二手 THERMAL TECHNOLOGY SAS-2000 #293597792 待售

网址复制成功!

单击可缩放

ID: 293597792

优质的: 2014

High temperature furnaces

Heating system power leads: Water cooled 350 MCM Size

Operating temperature: 2200°C

Hot zone operating temperature uniformity: ±2°C

Maximum change weight: 1000 Ibs

Vacuum level: 10 Torr

Horizontal

Front loading with motorized hinge front door

Automatic pneumatic clamping

Manual opening rear door

System frame / mezzanine suitable for clean room integration

Double wall water cooled stainless steel chamber

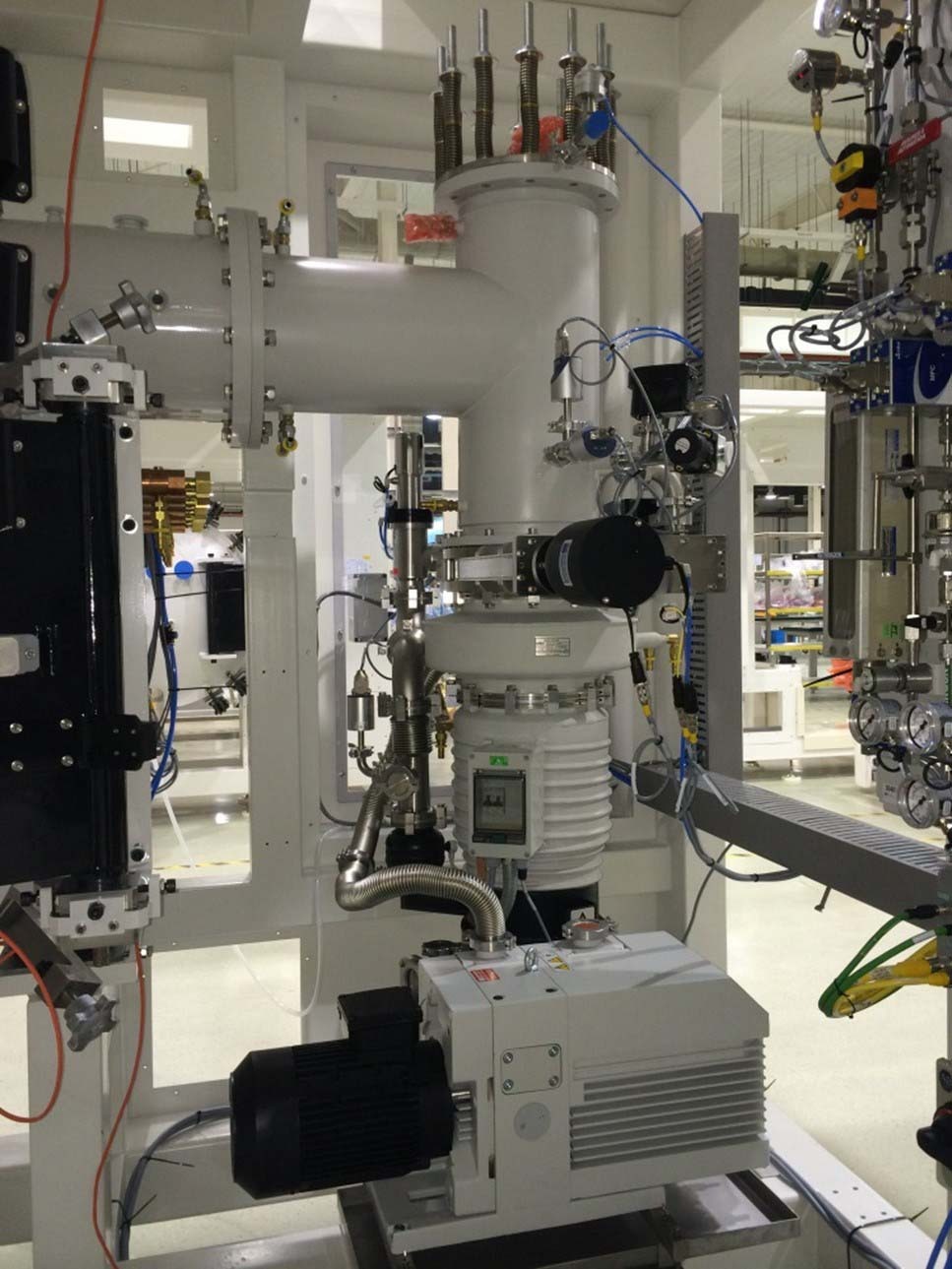

Doors and pump line

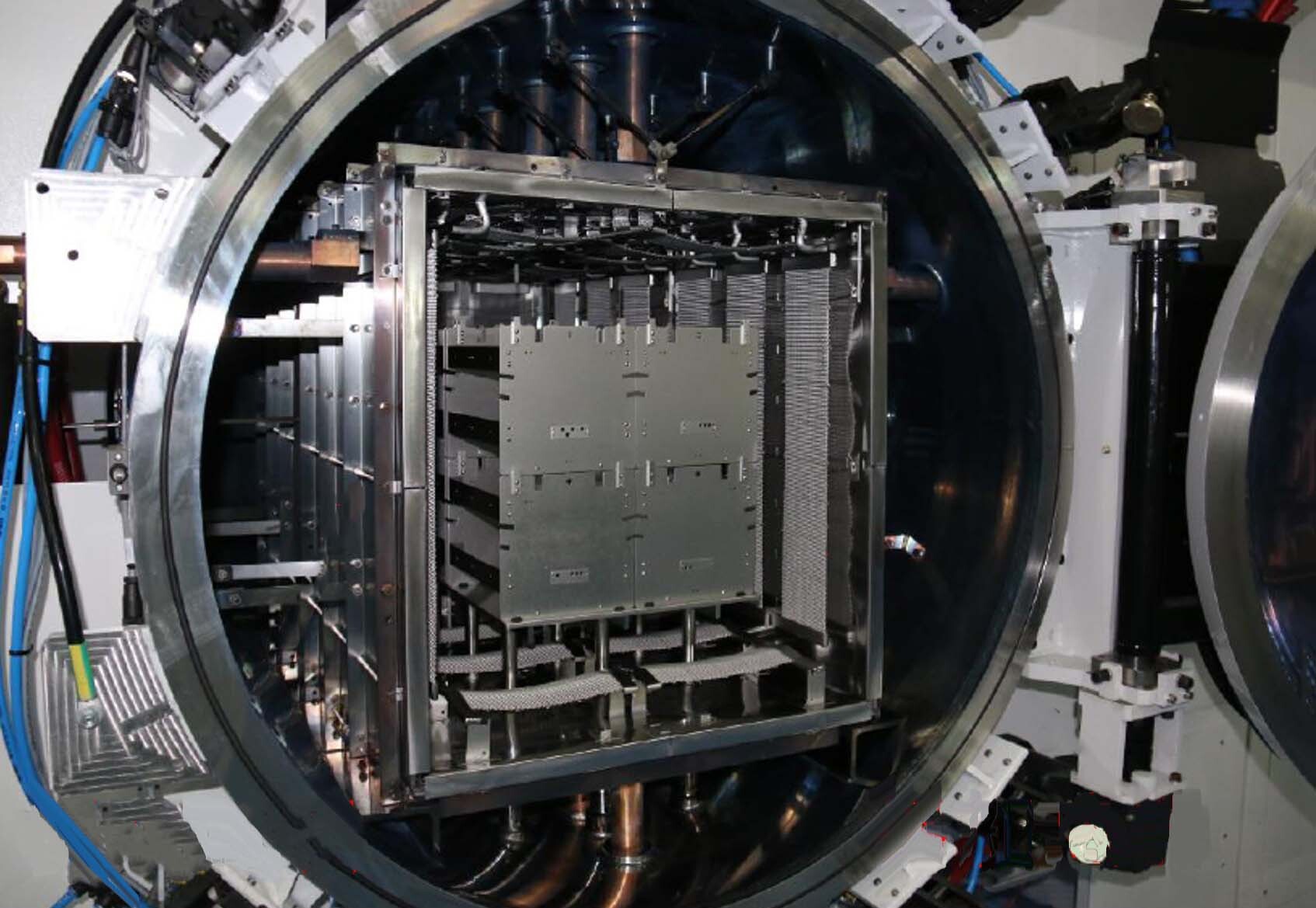

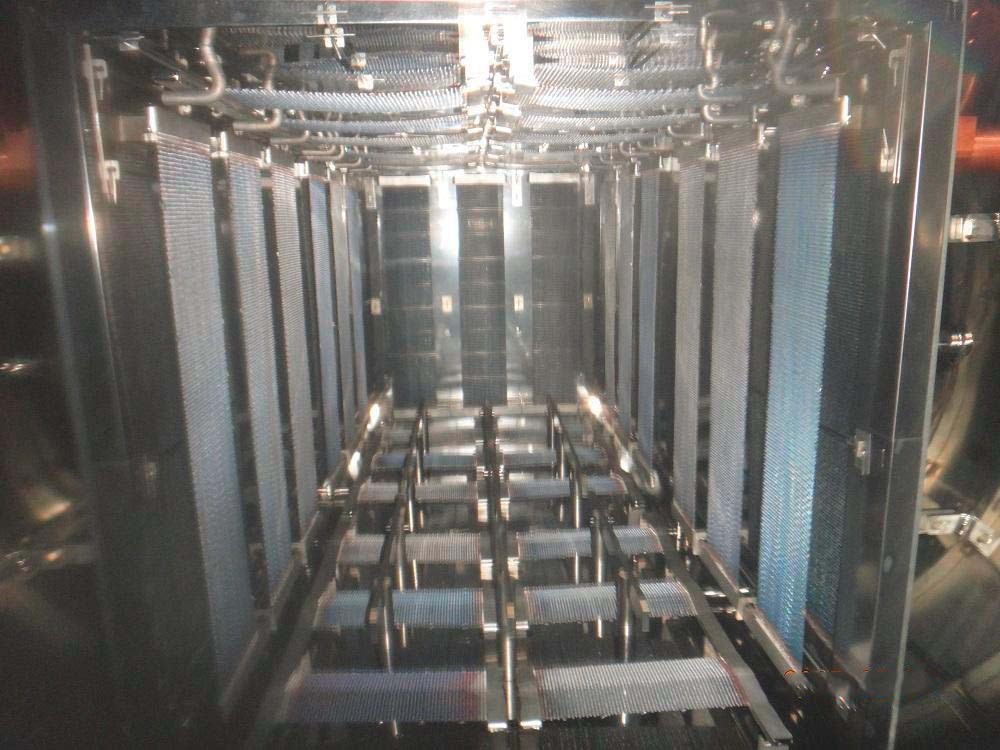

Metal shielded hot zone: Tungsten / Molybdenum shields

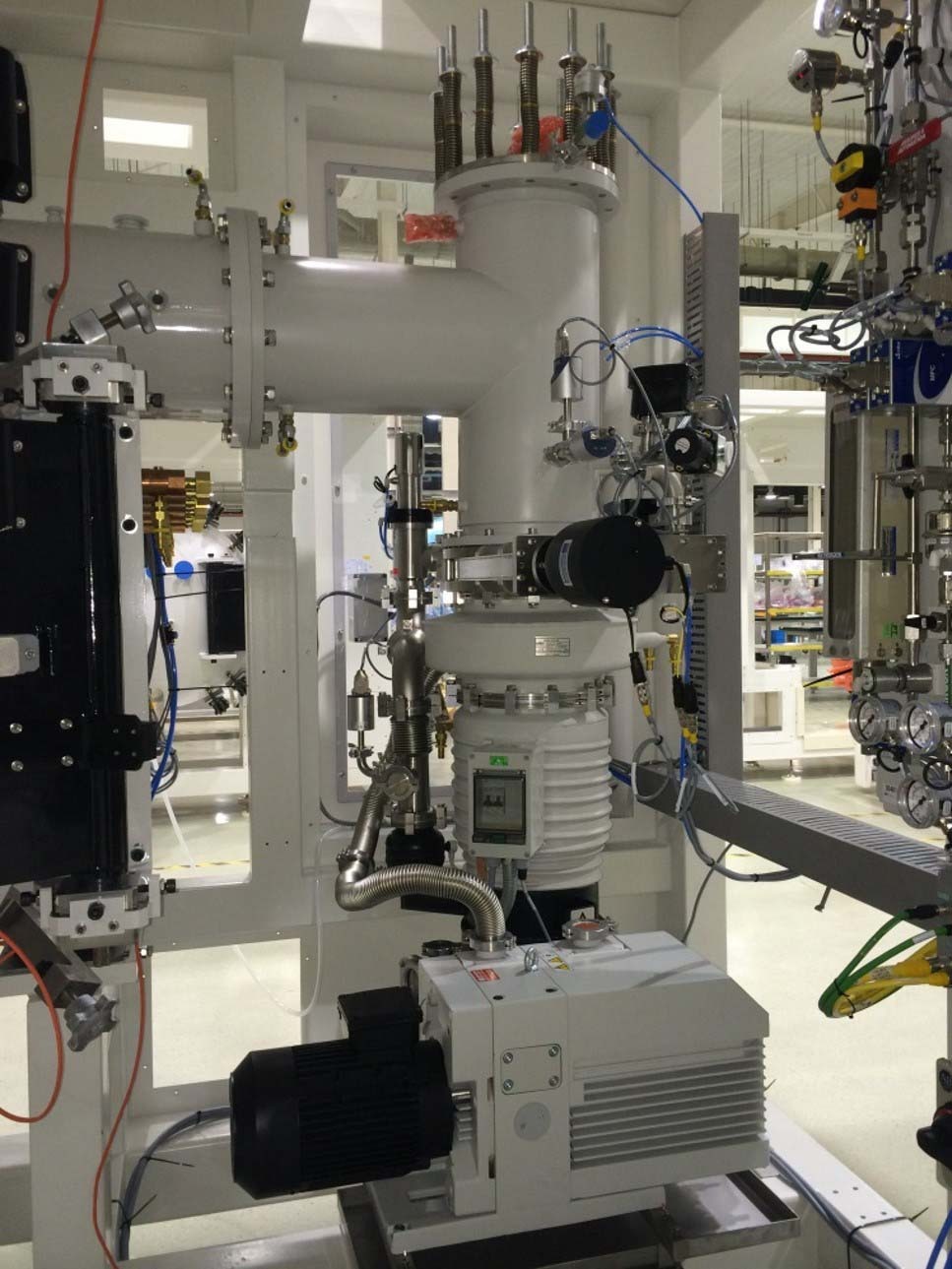

Diffusion pumped, 10"

With mechanical roughing pump

Water cooled inlet baffle

Technical:

Chamber materials:

304 L

Polished interior surfaces

Chamber ports:

Electrode ports: 24 on chamber, 3 on each door

Thermocouple and spare:

(18) NW16 on chamber

(2) Door

NW40 on pump line

Heaters: Tungsten mesh panels

Hot zone effective size: 16" x 16" x 36" (5+ cu ft)

Control system: Siemens PLC based

Heating zones:

(6) Top

bottom

(2) Sides

(2) Ends

Safety, Alarms, Interlocks:

Vacuum

Water flow

Air pressure

Over temperature

Single enclosure:

(4) 70 KVA transformers

(2) 35 KVA transformers

Thermocouples:

(6) Types C Control

Type C Over temperature

Vacuum gauge:

1000 Torr

Cold

Pump down (Clean and dry chamber):

45 Minutes to 5 m torr

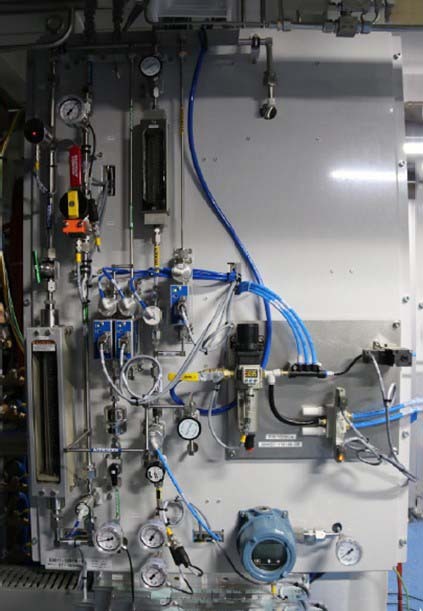

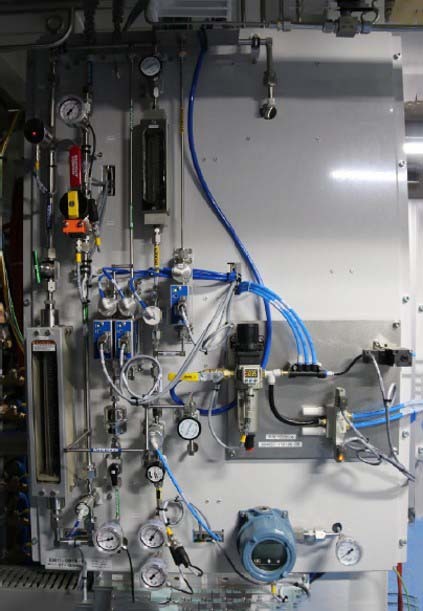

Gas system:

(3) Circuits: Nitrogen

Argon

Hydrogen

With mass flow controller, VCR Connection

Cooling water circuit:

(24) Active

(3) Spares

With flow and temperature monitoring

Top zone 70 kVA with 10 and 12 volt taps

Bottom zone 70 kVA with 10 and 12 volt taps

Left zone 70 kVA with 18 and 21 volt taps

Right zone 70 kVA with 18 and 21 volt taps

Front zone 35 kVA with 15 and 18 volt taps

Rear zone 35 kVA With 15 and 18 Volt taps

UPS For emergency shutdown: 24 VDC, 20 A.

Diffusion pump power supply: 230 VAC, Single phase, 20 A

Mechanical pump power supply: 230 VDC, 3 phase, 10 A

Power supply: 350 kVA, 3 Phase, 6 Zone.

2014 vintage.

THERMAL TECHNOLOGY SAS-2000是为陶瓷和半导体应用提供无与伦比的多功能性的下一代燃烧炉/炉。它提供高达2000 °C的均匀热,并具有独特的空气冷却设备,能够在最小热应力的情况下快速冷却。烤箱/炉有一个专门设计的腔室,在整个温度等温剖面上提供均匀的热分布。这样可以确保每个样品通过精确的温度控制来加热,从而在优化工艺结果的同时最大限度地减少样品的热应力。此外,还可以使用精确分区来有效控制离散的温度区域,以满足每个应用程序的精确需求。SAS-2000具有精确的控制器和先进的PID控制,可确保整个扩展温度范围内的过程控制准确而稳定。THERMAL TECHNOLOGY SAS-2000还提供了独特的空气冷却系统,以有效减少热冲击并延长敏感部件的使用寿命。风冷机组设计由具有可调温度控制的风冷鼓风机组成,提供精确的温度控制和精确的冷却速率。SAS-2000烤箱/炉也有一系列加热元件,可以预先设定用于各种应用,如批量回火、高温退火、金属合金等。加热元件采用专用机器设计,可确保最大限度的均匀加热和精确的热控制。加热元件也被设计成抗氧化,以便延长烤箱/炉的运行时间。THERMAL TECHNOLOGY SAS-2000有一个集成的高级用户界面,提供对过程参数的全面实时显示和控制。此高级界面允许用户根据其应用的特定需求配置烤箱/炉和PID工艺参数。它还提供了一个集成的自动调整功能,使烤箱/炉子设置的调整更加容易和精确。总体而言,SAS-2000为用户提供了无与伦比的性能和多功能性,同时提供了精确的控制和性能。这种烤箱/炉在提供良好的均匀热分布、精确的温度和冷却控制以及灵活的温度调节方面表现出色。利用内置的高级用户界面和先进的PID控制,THERMAL TECHNOLOGY SAS-2000可以实现精确可靠的应用结果。

还没有评论