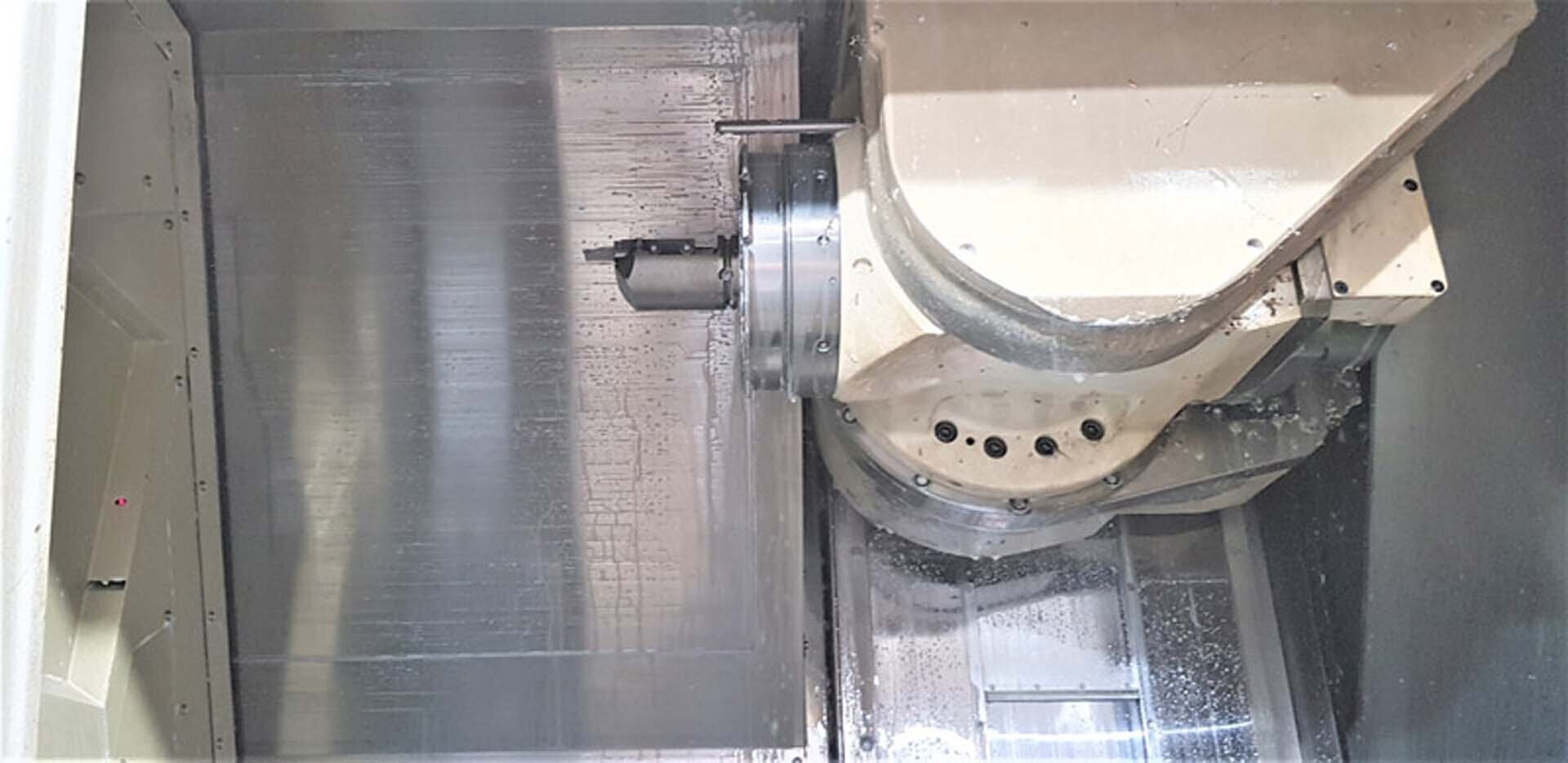

CNC Turning / Milling center

With sub-spindle and Y-axis

Maximum swing: 26"

Maximum swing over carriage: 19.5"-26"

Maximum chucking cutting diameter: 26"

Maximum cutting length: 40"

Maximum distance between standard chuck faces: 41.14"

Main spindle specifications (L):

Spindle nose: A2-6

Spindle bore: 2.99"

Maximum bar work: 2.0"

Spindle speed: 35 - 5,000 RPM

Spindle index (Programmable): 0.0001°

Spindle horsepower (Cont./30 Mins): 20/30 H.P. (A.C.)

Spindle torque (25% ED): 344.2 Ft-lbs

Right spindle specifications:

Spindle nose: A2-6

Spindle bore: 2.99"

Maximum bar work: 2" x 34.6" Deep from chuck face

Spindle speed: 35 - 5,000 RPM

Spindle index (Programmable): 0.0001° (C-Axis )

Spindle horsepower (Cont./30 min): 20/25 HP (A.C.)

Spindle torque (30 Min): 241 Ft-lbs

Turret and tooling specifications:

Type of turret: 1 Position

With ATC

Tool shank height: 1.0"

Boring bar maximum diameter: 1.5"

Magazine capacity: 40 Tools

Tool selection method: Random

Tool to tool ATC time: 1.3 Sec

Maximum tool diameter with all pockets full: 3.54"

Maximum tool diameter with adjacent pockets empty: 4.92"

Rotary tool spindle speed: 12,000 RPM

Rotary tool spindle horsepower (20% ED): 25 H.P. (A.C.)

Rotary tool torque (20% ED): 88.2 Ft-lbs

Maximum face mill: 4"

Maximum end mill: 1.25"

Maximum drill: 1.18"

Maximum tap: 1-8 UNC

Axis travels:

B-Axis: 225°

Y-Axis: ± 3.15"

X-Axis: 22.83"

Z-Axis: 41.14"

Second headstock W-axis: 41.34"

Axis rapid rates:

Y-Axis: 1024 IPM

X-Axis: 1496 IPM

Z-Axis: 1496 IPM

Second headstock W-axis: 1181 IPM

C-Axis: 555 RPM

Equipped with:

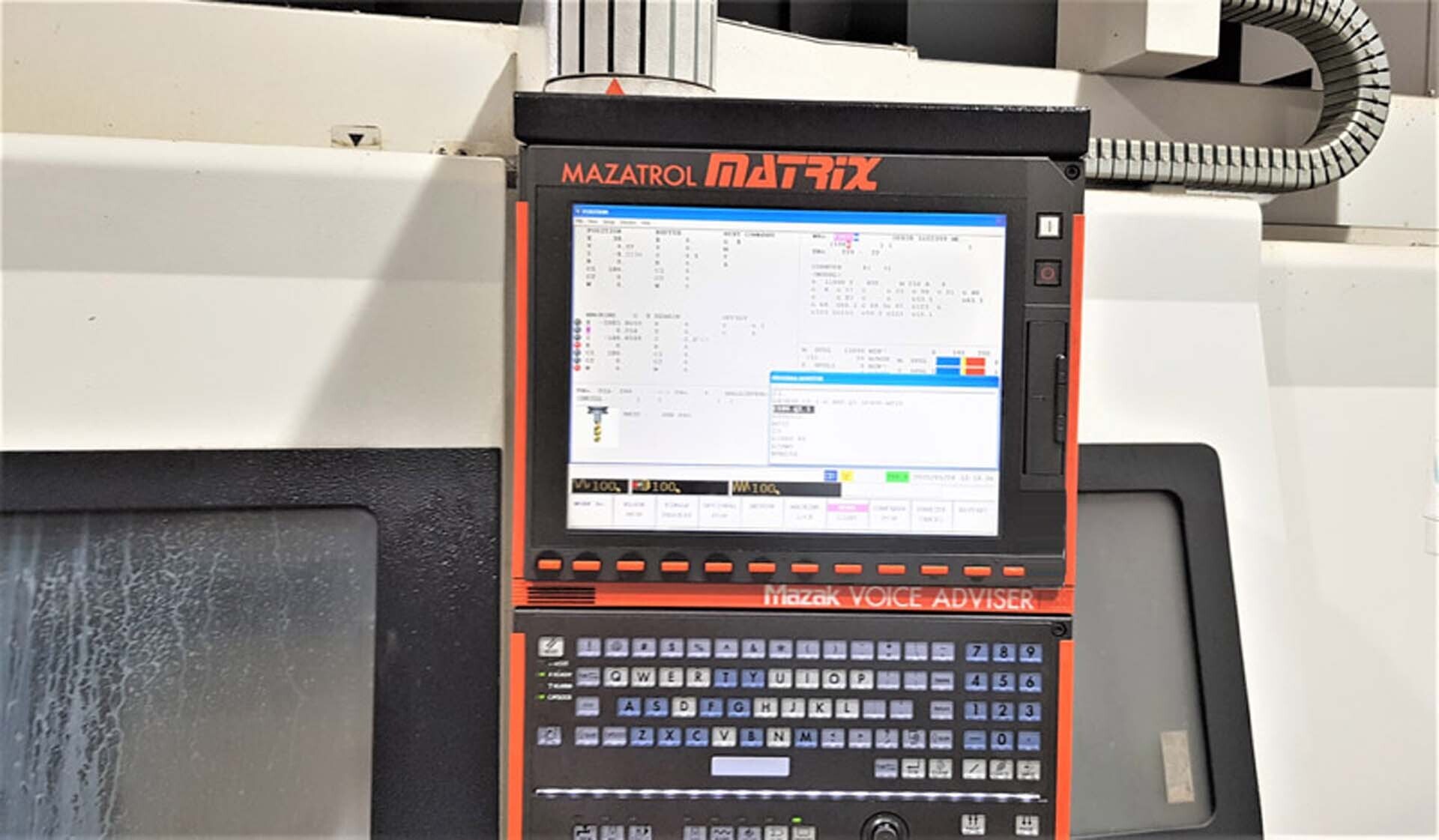

MAZATROL Matrix control

15" Color LCD

Spindle motor: AC 22 kW(30HP)

Spindle position 0.001° without C-axis

3-D coordinate conversion

5kg Thru clnt/flood clnt simul-flowable

8" Thru-hole chuck B-208a615 (1st spindle)

8" Thru-hole chuck B-208a615 (2nd spindle) absolute positioning sys (Linear axes) accuracy inspection

Active vibration control

Air requirements: 71 PSI / 24.7 CFM

Power requirements: 63 kVA

2011 vintage.

MAZAK Integrex 200-IVS是一种高精度三轴多任务数控机床,旨在提高各行业的生产率。这种坚固可靠的车削中心提供了多种CNC加工功能,可在一个设置中生成完整的复杂零件。MAZAK INTEGREX 200 IVS机的多用途设计,具有铣削、车削、钻孔、钻头和API(自动部件识别)功能,以及在一个操作中添加EDM。它能够处理多种材料,如低碳钢、铝、黄铜、铜和不锈钢。Integrex 200-IVS具有固态Meehanite铸件,在高速加工应用中具有热稳定性。它还具有加压润滑功能,以减少维护和磨损,并有助于延长机器的使用寿命。INTEGREX 200 IVS提供卓越的200 x 488毫米轴行程,可处理大直径、长和高的作业。此外,它的主轴孔是一个慷慨的ø65毫米,允许用户处理大,重部件容易。MAZAK Integrex的CNC功能200-IVS通过快速的设置时间来确保可预测的结果。本机配有配备24英寸彩色触摸屏界面的Mazatrol SmoothX系列CNC控制器,提供直观的工具选择。控制器还配备了2.2GHz 6核英特尔酷睿i7处理器,用于快速计算。为方便起见,此计算机还可在各种标准CAD/CAM软件包上运行。MAZAK INTEGREX 200 IVS是希望通过单一设置加工解决方桉最大限度地提高搅动速率和效率的用户的理想选择。将高精度铣削和车削功能与改进的周期时间和容量相结合,这台机器为各种制造应用程序提供了无与伦比的性能和生产率。该机床具有较高的动态精度和灵活的B轴,便于5轴加工,为任何现代化的制造工厂提供了完美的解决方桉。

还没有评论