二手 AMAT / APPLIED MATERIALS ECP SlimCell #9031142 待售

看起来这件物品已经卖了。检查下面的类似产品或与我们联系,我们经验丰富的团队将为您找到它。

单击可缩放

已售出

ID: 9031142

System, 12"

Factory interface: 3 FOUP stage

Anneal module: Anneal – A

SRD module: SRD – B

SLIM CELL module: CELL – B, CELL – D

IBC module: IBC – B

(16) Units:

1. EFEM

2. Buffer Unit

3. Annel Unit

4. Main System

5. Chemical Supplier #1

6. Chemical Supplier #2

7. Chemical Drain Unit

8. Chiller

9. Monitor Stand #1

10. Monitor Stand #2

11. Parts Box #1

12. Parts Box #2

13. Parts Box #3,

14. Parts Box #4

15. Lifter #1

16. Lifter #2

System Configuration:

Mainframe:

- Wafer Transfer Robot with two Blades x 1

- SLIM CELL TM Module x 2 (Cell - B, Cell - D)

- SRD (Spin Rinse Dry) x 1 (SRD - B),

- IBC (Integrated Bevel Cleaner) x 1 (IBC - B)

- In-Station (Pass Stage) under SRD x 4

- Independent Plating-solution Circulation System x 4

(for Anode and Cathode in each SLIM CELL TM Module)

- Mixing Unit for Plating-solution and Cleaning Fluid

- Fan Filter Unit (FFU)

Factory Interface (FI):

- Two Blade Robot

- FOUP Stage (ADO) x 3

- Aligner

- Fan Filter Unit

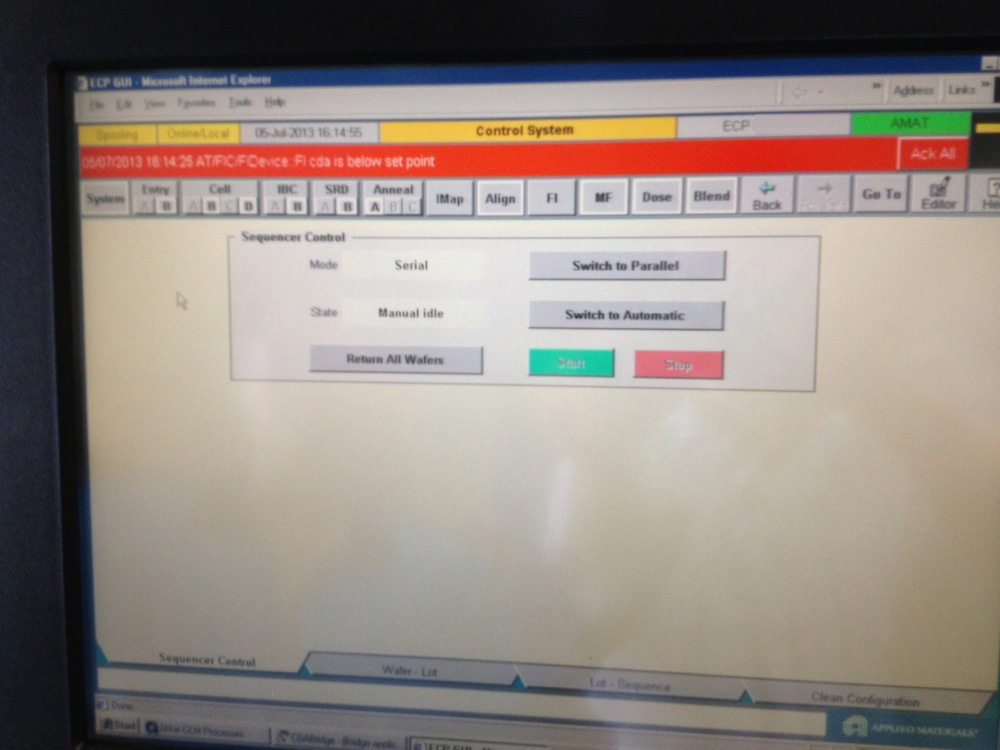

- GUI Computer controlling FI and Mainframe control systems

Heater / Chiller

Operator Interface x 2 (Main & Sub)

Anneal Chamber Module:

- Anneal Chamber x 1 (Anneal - A)

- Movement and Temperature Control, Gas Box

* Mainframes consist of 1) Mainframe, 2) FI and 5) Anneal Chamber Module

* Anneal Chamber is middle of Anneal Chamber Module and Anneal - A is above

the Anneal Chamber

Mainframe Details:

Frame

Fan Filter Unit: ULPA Filter (>0.12 μm, >99.999%)

Plating-solution Supply Unit

SLIM CELLTM Module

- Plating Head: 5 RPM to 400 RPM

- Plating Cell

- Plating-solution circulation system

Filter (Millipore, 0.05 μ, 20")

Temperature Control ± 1.5 deg C

SRD (Spin Rinse Dry): 50 ~ 2500 RPM

- Lower Cleaning Nozzle (one for DI and Chemical)

- Upper Cleaning Nozzle (one for DI)

IBC (Integrated Bevel Cleaner): 50 ~ 2500 RPM ± 20%

- Lower Cleaning Nozzle (three for each DI and Chemical)

- Upper Cleaning Nozzle (one for each DI and Chemical)I)

LBDU (Liquid Blend Dose Unit): ± 5 %

AC Box

- 208 VAC, 3 Phase, 175 A

Mainframe ROBOT

- Dual Arm Robot made by Roze, RS-485 (Ethernet) serial interface

Factory Interface (FI) Details:

FOUP Stage (ADO: Auto Door Opener)

- TDK for AMAT Specification

Link Tunnel

- Dual Blade Robot made by Yaskawa

Align Stage detecting Wafer Notch

Fan Filter unit: (>0.12 μm, >99.999%)

FI / Mainframe Control Unit with UPS (Window NT 4.0)

GUI (Graphic-User-Interface) Computer with UPS (Window NT 4.0)

Chiller Details

- Daiken for AMAT Specification

- Temperature Control Range: 5 ~ 22 deg C

Operator Interface Details

- LCD Touch Panel, Keyboard with Track Ball

- Desk Type or Roll-Around or Wall Mount Type

Anneal Chamber Module Details:

Anneal Chamber

- Gas Box: Mixing and Control of N2 96 %, H2 4% Process Gases

MFC, Flow Switch

- Heater (150 ~ 300 deg C), Cooler Plate, Arm

MTBF

1) MTBF Target : 250 hr

2) MTBF Target for each Unit

- Slim Cell 3400 hr

- IBC 3400 hr

- SRD 4000 hr

- Anneal 4500 hr

- MF Robot 6800 hr

- FI 5000 hr.

AMAT/APPLIED MATERIALS ECP SlimCell是利用电子回旋共振(ECR)沉积介电和导电膜的反应器。反应堆包括一个功能齐全的带有ECR微波源的工艺室、气体偏置输送框架、额外的气体输入、燃烧辅助清洁、工艺控制器、水循环和冷却系统以及精心设计的安全设备。反应堆的腔室为单壳透明石英和不锈钢结构。它是为高性能的重新激活离子蚀刻,等离子体消融和沉积操作而设计的。ECR微波源是一种高频发生器,它产生微波使室内的气体溷合物电离。气体偏置输送框架位于腔室的下部,从而可以精确控制离子的强度。额外的气体输入连接到腔室顶部,将惰性或腐蚀性气体输送到工艺腔室。燃烧辅助清洁系统是一个新的特点,其中受控的化学反应有助于保持一个清洁的腔室。它不需要同时进行复杂的真空清洗。它还减少了工艺后维护时间。该过程控制单元基于与Windows传输体系结构相连接的分布式设备机器。它旨在同时处理多个应用程序和配方,并与所有外围设备处理组件一起操作。该工具还能够对所有工艺参数进行实时反馈控制。水循环和冷却系统旨在为反应室的所有关键部件提供均匀的温度控制冷却。在反应器中采用钝化板设计,以最大限度地提高水速和散热。AMAT ECP SlimCell反应堆的安全资产包括各种安全功能,以防止事故和保护人员免受过度辐射和/或过热。APPLICED MATERIALS ECP SlimCell为沉积过程提供了出色的一致性和可扩展性,而其卓越的安全系统使其非常适合用于关键操作。全面的维护过程有助于使设备保持良好的工作状态,并确保性能一致。采用现代、集成的控制模型可以方便、精确地进行过程控制,使其成为研究和生产的最佳选择。

还没有评论