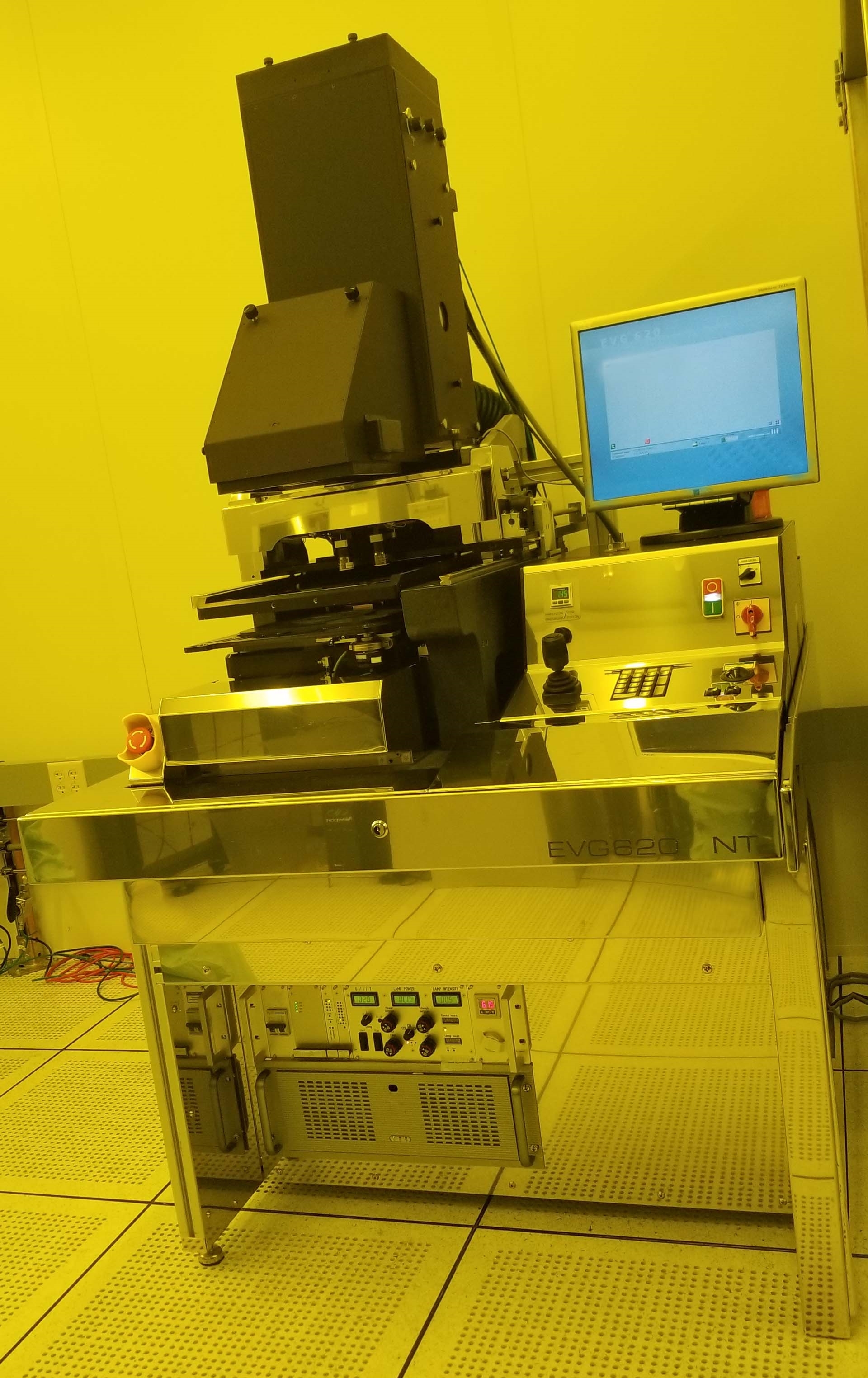

二手 EVG / EV GROUP 620NT #9191006 待售

网址复制成功!

单击可缩放

ID: 9191006

晶圆大小: 6"

优质的: 2011

Automated double side lithography system, 6"

Exposure modes:

Hard

Soft

Vacuum contact

Proximity

Separation distance: 0-300 μm adjustable

Wafer thickness: 0.1-10 mm (For top side configuration only)

Semi automatic loading

Mechanical pre-alignment on chuck

Quick change of mask and chuck

Flat screen for operator interface and alignment functions, 17"

PC Controlled operating environment

Granite base frame construction

Active vibration isolation

Password protected access levels:

Operator

Engineer

Maintenance

Back side alignment of wafers:

Mounted carrier

Deep etched back side alignment marks

Supports measuring of structures

Cross hair distance

Resolution with 10x objectives: 1.1 μm

Light source NUV: 500 W-1000 W

Lamp house: 350 W / 500 W Hg lamp

Optical sets in NUV range: 280-450 nm

Optimized parallel light:

±2%, 4"

±3%, 6"

UV Probes:

Diameter: 44.5 mm

Height: 16 mm

Optical set for wave length: 350 nm-450 nm

Light sources: NUV / DUV

Field lens, 6"

Dielectric mirror

Fly's eye lens

Alignment stage fully motorized

Fully motorized X, Y, Theta & Z alignment stage

With DC motor controllers

Automatic wedge compensation system

Optimized print gap control

WEC Contact force: 0.5-40 N adjustable

Top side microscope:

Motorized split field microscopes in visible light

With high resolution CCD cameras for top and bottom side

Travel range:

X: 30 (8)-150 mm

Y: -70 / +70 mm

Storage of objective positions

Digital zoom: 2x / 4x

Image magnification for fine alignment

(2) Objectives: 10x (3.6x - 20x)

Bottom side microscope:

Motorized split field microscopes in visible light

With high resolution CCD cameras

Bottom side alignment

Travel range:

X: 68 (48) mm-150 mm

Y: ± 12 mm

Digital zoom: 2x / 4x

Image magnification fine alignment with objectives

(2) Objectives: 10x (3.6x - 20x)

Rack unit EVG 620 mask aligner systems:

Integrates EVG 620 desktop alignment system

Vibration isolated

Robotic auto load system

Robot module for auto load cassette to cassette:

Size: 4"-6"

With non contact optical prealigner for wafers

With flat and notch

Standard: With vacuum from bottom side

Robot control fully integrated to EVG 620

Graphical User Interface (GUI)

Cassette station:

Send

Receive

Standby

(5) Cassette stations:

Cassette present sensor

Cassette empty sensor

Semi standard wafer cassette sizes

IR Light source: Bottom side objectives

IR-Transparent substrates

Bottom side microscope: IR Light source manipulation

IR Alignment of wafer to mask using top side microscope

IR Lamp position with recipe

Active cooled IR light source

Manual and automatic alignment processes

Usage of special IR objectives on topside microscope

Reduces bottom side microscope travel range

Pick and place handling option:

Programmable send / receive / standby cassette configurations

Up to 75 wafer processing on handling modules:

(3) Cassette stations

No operator intervention

125 wafer processing on handling modules:

With (5) cassette stations

No operator intervention

Hard UV-Nano imprinting:

UV-NIL Processes with hard stamps (Quartz glass)

Top chuck, 1" stamps (in diameter)

Bottom chuck:

Microscope slides:

10 x 10 mm

15 x 15 mm

25 x 75 mm

Diameter: 2"-4"

Soft UV-NIL and μ-CP:

PDMS Stamp to be mounted on glass back plane (5" square)

Bottom chuck, 4"

Loading frame, 1" Stamp

Contact free wedge compensation with spacers

Adjustable contact force for vacuum printing process

Top chuck with quartz windows for UV curing of resist

Optical alignment of stamp and substrate in two steps:

Separation of stamp and substrate: Rough alignment

Soft contact of stamp: Fine alignment

Vacuum contact: 100 - 850 mbar

Mask holder for 5" x 5" masks with loading frame

Bottom loading system

with automated vacuum transfer

Hard coated & lapped surface finish for mask contact area

Mask holder for 7" x 7" masks with loading frame

Bottom loading system with automated vacuum transfer

Hard coated & lapped surface finish for mask contact area

Universal wafer chuck, 4"

With spacers

For automated handling

Hard coated & lapped surface finish for wafer contact area

Universal wafer chuck, 6"

With spacers

For automated handling

Hard coated & lapped surface finish for wafer contact area

Manual filter changing unit without filter / carrier

Includes:

Bond alignment

Signal tower

Does not include cassette load

2011 vintage.

EVG/EV GROUP 620NT是一种掩模对齐器,旨在支持半导体制造等行业的先进电离辐射(电子束)和光学光刻要求。其对齐器提供精确的光掩模图样与晶圆表面对齐,确保了设备特征的精确复制和性能的均匀性。EVG 620NT具有先进的双梁设备,能够定位和定位各种模式,并具有亚像素精度和岩石-固体稳定性。它的广角光学提供了无与伦比的视场,并且可以一口气对齐大面积的图桉。此外,该系统还提供了一个高效的工作环境,具有现代化的GUI和几种易于操作的工具,包括用于处理掩码和晶圆的机器人技术。EVG EV GROUP 620NT的性能因其高分辨率成像单元而进一步提升,该单元采用12k x 12k像素CCD区域扫描相机,使用纳米级分辨率捕捉图像。一个集成的微米级自动级能够提供严密的配准精度和可重复性,因此模式可以定位在一个个位数的纳米精度在整个视野。620NT使用可扩展的模块化组件构建,用户可以在需要时轻松升级或修改设备。创新的体系结构和专用的数据通信线路提供极快的成像速度,扫描速度高达每秒1000万像素。为了跟上设备制造的快速变化,可以使用可升级的硬件平台进一步改进成像机。EVG/EV GROUP 620NT对于那些参与创建和复制高级半导体特性这一艰巨任务的人来说是一个强大而可靠的工具。它结合了尖端光学、高精度成像、坚岩平台和可升级硬件,确保了高效的工作体验和设备的统一、无缺陷的性能。

还没有评论