二手 HELLER 1809EXL #9247414 待售

网址复制成功!

单击可缩放

ID: 9247414

优质的: 2003

Reflow oven

Atmosphere: Nitrogen

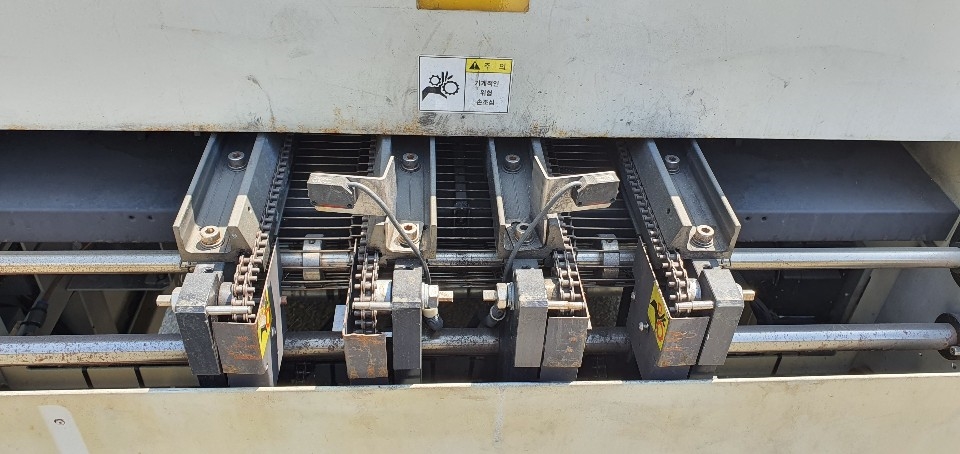

Conveyor type: Mesh

Computer control:

Standard computer

Recipe storage: >500

Flat screen monitor

Operating system: Windows XP

Monitor mount

Data logging

Password protection

Inert atmosphere:

Minimum PPM oxygen: 10-25 PPM

Nitrogen cooling

Sample port in reflow

Typical nitrogen consumption: 700-900 SCFH

Mesh belt conveyor:

Height from floor: 35.5" + 2.0" (90 cm + 5 cm)

Maximum PCB width: 10" (25 cm), 15" (38 cm), 18" (46 cm)

(Requires 30" heater modules) 22" (55.8 cm), 26” (66 cm)

Space required between PCB's: 0.0" (0.0 cm)

Conveyor length on-load: 6" (15 cm)

Conveyor length off-load: 6" (15 cm)

Heated tunnel length: 105" (254 cm)

Process clearance above mesh belt: 2.3" (5.8 cm)

Mesh belt pitch: 0.5" (1.27 cm)

Maximum conveyor speed: 74"/Min (188 cm/min)

Conveyor direction: Left to right

Conveyor speed control type: Closed loop

Edge hold conveyor system option:

Height from floor: 37.0" + 2.0" (94 cm + 5 cm)

Clearance above conveyor pins: 1.15" (2.9 cm)

Clearance below conveyor pins: 1.15" (2.9 cm)

Length of PCB support pins: 0.187" (4.75 mm)

Minimum / Maximum board width: 2.0" - 20" (5 –50.8 cm)

Requires 30” heater modules: 24" (61 cm)

Power width adjustment

Auto lubrication system

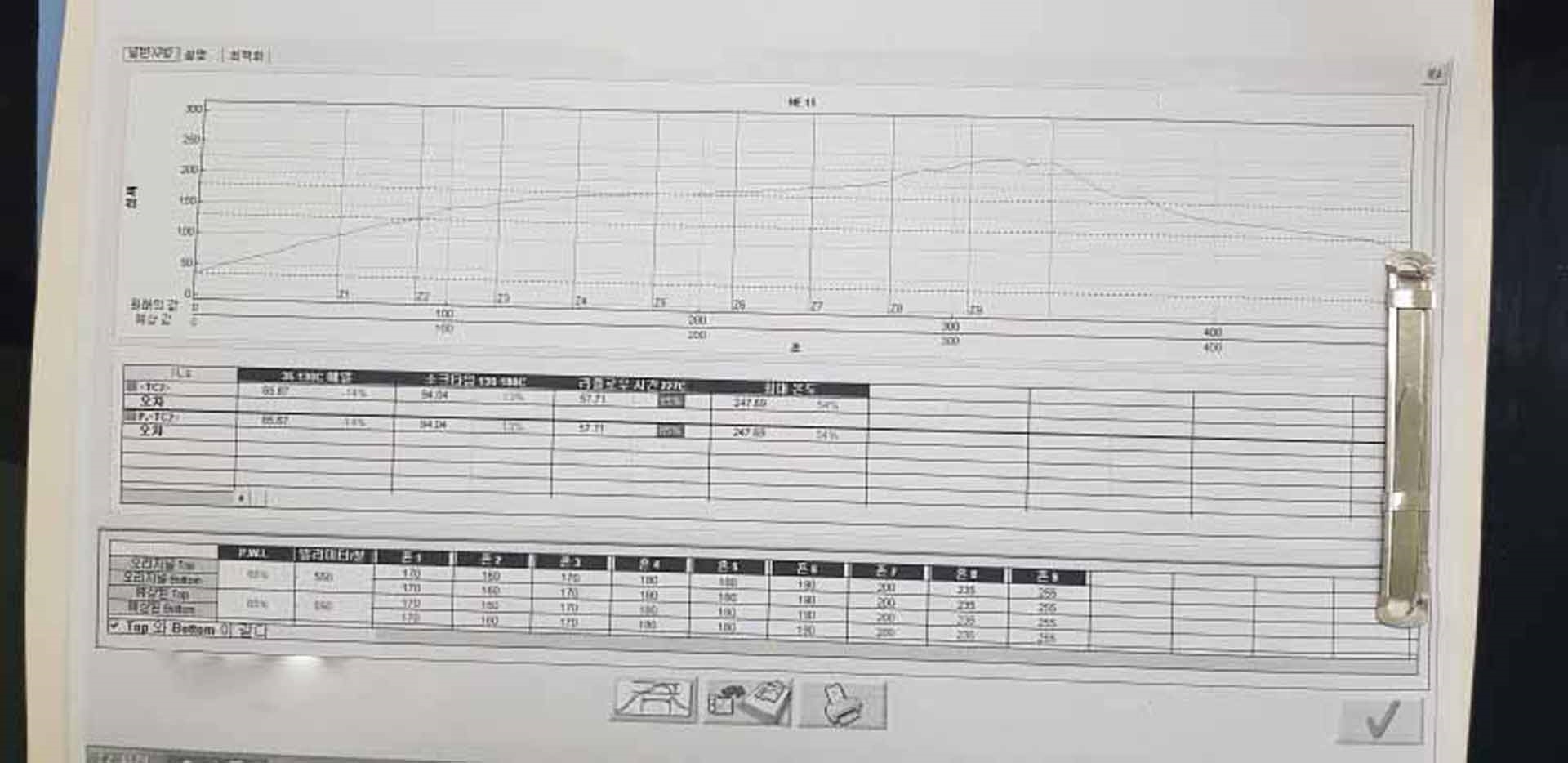

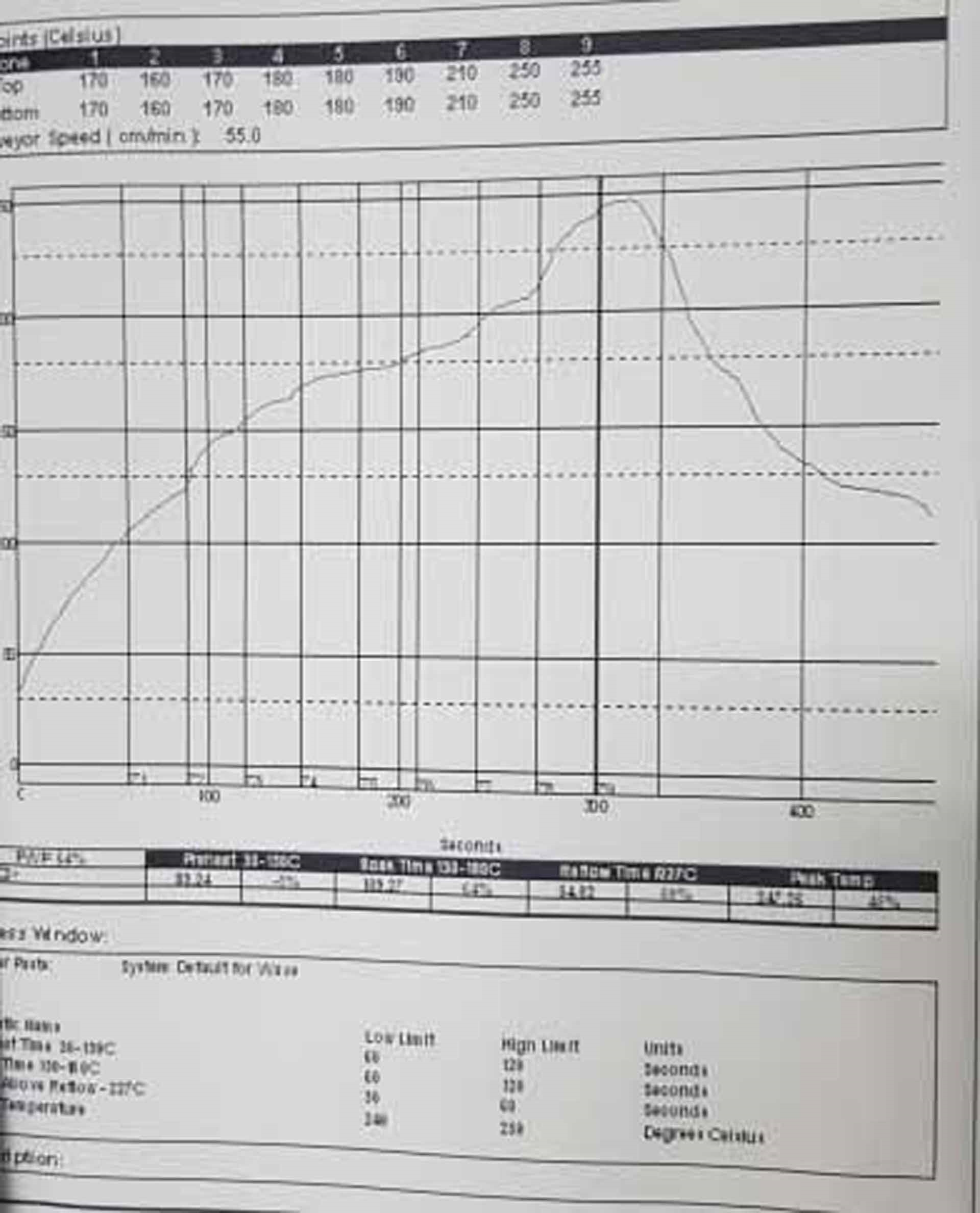

Forced convection zones:

(9) Top zones

(9) Bottom zones

Heater type: Instant response open coil

Heater material: Ni chrome

Temperature control:

Accuracy of temperature controller: +0.1°C

Cross-belt temperature tolerance: +3.0°C

Heater wattage per zone: 6000W

Temperature range standard: 25-350°C

Insulation type: Calcium silicate

Cooling systems: (2) Cooling zones

Features:

Signal light tower

Powered hood lift

(5) Thermo couple profilings

Power input: 480V, 3-Phase, 11-13 kW

Breaker size: 100 amps@480V

Typical run current: 25-30 amps@480V

Frequency: 50/60 Hz

Sequential zone turn on: Standard

No single phase operation

2003 vintage.

HELLER 1809EXL是为电子元件精密焊接而设计的先进回流炉。它利用对流加热设备,可以达到高达350°C(662°F)的温度。烤箱具有高效的散热系统,确保所有正在处理的电路板的最佳温度曲线。烤箱每秒可达到8°C (14.4 °F)的最大坡道速率,非常适合无铅工艺。此外,该炉还配有一个九区加热剖面,用于可靠和可重复的热剖面。此外,HELLER 1809 EXL采用自充气带技术,允许元件施加精确的力,优化放置精度和热传递。烤箱还具有集成的喷嘴界面和气动传送带部分,用于整个过程的质量控制。此外,它还具有温度感测功能,可容纳长度超过20英寸、宽超过14英寸的电路板。1809EXL专为各种工业焊接应用的高耐用性的强健设计而设计。它有一个内置的主动冷却装置,允许快速冷却,以及一个综合排气机理想的气流和通风。内部保温设计保证了热和过程的重复性,同时提供了一个非常耐用的炉。采用钢板和铝化钢制造,具有更大的耐用性。1809 EXL的控制工具配备了功能强大的Allen Bradley® PLC,并配有按钮、液晶显示器和LED指示灯,方便用户使用。此外,它还配备了10英寸高清触摸屏,便于访问。软件最多可以存储和召回40个热配置文件,并且还可以存储过程配方,以实现一致的可重复性。可以使用Modbus/TCP以太网协议功能远程监视和访问熔炉。HELLER 1809EXL已通过UL和CE标准认证,其不锈钢腔室具有独家终身保修。这使得HELLER 1809 EXL成为高级回流焊接需求的理想选择。

还没有评论