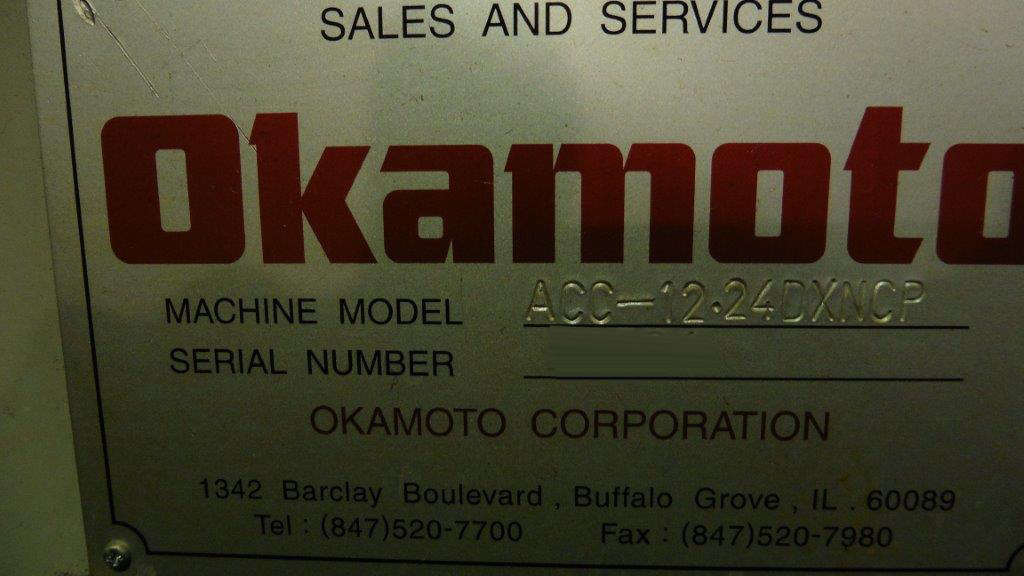

二手 OKAMOTO ACC-12-24DXNCP #9101611 待售

网址复制成功!

单击可缩放

ID: 9101611

优质的: 2007

CNC Profile surface grinder, 12" x 24"

FANUC 21i-MB CNC Control

Table capacity:

Nominal grinding capacity: 12" x 24"

Maximum height under 12" wheel: 13.6"

Longitudinal feed (X-Axis):

Table speed, infinitely variable: 3' - 82' Fpm

Maximum longitudinal table movement: 26.0" (Manual)

Feed per hand wheel revolution: 1.85"

Crossfeed (Z-Axis):

Maximum saddle travel: 9.0"

Intermittent traverse feed: 0.002" - 0.40" Ipm

Grinding feed: 0.001" - 40" Ipm

Rapid feed: 40" Ipm

Jog feed: 0 - 40" Ipm

Manual pulse generator: 0.00001", 0.0001", 0.001"

Grinding wheel:

Spindle motor: 5 H.P.

Wheel size: 12" Dia x 1.5" W x 5" B

Speed: 1,000 - 3,600 RPM

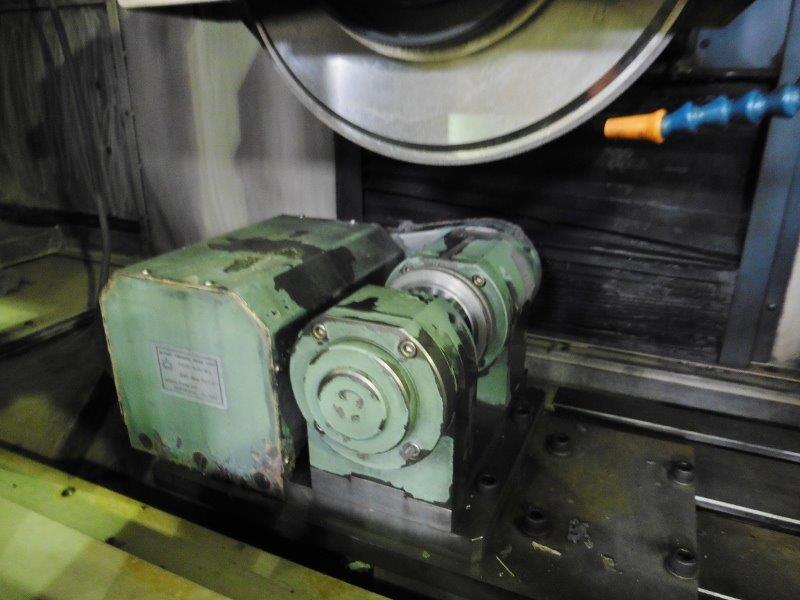

ASAHI Rdu-Wl Diamond rotary dresser

Oil temperature regulator unit

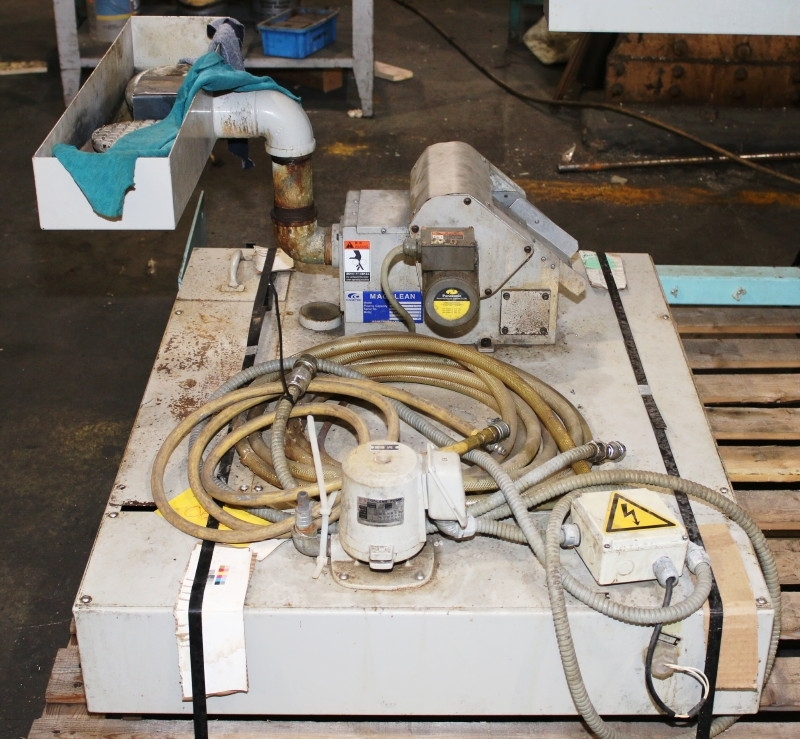

Coolant system with magnetic separator

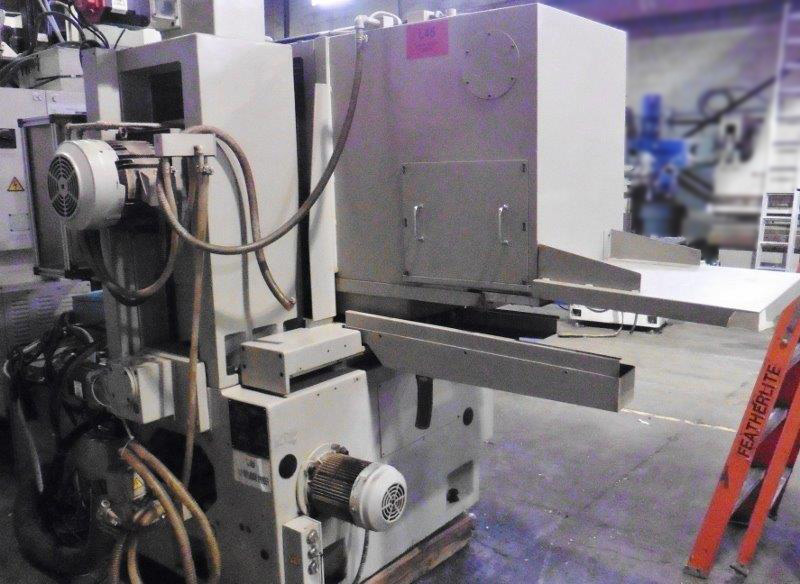

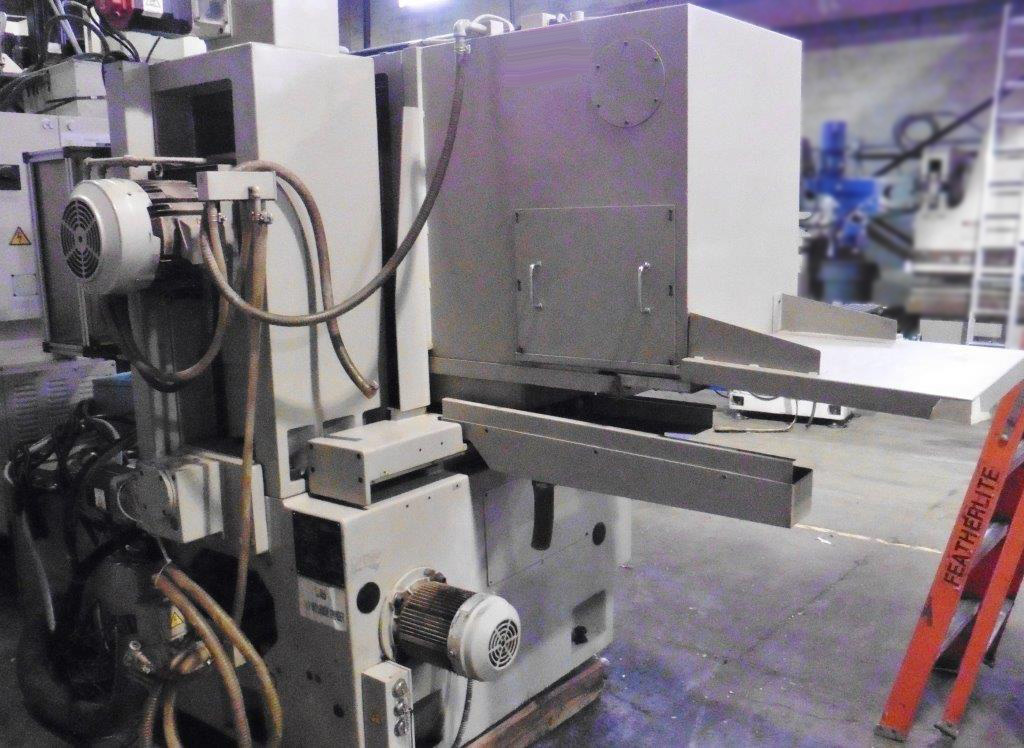

Machine tool enclosure

Case

Controlled axis: 2 Axis (2 SIM.)

3-Axis power operations

Minimum increment Y-axis (Vertical): 0.00001”

Z-Axis (Saddle): 0.00001”

Maximum programmable digits: ±8 Digits

Grind feed rate override: 0 - 150%

Rapid feed rate override: 0, 25, 50, 100%

Manual pulse feed increments: 0.00001, 0.0001, 0.001”

Preparatory functions: M-Codes (2-Digits)

Automatic acceleration / Deceleration

Manual continuous feed

Interpolation (Linear / Circular)

Dwell time

Machine lock

Skip function

Stored pitch error compensation

Dry run

Single block

Self-diagnosis function

Coordinate system setting

Pocket calculator type decimal point programming

Custom macro B (Option)

Inch / Metric conversion

Cutter compensation C

Input / Output interface: RS232C

Part program storage length: 262.5'

63-Registered programs

Built-in conversational programming system

Input programming system: Teach and drawing

Built-in conversational dress programming

Vertical and cross incremental feed

Automatic lubrication

Extended saddle and table ways

Double-walled column construction

Double vee way table and saddle construction

2007 vintage.

OKAMOTO ACC-12-24DXNCP是一种创新的晶圆研磨、研磨和抛光设备,旨在提高生产过程的吞吐量和质量。结合角度研磨概念,ACC-12-24DXNCP允许在单个腔室内的一个循环中同时研磨玻璃或硅片的两侧。OKAMOTO ACC-12-24DXNCP能够同时容纳多达24个晶片,它利用多种功能进一步增强研磨、研磨和抛光工艺。例如,该系统具有内置冷却剂切割流体和可调转速,以根据各种晶片、不同材料和用户喜好优化研磨效率。此外,ACC-12-24DXNCP还配备了集成和自动化的PLC(可编程逻辑控制器)研磨程序,通过简单的按钮控制提供动态精度和高速操作。集成的触摸面板显示屏可方便地访问单元参数,从而便于处理和缺陷分析。OKAMOTO ACC-12-24DXNCP设计具有振动、噪音和灰尘管理功能,以进一步提高用户的友好性。这些特性融合了获得专利的迷宫结构、先进的流体技术,以及一台可旋转的无油干空机,以尽量减少空气中的灰尘并减少产品污染,使其成为清洁环境的理想选择。ACC-12-24DXNCP还通过先进的研磨/抛光方法,如优化反射和先进的专业衍射研磨/抛光,进一步实现高水平的研磨和表面光洁度质量。最后,该工具通过多种用户模式、高级流程监控和可视化系统提供全面的流程控制和维护。总之,OKAMOTO ACC-12-24DXNCP是一项综合性资产,专门设计用于提高磨削、研磨和抛光过程中的产量和生产质量。提供用户友好、高效的界面以及各种先进的研磨和抛光方法以及维护功能,ACC-12-24DXNCP是许多工业应用的可靠且经济高效的选择。

还没有评论