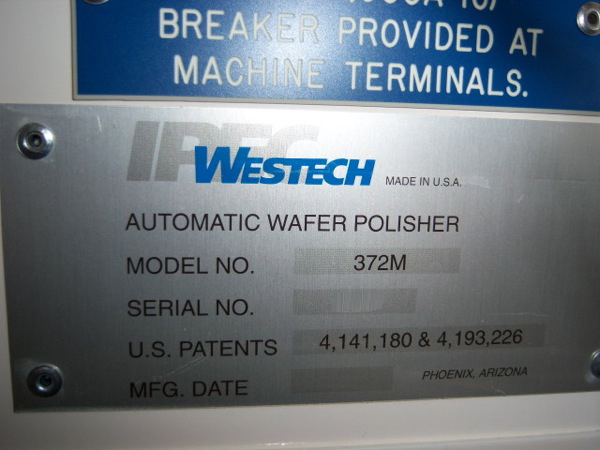

二手 IPEC / WESTECH / SPEEDFAM 372M #155037 待售

网址复制成功!

单击可缩放

ID: 155037

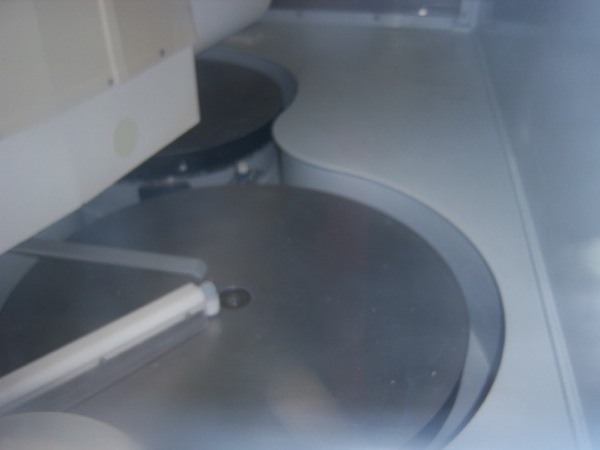

晶圆大小: 8"

ILD CMP Oxide/Poly Silicon/STI systems, 8"

Specifications:

Model 372 polisher mainframe

Novascan Model 210 thickness measurement system

32 bit Hardware Upgrade (Adtron Thincard system)

SECS I / II Host Computer Interface

Floppy Drive

Printer / Terminal Interface Software

Software-Controlled Process Variables with Hi/Low Limits

Dual Sensor Loadcup

SFI Load Station Sensor RFK

Gaard Arm pad conditioner

7.5 hp Final Platen Drive System

750 lb. Down-Force Polisher Arm

Closed-Loop Load Cell Down-Force Control

High-Pressure Primary Polish Station

TUFRAM-Coated Platen, 60 psi rating

Final Polish Station

TUFRAM-Coated Platen

1000 mL Flow Slurry Pumps (2 Primary - 2 Final)

Wafer Carrier Speeds (10-125 rpm)

Platen Speed (10-175 rpm)

Head Clean Station Quick-Dump Rinse Unit

Clean Station Float Sensor

Capacitance Level Sensor for Polish Tub

Slurry Manifold - BECO Valves

DI Manifold - BECO Valves

PRi compatible environmental hood

Moisture Sensor in Fluids Cabinet and System Base Interfaced

Process Chilled Water Temp Gauges and Flow Meters

Fluids Cabinet Exhaust

AWN Interface - Underneath

Mushroom-style Emergency Machine Off (EMO) Buttons

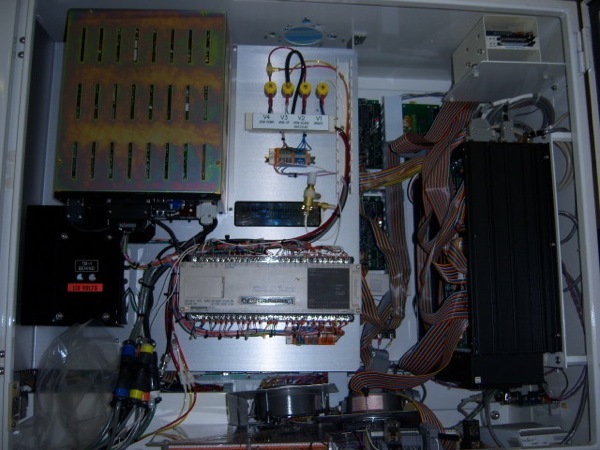

Electrical Cabinet

Heat-treated wood

Currently barrier bagged and crated.

IPEC/WESTECH/SPEEDFAM 372M是一种晶圆研磨、研磨、抛光设备,设计用于半导体晶圆加工。该机采用变速电机的三轴(x、y、z)级,产生均匀的研磨和抛光效果。它设计用于生产离散和连续晶片,最大晶片尺寸为3.2英寸直径。磨削、研磨和抛光系统具有许多高级功能,旨在确保精度和生产率。它配备了高度精确的3轴直流电动机驱动级以及步进电动机驱动,以确保精确和一致的研磨。该单元具有微处理器控制的研磨和研磨循环,可选择半径研磨、薄片研磨和晶圆研磨。它还配备了一个自动晶片装载机,并为每次操作选择了磨盘。除了其研磨、膝盖和抛光循环外,该工具还具有可激活的自动反向功能,以帮助防止材料粘在研磨介质上。它还具有可选的触摸感应功能,可监控资产温度和压力参数,以确保结果一致。此功能还有助于减少粒子堆积,因为它可以防止高速研磨循环。为了增加安全性,车型配备了多种防护功能。其中包括一个内置的紧急停止设备、一个超压阀和一个总运行时间功能,允许用户监控每次研磨操作的总运行次数。该系统还具有重量感应安全触发器,如果在磨盘上放置了太多的重量,就会关闭机器。此外,它还有一个芯片托盘和一个绝缘的护罩,以防止碎片被释放到环境中。总之,IPEC 372M是一种坚固的晶圆研磨、研磨和抛光装置,考虑到精度和安全性。它具有多种特性,旨在提高磨削操作的一致性和可重复性,同时提供额外的保护和精度。

还没有评论