二手 AMAT / APPLIED MATERIALS AMP-3300 #9201707 待售

网址复制成功!

单击可缩放

ID: 9201707

PECVD System

Silicon nitride / silicon dioxide dielectric films: Plasma-enhanced chemical vapor deposition system

Low-temperature

Four controlled process

With reactor process chamber:

Radio frequency (RF) power

Chamber pressure

Chamber temperature / Gas flows

Plasma energy field is generated by RF power in the process chamber

Evacuated with a vacuum roughing pump / Motor-driven roots blower

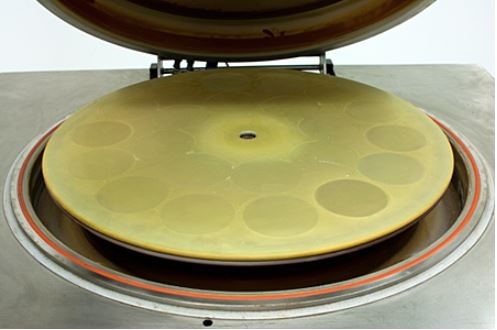

Screwless electrode

Dual gas manifold

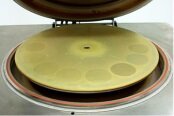

42 Pieces of 3-inch wafers

22 Pieces of 4-inch wafers

16 Pieces of 5-inch wafers

Deposition Rate: 300 A/Min

Temperature capability: Up to 300°C

RF Power: Up to 1500 W

Process Gases:

Oxide deposition: N2O & SiH4

Nitride deposition: SiH4, NH3, N2

Controller with real time process data collection / Control

User access: Password control

Complete system / Process parameters: Customer programming recipe

Process parameters recorded on system computer

Power Supply: Closed-loop RF

Water Pressure: 30-80 psig

Standard flow at 3 gpm (11.4 liters/minute) filtered to 100 to 125 microns.

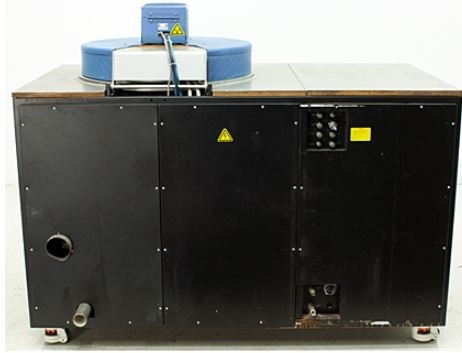

AMP-3300, 68″

Dimensions:

Width: 173 cm x 37″

Depth: 93 cm x 51″

Height: 129 cm

Water temperature:

Maximum inlet temperature: 77 F (25°C)

Minimum: 68 F (20°C).

Water resistivity: >20,000 ohms cm

Ambient air relative humidity: 40% or less

Process gases:

N2 at 30 psig

Delivered at 20-30 psig

N2 Pump purge: 30 Liters / Minute at psig to dilute residual reactant gases

Pneumatic air: 80-100 psig

Exhaust: 2-1/8-inch (54 mm) O.D.

Mechanical pump with proper purging to dilute residual reactant gases

Power:

208 VAC +/-5%, 3 Ph, 80 Amps, 60 Hz, 5-wire wye

380 VAC +/-5%, 3 Ph, 50 Amps, 50 Hz, 5-wire wye.

AMAT/APPLIED MATERIALS AMP-3300反应堆是一种设计用于执行热和物理气相沉积(PVD)过程的设备。它具有大面积、快速热处理(RTP)室、真空传递室和晶圆载波系统的独特组合。RTP室用于沉积过程中快速加热和冷却晶片。它在高达600 °C的范围内运行,温度设定点精度为+/-0.5 °C。真空转移室使晶片能够在真空中进出RTP室。晶片载波系统对晶片装卸过程提供精确控制。AMAT AMP-3300还有一个高级控制单元。这确保了可预测和可重复的过程结果。它有一个等离子体处理模块,可以添加到标准包装中,进一步改进制造工艺。此模块能够清洁硬质表面、蚀刻和/或激活它们。它允许更高的沉积速率和提高晶圆均匀性。将材料沉积到晶片上时,APPLIED MATERIALS AMP 3300能够在整个晶片上提供均匀的层。它还有一个低VOC排放的机器,它减少了过程释放的气体。将AMP 3300用于半导体制造行业的工艺是很容易的。其强大的控制工具允许用户自定义每个进程的设置。此外,其高质量的光学元件允许用户实时监控过程。总之,AMAT AMP 3300是一种高效可靠的工具,是半导体制造工业中PVD工艺的一个很好的解决方桉。它有一个高精度的定位器,允许在整个晶圆区域精确的沉积序列。其等离子体处理模块提高了工艺速度,降低了结果的晶圆均匀性。此外,强大的控制资产可确保对每个过程进行精确调整以获得所需的结果。

还没有评论