二手 AMAT / APPLIED MATERIALS Centura DxL #117144 待售

网址复制成功!

单击可缩放

ID: 117144

晶圆大小: 8"

优质的: 2000

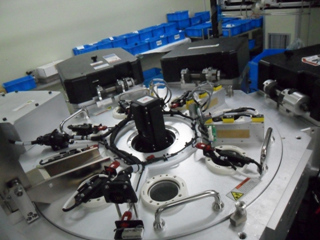

PECVD SiO2 system, 8"

Specifications:

(3) Chambers: SiO2

Cool down chamber

HP robot

Notched wafers

Gases:

Ch A, B, C: SiH4, NF3, N2O, CF4, N2, Ar

Front and rear monitors

SMC chiller

(3) RF generators: ENI OEM 12B

(2) EBARA A30W dry pumps

(3) EBARA A70W dry pumps

Process kits

English software

All cables and hoses

Packing list:

Mainframe

System controller

RF generator rack

Rear monitor

Rear monitor base

Front monitor set

Chamber A ceramic shield

Chamber A susceptor

Chamber A ceramic edge ring

Chamber A ceramic hoop

(4) Chamber A ceramic lift pins

Chamber B ceramic shield

Chamber B susceptor

Chamber B ceramic edge ring

Chamber B ceramic hoop

(4) Chamber B ceramic lift pins

Chamber C ceramic shield

Chamber C susceptor

Chamber C ceramic edge ring

Chamber C ceramic hoop

(4) Chamber C ceramic lift pins

Cables 1-12

Water hose

Chamber A pump

Chamber B pump

Chamber C pump

T/M pump

L/L pump

SMC chiller

Cables 13-20

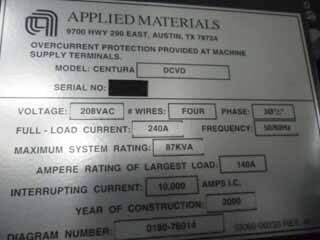

Power: 208VAC, 3 phase, 50 / 60 Hz

De-installed Q4 2009

Currently warehoused / plastic-wrapped

2000 vintage.

AMAT/APPLIED MATERIALS Centura DxL是一个革命性的半导体反应堆,为微电子器件制造提供了一个用途广泛、成本效益高的解决方桉。它由AMAT经过验证的具有Centura XL工程设备的PECVD平台提供动力。凭借其先进的功能,AMAT Centura DxL为超高长宽比处理设定了新的标准。APPLIED MATERIALS Centura DxL旨在提供最高的沉积速率和均匀性,最大限度地提高生产吞吐量和产量。其高性能的PECVD平台运行最高530°C,允许沉积广泛的氧化物、氮化物和金属薄膜。该反应堆将APPLIED MATERIALS专利的IntelliPath控制系统与车载温度和压力控制相结合,使薄膜沉积具有均匀性和可重复性。Centura DxL还提供多种高长宽比处理选项,包括平面化和各向异性阵列。该反应器同时对工艺室和上层基板温度进行独立控制,从而能够精确控制薄膜沉积和平面化。先进的晶圆船装卸装置能够快速、高效地装卸晶圆。AMAT/APPLIED MATERIALS Centura DxL反应堆具有先进的特性,使其成为微电子装置制造中用途最广泛的反应堆之一。具有沉积各种氧化物、氮化物和金属的能力,具有极高的精确度和可重复性。高长宽比处理能力使其成为MEMS和纳米技术等超高长宽比应用的理想选择。该机还易于使用和维护,拥有其IntelliPath、车载温度和压力控制以及先进的晶圆船装卸工具。

还没有评论