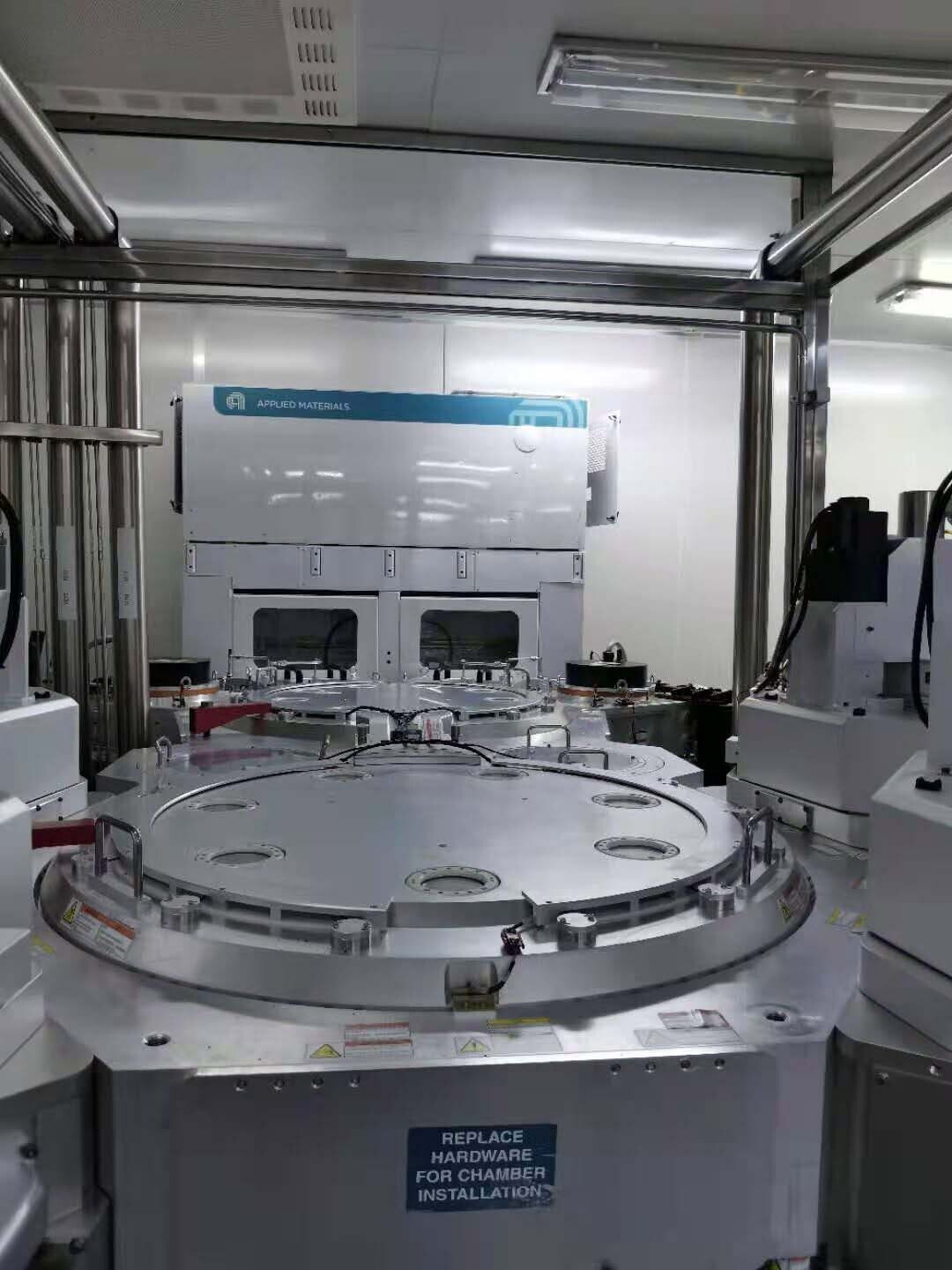

二手 AMAT / APPLIED MATERIALS Endura II #9315363 待售

网址复制成功!

单击可缩放

ID: 9315363

晶圆大小: 12"

PVD System, 12"

Wafer type: Notch

3E Impulse AIN System

Chamber location / Option

Level 1 / Endura II

Level 2 / Emerging

Position 1 / Impulse ALN

Position 4 / Impulse ALN

Position A / Cool down

Position B / Cool down

Mainframe

Motion controller

Particle management package

Chamber cool down gas lines

Single wafer load locks: HT SWLL without DEGAS module

XP Robot with enhanced high temperature wrists

Metal robot blade

Rack

CTI-CRYOGENICS Cryo Pump

(2) Cryo compressors

Cryo compressor voltage: 400 V - 480 V

Cryo helium lines: 75 ft

Heat exchanger hose: 75 ft

MFC Type: GF 125

Factory interface:

Front end module

Platform application: CPI

Gen 4 with KVM server and user interface

UPS

HT SWLL With STD / Opera

OHT WIP Delivery

(2) SELOP 7 Load ports

Info pad position: A / B

Colored lights

(8) Lights load port operator interface

E99 Carrier reader: TIRIS With RF

Upper E84 Data logging sensors and cables

Operator access switch

Top air intake systems

(4) Colors light tower

Rack

System monitors:

Flat panel monitor, 19"

Keyboard

Cables: 15 ft with 6 ft effective

Remote flat panel monitor, 19"

Cables: 75 ft with 65 ft effective

Impulse: Position (1, 4)

Biasable wafer pedestal HV E-Chuck

Shutter

Baratron gauge size: 100 mTorr

RGA Valve manual

Turbo cryo pump with water trap

DEGAS RGA Valve manual

(4) EBARA AA70W Pumps

(2) ADIXEN A100L Pumps

Rough pump voltage: 208 V

Umbilical:

AC Rack to mainframe: 75 ft

AC Rack to HX: 75 ft

AC Rack to rough pump: 75 ft

Mainframe to equipment rack: 75 ft

Power supply: 10 kW, DC.

AMAT/APPLIED MATERIALS/AKT Endura II是一种先进的等离子体蚀刻反应堆,设计用于广泛的动力和工艺项目。该反应器是深层各向异性、定向蚀刻、沉积、氧化和低温分解的理想选择。该系统利用高真空蒸发量同时沉积多达四种不同的沉积材料。它采用先进的气体输送和先进的等离子体控制。AKT Endura II能以每立方英尺0.1至5.5毫克的真空水平运行,使其能够进行快速、精确的沉积过程。AMAT Endura II专为高功率应用而设计,能够以高达10,000瓦的功率级别运行。它具有独立的电极倾斜度,提供蚀刻速率和均匀度的角度依赖性控制。Endura II还具有先进的洗涤器和过滤系统,以减少颗粒污染和降低系统维护要求。对于蚀刻和其他PW工艺,APPLIED MATERIALS Endura II利用双电感线圈产生高密度、用于蚀刻的软等离子体,以及用于沉积厚膜涂层的高功率电感。AMAT/APPLICED MATERIALS/AKT Endura II还具有应用额外线圈以提供高度定向蚀刻的能力。AKT Endura II具有无污染的石英喷嘴和管状结构,允许低压处理。通过不断地通过石英过滤器排出装有颗粒的气体,这种设计消除了关闭系统定期清洁腔室的需要。AMAT Endura II的创新技术允许精确和可重复的工艺,提供卓越的蚀刻、沉积和氧化能力。它还可以模拟100至1600°C的各种温度,允许广泛的独特应用。Endura II非常适合需要高功率、可重复过程和低温沉积的应用。它具有处理各种材料和基材的能力,并且可以根据尺寸、复杂性和功率要求在不同的复杂级别上使用。

还没有评论