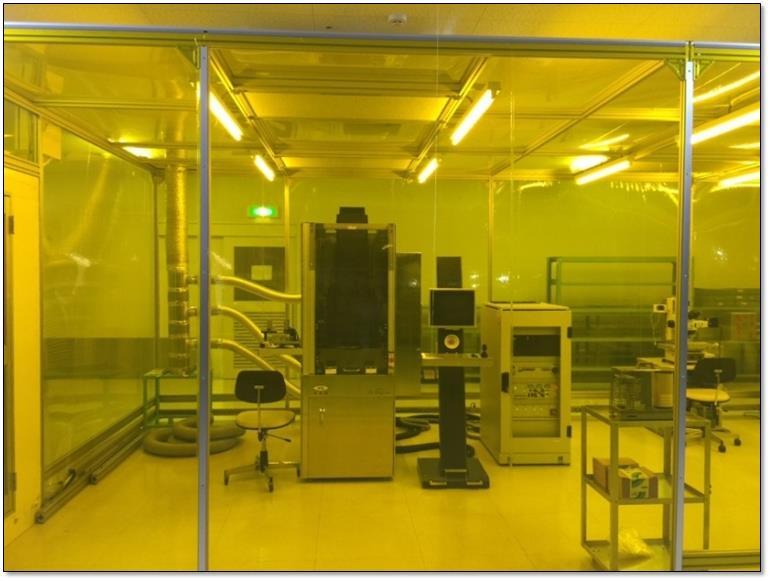

二手 EVG / EV GROUP IQ #9138247 待售

看起来这件物品已经卖了。检查下面的类似产品或与我们联系,我们经验丰富的团队将为您找到它。

单击可缩放

已售出

ID: 9138247

Nano imprint lithography system, 8"

Top-side alignment only

Manual load

Wiring removal

Basic unit 200mm:

Flat screen:17"

Self Diagnostics during machine startup

Automatic initialization:All motors,encoders,limit switches,sensors and pneumatic

Remote diagnostics

Quick change:Stamp holders and imprint chucks

EC declaration of conformity

PC controlled operating environment

Solid state drive and hard drive

Earthquake protection device

Software:

MS-windows

Process software ,processing and diagnostics

Automated recording

Storage of files in hard disk or network

Password protected

Internal wedge compensation unit:

Automatic wedge compensation

Motorized alignment stage:

X,Y,T alignment

High resolution alignment

(3) axis joystick

Reinforced stage drives

Top side microscope:

Fully motorized split field microscope

Travel range X: 90-200mm*

Travel range Y: -10-100mm*

(3) axis joystick control

Display and storage of microscope position

(2) Objective 5x

Automatic alignment for top and / or bottom side:

Vision system

Storage of stamp and patterns on hard disk

Top and bottom side alignment

Stamp and wafer alignment marks

Large gap alignment capability:

Alignment at substrate separations >50um

Alignment during UV molding

Alignment during UV bonding

Manual wafer loading capability:

Motorized swivel arm

software integrated

(2kg) Manual substrate loading/unloading

Wafer loading trays

Wafer loading frame for 200mm wafers/stamps:

Manual wafer loading on chuck

process integrated substrate vacuum fixing

Notch or flat with pins

External wafer thickness measurement station:

(3) Point wafer thickness detection

Contact less imprinting

(3) Sensors adjustable range :150-200mm

Designed Warped substrate :1mm

Manual Operation

Sensors range: up to 10mm

manual system only

500W-1000W Light source NUV:

Lamp house :500w or 1000w

NUV range:280-450nm

Optimized parallel Light:+/-3% on 150mm and +/-4% on 200mm

Adjustable plate: diameter 44.5mm and max.height 16mm

Optical set for wave length range 350-450nm:

NUV and DUV light sources

Field lens:200mm

Dielectric mirror

Fly's eye lens

Stamp holder for 200mm UV hybrid lens molding:

UV molding automated de-embossing function

Hard coat surface finish

Quartz backplane

Imprint chuck for 200mm wafers/stamps:

Bottom chuck: 200mm wafer

Top side alignment

Hard coat surface finish

Manual and automated loading

Software for UV hybrid lens molding:

UV molding process flow

Designed for puddle dispense

Recipe parameters and user guidance

Software to compensate with specified tolerance

Force control capability up to 400N:

Load cells implemented

Maximum controllable imprint: 400N

Force control during imprint

Force control during UV exposure

UV molding software

Tooling for 200mm UV bonding,stamp fabrication and MLM:

Top substrate holder

Special quartz backplane with edge vacuum groove

Mechanical clamping

Vacuum supply to backplane via tube

Software for master and sub-master replication:

UV molding process flow

Tooling for polymer stamp fabrication

Software to compensate product within specified tolerance

Software for UV monolithic lens molding:

UV molding process flow

UV molding tools for puddle dispense

Recipe parameters and user guidance

Software to compensate with specified tolerance

Diffuser plate for tooling for stamp fabrication + MLM:

Tooling for stamp fabrication + MLM

Diffuser plate onto backplane prior to UV exposure step

Diffuser plate for hybrid lens molding tooling:

Hybrid lens molding tooling

Diffuser plate onto backplane prior to UV exposure step

Recipe controlled microscope illumination spectrum:

Contrast improving illumination system

Increased pattern visibility

Improved alignment reliability

(3) Adjustable LED light sources per microscope

Autom.Arm for puddle dispense and de-ionization:

Motorized swivel arm

Software integrated

Programmable dispense arm/nozzle

Puddle dispense of imprint material: up to 4 lines

Right-hand side alignment

Host ionization system

Ionization system:

Ionization nozzle with power supply

De-ionizing of stamp and substrate

Syringe dispense system:

Syringes :up to 3

(2) Dispense lines

Universal resists applications

Resist with short shelf life time

Programmable dispense rate

Adjustable suck back

Different resist and polymer viscosity

Chemistry cabinet:

Housing with front door access

Encapsulating of syringe dispense systems / arm

Exhaust port

Prepared for later pump upgrade

Pre-installed weight cell

2011 vintage.

EVG/EV GROUP IQ Mask Aligner是一款高精度、高通量的晶圆级光刻设备,用于半导体行业对芯片、晶体管等电路元件等小型器件进行阵列设计。这种先进的工具提供超高分辨率的高线边缘粗糙度(LER)和覆盖精度,以提高设备性能和产量。利用先进的晶片级、激光干涉仪进行精确的晶片对准和运动控制,采用同步的步进重复方法,以快速、可重复的方式将所需图像投影到晶片上。EVG IQ Mask Aligner使用分束透镜将激光引导到矩形镜面上,该镜面将其反射到蒙版和光刻涂层晶片上,同时曝光,允许创建高级多层图样。光束分裂透镜也提供了一个光源到面罩和晶圆,使每一个暴露在光刻系统的光源光束的全强度。EV GROUP IQ Mask Aligner能够在标准对齐器上打印低于50 nm的特性,或者使用专用设备打印低于30 nm的特性,非常适合制造先进的IC和MEM设备。为了达到这样的小特性,该单元利用强大、高保真的数字步进电机来驱动镜头和曲柄机构,以精确地移动晶片,使晶片与晶片对齐,并进行拍打。这样就可以实现高度准确和可重复的打印过程。晶片由真空卡盘保持在适当位置,同时使用对准激光器调节晶片的位置,并确保它与掩模精确对准。这允许从打印到打印的真实迭加测量。最后,使用额外的紫外可见激光器扫描广泛的掩模和晶圆特征,减少打印之间的时间,使晶圆能够快速高效的处理。IQ Mask Aligner提供了卓越的模式精度,包括± 5nm的线宽控制和小于1nm的LER。该机也具有很高的可靠性,使用寿命超过20年。凭借快速的吞吐量能力和先进的平版印刷控制,该工具能够快速地制作出准确、复杂的图样。因此,它是寻求高精度、高通量晶圆级光刻解决方桉的半导体领域的一个宝贵工具。

还没有评论