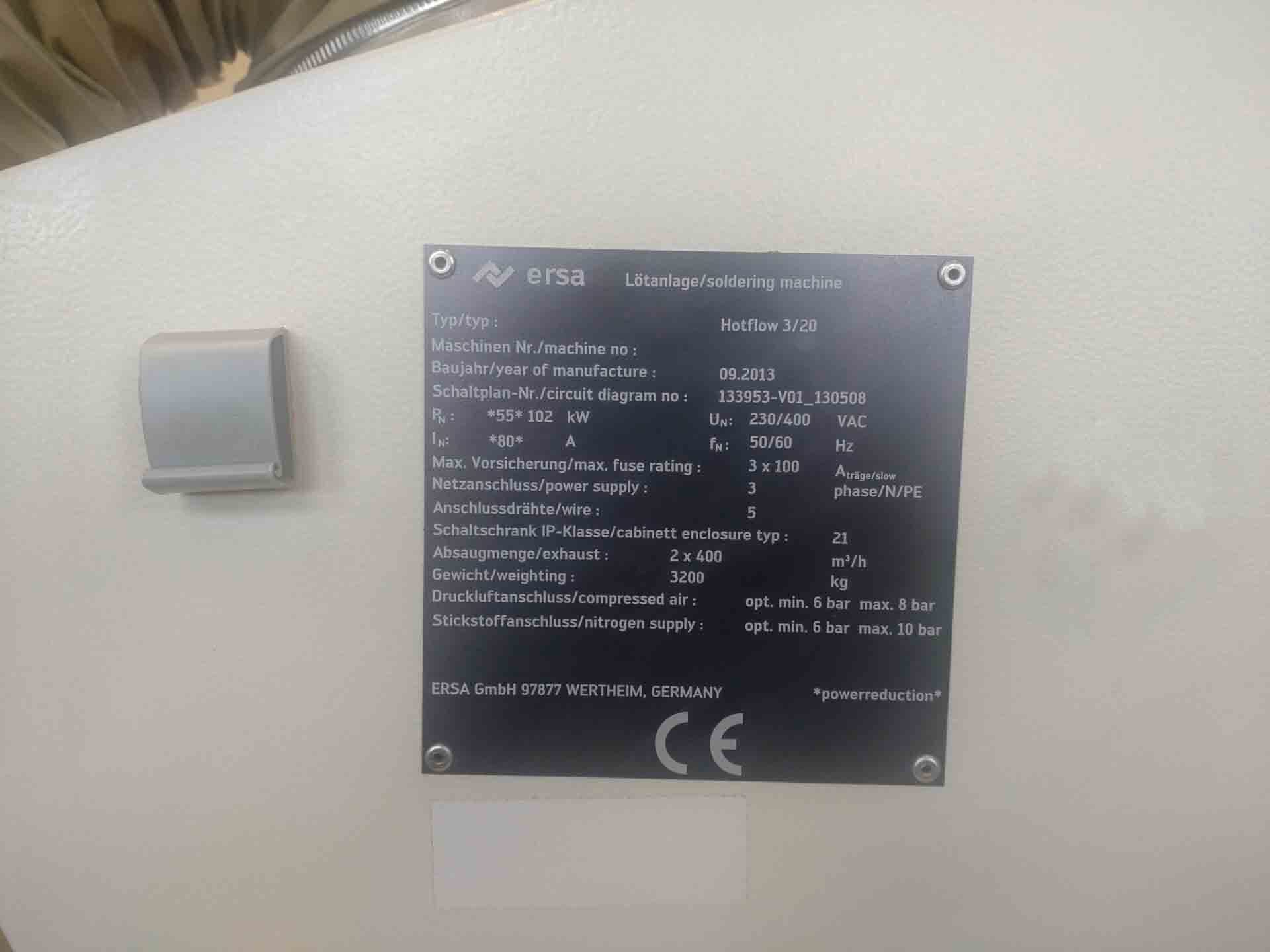

二手 ERSA Hotflow 3/20 #9377007 待售

网址复制成功!

单击可缩放

ID: 9377007

优质的: 2013

Reflow oven

(10) Heating zones

PCB Support

Water cooling system

Nitrogen setup

Smema

UPS

7-top side preheating zones

3-top and bottom-side peak zones

Automatic chain lubrication

Top and bottom-side motor cooling

Exhaust rating: (2) Stacks, 6"

Exhaust volume per stack: 400 m3/h

Safety device:

(4) Emergency-stop buttons

(2) Exhaust monitors

Dimension:

Length: 6,590 mm

Width: 1,530 mm

Height: 1,450 – 1,580 mm

Height (open): 1,810 – 1,940 mm

Weight: 3,200 kg

Paint: RAL 7035/7016

Process zone:

Process length: 5,190 mm

Heating zone: 3,700 mm

Cooling zone: 1,490 mm

Infeed/Outfeed zone: 700 mm

Process chamber width: 770 mm

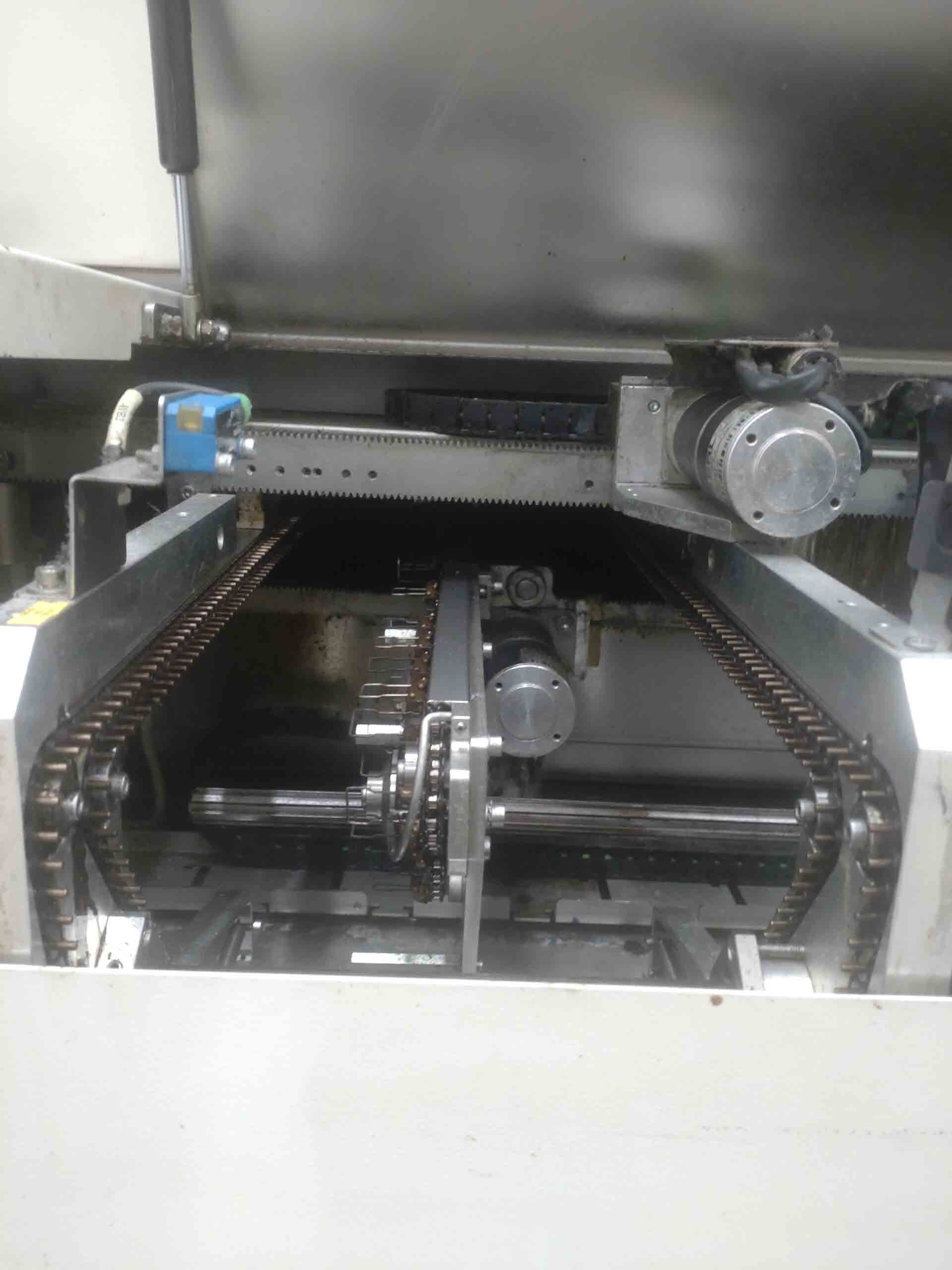

Conveyor system:

Working width: 45 – 580 mm

Working width: 45 – 580 mm (PCB center support)

Board clearance: +25/-37 mm (Standard)

Board clearance: +35/-37 mm (Option)

Center support pin height: 15 mm

Conveyor speed: 20 – 200 cm/min

Conveyor height from floor: 820 – 980 mm

Pin-and-chain conveyor: 3 mm

Edge clearance (option: 4 mm, 5 mm)

Heating system:

Convection share: 100%

Gas flow / module: approx. 500 m3/h

Convection modules: 10 top / 3 – 10 bottom

Preheating: 7 top / 7 bottom (option)

Soldering zone: 3 top / 3 bottom

Nominal rating / module: 3.3 kW

Electrical data:

Power: 5 Wires, 3x400 V, N, PE

Power tolerance range: ±10 %

Frequency: 50/60 Hz

Max fuse rating: 3 x 100 A

Nominal rating: 65 kW-104 kW

Reduced rating: 44 kW

Continuous rating for operation: 12-19 kW

Nitrogen option:

Gas injection: in process zone

Pressure control: 4.5-10 bar

Cooling:

Cooling zone: Ersa Multinet system

Coolant: water / R407C (option)

Ambient temperature: 32°C

Noise level: < 70 dB (A)

2013 vintage.

ERSA Hotflow 3/20是为大体积自动焊接应用而设计的回流炉。烤箱配备了先进的、专有的热流技术,利用红外吸收器提供精确、可重复的温度控制,用于整个工作区域的精确温度倾斜。Hotflow 3/20先进的热通量技术确保了均匀的温度分布,从而保证了一致可靠的制造过程。与传统的回流炉不同,ERSA Hotflow 3/20不需要外部热电偶,节省了设置时间,消除了潜在的故障点。这种自我调节技术确保操作员能够获得精确地针对其应用程序需求定制的温度配置文件。Hotflow 3/20的优化组件还可以降低PCB的热应力,从而提高产品可靠性。空运系统不断循环凉爽的大气,为操作员带来更舒适的环境,降低出错风险。Hotflow 3/20回流炉具有强大的加热系统,具有高达20 KW的加热能力,这意味着它能够达到任何焊接任务所需的温度。Hotflow 3/20还具有特别大的工作区域1500 mm x 480mm,使其能够在不影响均匀性或速度的情况下处理最大的焊接任务。标准的安全特性包括一个封闭的、循环的腔室,保证操作员的安全.此外,Hotflow 3/20还包括一种节能ECO模式,该模式可自动监控和调整加热元件,以确保能耗降至最低。Hotflow 3/20回流烤箱是一款经济实惠、功能强大的工具,即使在大型生产运行中也能持续提供焊接良好的多氯联苯。Hotflow 3/20具有可靠的加热系统、先进的气流技术和简单的界面,是任何具有自动焊接需求的PCB制造操作的理想选择。

还没有评论