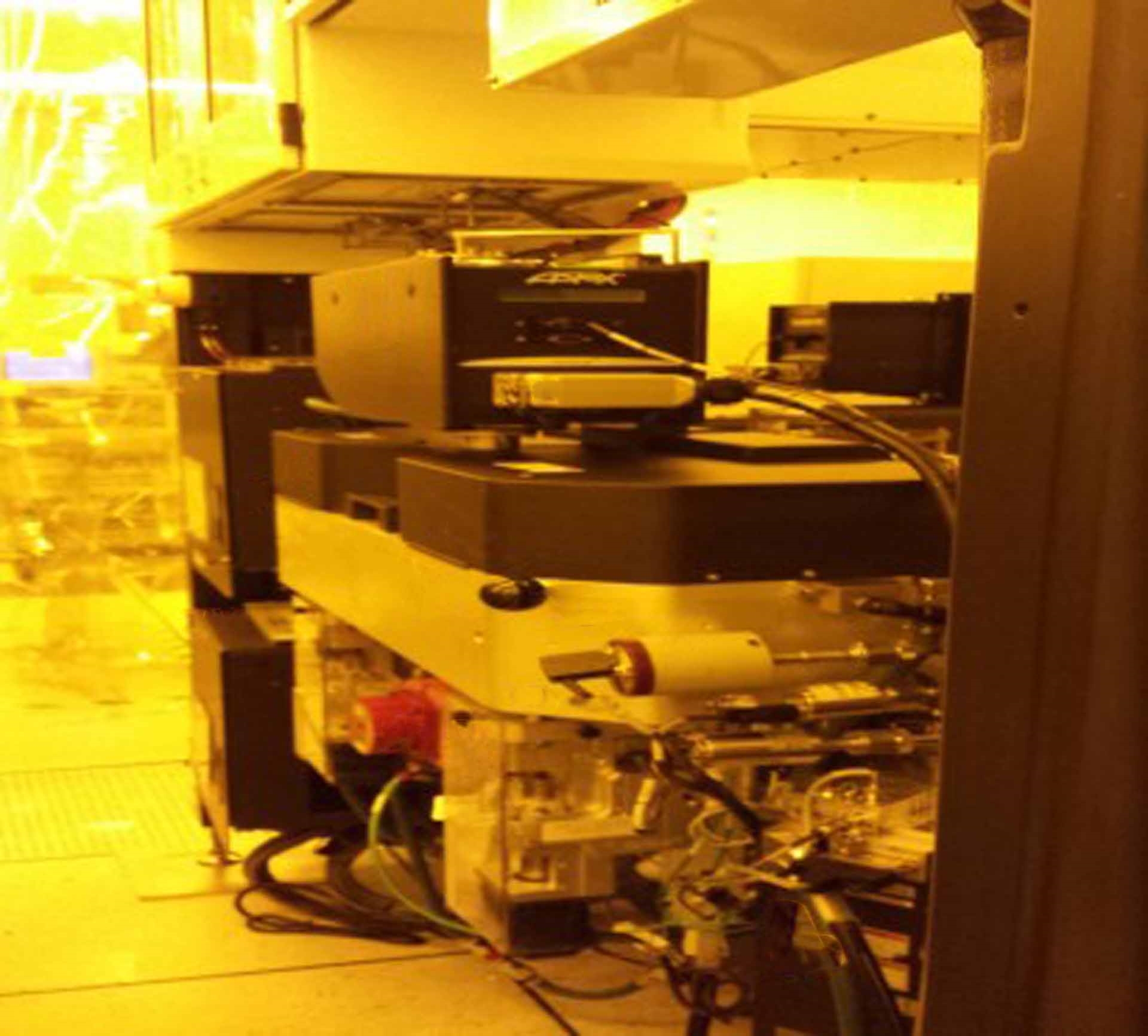

二手 AMAT / APPLIED MATERIALS Producer III #9223648 待售

网址复制成功!

单击可缩放

ID: 9223648

晶圆大小: 8"

优质的: 2004

Shrink system, 8"

Process: SILCU

CIM

(3) Twin chambers

Hardware configuration:

SMIF: (4) ASSYST Indexers

Handler system:

SMIF Front end robot

VHP Buffer robot

(3) Process chambers

Heat exchanger: Steelhead

High RF generator: (4) RFG 2000-2V

DPA RF Generator: ENI DPG-10

Platform type: Producer shrink

Chamber A & B & C:

Chamber body effective volume (Syscon):

Chamber A: 12980

Chamber B: 13275

Chamber C: 13300

SiH4_H: 1 SLM

SiH4-L: 300 Sccm

NH3 HI: 1 SLM

N2O HI: 3 SLM

N2O LO: 500 Sccm

N2: 10 SLM

NH3: 500 Sccm

Ar: 5 SLM

He: 10 SLM

Number of gas lines / Name: 10

RF1 & RF2 Generator (Max Power / Brand): 2000 W

Foreline pump (EBARA AAS 100WN): 10000 L/Min

Baratron off-set 626 MKS: 10 T

Lift pin type: Free drop

Lift pin speed (Timing of movement): 3580

Load lock: A & B

Configuration:

Pump capacity (EDWARDS BOC): IPX 100A

Difuser: ENTEGRIS 60 PSIG

Venting N2 flow rate: 10 SLM

Venting time: 57 Sec

Pump time: 65 Sec

Baratron Range / Brand / Off-Set: 325 Moducell MKS

Pressure set point for LL pumping switching: 45 Sec

Time delay for LL door open: 10 Sec

Transfer chamber:

Type of robot / Robot blade: Super blade

Robot speed with wafer / Runrate / Slope:

300000 / 210000

230000 / 120000

Robot speed without wafer (Ext/Rot):

200000 / 325000

230000 / 325000

MFC N2 Flow setting: 10 SLM

Chamber base pressure ( Actual / Alarm): 208 mTorr

Wafer transfer - chamber: 300 mTorr

Buffer pressure transfer chamber - wafer: 320 mTorr

Other periphere:

SiH4 HI: 29.6, 30, 36

NH3 HI 27.6, 27.8, 29

CDA Pressure: 85

HX Temperature / Flow rate: 75

N2 (P): 27

SiH4 LO

NH3 LO

N2O: 30

NF3

2004 vintage.

AMAT/APPLIED MATERIALS Producer III是制造半导体晶片的先进等离子体反应器。AMAT Producer III利用电子回旋共振(ECR)源创建了一个均匀、高密度的等离子体,这对于芯片生产中沉积多晶硅栅极电介质和铜互连等薄而精确的材料层至关重要。APPLIED MATERIALS Producer III设计允许对现有系统进行最佳的过程控制。其专利晶片密闭体积和低噪声技术在晶片的每个区域保持极均匀的沉积。生产者III也极具能源效率,功耗降低,附带热量开发最小。所有这些组合使得AMAT/APPLIED MATERIALS Producer III能够改善半导体制造商的芯片生产实践。AMAT Producer III以以前的AMAT Producers I和II为基础,增加了几个关键功能。它提供了两个独立的射频电源,可以从晶圆的底部和顶部独立控制沉积,允许超过200层的生长。它还配备了专有的UHP(Ultra High Pressure)系统,保持超均匀气体流过晶圆,更精确地调节工艺条件。应用材料生产商III也允许高度的灵活性沉积.它可以将统一的薄膜应用于整个晶片或根据应用程序选择区域。每个区域都有可编程的参数,可以针对各个沉积过程进行调整,允许用户自定义设计过程。它还具有高级诊断和数据日志记录功能,可以对进程进行脱机分析。生产者III是一种高度先进的等离子体反应器,旨在提供最精确和可重复的沉积结果。随着工艺控制、灵活性和能效的提高,AMAT/APPLIED MATERIALS Producer III为芯片制造工艺提供了无与伦比的支持。

还没有评论