二手 CVC 601 #28214 待售

网址复制成功!

单击可缩放

ID: 28214

晶圆大小: Up to 8"

优质的: 1986

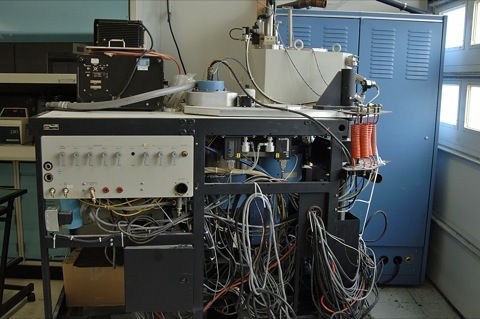

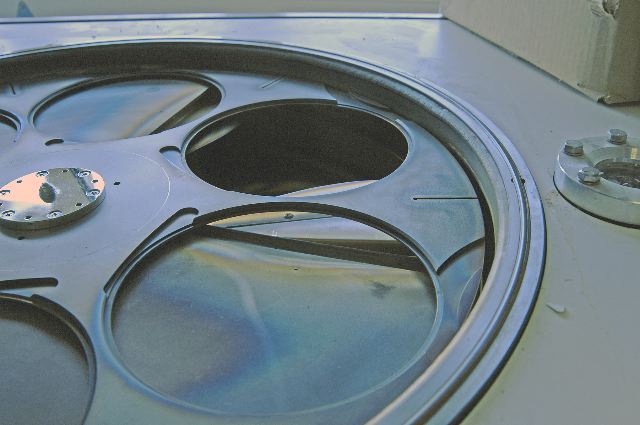

Batch type production sputtering system, up to 8"

Currently setup for Argon and Oxygen with the possibility for Nitrogen

Computer and cryopump included

Works in manual mode

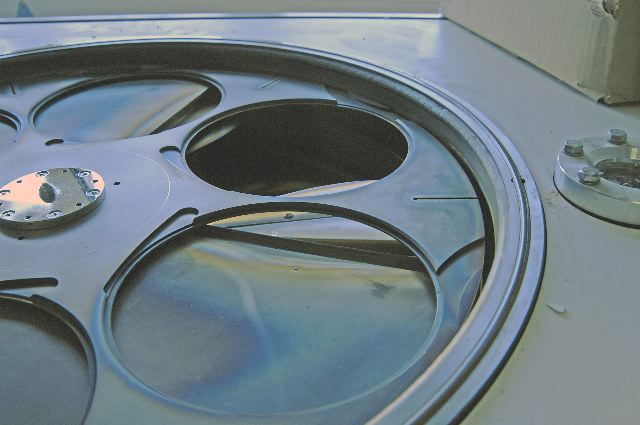

4 targets / wafer holders

Top loading machine

(Qty 4) work stations in the flat bottom of the 7" high work chamber

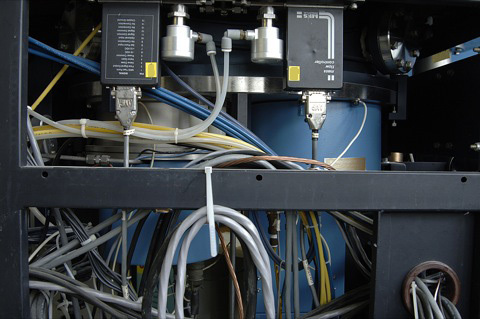

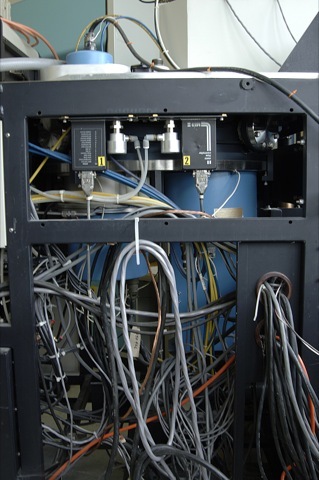

(Qty 2) DC stations

(Qty 1) RF station

(Qty 1) Ion cleaning station

Work heater / sintering accessory in the lid

Accessories for sputtering in several modes including DC Diode, RF Diode, DC Plasma Enriched Deposition ( PED, planar magnetron) and RF PED

Composed of a relay rack control center and cabinet which contains the vacuum chamber and pumping system

The computer interface is a Gould Model 484 Programmable controller

The DC Sputter Supply is an 10 KW Advanced Energy MDX Magnetron Drive

Unit has a CVC 3 KW AC Power Supply and a CVC 1 KW AC Supply

(Qty 4) Targets include:

Barium Titinate

Molybdenum Trioxide

Inconel

Titanium or Silicon

There are 4 target positions:

(Qty 1) RF Magnetron gun and matching unit

(Qty 2) DC Diode Sputtering unit with magnets in them for magnetron sputtering

The 4th target position has an Ion Cleaning Source

Project used only the RF PED Target position, DC targets were not used, in manual mode

Previous project used system with a P190/484 Programming panel

(Qty 2) Mass Flow Controllers

There is a cryo controller for N2-purge, and regeneration

Log book included

Packaged and stored

As-is

1986 vintage.

CVC 601是Cambridge Vacuum为一系列科学应用开发的最先进的溅射系统。它由一个带有阳极和阴极的大型真空室组成,可以调整以允许样品插入和工作距离。阴极由不锈钢制成,而阳极由钨构成。溅射室被封闭在一个手套箱中,通过它抽出空气以产生高真空。一种气体,如氦气、氙气或氮气,可以用来填充腔室。为阴极充电,它连接到高压电源。电压可以设置为3000V。601包含各种控制系统,包括过程控制单元(PCU)、电源控制单元(PCU)和冷却控制单元(CCU)。为保证运行平稳,有两个水冷通道和高纯度石墨支撑板。为了安全起见,CVC 601配备了一个真空计传感器来监控溅射的效果。使用前,必须将601烘烤至所需温度(通常800 °C,持续数小时),以除去水分和其他潜在污染物。完成此操作后,可以打开系统并启动进程。溅射过程从电源给阴极充电开始。这就产生了一个直流场,电子被加速到阳极。当电子与阳极接触时,它们被吸收,阳极表面上的物质被溅射掉,溅射的物质再覆盖目标物质,形成各层。溅射过程完成后,剩余的材料可以用刮刀从阳极上除去。然后,CVC 601可用于进一步处理,例如退火、蚀刻和沉积。总体而言,601溅射系统是参与薄膜加工的科学家和工程师的宝贵工具。其先进的控制系统确保了结果的准确性和可重复性,在高温下充电、溅射和退火的能力是无与伦比的。它灵活的设计还可以轻松扩展和开发,从而为单个应用程序提供最佳定制。

还没有评论