二手 TAMARACK 161B #165720 待售

网址复制成功!

单击可缩放

ID: 165720

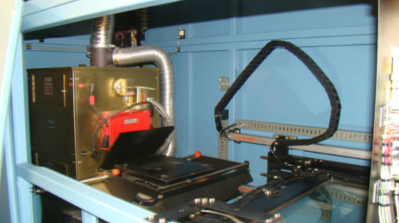

Printed circuit board exposure system

Specifications:

Semi-automatic machine

Used to provide rapid and precise alignment of large PCB panels

Components:

Panel alignment / exposure station

Collimated illuminator

Pneumatic valves

Sequencer

Alignment / exposure station:

Provides the facilities for aligning the P.C.B. panel with respect to the artwork and providing vacuum contact for exposure

Mylar cover frame is hinged toward the rear of the machine to allow raising of the frame for changing the panel and artwork

Collimated illuminator:

Provides a condensed beam of ultra-violet light of uniform intensity for use in exposing the panel

Shutter within the illuminator opens for a preset interval to accomplish the exposure

(2) modes of exposure control are available to operate the shutter: constant time and constant energy

Constant time is set in on the exposure time in seconds

In the constant energy mode, exposure energy in millijoules per centimeter squared (mJ / cm) is set on the exposure energy thumbpot

Light source for the collimated illuminator: high pressure mercury arc lamp mounted in a forced air cooled housing

Housing is designed to contain and withstand lamp explosion

Lamp is positioned near the first focus of an ellipsoidal reflector

(3) Thumbscrews provide the means of moving the lamp along the X, Y, and Z axes in order to obtain the proper lamp position

Ellipsoidal reflector directs the reflected light toward a distant second focus thus avoiding the possibility of lamp damage due to reflection of energy onto critical parts of the lamp

Ultra-violet light from the ellipsoidal reflector is turned twice to reach a second focus located at the lenticular integrator

Dichroic mirrors which turn the ultra-violet light pass most visible light and infra-red energy which are thus dissipated as heat within the lamp house and exhausted out of the system

Lenticular integrator, located at the second focus of the ellipsoidal reflector, collects the ultra-violet energy and directs it toward the collimating mirror in such a manner as to approximate a point source of light

Mirror collimates the light from the integrator so as to form a beam of light exhibiting uniform intensity over its beam width

Shutter which controls panel exposure is located just ahead of the lenticular integrator

An associated panel switch provides the means of holding this shutter open for the purpose of lamp intensity and focus adjustments or placing it under the control of the digital timer or integrating exposure controller during panel exposure

Panel size: 19" x 25"

Pneumatic panel:

Located inside the machine above the side control panel

Panel supplies air pressure and vacuum to all air operated systems through the machine

Solenoid valves are operated on 24V DC and controlled from the sequencer and pushbuttons

Sequencer:

Control of the 161B is accomplished by a Mitsubishi programmable controller located on the pneumatic panel

Manual switch panel is also mounted on the pneumatic panel

Side control panel:

Used to start and stop all functions of the machine

Main power contactor enable

Lamp ignitor

Lamp exhaust temperature, alarm and lamp meter (resettable)

Machine control power

Front control panel:

Timer and integrating exposure control switch are used to pick the mode of exposure

If the machine is used in the time mode, the exposure time in seconds must be set

When constant exposure energy is required, the IEC will measure the quantity of energy at the panel / exposure plane and control the shutter to maintain the same exposure energy independent of light intensity

Bullnose:

Contains a light table to aid alignment of the artwork to the substrate

The start cycle switches must be actuated simultaneously to begin print drawer movement

Top and bottom vacuum switches, gauges, emergency off switch and final cycle switches are also on the bullnose.

TAMARACK 161B是一种先进的口罩生成和生产设备,旨在快速生产具有出色分辨率的高质量口罩。该系统能够生产各种不同类型的掩码,从基本设备到3D立体光刻掩码。161B使用最新技术,能够生成层定义文件,这些文件用于创建掩码所需的物理层。该装置采用了强大的光学对准机器,可实现简单高效的掩模生成,并采用先进的成像算法实现最佳对准和掩模质量。该工具还采用了最先进的电子束光刻资产,以提高分辨率和生产速度。TAMARACK 161B专为快速吞吐量和易于操作而设计,非常适合所有类型的掩模制造应用。与现有的口罩生产系统相比,该模型具有几个关键优势,包括提高成像精度和速度、精确对准和配准多层、降低材料成本以及支持多级口罩生产。通过强大的设计和集成功能,161B能够满足各行业设备制造商的需求。该设备能够执行各种任务,如摄影、平版印刷和各级电路成像。此外,通过包括CAD(计算机辅助设计)设施,该系统提供了全自动的掩码生成过程,从而更容易开发复杂的电路和体系结构。TAMARACK 161 B的集成图像数据管理单元允许用户轻松准确地存储和检索设计。该机器还能够合并故障分析、测试测量和过程集成等附加功能。为了跟上口罩制作技术的最新进展,161B定期收到升级和更新。为客户提供软件更新、定期维护和访问专用的客户服务,让您轻松体验。TAMARACK 161B是一种可靠、高效且具有成本效益的口罩生产和生产工具,是满足所有口罩生产需求的理想资产。

还没有评论