二手 AMAT / APPLIED MATERIALS Producer SE #9182254 待售

网址复制成功!

单击可缩放

ID: 9182254

晶圆大小: 12"

优质的: 2006

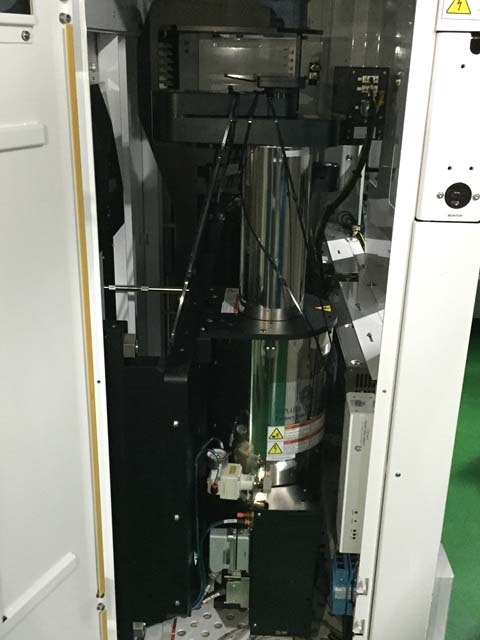

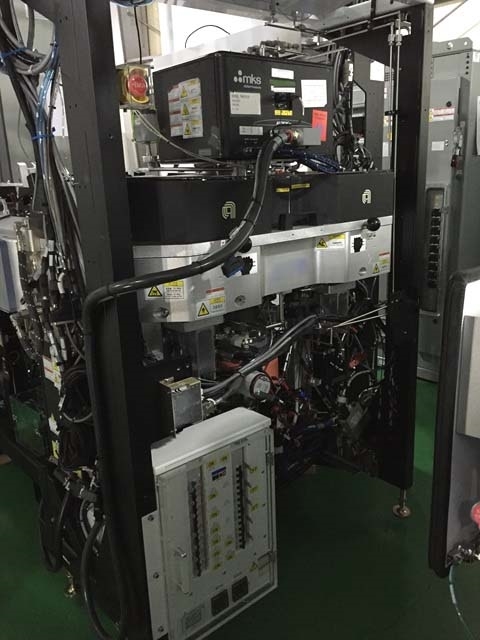

CVD System, 12"

(2) Chambers

Customer fab options:

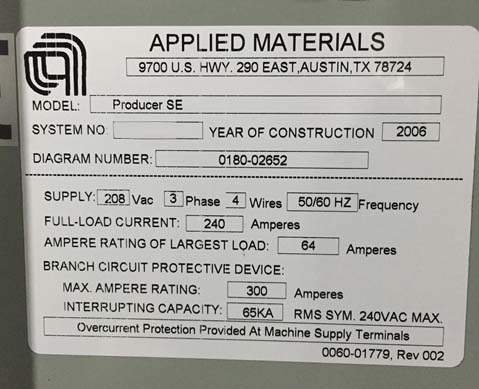

Electrical requirements:

Line frequency: 60Hz

Line voltage: 200/208 VAC Platform

Chambers:

Chamber A and B:

Chamber process: XJ (PE Silane twin)

RF1 Generator: APEX 3000

Gas delivery:

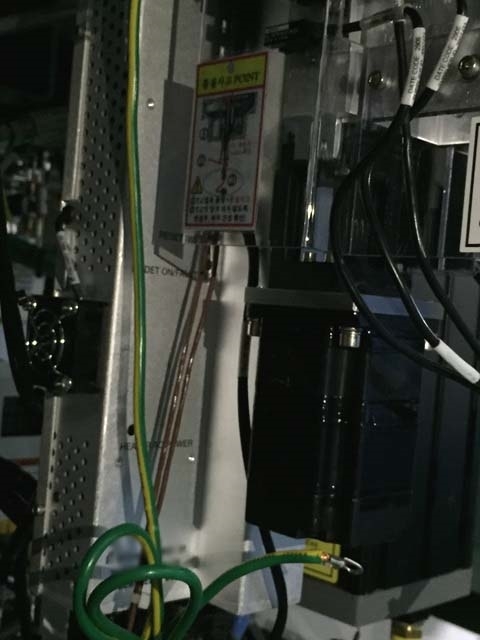

Gas pallet type: Surface mount vertical

Regulated gas panel: No

Regulated TMS: No

Gas feed: Top

Gas panel cabinet exhaust: Top

Facilities interlock indicator: No

Facilities / Scrubber interface output: Fault

Transducers: Setra

Filters: Nippon

Manual valves: Hamlet

Pneumatic valves: Hamlet

Liquid source: No

Gas pallet configuration supplement:

Chamber A:

Gas line stick position / Process gas / MFC Size / Regulator (Yes, No) / Transducer (Yes, No)

#1 / C3H6 / 3000sccm / No / No

#3 / NF3 / 1000sccm / No / No

#8 / 02 / 30000sccm / No / No

#9 / AR / 15000sccm / No / No

#10 / HE / 5000sccm / No / No

#11 / O2 / 15000sccm / - / -

#12 / AR CLN / 10000sccm / No / No

#13 / N2 CLN / 15000sccm / No / No

Liquid 1 / P-N2 / - / No / Yes

Liquid 2 / P-N2 / - / No / Yes

Chamber B:

Gas line stick position / Process gas / MFC Size / Regulator (Yes, No) / Transducer (Yes, No)

#1 / C3H6 / 3000sccm / No / No

#3 / NF3 / 1000sccm / No / No

#8 / O2 / 30000sccm / No / No

#9 / AR / 15000sccm / No / No

#10 / HE / 5000sccm / No / No

#11 / O2 / 15000sccm / - / -

#12 / AR CLN / 10000sccm / No / No

#13 / N2 CLN / 15000sccm / No / No

#17 / P-N2 / - / No / Yes

#18 / P-N2 / - / No / Yes

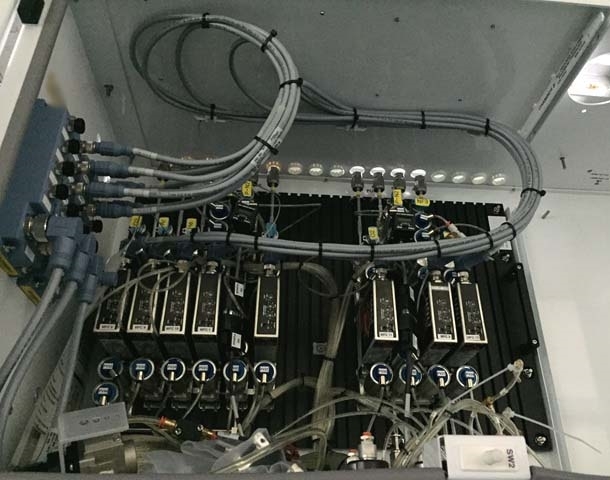

Mainframe:

Local center finder: Yes

Cu Wafer sensor: No

MF Ch Harness installed: A & B

Third MF IO motion card

Robot blade: Standard VHP

Factory interface options:

300mm Factory interface 5.3 options:

WIP Delivery type: OHT

Pre alignment and centering: Single axis aligner

Wafer pass thru & storage: 8 Slot wafer pass thru

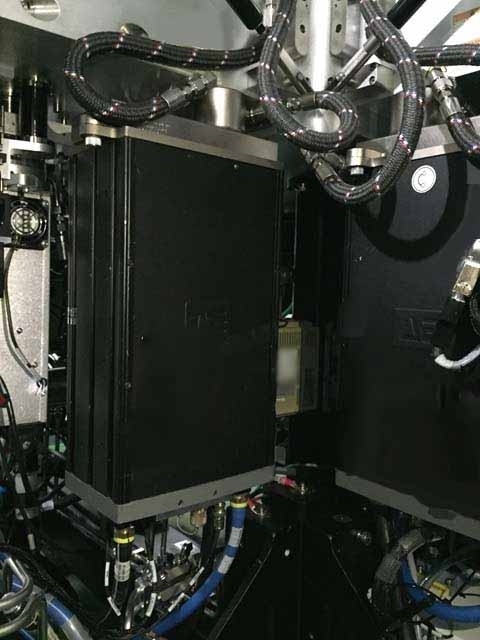

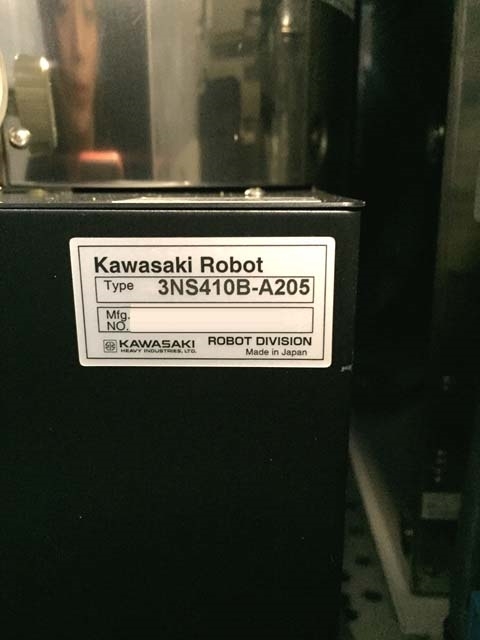

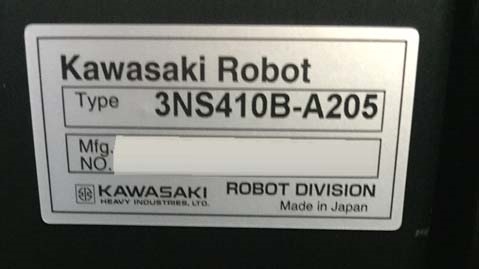

Atmospheric robots: KAWASAKI 2 fixed robots with edge grip

Remote control system cabable: Yes

Docked E99 reading capability: No

Load port types: Enhanced 25 wafer FOUP

Load port operator interface: Standard 9 light

Configurable color lights: No

Docking flange shield: No

Air intake system: Front facing intake plenum

E84 Pl/O Sensors and cables: Upper E84 sensors and cables

OHT Light curtain: Light curtain

Carrier ID host interface: Yes

Light towers: (3) Colors configurable

Fast data gateway software: No

Heat exchanger / Chiller:

Heat exchanger

AMAT HX hose and manifolds: No

Remote AC:

Facilities UPS interface

Chamber configuration:

Ch A / Ch B:

BFC

2" Foreline

T/V Type: 683B

RF Filter: (0090-05813)

RPS

FFU Controller

2006 vintage.

AMAT/APPLIED MATERIALS Producer SE(等离子体增强型外延反应器)是一种商用级等离子体外延工艺,用于硅和非硅基板上的高质量半导体生长。AMAT Producer SE使用高度可靠、精密且具成本效益的生产平台提供全流程控制。该反应器能够提供高质量的薄膜,具有极好的均匀性和极好的工艺调整灵活性。它是最先进、成本效益最高的等离子体外延工具,是大批量生产的理想选择。APPLIED MATERIALS Producer SE提供了一系列功能,例如独特的并行等离子体源配置、可调节的狭缝快门技术、低缺陷密度以及多种沉积工艺功能。平行等离子体源的配置使得晶片到晶片的过程均匀性和优越的掺杂均匀性跨越大晶片直径。可调节的狭缝快门技术提供了等离子体扩散深度的精确控制,并消除了由于门偏差变化而产生的变化。此外,低缺陷密度和广泛的薄膜沉积能力保证了无缺陷、高性能薄膜的高产率,并能够根据特定的设备要求定制薄膜性能。该反应堆非常适合设备制造,从200毫米到300毫米晶圆缩放,最小特征尺寸能力为8纳米。适用于许多不同的沉积过程,包括硅和非硅基板,如氮化硅、低压CVD、PECVD、SiGe和HFO。Producer SE processor has the capility for three separative step-flow processes automatically into standard processing and the ability to combined differAMAT/APPLIED MATERIALS Producer SE还提供在广泛温度范围内的批量处理以及高速率沉积和更快的烘烤时间。该反应堆的高精度电源可精确控制薄膜厚度到0.5-1.0nm的氧化物厚度。可以对反应堆进行多种非侵入性诊断,如压力摆动分析、射频测试、晶圆监测、沉积均匀性验证等。最后,AMAT Producer SE在性能和可靠性方面超过了行业要求,其在产品寿命内的径向漂移极低。总体而言,APPLIED MATERIALS Producer SE是用于各种半导体应用的高质量外延膜沉积的最可靠、最具成本效益的工具。它提供了广泛的特性和功能,确保了卓越的工艺一致性和出色的工艺调整灵活性,从而实现了高级半导体器件的大批量制造。

还没有评论