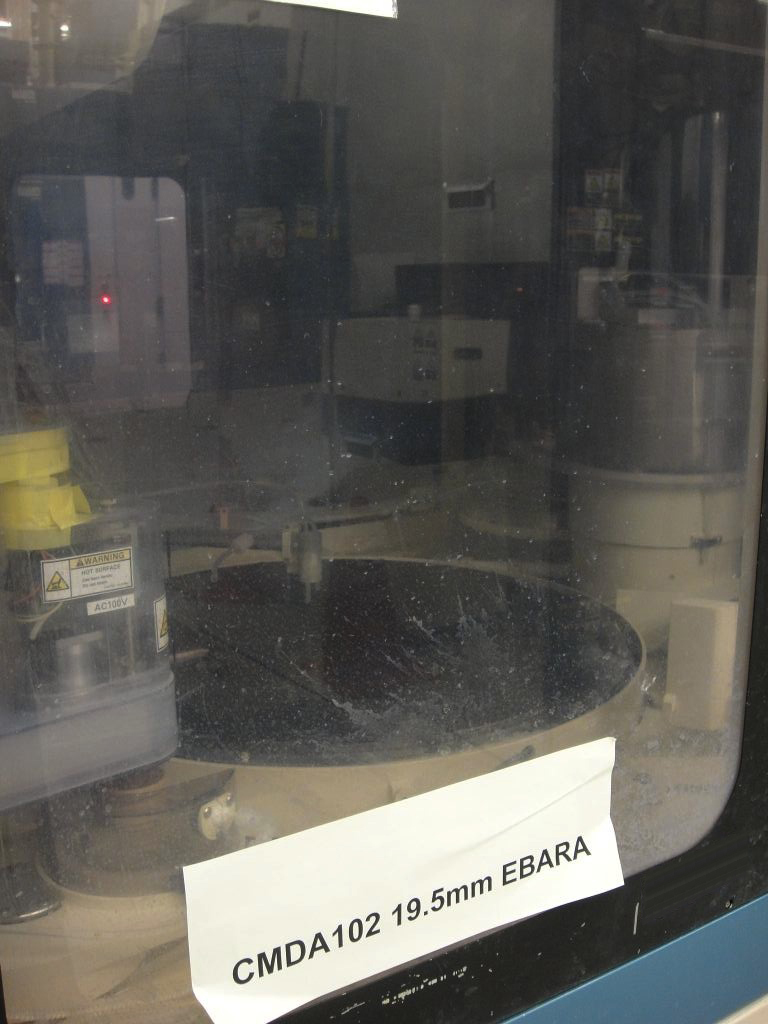

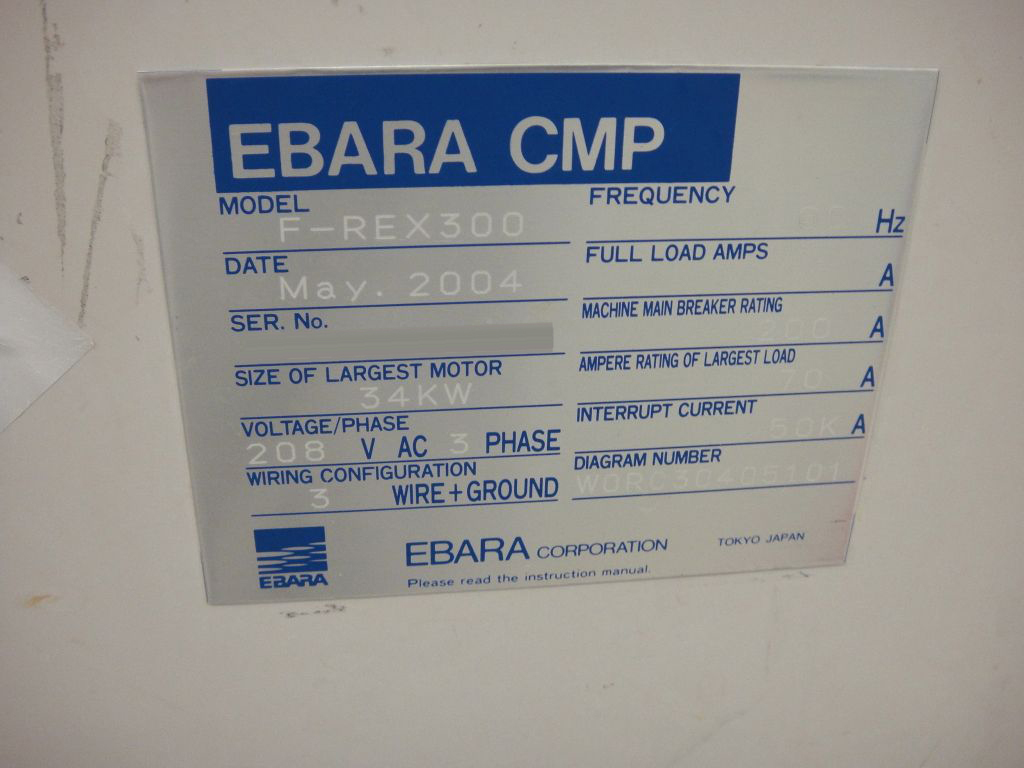

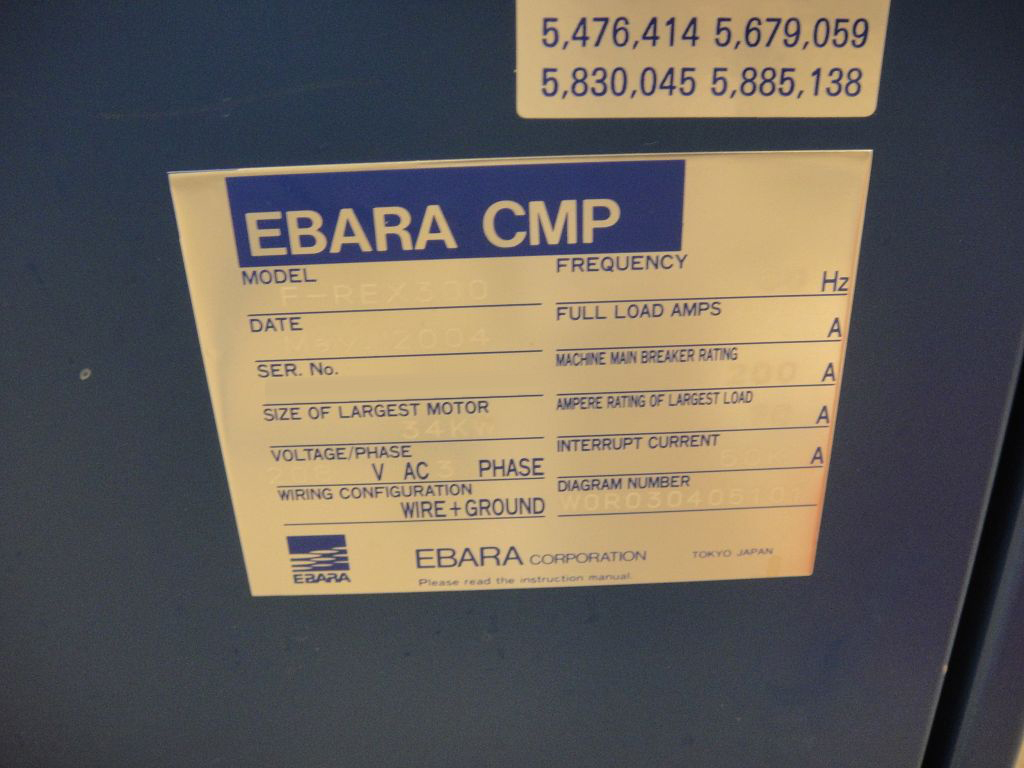

二手 EBARA Frex 300 #9017351 待售

网址复制成功!

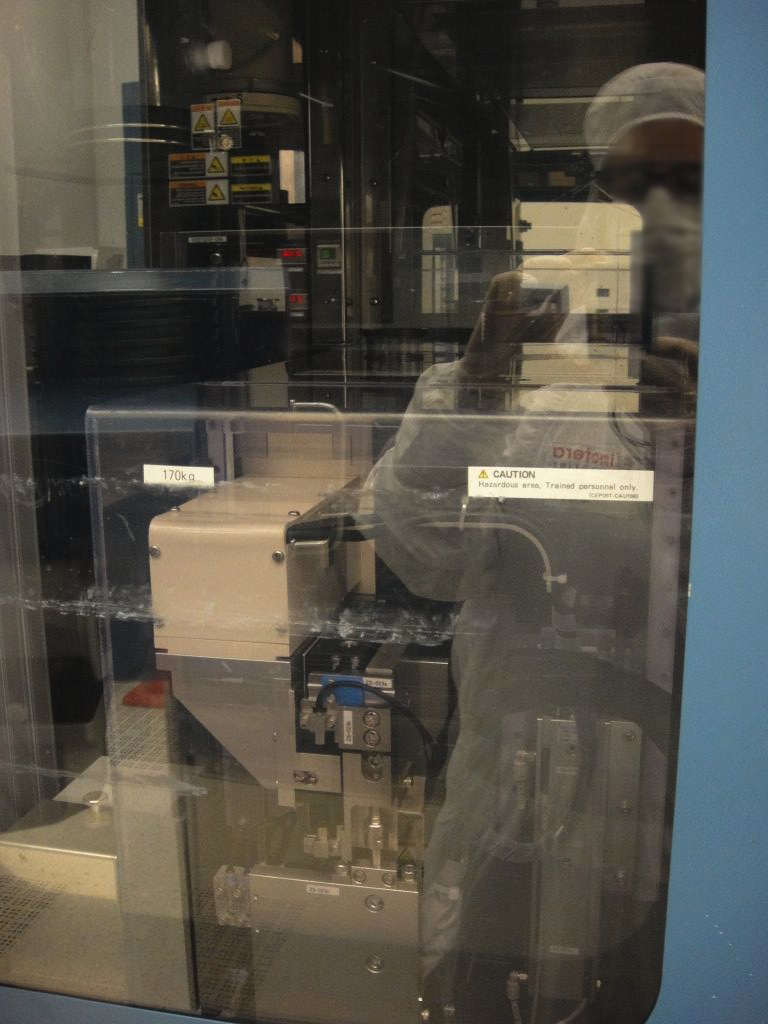

单击可缩放

ID: 9017351

晶圆大小: 12"

优质的: 2004

Poly / STI CMP system, 12"

Factory Interface (FI):

Frame config: metro ready

Load-port type: (4) Asyst ISO

Pre-aligner

Wafer handling robot: track type with dual end effecter

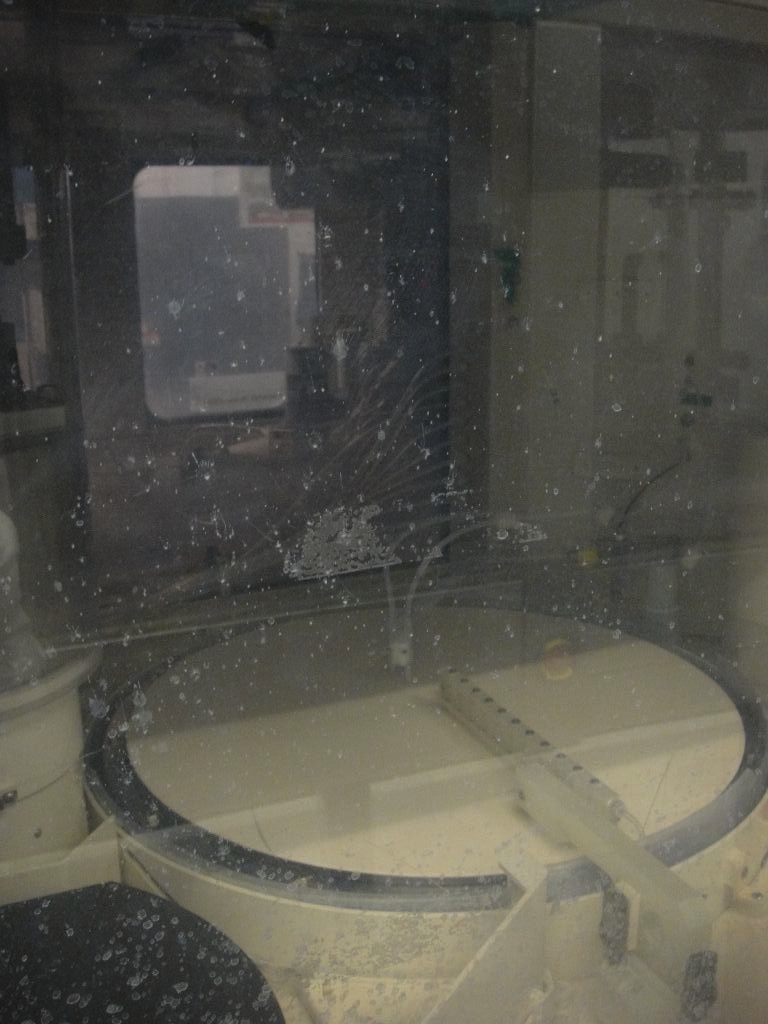

Polisher (L/R):

Process (L/R): STI

Polishing heads: 300 mm AL head, gen. II

Endpoint: TCM and friction

Platen type (speed): ceramic (SIC), 10-150 rpm

Pad type: IC1000

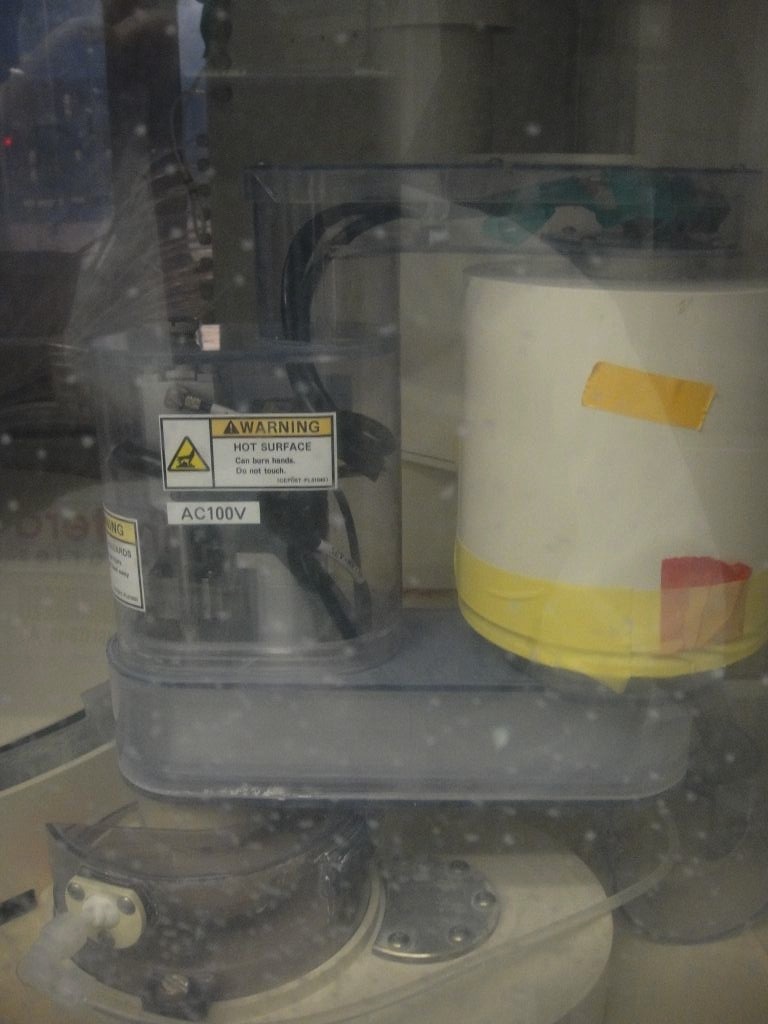

Platen pad conditioner: scan dresser 4” disc (3M 5122-AB), sweep driven

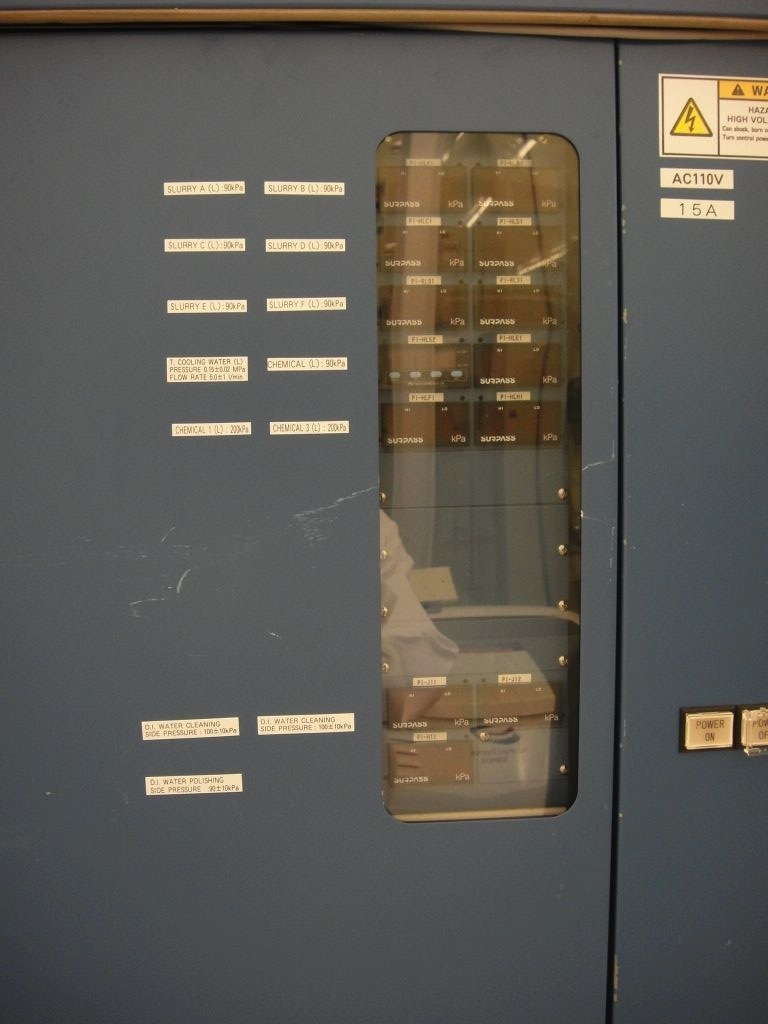

Slurry delivery: closed loop (CLC) delivery

Slurry flow range: 25-250 mL/min (low flow rate)

Slurry line 1: HS-8800

Slurry line 2: none

Slurry line 3: none

Wafer slip-out sensor: yes

Wafer loss camera: no

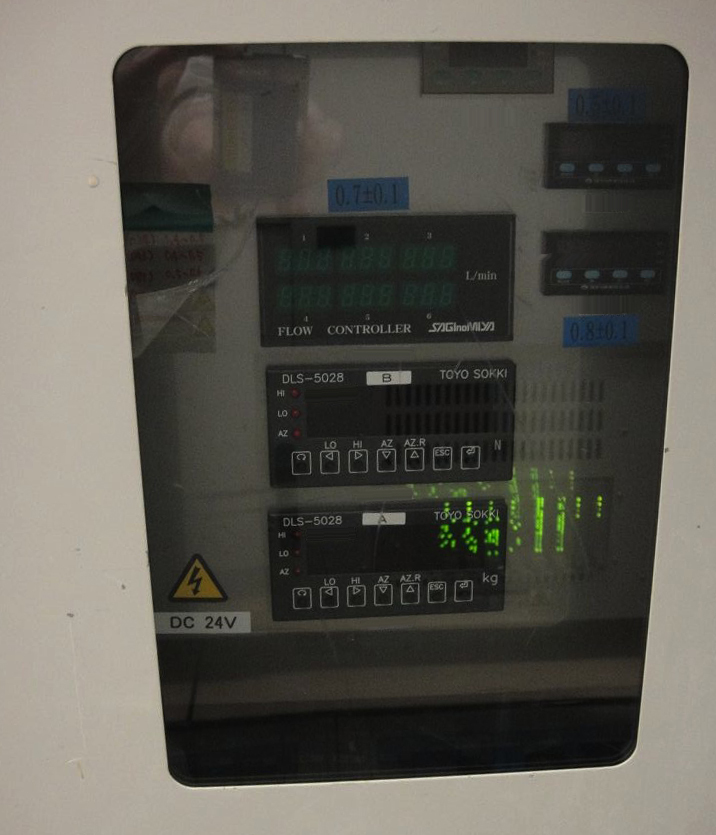

Platen cooling flow monitor: Tokyo KEISO

Platen cooling temp monitor: user configurable alarm settings

Dresser DIW flow meter: flow range 1.0-1.5 L/min

Atomizer: yes

Endpoint (L/R):

Table current monitor (TCM): yes

Multi-process monitor ME20 for EPD: yes

Metrology option: none

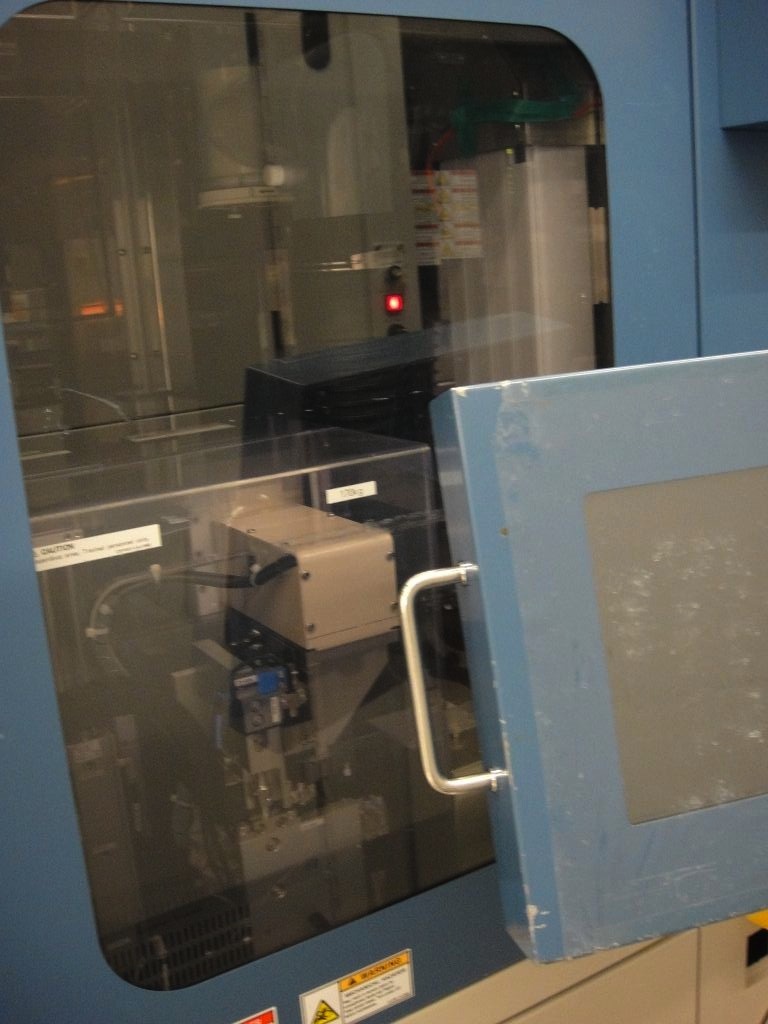

Cleaner (L/R):

Cleaner 1 type: roller brush

¬ Note: no megasonic

¬ Chem. delivery type: (1) chem CLC 0.0-1.0 L/min (alarm capability)

¬ Chemical 1 upper flow meter: 0.0-1.0 L/min

¬ Chemical 1 lower flow meter: 0.0-1.0 L/min

¬ Chemical line 1: HF

¬ Chemical line 2: n/a

¬ Bevel edge cleaning: yes

Spin rinse dryer: pencil brush

¬ Chem delivery type: (1) chem CLC 0.0-1.0 L/min (alarm capability)

Options:

Robot D: Yaskawa

Robot R: Yaskawa

Robot L: Yaskawa

Status lamp (RYGB, front/rear)

Monitor 1: front

Monitor 2: L-side

Monitor 3: R-side

EPD monitor: R-side

Software:

Main SW ver: 7.5.02

CPU-1 (OS/9) ver: 7.5.02

CPU-2 (OS/9) ver: 7.5.00

Touch panel control ver: 7.5.00

Touch panel drawing ver: 7.5.00

Online ver: 7.5.00

ME10/ME20 ver: 2.4.30.0

Communication:

Controller (logic): VME

Controller (process database): touch panel

Heat exchanger / chiller:

(1) Advanced Thermal Sciences SX-21

Facility:

Seismic support: bracket locations to be provided

Chemical connections: bottom

Exhaust connections: top

Gas connections: bottom

Drain connections: bottom

Power requirements: 208 VAC (3.4 kW) , 200 A, 3 phase, 3 wire+ground, 60 Hz

2004 vintage.

EBARA Frex 300是一种晶圆研磨、研磨和抛光设备,能够在高生产率下取得优异的效果。这种自动化系统的设计目的是使晶片的直径达到300毫米,高效可靠地产生优越的结果,精确度不超过1微米。该单元利用材料去除技术来达到最高水平的表面光洁度。它可以同时加工多种基材,并具有各种晶片的内置工艺参数。机器由图形用户界面(GUI)控制,便于操作和调整。当EBARA FREX-300与ELID(电解过程中敷料)磨削配合使用时,能够在许多类型的基材上实现较高的去除率。这一过程利用固定的金刚石砂轮来去除材料,然后使用不旋转的磨料垫来平整和完成工件。与传统的研磨方法相比,这提高了表面平整度。F-REX300配备了自动主轴更换器,允许在不同晶片和不同工艺之间快速过渡。该工具使用了广泛的研磨主轴和工具,以满足各种生产需求。主轴更换器是可编程的,能够快速准确地从一个操作移动到下一个操作。资产具有用于检查任何错误的自我诊断模型,以及用于帮助快速识别任何问题的可视警报。内置的安全措施旨在保护设备免受损坏,并确保晶片不会受到损坏。FREX-300还被设计为节能,能够通过使用高效的电机和先进的控制系统实现显着的节能。总体而言,EBARA F-REX300是一种先进的晶圆研磨、研磨和抛光系统,能够产生优异的精度和可重复性。此单元是大容量应用程序的理想选择,可为用户提供高效、可靠且经济高效的生产需求解决方桉。

还没有评论