二手 ASM / ACCU-FAB Epitaxy / 1250 #156237 待售

网址复制成功!

单击可缩放

ID: 156237

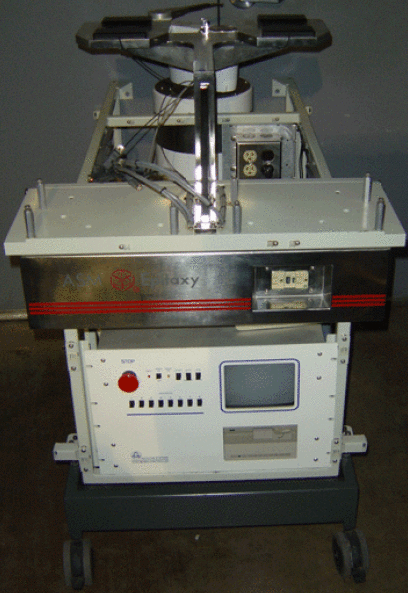

EPI reactor

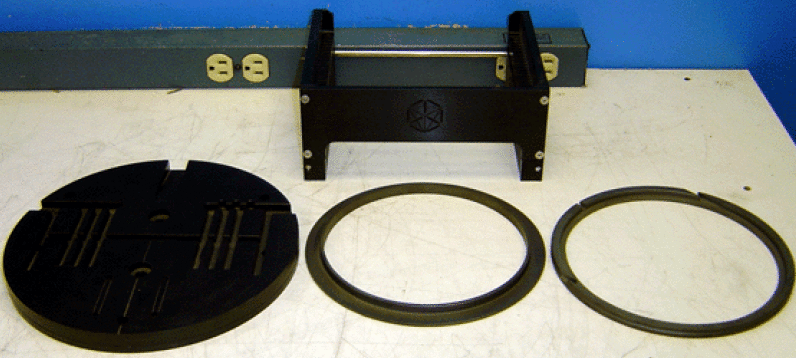

Includes:

ACCU-FAB 1250 max servo motion controller system:

Power: 115 VAC +/- 10%, 50/60 Hz, Single Phase, 1500 VA Max

EPI reactor loader

Built to interface EPI reactor with a Smith interface

(1) 8" cassette (up to 26 wafers)

ACCU-FAB 1250 servo controller:

19" rack mountable chassis

AT bus

Two RS-232 ports

64k non-volatile CMOS memory

(10) Relay outputs

(12) Optically isolated inputs

5.25 or optional 3.5 floppy disk drive, hard disk, and 1 MB RAM

Built-in CRT and keyboard

ACCU-FAB Accubot:

Compact, clean-room compatible

Four-axis SCARA style robot

Four independent joints, cassettes can be located side-by-side vs radially

Range of Motion:

Standard Axis 1 (Z): 9.25 Inches

Custom Axis 1 (Z): 9.3 to 30.0 Inches available

Axis 2: +/- 157

Axis 3: +/- 179

Axis 4: +/- 169

R1 (centerline A1 to centerline A2 = 15.0 inches to tool flange): 7.5 Inches

R2 (centerline A2 to centerline A3): 7.5 Inches

Repeatability: +/- .002 Inch

Weight: 86 Pounds (Does not include the entire item or Shipping I believe)

Maximum Speed:

Axis 1: 10 in. /sec.

Axis 2: 180 / sec.

Axis 3: 180 / sec.

Axis 4: 180 / sec.

Accelerations: 32 inch / sec^2, 540 / sec^2

Payload:

At maximum speed: 3 lbs.

At reduced speed: 6 lbs.

Allowable end effector moment of interia: .02 inch-pounds-sec^2.

ASM/ACCU-FAB Epitaxy/1250是用于外延的一种工艺设备,是一种在单个基板表面上生长不同材料层的技术。具体来说,ASM 1250是一种水平炉,设计用于在半导体(Si、GaAs、InP)和光学基板上生产外延层,广泛应用。1250是由可插入的晶圆独木舟、氧化剂、负载锁、加热器和石英管内的载气组成的多区炉。该炉可处理多达12英寸晶圆,并配有直径4英寸的石英管,管长30.5cm。这使得1250在整个基板表面具有更大的温度均匀性,并支持更高的工艺精度。它还允许外延基板在固定的温度梯度上接收连续的气体流动。1250包括一个多区域控制系统,能够在关键区域进行精确的温度控制。这有助于提高工艺参数的外延均匀性和可重复性。此外,1250还配备了辅助组件,如流量控制器、压力指示器、转子计、质量流量控制器和气泡控制器等。这些组分允许气体的精确和均匀的剂量和载流子流入外延过程。1250还包括一个伺服控制平台和嵌入式微处理器,方便远程监控外延过程。这样可以确保过程的安全、准确和可重复操作。总体而言,ASM Epitaxy/1250反应堆是在半导体和光学基板上生产外延层的最先进的工艺设备。它是优质可靠半导体器件生产商的理想选择。凭借其精确的温度控制、低廉的维护成本以及便捷的远程监控能力,1250可以为广泛的应用提供外延要求。

还没有评论