二手 MAZAK Integrex i-200S #9362731 待售

网址复制成功!

单击可缩放

ID: 9362731

Multi-axis CNC turning center

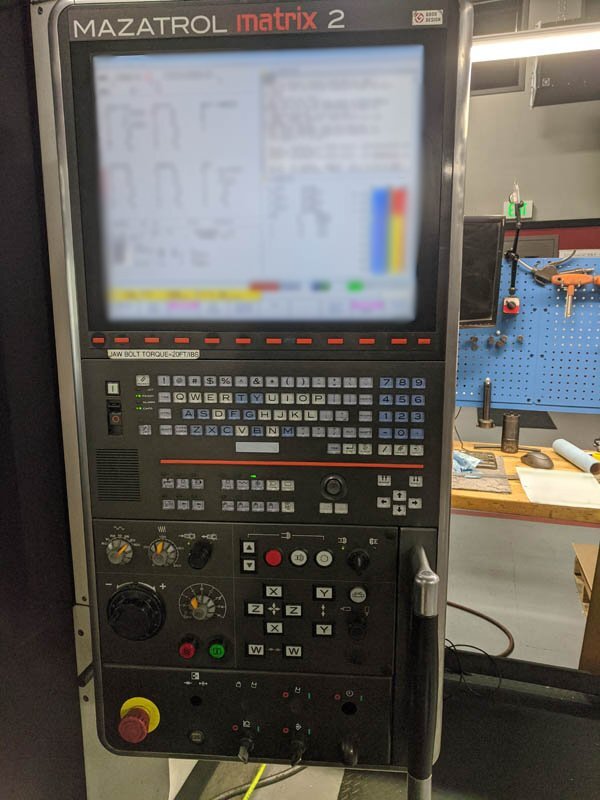

MAZATROL Matrix II Control

Color LCD, 19"

3-D Coordinate conversion

Shape compensation for rotary axes

Milling spindle synchronous tapping

Cardbus I/F: Type II slot

Lan port

USB-I/F

Y-Axis control

Absolute positioning system (Linear axes)

XYZ Pitch error compensation input

Coolant through milling head

Automatic tool eye

Auto chuck jaws open / Close

Coolers for ball screw X-Axis

5-Axis machining package

Relocation device

Chip conveyor side disposal

Work measuring system RMP60 probe

High pressure coolant: 1000 PSI

Air requirement: 71 PSI / 12.7 CFM

Main spindle:

Chuck, 8"

Maximum swing: 25.9"

Maximum cutting diameter: 25.9"

Maximum swing over cross slide: 25.9"

Maximum cutting length: 39.8"

Spindle nose: A2-6

Spindle speed: 35 - 5000 RPM

Spindle index: 0.0001°

Spindle horsepower: 20/30 HP (AC)

Spindle bore: 2.99"

Spindle torque: 344.2 Ft-lbs

Maximum bar work: 2"

Second spindle:

Chuck, 8"

Spindle nose: A2-6

Spindle speed: 35 - 5000 RPM

Spindle index: 0.0001°

Spindle horsepower: 20/25 HP (AC)

Spindle bore: 2.99"

Spindle torque: 240 ft-lbs

Turret and tool:

Type: 1 Position with ATC

72 CAPTO Tool magazine

Tool selection method: Random shortest path

Tool to tool ATC time: 1.3 sec

Maximum tool diameter with pockets full: 3.54"

Maximum tool diameter with pockets empty: 4.92"

Maximum tool length: 15.75"

Maximum tool weight: 26.5 lbs

Rotary tool spindle speed: 15 - 12000 RPM

Rotary tool spindle horsepower: 30 HP (AC)

Rotary tool torque: 88.5 Ft-lbs

Axis travels:

B-Axis: 240°C (-30°C + 210°C, 0.0001°)

Y-Axis: 9.84"

X-Axis: 24.21"

Z-Axis: 42.4"

Second headstock W-Axis: 41.97"

Axis rapid rates:

X and Z-Axis: 1969 IPM

Y-Axis: 1575 IPM

Second headstock W-Axis: 1181 IPM

B-Axis: 40 RPM

C-Axis: 555 RPM

Floor space (WxL): 110.24" x 157.1"

Machine height: 107.1"

Machine weight (36t): 28,880 lbs

213 PSI Thru coolant flood coolant simul-flowable

C-Axis: 0.0001 degree increment (1st Spindle)

2nd Spindle C-Axis with C1-C2 0.0001 degree increments

Chuck air blast 2nd spindle

Rotary tool spindle speed: 12,000 RPM

B-Axis: 0.0001 Deg / Contouring (Requires EIA/ISO)

MT Connect prep

8" Thru-hole chuck B-208A615 1st spindle thru-hole cyl S1552

8" Chuck B-208 2nd spindle with non-thru hole cyl Y-1225

Operating system: Windows 7

Power supply: 62.61 kVA

2013 vintage.

MAZAK Integrex i-200S是一种多轴机床,它将车削、铣削和垂直加工过程合并为一个集成的系统。这台数控机床生产率高,质量、精度高,生产简便.Integrex i-200S配备了一个16英寸的Chuck和由二十四(24)个刀具站组成的自动化刀具更换器。加工中心在主轴和子主轴上有两个C轴旋转轴,用于复杂的索引。铣削主轴由15HP交流电机驱动,主轴转速为3,500 RPM,非常适合重型加工。MAZAK Integrex i-200S有一个电机驱动的转塔,带有两个独立的C轴旋转工具。该机设计用于执行一般车削、钻孔、钻孔、钻孔和螺纹等多种加工操作。它还配备了内置探测系统和高级软件功能,以增强自动化。Integrex i-200S提供高精度加工,错误率为.0002英寸(0.5毫米)或更低。它还能够实现不到一(1)分钟的周期时间,并提供快速的刀具变更以及内置的全自动刀具更换器。MAZAK Integrex i-200S的封闭式设计具有直观、易于使用的高度可靠的控制系统。其控制面板采用彩色触摸屏面板,可快速方便地访问操作和功能。它还有一个内置的可编程内存,存储多达200个用于快速设置和生产的例程。总体而言,Integrex i-200S为各种加工操作提供精确可靠的加工。它具有高效的设计和快速的刀具更换功能,可提供高生产率和高质量的加工。该机器非常适合广泛的市场使用,包括航空航天、汽车、塑料、医疗和建筑市场。

还没有评论