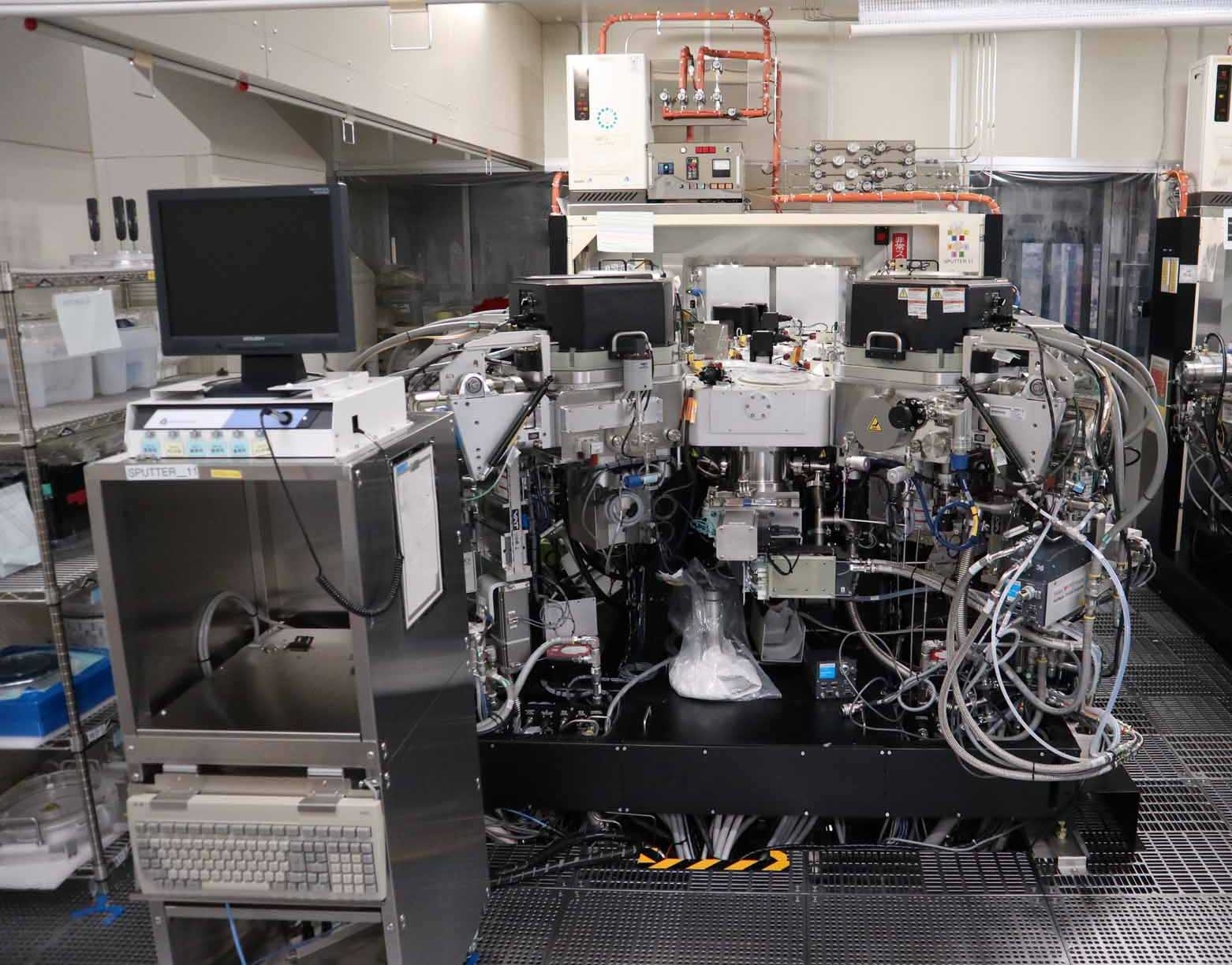

二手 AMAT / APPLIED MATERIALS Endura 5500 #9219406 待售

看起来这件物品已经卖了。检查下面的类似产品或与我们联系,我们经验丰富的团队将为您找到它。

单击可缩放

已售出

ID: 9219406

晶圆大小: 8"

优质的: 2001

System, 8"

Wafer shape: SNNF

MF Facilities: Bottom

Chamber 1: STD WC Body

Process 1: ESC AL

Chamber 2: Wide body

Process 2: TTN

Chamber 3: Wide body

Process 3: TTN

Chamber 4: Wide body

Process 4: Ti

Chamber A: Pass through

Chamber B: Cooldown

Chamber C/D: PCII

Process C/D: Oxide etch

Chamber F: O/D With temp

Heat exchanger 1: NESLAB I

Loadlock pump type: iL600

Transfer robot type: HP+

Transfer robot blade: Metal

Buffer robot type: HP+

Buffer robot blade: Metal

Wafer sensor: Mini beam

Loadlock type: Narrow BD without tilt out

System umbilical: 50 ft

EMOs: Turn to release

Hard drive: SCSI

(2) CRTs

GEM: No

OTF: No

No Facility power (UPS)

No loadlock pump

Loadlock slit valve O-rings: Viton (Black)

Heat exchanger 1: NESLAB

Heat exchanger 2: M-Pack

Main AC box: 480 V, Wide type

Chamber A:

Chamber type: Pass through

Chamber lid: STD Lid

Lift hoop & finger

Pedestal type: Standard

Chamber B:

Chamber type: Cooldown

Gas valves: Fujakin

Heater / Cathode cooling: PCW

Chamber lid: STD Lid

Pedestal type: Standard without TC option

Chamber C:

Chamber type: PCII

Manometer config: Single

Manometer 1: 100mTorr

No shutter option

Chamber process: Oxide etch

Lid type: RF Resonator

RF Gen / DC supply 1: COMDEL CPS-1001S

RF Gen / DC supply 2: RFPP LF10A

RF Match: 13.56 MHz

No endpoint system

Process kit type: PIK-I

Chamber pump: EDWARD iL70

Turbo pump: LEYBOLD

No heated valve stack

Gas MFC Size MFC Type MFC Number Gas stick

N2 20 SCCM STEC 4400 MFC9 (2) Manifolds

N2 300 SCCM MC-3102E-NC MFC10 (2) Manifolds

Chamber D:

Chamber type: PCII

Manometer config: Single

Manometer 1: 100mTorr

No shutter option

Chamber process: Oxide etch

Lid type: RF Resonator

RF Gen / DC supply 1: COMDEL CPS-1001S

RF Gen / DC supply 2: RFPP LF10A

RF Match: 13.56 MHz

No endpoint system

Process kit type: PIK-I

Chamber pump: EDWARD iL70

No heated valve stack

Gas MFC Size MFC Type MFC Number Gas stick

N2 20 SCCM STEC 4400 MFC12 (2) Manifolds

N2 300 SCCM MC-3102E-NC MFC13 (2) Manifolds

Chamber 1:

Chamber type: STD WC Body

Manometer config: Single

Manometer 1: 100mTorr

No shutter option

Chamber process: ESC AL

Lid type: 12.9"

RF Gen / DC Supply 1/2: AE MDX-L12M

Susceptor / Pedestal: MCA ESC

Heater / Cathode cooling: NESELAB I

No endpoint system

Gate valve position: 3 POS

Process kit type: ESC AL

Chamber pump: Cryo pump (OB8F-3 Phase)

No heated valve stack

Gas MFC Size MFC Type MFC Number Gas stick

N2 100 SCCM STEC 4400 MFC18 (2) Manifolds

N2 20 SCCM STEC 4400 MFC9 (2) Manifolds

Chamber 2:

Chamber type: Wide body

Manometer config: Single

Manometer 1: 100mTorr

No shutter option

Chamber process: TTN

Lid type: 12.9"

RF Gen / DC Supply 1: AE MDX-L12M

Susceptor / Pedestal: 101

No endpoint system

Gate valve position: 3 Pos

Process kit type: (2) Ti/TiN

Chamber pump: Cryo pump (OB8F-3 Phase)

No heated valve stack

Gas MFC Size MFC Type MFC Number Gas stick

N2 300 SCCM STEC 7440 MFC9 (2) Manifolds

N2 100 SCCM STEC 4400 MFC10 (2) Manifolds

Chamber 3:

Chamber type: Wide body

Manometer config: Single

Manometer 1: 100mTorr

No shutter option

Chamber process: TTN

Lid type: 12.9"

RF Gen / DC Supply 1: AE MDX-L12M

Susceptor / Pedestal: 101

No endpoint system

Gate valve position: 3 Pos

Process kit type: (2) Ti/TiN

Chamber pump: Cryo pump (OB8F-3 Phase)

No heated valve stack

Gas MFC Size MFC Type MFC Number Gas stick

N2 100 SCCM STEC 4400 MFC2 (2) Manifolds

N2 300 SCCM STEC 4400 MFC3 (2) Manifolds

Chamber 4:

Chamber type: Wide body

Manometer config: Single

Manometer 1: 100mTorr

No shutter option

Chamber process: TTN

Lid type: 12.9"

RF Gen / DC Supply 1: AE MDX-L12M

Susceptor / Pedestal: MCA ESC

Heater / Cathode cooling: NESELAB I

No endpoint system

Gate valve position: 3 Pos

Process kit type: ESCAL

Chamber pump: Cryo pump (OB8F-3 Phase)

No heated valve stack

Gas MFC Size MFC Type MFC Number Gas stick

N2 20 SCCM STEC 4400 MFC4 Single

N2 100 SCCM STEC 4400 MFC5 (2) Manifolds

N2 200 SCCM STEC 4400 MFC6 (2) Manifolds

Missing ES chuck

System power: 200 VAC, 60 Hz, 3 phase, 343 A,150 kVA

2001 vintage.

AKT (AMAT) AMAT/APPLICED MATERIALS/AKT Endura 5500是为生产先进半导体而设计的高性能、独立式反应堆。AKT Endura 5500能够实现多种基材和材料的高吞吐量和低缺陷率。该设备采用可扩展的模块化体系结构,支持最先进的半导体工艺和制造技术。AMAT ENDURA 5500配备了多种独特的功能,可确保最佳的生产效率。它有一个高性能的晶圆处理系统,可以让晶圆快速轻松地加载。APPLICED MATERIALS Endura 5500还具有自动晶圆映射单元,可确保晶圆加工的均匀性。此外,该机器还具有一个高级工艺控制工具,可连续监控工艺温度和其他关键参数。AMAT Endura 5500旨在为大批量生产提供卓越的生产可靠性。它具有先进的冷却资产,可确保高效运行并最大程度地减少停机时间。此外,Endura 5500还采用了空气排气过滤、真空控制和温度调节等环保措施。这确保了在生产环境和实验室环境中的安全运行。在美学方面,ENDURA 5500具有诱人、圆滑的设计。该模型设计为自成一体,具有易于学习和使用的直观用户界面。该设备还具有一系列可选功能,例如用于分析晶片的高级扫描仪,可以添加这些功能以进一步提高其性能。除了令人印象深刻的性能和美观外,APPLIED MATERIALS ENDURA 5500还提供一系列提高生产力的功能。它专为高吞吐量和低缺陷率而设计,可满足各种光学、晶圆和工艺要求。此外,系统的高级控制单元提供了有关流程参数的详细数据,使用户能够根据需要调整流程。AKT ENDURA 5500是一种极可靠的反应堆,为用户提供了高度的工艺灵活性。它是大容量半导体生产应用的理想解决方桉,非常适合实验室和生产环境。

还没有评论