二手 APPLIED MATERIALS P 5000 Mark II #67130 待售

看起来这件物品已经卖了。检查下面的类似产品或与我们联系,我们经验丰富的团队将为您找到它。

单击可缩放

已售出

ID: 67130

Metal etch system, 6"

Configuration details:

Precision 5000 Mark II MxP Etch system 6”

Mark II mainframe containing load lock chamber

Cassette to cassette wafer handling

VME system controller with hard disk and floppy disk storage

28 line compatible on-board gas panel

Bolt down load lock chamber lid and load lock purge system

Microprocessor controller including CRT display, self diagnostics, host computer interface via RS232 port SECS II protocol

Standard floppy and hard disc (170NMB) storage

Etch chambers include:

Temperature controlled pedestal

Magnet modules and cylinder lift mechanisms

Slit valve, gas distribution components

RF isolator, RF match

Capacitance manometer, throttle valve

Independent helium cooling

Integrated end point detector

Remote package including pumps, RF power supplies, heat exchanger, NESLAB recirculator, main AC box and other facilities

Fifty foot remote package cable length

Features:

(2) metal etch chambers and one strip chamber system

Chamber A: 6” clamped metal etch process kit

Chamber B: 6” clamped metal etch process kit

Chamber C & D: 6” advanced strip and passivation chamber

Including 1200 Watt generator process kit, hardware gas distribution plate and MFC controller gas line per chamber

6” metal etch process kit with:

AL etch ceramic fingered basic kit 0240-31587E

0.95” fingered ceramic focus ring 0240-09757E

Tapered head SiC DC Pick-ups 0240-31359

Unilid gas distribution plate - 119holes 0020-32259

6” advanced strip and passivation chamber process kit basket style wafer support

Gas panel A&B: BCL3, Cl2, CF4, N2, SF6 / C: O2, N2, H2O

Through the wall system

Heat Exchanger AMAT 1 and Heat Exchanger AMAT0

(1) NESLAB HX150 is missing

(1) etch chamber is leaking glycol (can be repaired but it is better to change the body chamber)

Second chamber has been repaired for the same problem

Machine was in production until Q3 2009

Currently installed in fab

Gases are purged and the machine is powered off

Can be inspected and powered on to see software only

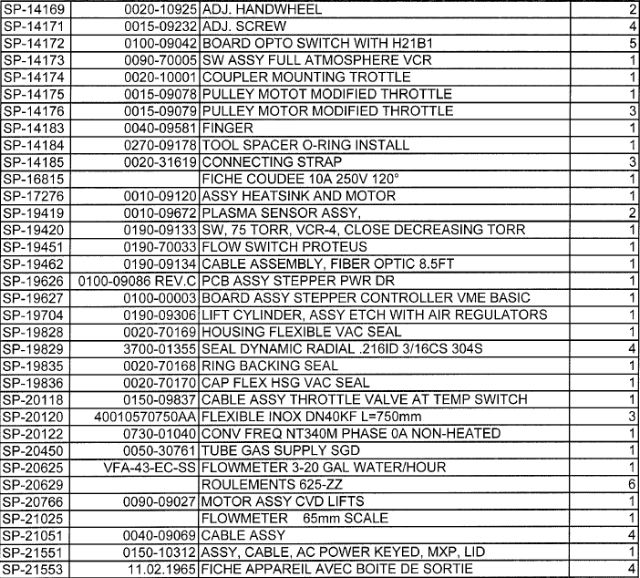

Spare parts available, list is shown in photos

1998 vintage.

APPLICED MATERIALS P 5000 Mark II是为多种材料的多级沉积过程而设计的高性能可配置并行处理反应器。它是市场上最先进的沉积设备,提供无与伦比的工艺灵活性和监控能力。APPLICED MATERIALS P5000 MARK II是一个大容量的生产过程反应堆,可容纳5.5 x 4.0米大小的腔室,给它最多20个同时的腔室,总吞吐量超过8,400晶圆每小时。它能够精确处理从75毫米到300毫米的各种晶圆尺寸,并且能够在单个反应堆室内进行各种现场诊断、质量保证测试和电气特性鉴定。该系统提供了业界领先的过程控制和一致性级别,具有自动剂量控制、腔室循环、结果报告、参数优化以及故障检测和预防等功能。P 5000-MARK II还具有先进的可更换基座,专为快速过程维护和更换工具而设计。其晶片盒和高性能气体输送装置确保了一致的过程重复性和均匀性。一个集成了多个真空泵和排气口的真空机提供可靠的操作和尽量减少任何过程泄漏。APPLICED MATERIALS P 5000 MARK II是专为制造先进半导体材料而设计的,包括碳化硅、氮化氙、二乙烯化散铜的。它能够执行一系列沉积过程,包括径向等离子体、溅射、光照和原子层沉积(ALD)。其HMI软件提供所有腔室参数的图形监测和趋势分析,以及全喷雾分析和优化。P 5000 MARK II是可靠、高通量、精度和灵活性最高的工艺反应堆的完美选择。凭借其先进而集成的HMI,它为满足最严格的生产要求提供了经济高效的解决方桉。其可靠、一致和自动化的流程重复性确保了最高的产量、质量和吞吐量。

还没有评论