二手 AMAT / APPLIED MATERIALS Centura Ultima HDP CVD #62203 待售

看起来这件物品已经卖了。检查下面的类似产品或与我们联系,我们经验丰富的团队将为您找到它。

单击可缩放

已售出

ID: 62203

晶圆大小: 8"

优质的: 2000

Etcher, 8"

(2) Ultima chamber

(1) Ultima plus chamber

Technology :IMD

Wafer Size : 8"

Wafer Shape : SNNF (Semi Notch No Flat)

Software Version : B4.3.14

CHAMBER TYPE AND LOCATION

Ch A : Ultima HDP-CVD

Ch B : Ultima HDP-CVD

Ch C : Ultima + HDP-CVD

Ch E : Multislot Cool Down

Ch F : Orientor

CHAMBER A,B Ultima HDP-CVD :

Nozzle : Long/Long Side

Clean Gas Distribution : Baffle

Turbo Pump : Ebara ET1600WS w/ HVA

Wafer Temperature Monitoring : Yes

Top Gas Feed : Without Top O2

Dual Independent He Control : Standard 10/10 TORR

Clean Method : Microwave

CHAMBER C - Ultima + HDP-CVD :

Nozzle : Long/Long Side

Clean Gas Distribution : Baffle

Turbo Pump : Ebara ET1600WS w/ HVA

Wafer Temperature Monitoring : Yes

Top Gas Feed : Without Top O2

Dual Independent He Control : Standard 10/10 TORR

Clean Method : Top Mount

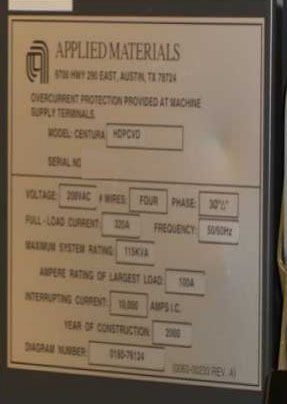

EXISTING ELECTRICAL REQUIREMENTS

Line Frequency : 60Hz

Line Voltage : 200/208V

Line Amperage : 600A Platform

EXISTING SAFETY EQUIPMENT :

EMO type : Turn to release EMO

EMO Guard Ring : Yes

System Labels : English w/Chinese Non-simplified

System Smoke Detector : Controller

EXISTING MAINFRAME :

Mainframe Type : Ultima HDP w/Multislot

Frame Type : Standard Frame

System Placement : Through the Wall

Mainframe Skins : No

Mainframe Exhaust Duct : No

Mainframe Facilities Connection : Back

Robot Type : HP Robot

Robot Blade : Ceramic

Loadlock Cassette : Narrow Body

Narrow body Loadlocks : Cassette Present Sensor

Loadlock Wafer Mapping : Basic

N2 Purge Type : STEC 4400MC 10 Ra Max

EXISTING GAS DELIVERY :

Gas Panel Surface Finish : Standard Gas Panel

MFC Type : STEC 4400MC 10 Ra Max

Valves : Fujikin 5 Ra Max

Filters : Pall Ni 10 Ra Max

Transducers : MKS w/ Display

Regulators : Veriflo

System Cabinet Exhaust : Top

Gas Panel Gas/Flow Direction Labels : Yes

APC Seriplex Cover : Yes

Gas Panel Doors : Solid

Gas Pallet Configuration :

Chamber A, B, C

Gas Stick/Process Gas/MFC size/Regulator/Transducer

#1 SiF4 100 Y Y

#2 O2 400 Y Y

#3 SiH4 200 Y Y

#4 Ar 300 Y Y

#5 SiH4 20 Y Y

#6 Ar 50 Y Y

#7 NF3 2000 Y Y

#8 Ar 2000 Y Y

REMOTES :

RF Generator Rack - Ultima Gen. Rack

ASTEX 80S09mW (3)

Quantity : Two

Ultima Stand-Alone RF Generator Rack : Yes

Generator Rack Cooling - RF Gen Rack Manifold with Quick Disconnect Ultima Gen Rack H20 Connection - Barbed Brass

Existing Heat Exchanger : SMC Thermo

Umbilicals :

System Controller Signal Cable Length : 55ft

RF Gen Rack Cable Length : 50ft

Ultima Stand-Alone Generator Rack : 98 ft

HX Hose Length : 50ft

HX Cable Length : 50ft

Pump Cable : 50ft

Ultima Microwave Generator Cable Length : 50 ft

Ultima WTM Cable Length : 32.8 ft (10m)

Vacuum Pumps, Exhaust Scrubber not included in sale

Currently crated and stored

System Can be inspected

1999-2000 vintage.

AMAT/APPLIED MATERIALS Centura Ultima HDP CVD是一种化学气相沉积(CVD)反应器,具有专有的热壁输送等离子体(HWDP)处理室。这种反应堆是专门为便利化学气相沉积一系列具有优化的热均匀性和等离子体均匀性的材料而设计的。反应堆使用化学前体在金属、硅或陶瓷等基板上创建材料层。该反应器能够产生难以置信的高密度等离子体辅助沉积(HDP)薄保形层,是从半导体封装和先进互连到生物医学和纳米技术相关应用的理想工具。AMAT Centura Ultima HDP CVD反应堆设计为在CVD过程中提供最大的均匀性和可重复性。HWDP处理室的设计允许前体的精确蒸发,这些前体在与热等离子体源接触时转化为等离子体状态。这个等离子体源具有高度的均匀性,为得到的涂层在整个基板上提供了一致的层厚度。此外,HWDP腔室设计消除了冷却的需要,允许更高的温度控制,以改善层密度。在整个腔室中使用温度传感器还可以实现精确的温度控制,以改善层的均匀性和性能控制。APPLICED MATERIALS Centura Ultima HDP CVD反应堆也被设计为促进高通量性能。加工室设计为在低压下运行,允许前体和过程控制气体的高流量。可以利用这种高吞吐量最大限度地提高产量和产量,同时保持最高级别的工艺和质量控制。Centura Ultima HDP CVD是各种CVD应用的绝佳工具。从制造半导体封装的高密度层到生物医学材料和纳米技术,这种反应器的特点是能够促进涂层的沉积,提高了均匀性和可重复性。这种反应器非常适合需要精确控制层厚度、温度和均匀性的应用,能够为最先进的技术沉积HDP层。

还没有评论