二手 KLA / TENCOR 2132 #139716 待售

网址复制成功!

单击可缩放

ID: 139716

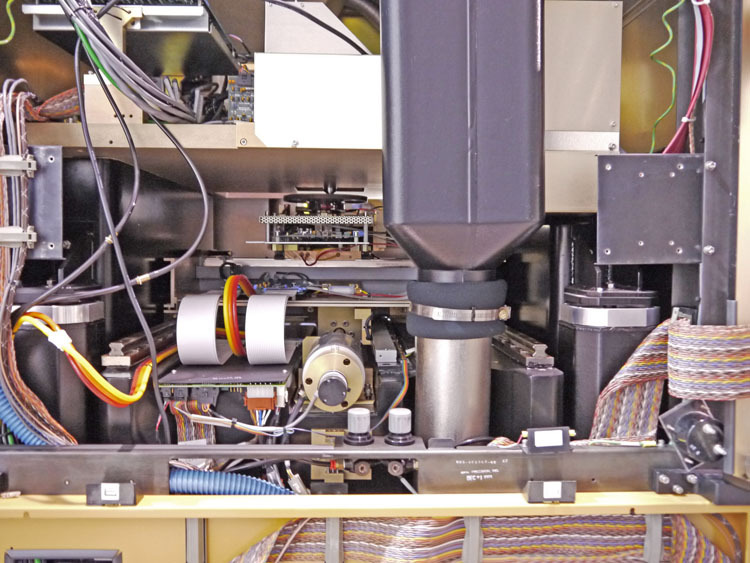

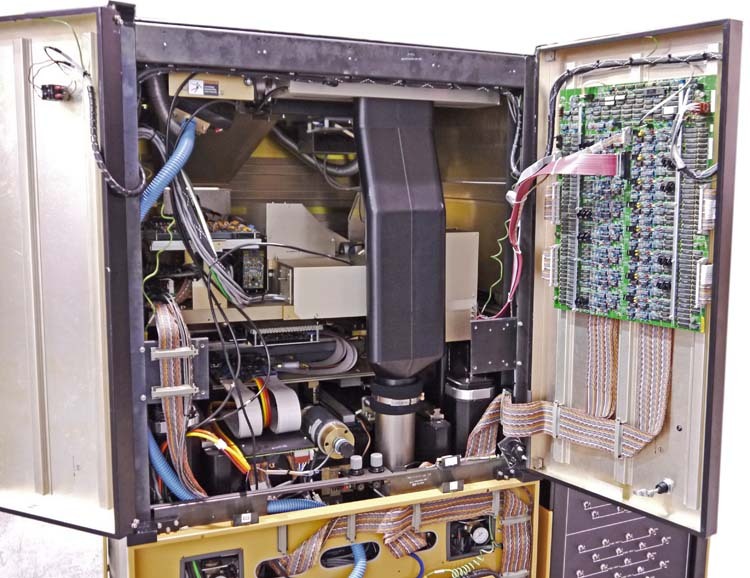

Wafer defect inspection system

Includes:

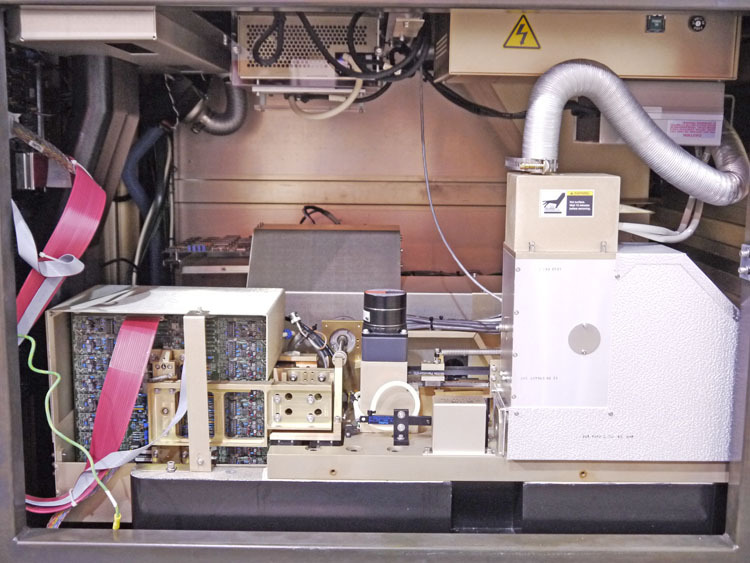

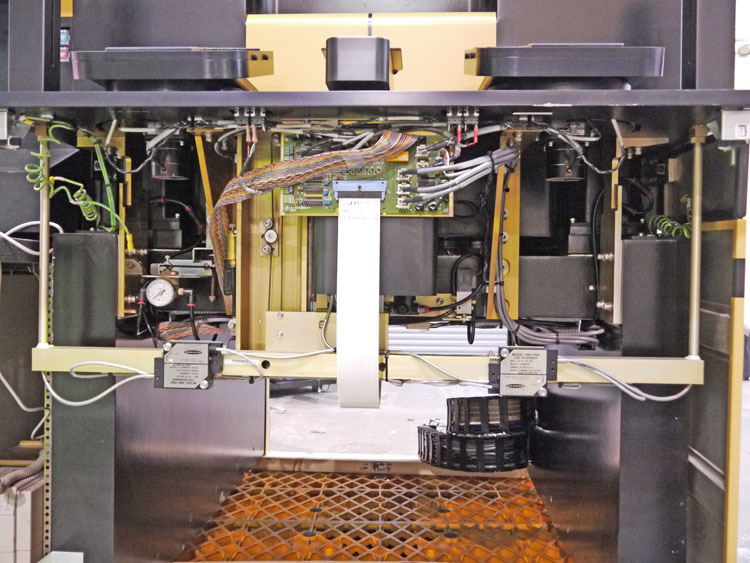

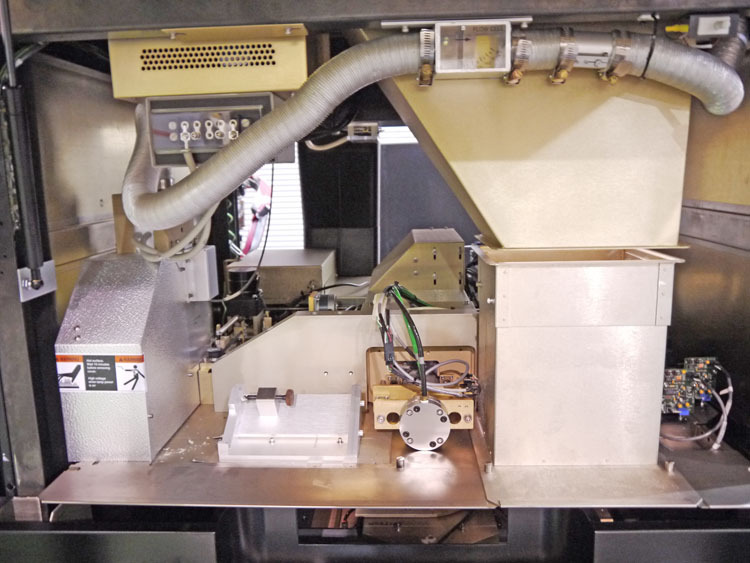

KLA / TENCOR 2132 wafer inspection unit (primary)

KLA / TENCOR 2132 wafer inspection unit (secondary)

KLA / TENCOR 2552 data analysis station

KLA / TENCOR 2132 power line conditioner

Specifications:

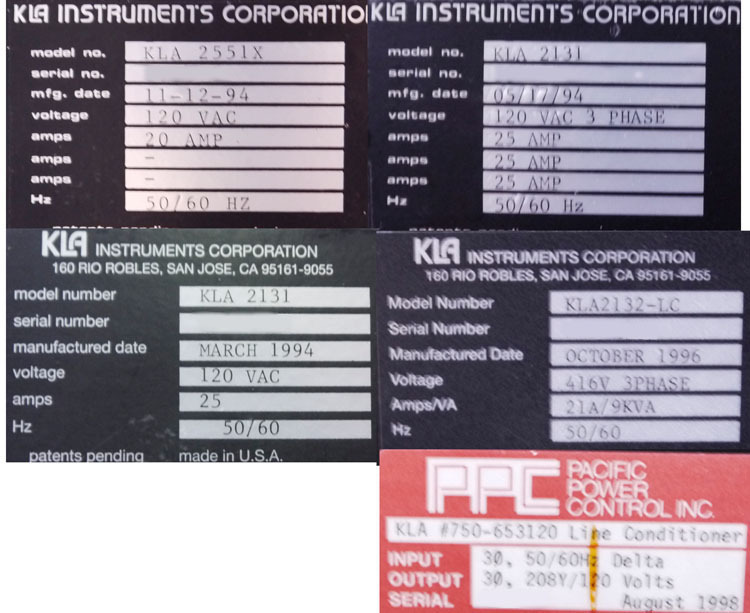

KLA / TENCOR 2132 wafer inspection unit (primary):

Label model: KLA-2131, front panel reads "2132"

Chuck installed: 8"

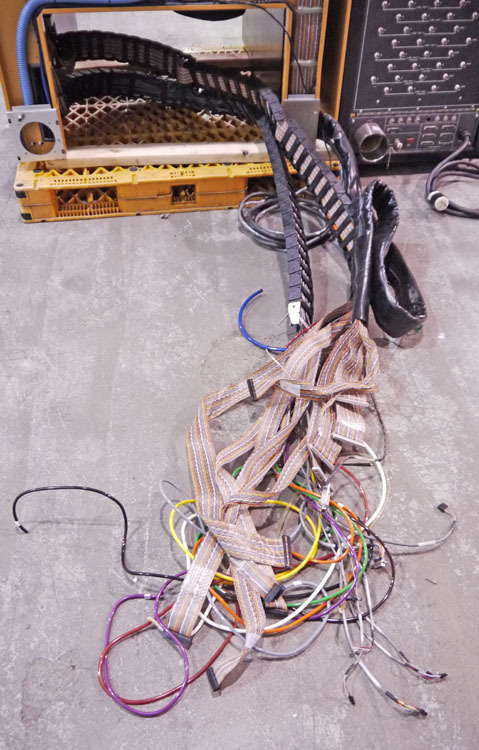

Power cable intact, all other cables cut

Front upper panel cover shocks / struts are worn

Missing: PC, 1-2 body panels

Power rating: 120VAC, 25A, 50/60Hz

1994 vintage

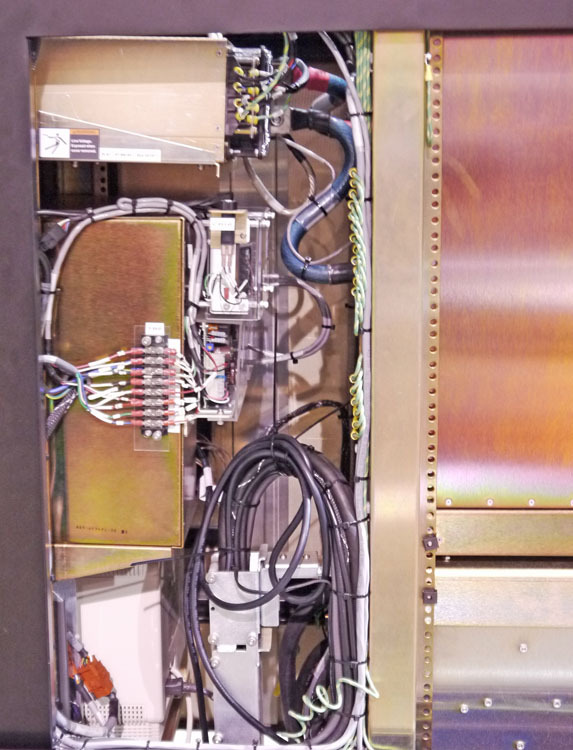

KLA / TENCOR 2132 wafer inspection unit (secondary):

Label model: KLA-2131, front panel reads "2132"

Body panel does not fully mount

Power rating: 120VAC, 3-phase, 25A, 50/60Hz

1994 vintage

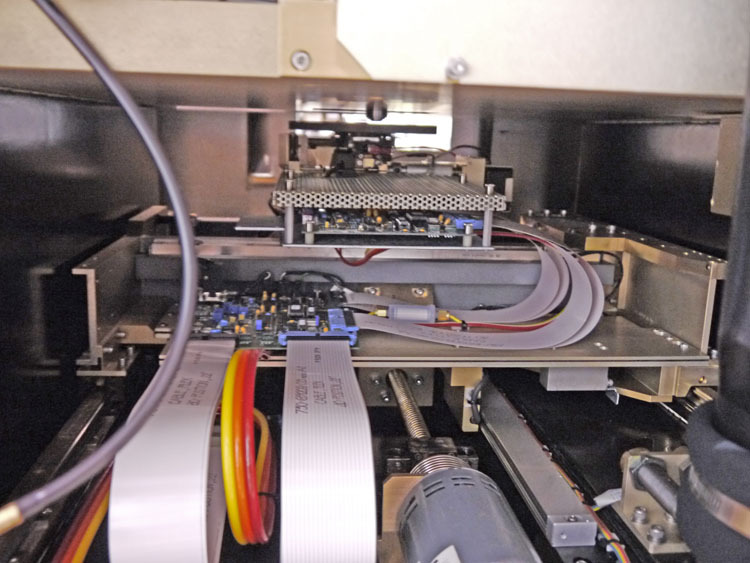

Components:

KLA PC/IF 486/66 PC system, p/n 750-660859-00

Dual monitors

Keyboard

Trackball

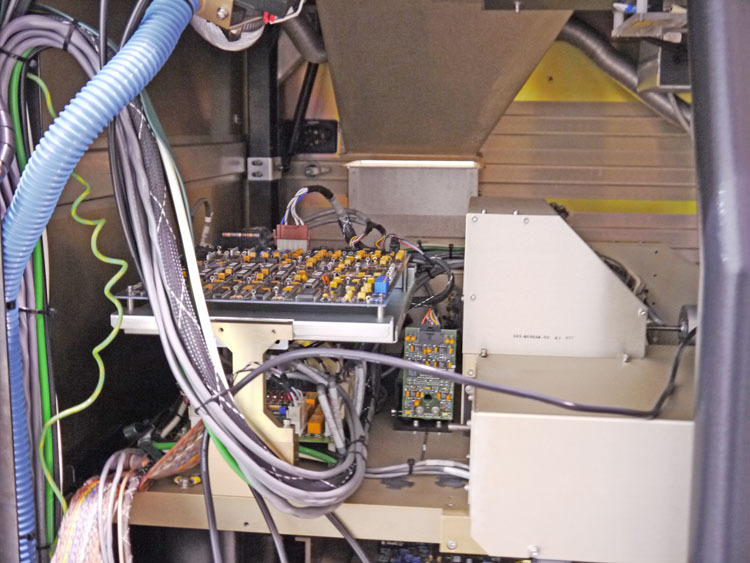

Modules installed:

KLA PC/IF 486/66 PC system, p/n 750-660859-00

KLA Memory Controller Phase 3, p/n 710-658232-20

FAB, p/n 710-658085-00

(2) Mass Memory 2 Phase, p/n 710-658051-20

(2) KLA CornerTurn 3, p/n 710-655651-20

(2) Y-Interpolator, p/n 710-658172-20

(2) X-Interpolator, p/n 710-658177-20

UNIQUENESS Processor, p/n 073-658045-00

Alignment Processor Phase 3, p/n 710-658041-20

Alignment Processor (AP1), p/n 710-65803620

Defect Filter (H.R.), p/n 710-659724-00

Defect Processor Phase 3, p/n 710-658075-20

KLA DP, p/n 710-650099-20

KLA DD, p/n 710-650044-20

KLA DF FAB PH3073, p/n 073-65836-00

IB Module

RIF Module

KLA / TENCOR 2552 data analysis station:

Label model: KLA-2551X, front panel reads "2552"

Power rating: 120VAC, 20A, 50/60Hz

1994 vintage

Components:

INTEL XBASE8TE8F-C PC computer tower

APC BackUPS

Dual monitors

Keyboard

Trackball

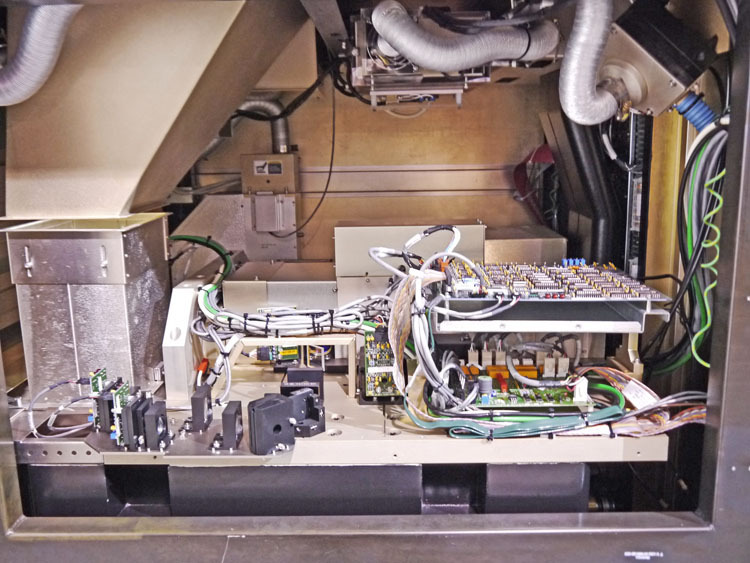

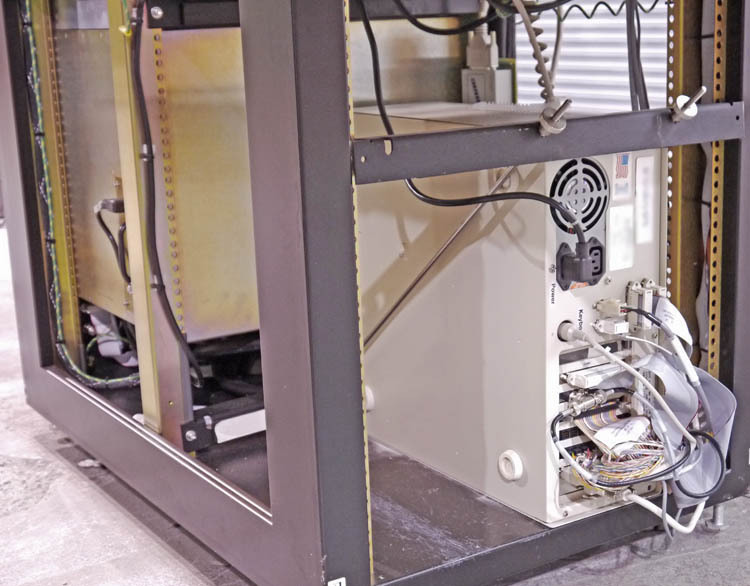

KLA / TENCOR 2132-LC power line conditioner:

P/N: 750-653120

Power rating: 9kVA, 416V, 21A, 3-phase, 50/60Hz

Input: 3-phase, 50/60Hz

Output: 3-phase, 208V/120V

1996 vintage

System currently de-installed.

KLA/TENCOR 2132是一款功能齐全、自动化的面罩和晶圆检测设备。它具有先进、高性能的传感器和先进的成像技术,可用于高精度、精确的检查。该系统采用明线、明亮缺陷、暗区缺陷成像传感器,改进缺陷分类,高速自动缺陷审查和缺陷处理。该设备可提供无与伦比的缺陷识别和精确的缺陷处理,每小时最多可处理60个晶圆。它是一种非接触式、无破坏性的机器,在整个检测过程中确保晶片对基板的完整性。凭借其先进的传感器技术,该工具能够分析各种基板,包括硅、光刻胶、玻璃和陶瓷,尺寸可达300毫米。资产的先进成像技术包括各种成像模式,从而能够检查任何等级的半导体晶圆。晶片表面的高分辨率图像通过各种透镜和光学预设来捕获,从而能够快速、轻松地全面概述晶片。有三种类型的成像模式可用于特定于任务的检查:高放大倍率图像、平面图像、3D图像。该模型还提供了改进的缺陷分类和分类功能。通过将明亮的线条、明亮的缺陷和深色缺陷图像与不同角度的光相结合,该设备能够高精度地表征缺陷。缺陷会自动实时分类,并根据其性质的严重性分类成组。使用高级3D缺陷分析模块,可以创建晶圆表面缺陷的详细3D映射。KLA 2132是一个非常宝贵的工具,用于检测和处理缺陷,提高精度和准确性。它具有强大的特性,有助于提高产量和减少晶片废料,以满足各种晶片检验需求。

还没有评论