二手 AMAT / APPLIED MATERIALS Endura 5500 #9030866 待售

看起来这件物品已经卖了。检查下面的类似产品或与我们联系,我们经验丰富的团队将为您找到它。

单击可缩放

已售出

ID: 9030866

PVD system, 8"

System software ver: C8.622

System Platform: Endura

Wafer Shape: SNNF

EMO Type: Turn to Release

CE Safety Mark: English

CIM Configuration: SECS

SBC Version: V452

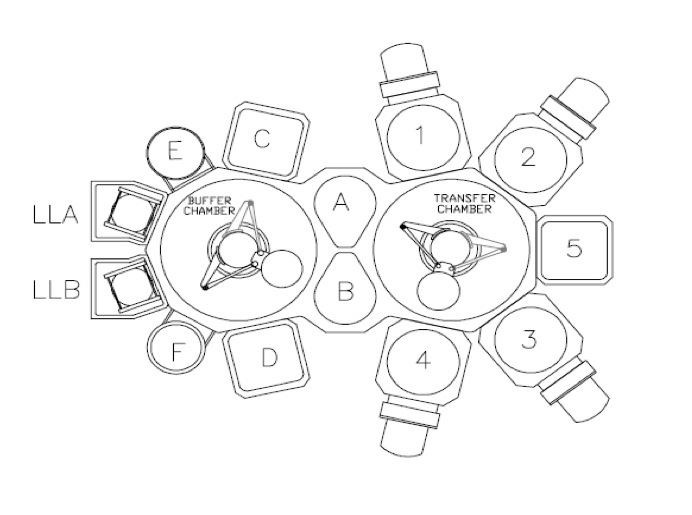

Mainframe Configuration:

Buffer Robot Type: HP

Buffer Robot Blade: Thin Metal

XFER Robot Type: VHP

XFER Robot Blade: Original Metal

Lid Hoist: Yes

Status Light Tower: RYG

Remote Monitor: Table Mount

Sub-System Configuration:

(1) Chiller: Model: None

Cryo Pump Type: CTI Cryo- on board 8F

Cryo Pump Power: 3 Phase

(2) CompressorS

Compressor Type: 9600

Loadlock Configuration:

Loadlock Type: Narrow body

Auto Rotation: Yes

Cassette Type: 8"

Mapping Function: WFM

Vent Type: Variable Speed

Fast Vent Option: Yes

LLKs NB w/Auto Tilt

A Pass-thru

B Cool Down

E O/D (Std)

F O/D (Std)

C PCII w/Cryo Std

D PVD TiN 101

1 PVD Tungsten (W) HT-ESC - Chamber has UV Flash for ESC E-Clean

2 PVD Hot-Al HT-ESC - Source Assy missing, Process kit still intact.

3 PVD Hot-Al HT-ESC - Source Assy missing, Process kit still intact

4 PVD Al/Cu SLT-ESC Complete

5 Iso-Valve (Manual) -

Bfr HP

Txfr VHP (Style Lid)

PVD Hot-Al Chambers: These are Water-Cooled Chamber bodies (can't use for other processes which use Wide-Body Chambers

Gas Information:

Gas Box Pneumatic Valve: Single

Pneumatic Valve Type: Veriflo

Manual Valve Type: Veriflo

MFC Type: FC-780C

Gas Line Out: Out The Back

Modules:

M/F Yes

Sys/AC Yes

EQ1 Yes

EQ2 Yes

Main/AC Yes

AC Dist Box Yes

Cryo Comp 3 - 9600

Heat Ex Yes, Neslab III

Pumps No Pumps included with any tools

Lift Hoist non-AMAT, Gantry & 250lb hoist

Umbilical Configuration:

Controller to Main AC: 50 Feet

Controller to Mainframe: 50 Feet

Mainframe to Generator: 50 Feet

Remote Monitor: 50 Feet

Mainframe to Compressor: 50 Feet

Main AC to pump: 50 Feet

AC Box to Heat Exchanger: 50 Feet

Controller to Gen Rack: 50 Feet

Gen Rack to Gen Rack#2: 50 Feet

Electrical Configuration:

Line Voltage: 200V

Full Load Current: 487A

Remote Transformer: No

Frequency: 60Hz

Missing Parts:

Chamber E: Orientor PCB

Chamber F: Orientor PCB

Chamber 2: Missing upper chamber lid

Chamber 3: Missing upper chamber lid

Chamber C: Missing upper chamber lid

1995 vintage.

AMAT/APPLIED MATERIALS/AKT Endura 5500是一个单一晶圆加工反应器,具有先进的功能,适用于广泛的半导体加工应用。这种直观设计的反应堆旨在最大限度地提高生产率和工艺灵活性,使用户能够执行具有卓越工艺能力的非平面、平面和复杂的设备结构。AKT Endura 5500配备了由其先进的三区供暖制冷技术提供动力的无与伦比的热能力,使用户能够准确控制温度,在整个晶圆面上均匀反应。这种热性能进一步配备了均匀流动介质注入技术,提供了对工艺气体的精确控制和均匀分布。因此,用户能够以可重复和一致的性能实现最佳影片配置文件。反应堆的其他功能包括高可用性、减少停机时间和出色的过程控制。在安全和环境保护方面,AMAT ENDURA 5500符合UL/CSA等安全标准,具有像密封外壳这样的特点,以保护人员不受危险工艺材料的潜在影响。此外,反应堆还配备了先进的诊断工具,便于进行有效的监测以及额外的工艺验证。与传统的热过程相比,反应堆还提供了改进的过程均匀性和扩展的过程窗口,从而提高了灵活性和吞吐量。除了卓越的散热性能外,APPLIED MATERIALS ENDURA 5500还为用户提供灵活的控制选项,并提供可编程的进纸/通风口选项和支持高效现场过程控制的高级I/O配置。此外,反应堆利用化学安全壳和低流量模式,以实现高效运行和优化产量。利用它的精密运动控制器,用户能够实现小的,但精确的运动控制与快速校准,并集成到第三方系统也是可用的。综上所述,AMAT/APPLIED MATERIALS/AKT ENDURA 5500是一个功能强大、用户友好且安全的反应堆,可最大限度地减少浪费和总体成本。它提供节能技术、卓越的散热性能、缩短的停机时间和出色的工艺控制,使其成为半导体行业的最佳选择。

还没有评论