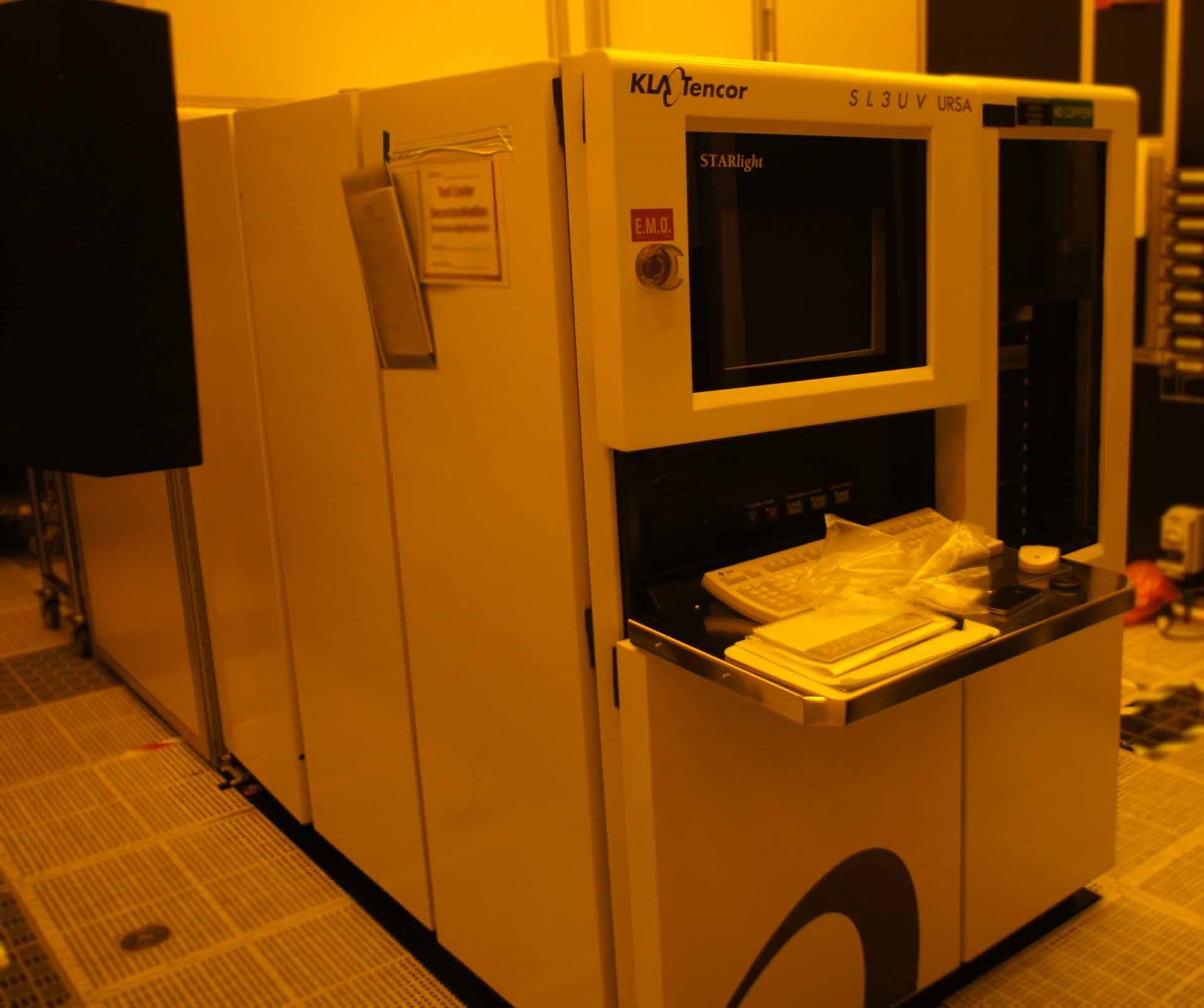

二手 KLA / TENCOR STARlight SL3 UV URSA #9058370 待售

看起来这件物品已经卖了。检查下面的类似产品或与我们联系,我们经验丰富的团队将为您找到它。

单击可缩放

已售出

ID: 9058370

Inspection system, 6"

Automation:

KLA RF File format output

Klarity analysis

Automatic error recovery

System output:

Minimum output capability (Reticles per week):

0.25 um pixel size with 100 x 100 mm inspection area: 100

Minimum run rate (Reticles / Hour):

0.25 um pixel size for 100 x 100 mm inspection area: 0.7

0.375 um pixel size for 100 x 100 mm inspection area: 1.3

0.5 um pixel size for 100 x 100 mm inspection area: 1.9

Process capability:

Box handling

Manual load

NIKON Reticle, 6"

Upgraded to HR (High resolution)

Mask basic inspection capability:

OPC Inspection

APSM (DAP Design) Inspection

EPSM Inspection capability including EPSM and full ternary

Shifter transmission: ≤40% at 364 nm wavelength

Review capability:

Transmission review

Reflective review

On line review

Repeat review

Sizing capability

Offline view (Not classification)

Offline classification option

Show new defect capability

Recipe setup / Automation:

Auto setup capability

Light tower

Selectively inspect: Glass, pellicle or chrome surfaces

Maximum recipe setup time: 15 Minutes

Three level password protection capability: Operator, engineer & FSE

Continuous vs single-step operation capability

Auto loader cycling capability

Barcode reading capability

Networking capability

Auto operation capability with existing recipe

Minimum inspectable mask characteristics:

Minimum pitch larger than or equals to twice of the minimum line width:

Minimum inspectable main feature size (nm) at:

0.186 um pixel size (Option): 400

0.25 um pixel size: 500

0.375 um pixel size: 750

0.5 um pixel size: 1000

Minimum pitch larger than or equals to 2.5 times of the minimum chrome line width:

Minimum inspectable main feature size (nm) at:

0.186 um pixel size (Option): 220

0.25 um pixel size: 320

0.375 um pixel size: 560

OPC Features:

Minimum inspectable OPC serif / Inverse (nm): 200

Minimum inspectable OPC jog (nm): 14

Inspection characteristics:

Within tool matching: ≤5%

Tool to tool matching: ≤10%

False defect rate (Defects/cm²): 0.1

For inspection area > 10 cm²: 0.1

Sensitivity on pellicle @ 98% capture rate (nm): 4000

Sensitivity on glass @ 98% capture rate (nm):4000

Minimum pitch larger than/or equals to twice of the minimum line width:

Sensitivity on chrome @ 98% capture rate (nm) at 0.186um inspection pixel size

PSLs (Option) EPSM capture rate on shifter substrate @ 90.4%: 140

Sensitivity on chrome @ 98% capture rate (nm) at 0.25um

EPSM Capture rate on shifter substrate @ 90.4%: 180

Sensitivity on chrome @ 98% capture rate (nm) at 0.375um

Sensitivity on chrome @ 98% capture rate (nm) at 0.50um

Minimum pitch larger than or equals to 2.5 times of the minimum chrome line width:

Sensitivity on chrome @ 98% capture rate (nm) at 0.186um

Sensitivity on chrome @ 98% capture rate (nm) at 0.25um

Sensitivity on chrome @ 98% capture rate (nm) at 0.375 um

Inspection pixel size on reticle using PSLs: 350

Sensitivity on chrome @ 98% capture rate (nm) at 0.5 um

Inspection pixel size on a reticle using PSLs: 500

Exclusion zones:

Pelliclized plate:

Exclusion on chrome side (mm)

For 0.25um pixel or greater: 3.5

For 0.186um pixel: 5.5

Exclusion on pellicle (mm): 1

Exclusion on glass (mm): 3

Unpelliclized plate:

(3) Exclusion on 6" back glass

(3) Exclusion on 6" front side

1999 vintage.

KLA/TENCOR STARlight SL3 UV URSA是使用专利双波长UV成像技术的先进掩模和晶圆检测设备。它消除了对外部光源的需求,使晶片能够直接成像,具有最大的成像精度和高信噪比。KLA STARlight SL3 UV URSA设计用于面罩和晶片应用的自动化、独立检测,包括晶片凹凸检测、石刻/蚀刻检测、光掩模检测、迭加检测以及各种缺陷检测和分类任务。该系统是围绕一台全自动、单波长和双波长的紫外线成像发动机构建的,其大视野可达17厘米x 17厘米。它提供了紫外线图像采集所需的必要紫外线照明。其坚固的结构、稳定的热环境和高性能的光学器件确保在整个视场上进行精确的成像。集成的降噪单元有助于降低背景噪声并提供高对比度图像。该机配备了最先进的图像处理平台。它具有基于先进模式识别技术的快速、直观、精确的缺陷检测算法。自适应信号增强功能会自动调整以适应不断变化的条件,从而检测到最小的缺陷。该工具还提供集成的分析和测量功能,以实现高级过程控制和优化。TENCOR STARlight SL3 UV URSA具有基于Windows的用户界面,可提供易于使用和高效的操作。它包括一整套易于使用的工具,可以方便地获取和评估数据。该资产支持网络连接,并与流行的制造软件包兼容,从而实现了与现有生产线的灵活集成。STARlight SL3 UV URSA是用于检查掩模和晶圆应用的功能强大且功能丰富的模型。其先进的双波长成像技术和广泛的图像处理能力提供了最大的准确性和可靠性。结合灵活的集成能力,是自动化掩模和晶圆检测的理想解决方桉。

还没有评论