二手 ACCUSPUTTER AW 4450 #9201786 待售

网址复制成功!

单击可缩放

ID: 9201786

晶圆大小: 8"

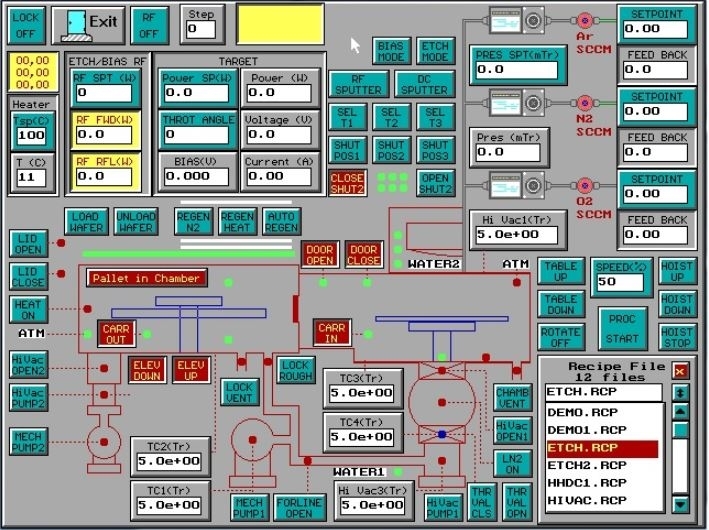

Sputtering system, 8"

Wafer loading: Manual

With load lock

Cathodes: (3) Delta shapes / (4) Circle shapes

Sputter methods: RF / DC

Diode / MAGNETRON

Gas lines: 1~3 MFC

Options:

Gas lines with MFC

N2

O2

Customized

Lamp tower alarm with buzzer:

Mechanical pump / Dry pump for process chamber and load lock

Independent mechanical pump / Dry pump for process chamber

Chiller for cooling plates and table

Turbo pump for load lock

Load lock lamp heating function: Up to 200°C

Chamber lamp heating function: Up to 300°C

Plasma etch function

Bias function

Co sputter function

Reactive sputter function

Main frame

28" Diameter SST chamber top plate with ports and cathodes:

Configuration I II

Cathode shape Circle Delta

Cathode size 8" Delta

Cathode quantity 1 to 4 1 to 3

Sputter power supply:

Configuration I II III

DC Power 5 kW 10 kW -

RF Power 1kW 2 kW 3 kW

Pulse DC power 5 kW 10 kW -

Process chamber:

8" Diameter x 12" High stainless steel cylinder with 6"

CF Flange view port and load lock port

28" Diameter stainless steel base plate

11/2" Air operated roughing isolation valve

Air operated gas inlet valve

Air operated vent valve

11/2" Blanked-off leak check port

Removable deposition shields

23" Diameter, 3-position water cooled annular substrate

Table with variable speed motorized table drive

Full circle shutter and vane shutter

Chain drive pallet carrier transport

Heavy duty electric hoist

Load lock:

30" x 28" x 8" Stainless steel load lock chamber

Aluminum cover

Chain drive pallet carrier transport

2" Air operated roughing isolation valve

Air operated vent valve

23" Diameter molybdenum annular substrate pallet

Elevator for pallet up and down function

Vacuum systems for process chamber:

(2) Stage cryo pumps

With 1000 l/s pumping speed for air

Includes:

Chevron

Water cooled compressor and lines

Automatic regeneration controller

Plumbing kit, 71/2"

Aluminum air operated gate valve: 6" ASA

Air operated venetian blind throttling valve

Mechanical pump or dry pump for process: 36.7 Cfm

Chamber and load lock

Gas line with MFC

Ar, 200 SCCM, customized

Power box: AC 380 V / 208 V / 3 Phase.

AW 4450是一种先进的薄膜沉积设备。这一件工业设备的设计目的是在硅片、电线、纤维、电子元件等多种基板的表面上创造出薄薄的金属和介电层。利用物理气相沉积,AW 4450以高效的方式生产出厚度均匀一致的薄膜。ACCEPUTTER AW 4450由一台频率范围为13.56 MHz或40 kHz的先进射频(RF)发电机供电。这允许精确而有力的溅射,使具有非常一致特性的薄膜以高度可重复的方式沉积。此外,射频功率是可调的,给用户精确控制沉积速率和层厚度。AW 4450配备了能达到1.3 × 10-4 Pa的高真空室、自动真空设置,以及与差动泵送工艺室集成的涡轮泵。这样可以精确地控制溅射涂层的过程。此外,系统还可以容纳50毫米的样本量。利用其HVQ极性控制,ACCUSPUTTER AW 4450还可以以更高的精度和控制能力沉积多层薄膜。为保证优质产品,AW 4450配备了先进的控制和监控系统。这包括工艺电位监视器、基板偏置电压监视器和等离子体电位监视器,所有这些都可以实时监控。此外,机组还配备了质量流控制器,以确保整个过程中过程气体的纯度保持一致水平。ACCUSPUTTER AW 4450是一款功能强大且高度精确的溅射机,旨在处理广泛的溅射应用。通过其精确的射频功率调节、高真空室、溅射室差动泵送、精确的控制和监控系统以及处理高达50毫米样本量的能力,该工具是精确度和重复性至关重要的一系列工业应用的理想选择。

还没有评论