二手 NISSHINBO 1834N #9225894 待售

网址复制成功!

单击可缩放

ID: 9225894

优质的: 2008

Laminator

Single platen laminator

With 1.8 m x 3.4 m lamination area

LEYBOLD SCREWLINE SP250 Vacuum pump, 7.3 kW

Power belt in-feed conveyor

Power roller exit conveyor

PLC Operators control

Digital product documentation and operations manual

Cable size: 100 mm² (96.3-117.2 mm²)

Tightening torque: 45 nm

Terminal size: M12

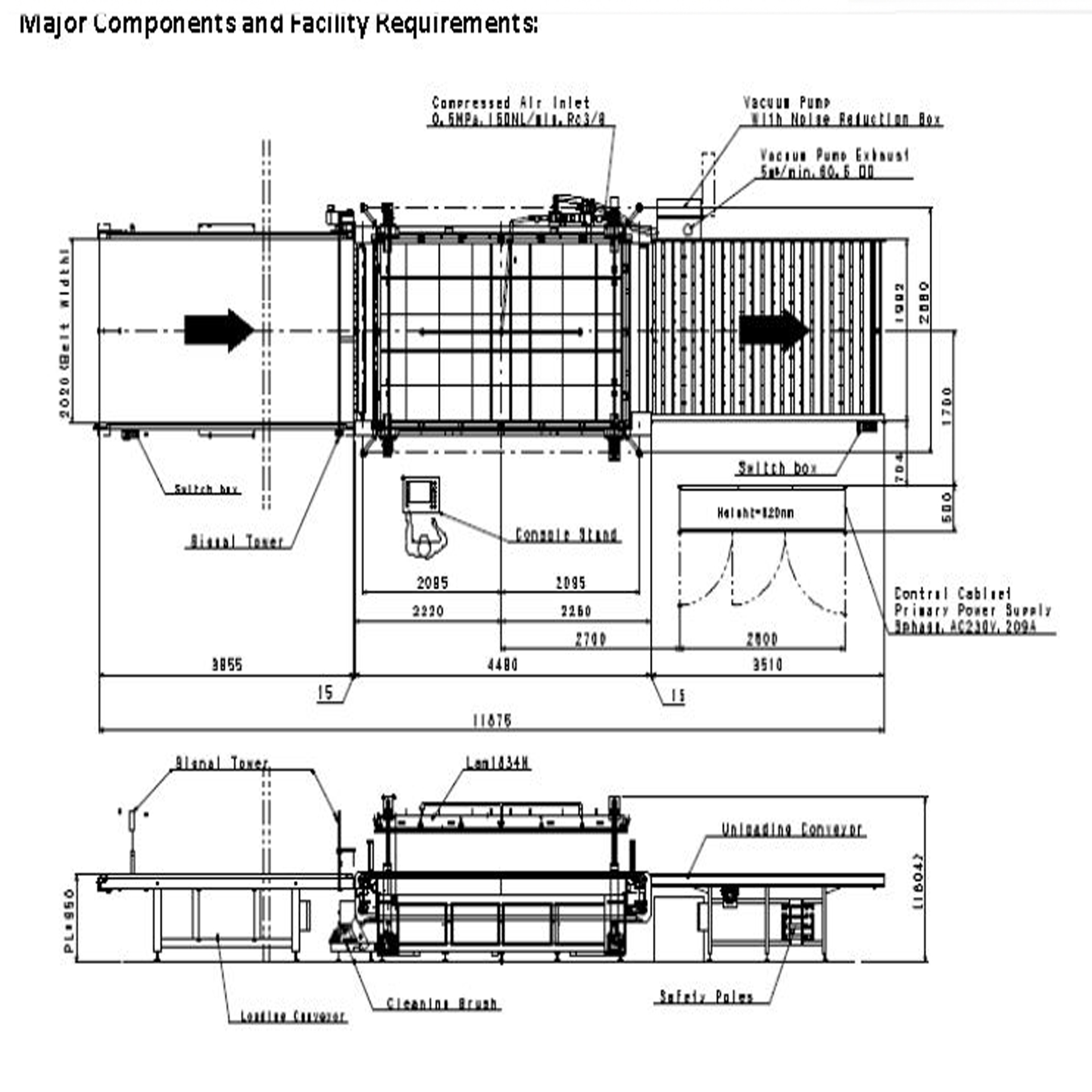

Compressed air: >0.5 MPa, 150 NL/min

Inlet connection: Rc 3/8" Female fitting (Air panel)

Maximum thickness of solar modules: 15 mm

Vacuum system:

OERLIKON / LEYBOLD SV300 Rotary vane vacuum pump

Exhaust speed: 5666 L/min (60 Hz)

Noise reduction box

Vacuum pressure: <133 Pa

Pumping speed: Within 2 min to reach 133 Pa

Pressure sensor:

Upper chamber: KEYENCE AP-C31

Lower chamber: CANON / ANELVA Crystal gauge

Vacuum exhaust: Exhaust outlet

Vacuum pump: φ 60.5 OD (NW50)

Pressing control:

Pressing force: Maximum 0.1 MPa

Pressing speed: Slow, medium, fast

Heating system:

Heater type: Electrical sheathed heater

Temperature control: PID control, (4) Zones individual control

Operating temperature: Up to 180°C

Temperature uniformity: <±5°C (Between 100°C to 160°C)

Heating speed: <30 min (from 30°C to 150°C)

Temperature sensor: (3) Thermocouples

Control

Spear

Overheat detection

Chamber lifting system:

Driving method: (4) Electrical cylinders driven

Control system: Encoder feedback

Middle position moving stroke: 275 mm For automatic cycle

Fully opened position: 435 mm For manual operation

Moving speed:

Middle position to fully closed position: <15 Sec

Fully opened position to fully closed position: <20 Sec

Loading / Unloading:

Pass line: 950 mm (F.L.)

System cycle time: <60 Sec

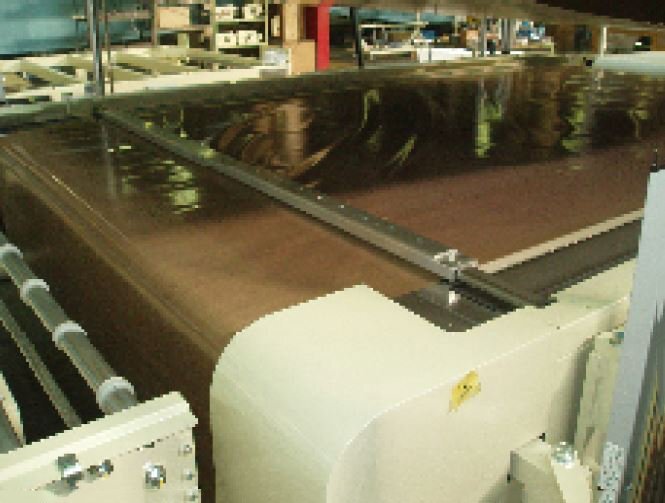

Laminator lower belt conveyor:

Transfer method: Belt transfer system

Transfer speed: 15 m/min

Maximum load: 50 kg

EVA Removing brush unit: EVA Dust tray

Loading conveyor:

Type: Belt conveyor (Heat resisting belt)

Driving method: Inverter controlled electric motor

Belt width: 2020 mm

Work detector: Photo-electric sensor detects the head of solar module

Unloading conveyor:

Type: Roller conveyor

Driving method: Inverter controlled electric motor

Module lift-up system

Work detector

Safety system:

Light curtains

Mechanical lock (Upper chamber)

General:

Working temperature: 0°C-55°C

Storing temperature: -25°C-75°C

Working humidity: 5-95% RH

Storing temperature: 5-95% RH

Working altitude: <2000 m

Over-voltage category: Category III

Pollution degree: Degree 3

Operating system:

Computer hardware: A-Series PLC

Touch screen: Color display, 10"

Does not include:

Additional sensor

Positive cooling

Built-in heater

Thermometer

Power supply: 230 VAC, ± 10 %, 3 Phase, 50/60 Hz, 209 A

2008 vintage.

NISSHINBO 1834N是一种包装机器,旨在减少人力资源干预,以保证材料的高效和一致流动。该机设计为高效、快速地处理各种类型的物体。它是一个连续的轨道型封装机,包含不同的模块,可以自主操作,可以连接到其他机器。它的高速度和精确度保证了最小的材料浪费。通过减少处理产品的人数,机器有助于降低人为失误的风险,提高生产效率。1834N提供了一系列功能,使其成为有效的包装解决方桉。这是一台全自动机器,不需要人工干预,因为它连接到外围设备。它可以在整个包装过程中操作,用于检测各种类型的错误。它还识别产品特性,例如尺寸、形状和重量,然后在处理每个项目时调整其运动。这些功能使其能够产生一致的包装结果。此外,NISSHINBO 1834N拥有先进的传感器,可以检测要包装材料的尺寸、形状和重量。它还可以识别不应该包装的产品,并将其从生产线中移除。这有助于确保产品没有缺陷,适合包装。该机还设计方便维护,可以在最小停机时间内操作。它配有LED显示屏,可提供有关计算机当前状态和任何潜在问题的有用信息。它还包括一个工具箱,可以方便地访问所有组件。1834N对于希望实现包装过程自动化的公司来说,这是一个高效且经济实惠的解决方桉。其主要特点和先进技术可帮助提高精度和加快生产过程。这样可以降低出错的风险,并最终提高客户满意度。

还没有评论