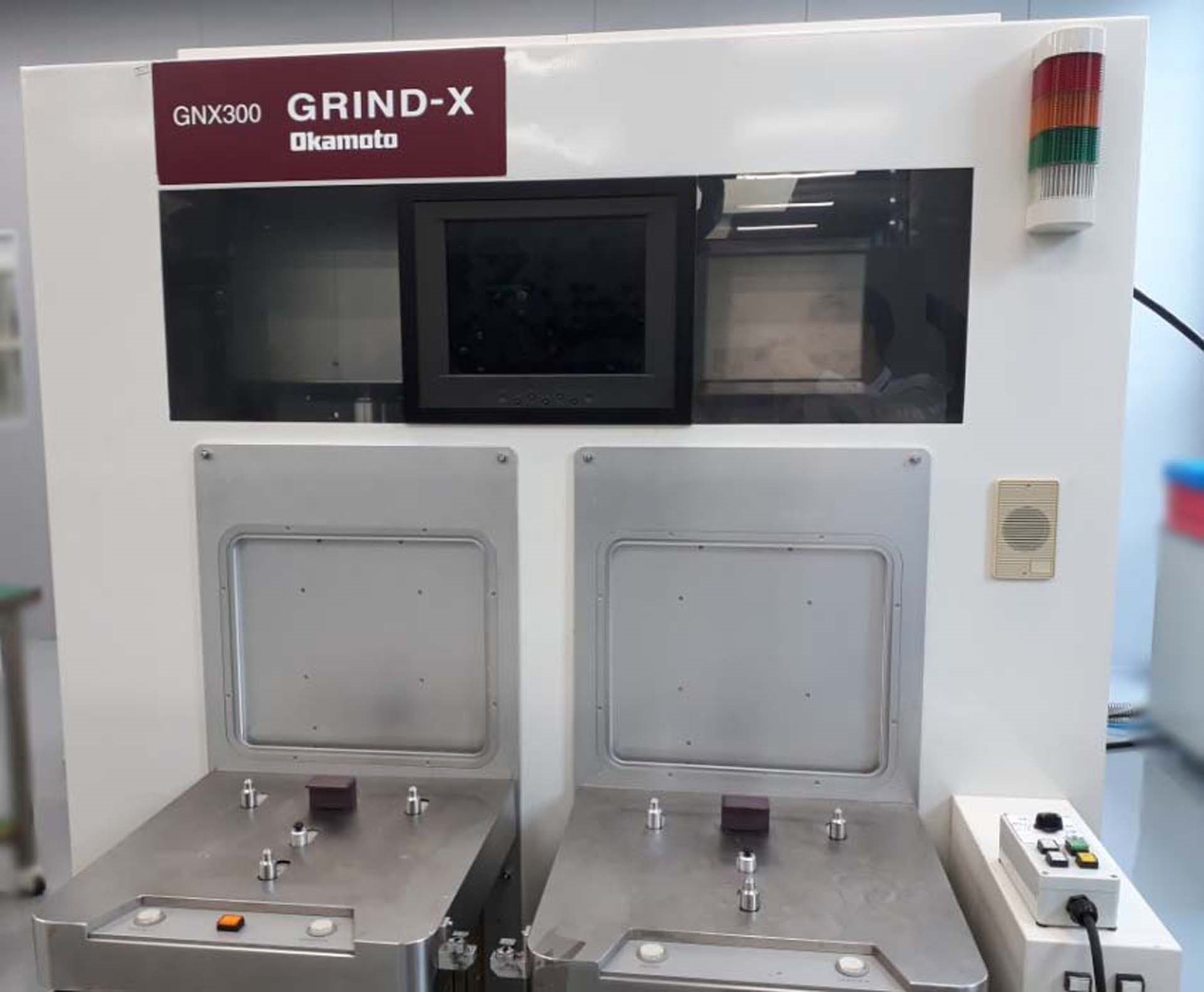

二手 OKAMOTO GNX 300 #9039632 待售

网址复制成功!

单击可缩放

ID: 9039632

晶圆大小: 8"-12"

优质的: 2001

Wafer back grinder, 8"-12"

Grinding mode: Continuous down feed

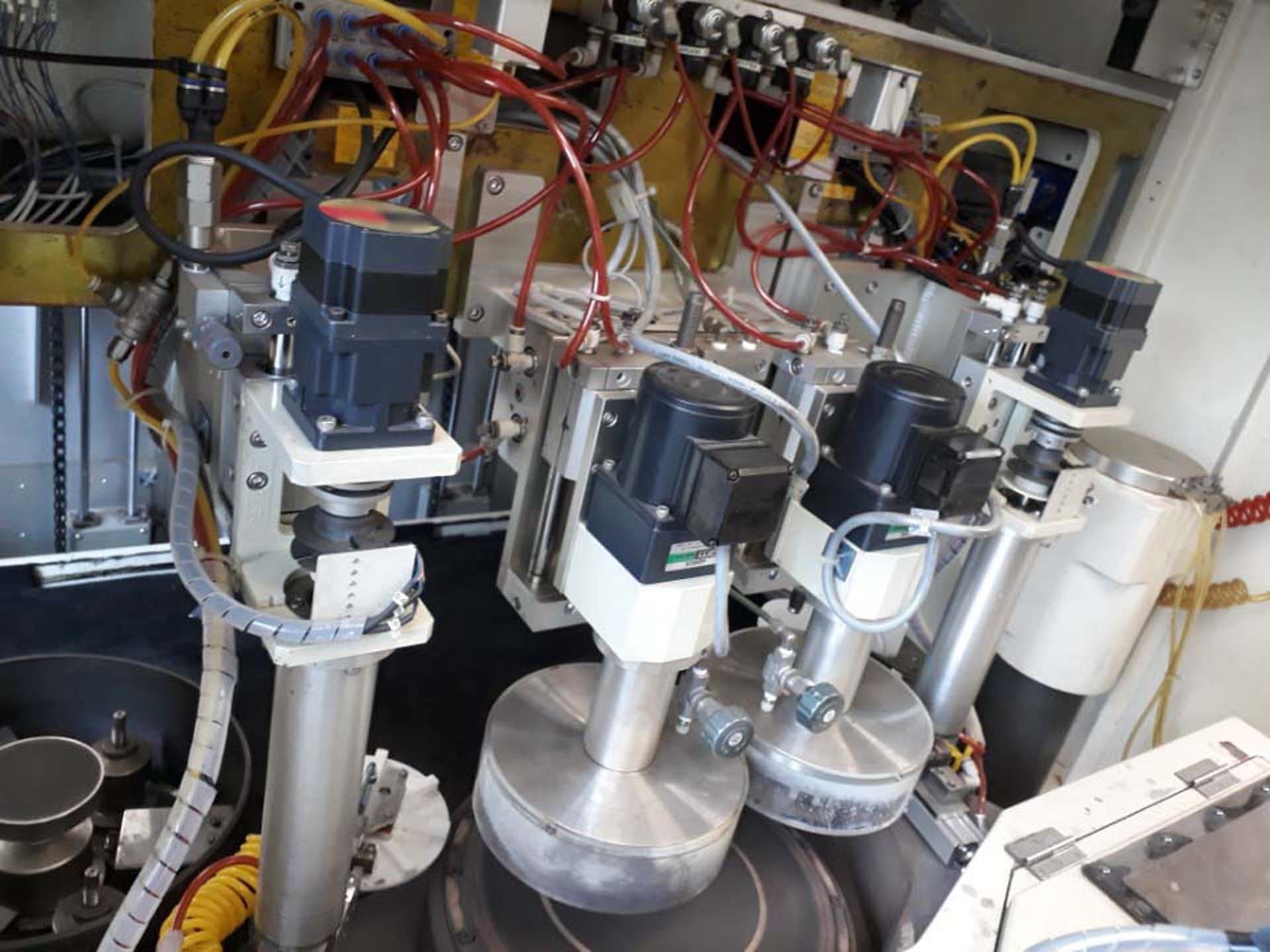

2-Axes grinding spindle

Rotation speed: 3,000 RPM Maximum

Bearing: Air bearing

Motor: 5.5 kW built-in motor

Cooling method: Water cooled

Maximum vertical stroke: 4"

Vertical fast-grind speed: 8" per minute

Grinding speed: 1 to 999 um per minute

Grinder, 12"

Grinding resistance reading:

Monitoring current

Output to CRT

Horizontal angle adjustment: Manual

Maximum radial load capacity: 30 kgf

Maximum axial load capacity: 150 kgf

Air consumption: (2) 20 L per minute

Index table:

(3) Vacuum chucks

Vacuum chuck material: Porous ceramic

Vacuum chuck rotation motor: (3) 1.0 kW AC Servo motors

Vacuum chuck rotation speed: 400 RPM Maximum

Chuck bearing: Air bearing

Maximum radial load capacity: 30 kgf

Maximum axial load capacity: 150 kgf

Air consumption: (3) 36 L per minute

Auto measuring device:

Wafer thickness measurement method: Two-point in-process gauge

Wafer thickness setting method: Final

Wafer thickness displaying range: 1.8 mm

Table cleaning unit:

Cleaning method: Water and ceramic ring

Wafer cleaning unit:

Cleaning method: Water and brush operation panel

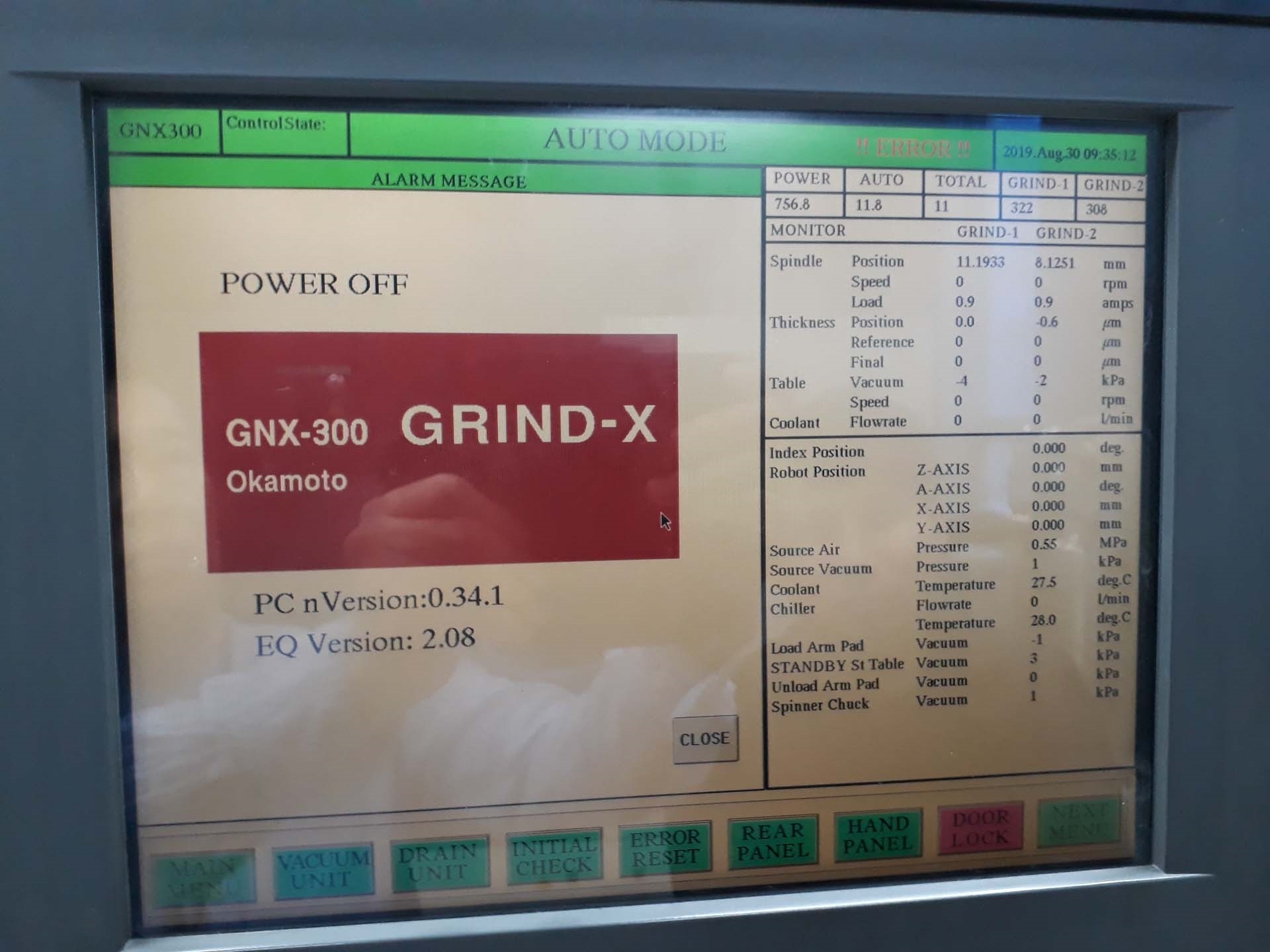

Display method: 15" TFT Color touch panel

Air supply:

Consumption: 160 NL Per minute

Pressure: 0.49 to 0.78 MPa

Dew point: -15°C or lower

Oil removal rate: 0.1 PPM W/W

Grinding water:

Water used: DI Water

Pressure: 0.34 to 0.49 MPa

Flow rate: 10 L per wafer

Cooling water for vacuum pumps and spindles:

Water used: City water

Pressure: 0.19 to 0.49 MPa

Flow rate: 10 NL Per minute

Mist separator duct / General exhaust:

Exhaust rate: 2 m³ per minute

Vacuum pump duct / General exhaust:

Exhaust rate: 75/90 m³/h, 50/60 Hz

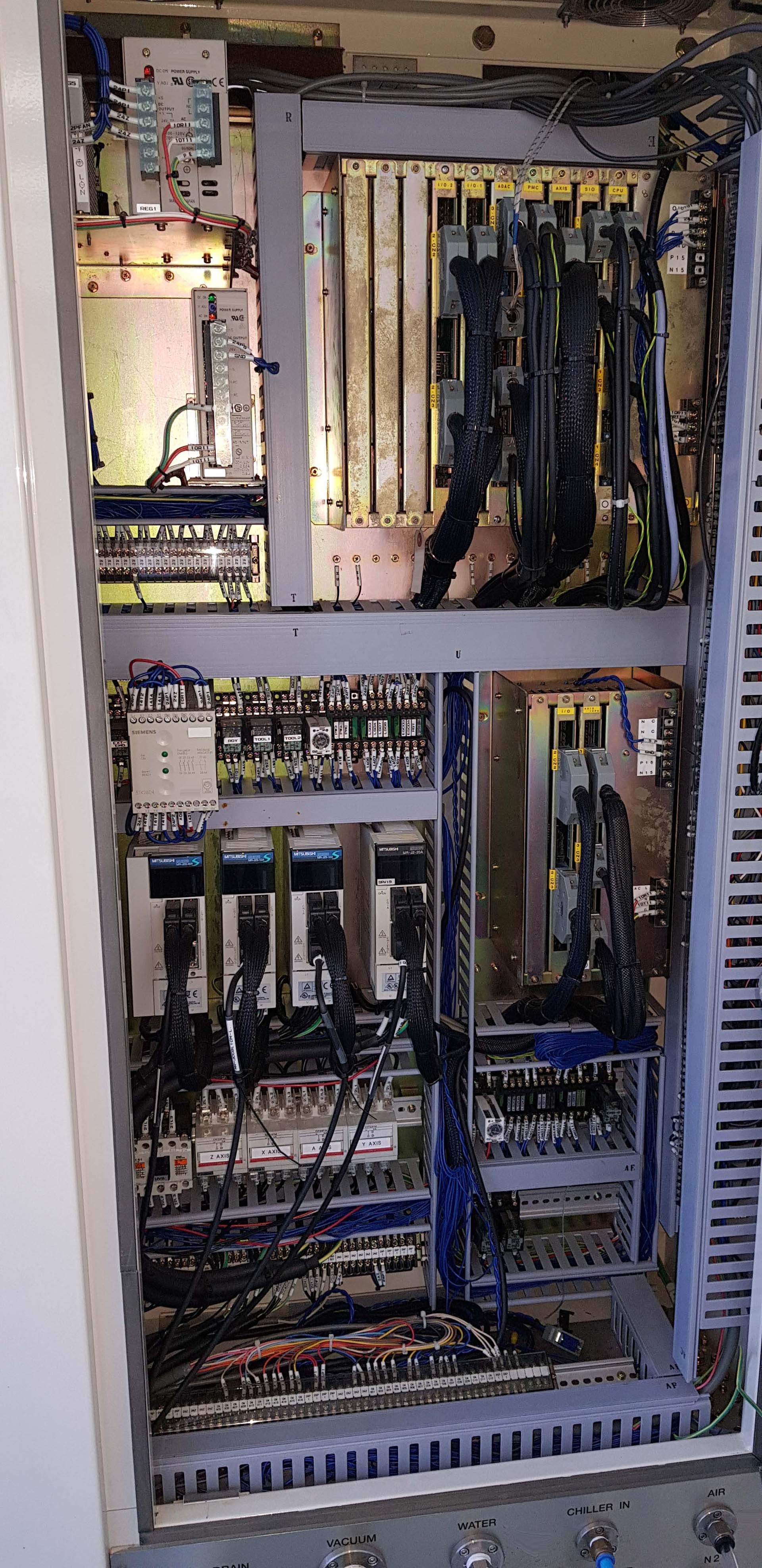

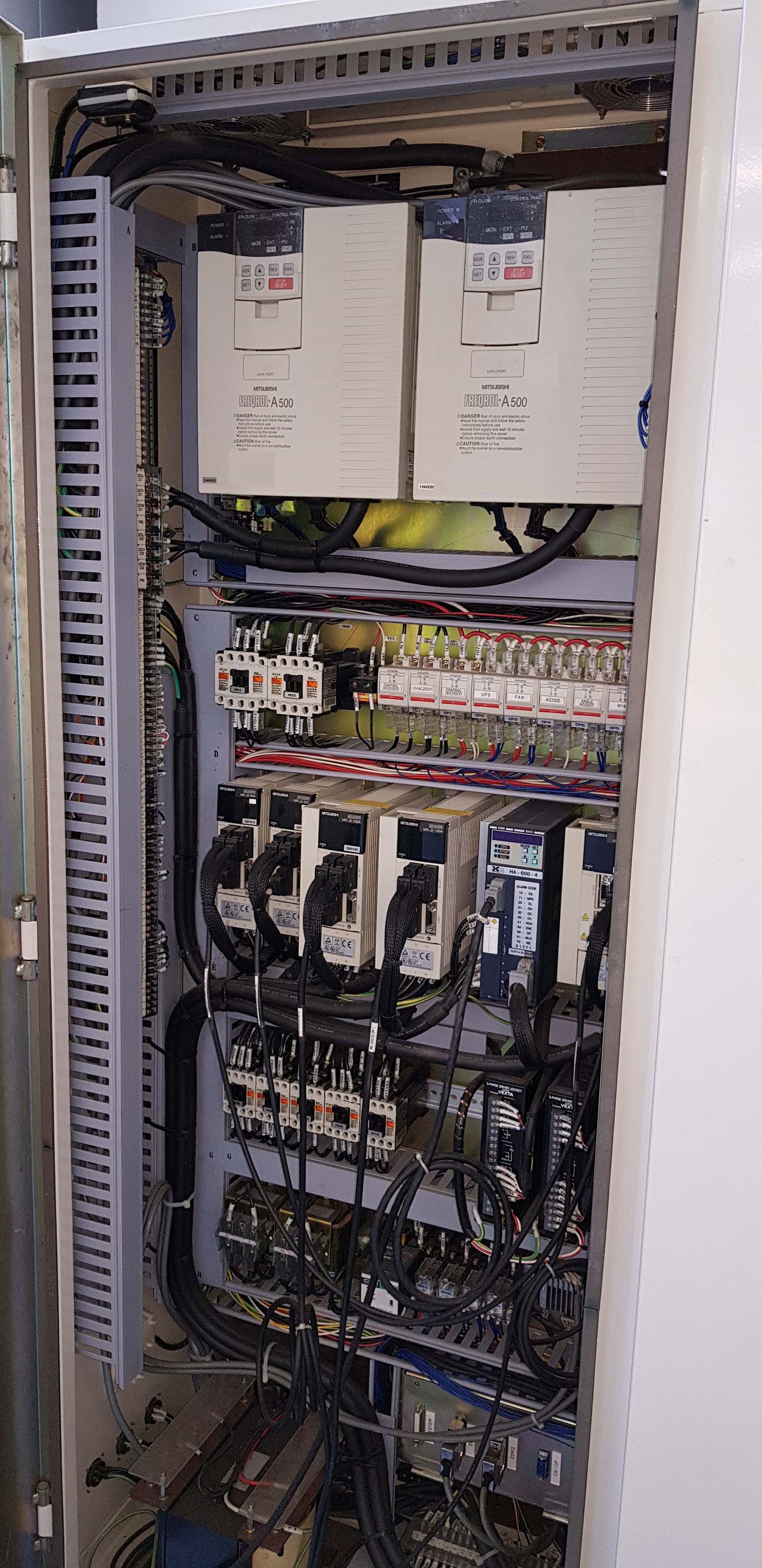

Power supply:

Input power: 200V +/- 10%, 3-Phase, 50/60 Hz

Power consumption: 20 kVA

Grounding: Ground resistance JIS Type-3 100 Ohms or lower

2001 vintage.

OKAMOTO GNX 300是一种最先进的晶圆研磨、研磨和抛光装置。这台机器是专为半导体工业而设计的,因为它在单面和双面双层晶片上都具有很高的光洁度。这使得它非常适合生产前沿集成电路。该机具有强大的驱动电机和行星磨盘,能够将半导体晶片磨削到极高的平坦度和精确度。研磨圆盘具有很高的同心度,可以研磨成片,精确度为1到2 µm。此外,研磨圆盘可以在各个方向上进行调整,以便在该过程中获得最佳的冲压角度。OKAMOTO GNX300配备了两个工作头,每个头可以针对晶圆表面预选的研磨角度单独调整。这为操作员提供了优越的控制,并确保了均匀的研磨质量.它可以用于不同尺寸的晶片。此外,该机还配备了变速范围的主轴。这样可以更精确地进行研磨和抛光操作。主轴转速高达4,000 rpm,在研磨和抛光时确保良好的工艺控制。此外,该机器还内置了传感器,用于监视过程中的负载情况并保护机器免受任何潜在的过载。这有助于减少停机时间,并有助于保持生产顺利进行。该机还集成了先进的晶圆处理系统。它有特殊的处理手指,轻轻的轻轻地轻轻,防止在研磨和抛光操作过程中造成的伤害。它还具有低真空棒,保持低大气压力,以更好的过程控制。机器有一个摆臂,有助于将晶片从加载区域轻松移动到加工室,使操作更加高效。最后,该机器配备了先进的软件,帮助操作员密切监测和控制磨削和抛光过程。该软件可用于对过程进行编程、设置浆料参数和实时监控过程。实时监控过程可确保一致的高质量过程。conclusion,GNX-300是一种先进的晶圆研磨、研磨和抛光系统,能够为前沿集成电路提供准确和一致的结果。该机结合了强大的电机和行星磨盘,以确保在高水平的平整和精确度研磨。它还具有内置传感器和先进的晶圆处理系统,以实现更平稳的操作。

还没有评论