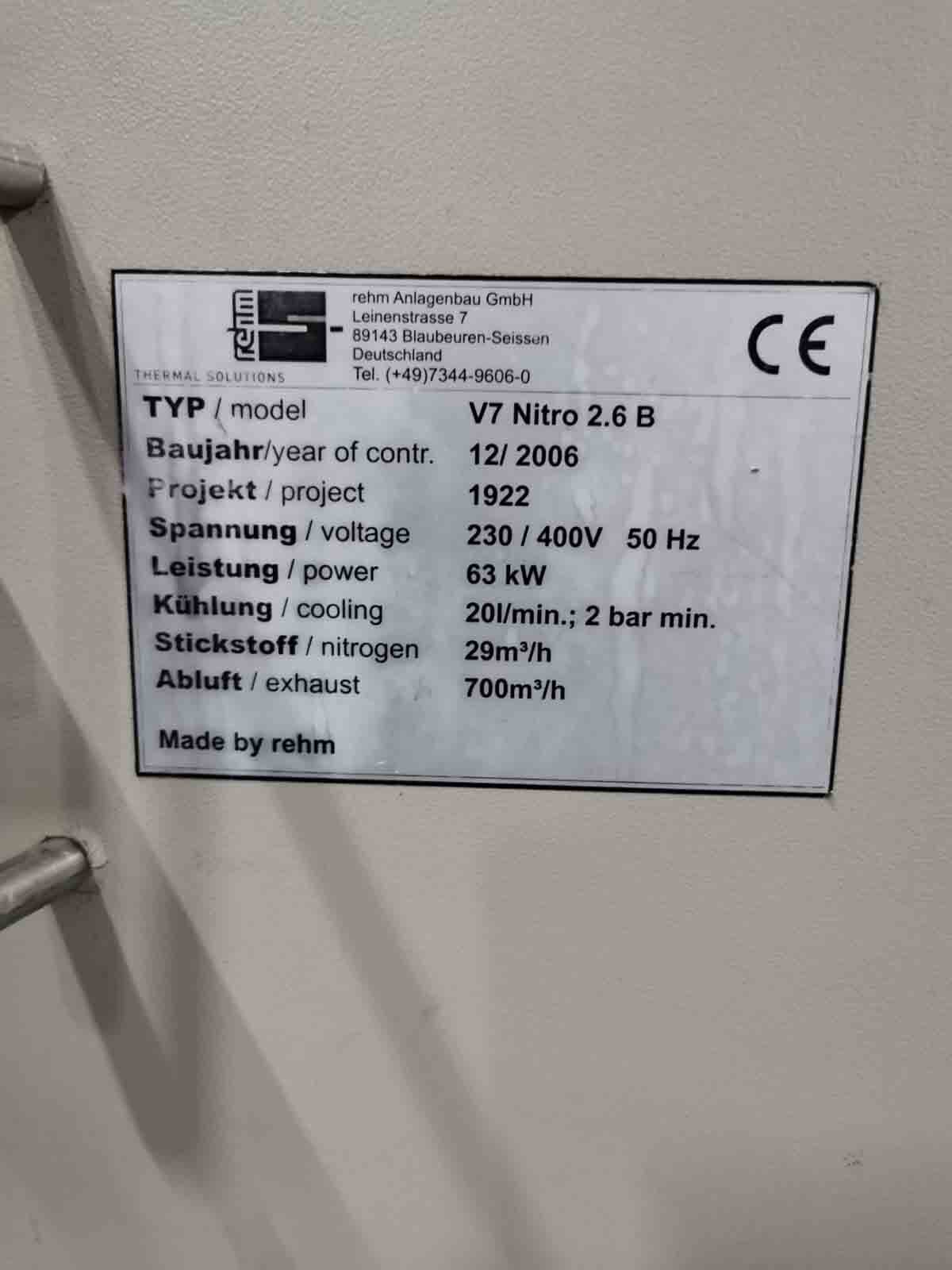

二手 REHM V7 Nitro 2.6B #9235989 待售

网址复制成功!

单击可缩放

ID: 9235989

优质的: 2006

Reflow oven

(6) Heating zones

Cooling zone

Nitrogen / Air operation

Height with open hoods, 86.61"

Required area: 7.7 m²

Load per unit area: 400 kg/m²

Voltage supply

Nitrogen

Length of inlet table, 9.84"

Length of outlet table, 9.84"

Length: 102.36"

Pin chain conveyor:

Conveyor system height: 900 mm ±75 mm / 35.43", ±2.95"

Width:

Single conveyor ±0.5mm:

Min 3.15" (MU-lowest position) / 3.94" (MU-highest position) - Max 15.75" (option 18.11")

Dual conveyor ±0.5mm:

Min 3.15" (MU-lowest position) / 3.94" (MU-highest position) - Max 8.5"

Clearance above conveyor, 1.18"

Clearance below conveyor, 0.78"

Adjustable conveyor speed: 7.09" - 70.87" per minute

Tolerance conveyor speed: <= 0.354" per minute

Conveyor system height: 35.43" ±2.95"

Mesh belt conveyor:

Width mesh belt conveyor: 15.77"

Adjustable conveyor speed: 7.09" - 70.87" per minute

Tolerance conveyor speed: < 1%

Cooling water at external cooling:

Connection: M 28 x 1.5 (0.87" Cu tube)

Cooling water flow: between 10-20 l/min/158.5-317 gal/hr

Operating pressure: 2 bar / 29 psi - 5 bar /145 psi

Differential pressure: 0.5 bar / 72.52 psi

Voltage supply consumption:

Type of power system: 5-wire system (L1, L2, L3, N, PE)

Voltage supply: 230/400 VAC ± 5%, 50 Hz

Connected load without bottom heating V7 nitro: 44 kW

Connected load with bottom heating V7 nitro: 53 kW

Connected load +5kW, with internal cooling

Operating capacity without bottom heating V7 nitro: 11.0 kW

Operating capacity with bottom heating V7 nitro: 13.3 kW

Operating capacity +2 kW, with internal cooling

Nitrogen supply:

Connection: M16x1 (10.472" Cu tube)

Nitrogen supply pressure: 6 bar/87 psi - 10 bar /145 psi

Operating pressure: 5 bar/72.52 psi

Nitrogen consumption (single conveyor at <100 ppm in peak):

25 - 29 m³/h 14.71 -17.06 ft³/min

Exhaust:

Exhaust socket diameter: 5.91"

Exhaust at min 3 mbar under pressure V7 nitro: 600 m³/h/353.36 ft³/min

Exhaust temperature: < 50°C / 122°F

Exhaust external cooling / warm + clean air:

Exhaust socket dimensions: 28.15" x 11.82"

Exhaust surrounding temperature: 2400 m³/h /1413 ft³/min

Exhaust temperature: < 50°C / 122°F

Heating:

(4) Preheating zones

(2) Peak zones

Length of zones: 15.75"

Cross profile (Delta T:Tmax thin): ±2.5 Kelvin

Permissible soldering temperature

Preheating zones, 300°C / 572°F

Peak zones, 350°C / 662°F

Heat transfer through forced convection

Gas circulation per heating zone: 600m³/h / 353.15 ft³/min

Cooling zone: Length: 49.21"

Warm up time: 30 minutes

Specification: 5K / 4 sigma

Maximum noise level without internal cooling: 72dBA

Maximum noise level with internal cooling: 75dBA

Room temperature: between 15°C and 32°C / 59°F and 89.6°F

Humidity: between 30% and 75%

Oxygen: < 100 ppm in peak zone

Center support:

Center support V7: link chain, 20mm

Center support position: 1.97" - 3.78" (Option 16.14"/18.03")

2006 vintage.

REHM V7 Nitro 2.6B回流炉是在印刷电路板或类似电路基板上焊接电子元件的工业工具。它由丙烷/丁烷气体加热器提供动力,该加热器提供多达12个阶段的温度控制,以获得准确的焊接结果。烤箱的工作面积为890 x 420毫米,允许板长和宽可达25厘米。V7 Nitro 2.6B烤箱利用红外辐射均匀加热电路板的所有区域,提供均匀、均匀的焊料熔化温度。它还使用强制对流空气冷却焊接接头,以确保达到可靠和一致的温度。烤箱配备了多种内置特性,保证了可靠的效果。它有一个自动双定时器,可调0-60分钟,以确保准确的焊接时序。它也有200个程式记忆体,这样可以根据需要储存和召回各种板型。集成真空系统用于确保电路板保持平整,并防止加热和冷却过程中的任何接触中断。其他特点还包括一个检查过程的窗口、重型不锈钢绝缘双壁腔室,以及一个坚固的工业强度滚筒输送机,方便板装卸。烤箱具有多种安全特性,保证操作员和设备的安全。带有可调延迟计时器的自动门锁系统可防止意外打开或关闭腔室从而中断过程。此外,还安装了安全传感器,以确保在工艺过程的中间未打开腔室。内置灭火系统采用惰性气体防火,有能力在发生火灾时自动关闭烤箱。REHM V7 Nitro 2.6B回流炉是增强电子元件焊接的可靠工具。其特点保证了采暖和制冷过程的均匀,安全特点保证了工人和设备的安全。

还没有评论