二手 AMAT / APPLIED MATERIALS Vantage Radiance #293587171 待售

网址复制成功!

单击可缩放

ID: 293587171

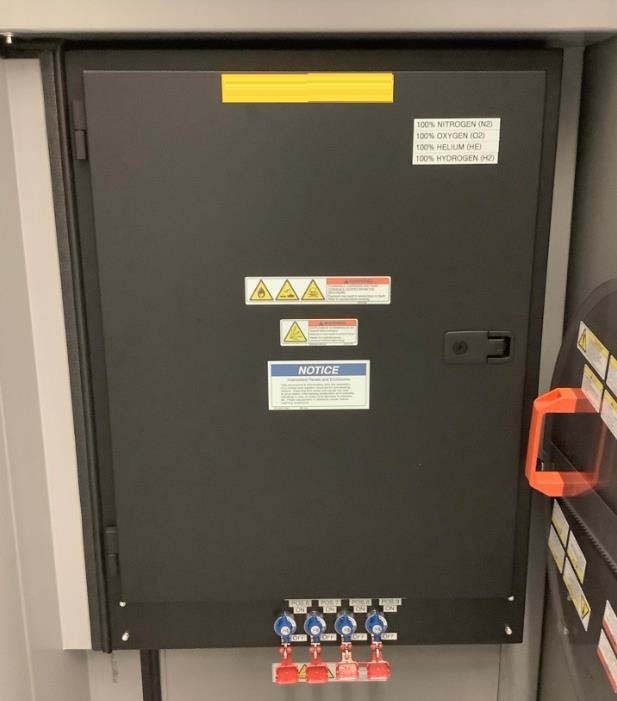

Rapid Thermal Processing (RTP) system, 12"

Process: RadOx

(2) Chambers

Wafer type: SNNF

Platform type: Vantage 3.X

Position A and B: (V352) RadOx2

Chamber A and B process: Toxic RP

OHT WIP Delivery

Dual 2-slot active cool down station

No remote control system

E99 Docked reading capability

Load port: SELOP 7

Load port operator interface: Standard (8) lights

Configurable colored lights

Top air intake system

Upper E84 interface enabled OHT

Upper E84 PIO sensors and cables

E99 Carrier ID: TIRIS With RF

Operator access switch

4-Color configurable light towers

Interface A option

eDiagnostic

Out the back connection type: RP

Out the back connection H2

(2) Water cooling chambers

RP Integration hardware: Chamber A and B

Standard RAGB rear light tower

Vantage skin: (2) Toxic chambers

IPUP Transfer pump

Open loop tuner

MFC Type: STEC

Core anneal and RTO

Monitor 1: Flat panel with keyboard on stand, 17"

Monitor 2: Flat panel on stand, 17"

Monitor 1 and 2 cables: 25 ft with 16 feet effective

SEMI F47

Semi S2 compliance

RTP Chamber type: Radiance RadOx2, 12"

Technology option: Open loop tuner

MFC Type: STEC

Core anneal and RTO

Rotation type: WRLD Toxic

Low flow O2: 5 SLM

High flow O2: 50 SLM

Oxygen analyzer

H2:

High flow

Low flow

Side inject

No process N2 for flammable MNFLD

Gas pallet type: TOXIC RP Common gas pallet

No MWBC improvement kit

Chamber integration lines: RadOx2

RP Pump cable: 81 Feet

Base ring: RadOx2 base ring

Line 1 / N2 (N/O), 50 SLM

Line 2 / O2, 50 SLM

Line 3 / O2, 5 SLM

Line 6 / H2, 15 SLM, Side inject high flow

Line 7 / H2, 22 SLM, High flow

Line 8 / H2, 2 SLM, Low flow

Line 10 / N2 (P/P), 30 SLM Restrictor

Line 11 / He, 30 SLM

Line 12 / N2 (BP), 50 SLM

Line 13 / N2 (Maglev), 100 SLM

Docking station FST install kit

Does not include Hard Disk Drive (HDD)

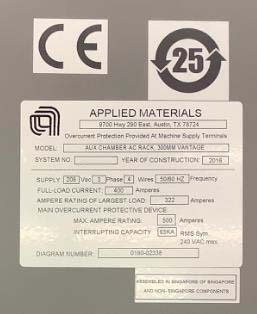

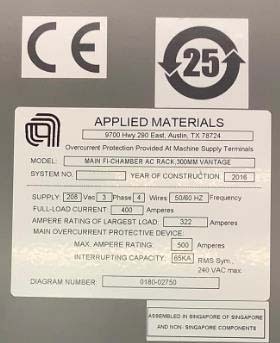

2016 vintage.

AMAT/APPLIED MATERIALS Vantage Radiance是一种快速热处理器,在真空环境中运行,可高效处理半导体器件制造的晶片。设备采用先进技术,使温度值在快速热过程中得到精确控制。此外,系统可以将材料转换为改变形式,包括无定形、多晶、单晶结构,以及多层结构。这也可以用来改善层的均匀性和微结构性质。Radiance单元的主要部件包括一个锁载室、一个闪光灯和一个高真空框架。装载室是晶圆装卸的机器的主要区域。闪光灯用于加热腔室内部,而高真空框架维持真空环境。此外,该工具还包括高级工艺控制模块,用于在快速热处理过程中监测温度、压力和其他参数。资产的最高处理温度为1000 °C,单个循环最多可处理12个晶圆。这样可以提高生产效率和缩短周期时间。该型号还配备了行业标准的晶片处理设备,配有自动卡带到卡带转运站,以及自动对准检测。这使得系统易于设置、操作和维护,并提高了可靠性和性能。Radiance单元使用先进的控制技术来确保每个快速热过程的准确性和可重复结果。它包括晶圆温度和闪光灯强度之间的内置反馈回路,允许机器在晶圆的整个表面保持恒定一致的温度。这确保了一致的热处理结果。此外,该工具还内置了压力监控资产,可实现整体精确控制。Radiance模型不仅具有将材料快速转换为改变形式的能力,还可以用于快速退火材料。这一过程可用于减少晶体缺陷,增加接触阻力,并在所需材料深度内增强掺杂剂活化。因此,Radiance设备由于其灵活性、准确性和可靠性,是半导体器件制造商的绝佳选择。

还没有评论