二手 AMAT / APPLIED MATERIALS Mirra Integra #9265796 待售

网址复制成功!

单击可缩放

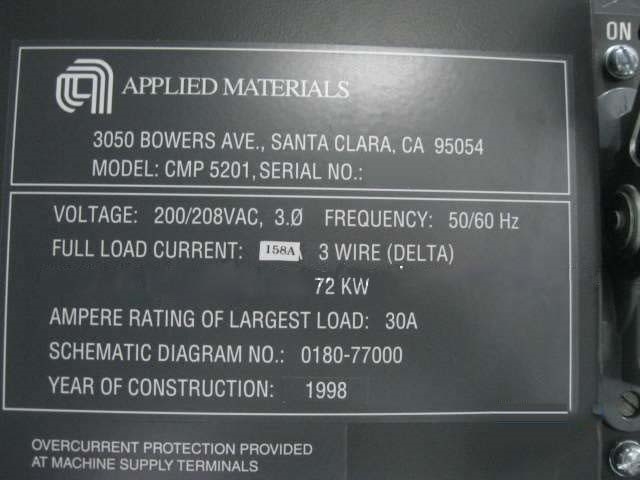

ID: 9265796

晶圆大小: 6"

优质的: 1998

System, 6"

Box 1:

Type: Through-the-wall

(4) SMIFs

CPU Board type: 400 MHz or Higher

Box 2: Mirra Track

Box 3: Oxide

Box 4: Dry in / Dry out

Box 5:

Signal lamp tower

No Bolt-on SMIF

No integrated SMIF

Box 6:

Cassette tank: Standard

Robot type: 112" Stand alone

Cleaner type: ONTRAK

Spray gun: Single

No In-situ removal rate monitor

No IPM

Box 7:

Polish heads: Titan 1

Rings: AFP

Wafer loss sensor: Dual sensor

Box 8:

Teflon coated platens

Pad type: IC 1000

Pad conditioner head: DDF3

Pad conditioner disc: TBW

Universal disk holder

Temperature control: None

Box 9:

Slurry / Platen used

Flow rate: Standard

Dispense arm: Standard

No slurry flow monitors

Box 10:

Nova type: Wet out

No interface monitor

No notch finder

Box 11:

Membrane type: FPDM

4-Port UPA upper

Box 12:

Polish heads: 6" Titan

Grooved retaining rings

Dark pad wafer loss sensor

Box 13:

Pad type: IC 1000

Pad conditioner disc: ABT

Universal disc holder

Box 14:

MESA Cleaner type

On-board mixing

Chemical A: Ammonia Hydroxide

Pressurized delivery type

Precision spray bar

CLC Brush box with on-board mixing

Scrubber 1 and 2:

Brush type: Rippey microclean

Delivery type: Direct feed

Manuals and cables included

Power supply: 208 V, 3 Phase

1998 vintage.

AMAT/APPLIED MATERIALS Mirra Integra是一种晶圆研磨、研磨和抛光设备,设计用于高效加工具有多种研磨介质的脆性材料。该系统用于各种应用,包括生产半导体和MEMS器件。该单元由一个装有磨轮和研磨板的基本单元和一个控制器单元组成,该控制器单元允许用户控制研磨设备并调整参数以满足所需的结果。AMAT Mirra Integra拥有坚固的结构,包括铝制底盘、不锈钢工作板和陶瓷元件。应用于APPLIED MATERIALS Mirra Integra的研磨机精度和精度都很高。磨轮的设计目的是在整个材料表面提供一致的结果。对磨削介质进行了优化,减少了板材磨损,最大限度地减少了工件损坏。此外,研磨介质还能够容纳表面不同的基板。Mirra Integra的研磨板设计为提供均匀的研磨表面,将应力均匀地分布在整个工作表面。这有助于减少工件上的应力,从而降低表面粗糙度并改善零件寿命。研磨板配有两个可调节的夹具,使其能够根据特定的应用要求进行调整。AMAT/APPLIED MATERIALS Mirra Integra的抛光工艺采用化学和机械方法相结合,达到了高质量的抛光效果。所使用的抛光介质经过精心设计,可实现受控且一致的精加工过程,从而获得非常精确的结果。AMAT Mirra Integra的自动化过程控制机器允许用户调整研磨设备参数以确保最佳效果。控制器还提供工件表面粗糙度的反馈,并且在超出预定阈值时可以触发警报。总体而言,APPLIED MATERIALS Mirra Integra是一种非常先进和可靠的晶圆研磨、研磨和抛光工具,可用于在极少数时间内获得高精度结果。

还没有评论