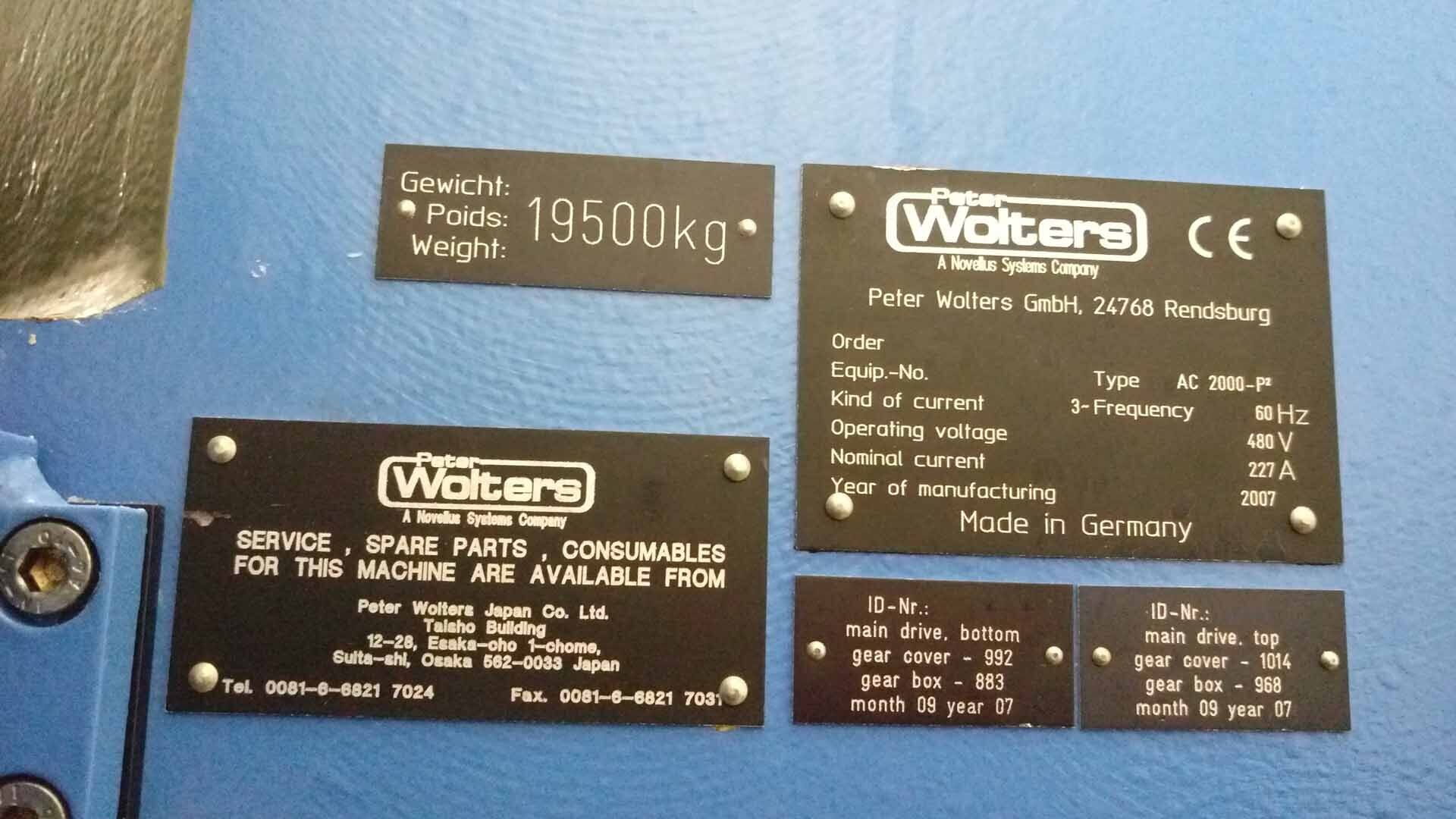

二手 PETER WOLTERS / LAPMASTER microLine AC 2000-P2 #9352425 待售

看起来这件物品已经卖了。检查下面的类似产品或与我们联系,我们经验丰富的团队将为您找到它。

单击可缩放

已售出

ID: 9352425

晶圆大小: 12"

优质的: 2007

Double side polishing machine, 12"

Wheel dimensions:

Outer: 1935 mm

Ring width: 686 mm

Thickness: 80 mm

Wheel distance: 190 mm With 80 mm wheel thickness

Pneumatic:

Maximum load pressure: 3500 daN

Compressed air: 6,5 Bar

Electronic equipment:

Servo drives digitally controller

Upper wheel: 46 kW/40 min⁻¹

Lower wheel: 46 kW/40 min⁻¹

Inner workpiece drive: 7,5 kW/min⁻¹

Outer workpiece drive: 7,5 kW/min⁻¹

Hold the drive aggregates for lower working wheel and workpiece drive

Electromechanical height adjustment for outer and inner pin ring

Splash guard pan

Assembly connections for easy access

Pneumatic load control

Interception device

Weighting device

Drives

Working wheels

Safety device

Corrosion resistant design

Electric switch cabinet (Air cooled)

CNC Controller

Operating panel

Polishing media connection and metering

Slurry distribution system

Polishing media collecting channel

Tool kit

Basical range of CNC Control S7-400 With visualization

Pressure control via proportional valve and pressure sensor

Display of the actual pressure value

13-Pressure ranges

Variable speed of rotation change in each pressure range of each drive

Variable change of rotation direction

Automatic swiveling in / out

5-Conditioning program with recorded inception heights

Alternative list for selective programming functions:

Swiveling device

Starting of the drives

Feeding of the polishing media

Wet mode

0020: Brush program

0030: Cooling water temperature monitoring

0040: Rinsing and spraying device (Chemical polishing)

0050: Spraying device

0060: Levelling device for horizontal adjustment of the upper working wheel

0070: Epicyclic work holder drive system

0080: (2) Polishing wheels

0090: Back up

Options:

0100: Power backup

0110: Polishing compound connection

0120: Cable identification

0130: Mixing block

0140: Taiwan electrics

Electrics: 460 V

UPS: 230 V

0150: Packing

0160: Commissioning

0170: Status light

0180: Loading counter

0190: Second hand operation station

0200: Shower guns for DI- Water

0210: (2) Heating / Cooling aggregate (WRK) 12760 W

0220: Heating / Cooling aggregate Heating possibility up to 55°C

0230: Fittings for cooling water circulation system with refrigeration unit

0240: 6-Step polishing program

0260: Fiberglas cable

0270: Separate drive security

0290: Signal tower with LED

0300: Indication of signal tower

0310: Upgrades

0320: 80-Polishing feed holes

0330: Anti-syphoning package

0340: Measuring device (Flatness)

0350: Distance block set

0360: Steel straight edge, 2000-0 mm

0370: Additional cable length

0380: Engineering costs

0390: PDR System

Power supply: 400 V + 6%-10% (Acc. DIN IEC 38)

Frequency: 50 Hz

Control voltage: 203 V / 24 VDC

2007 vintage.

LAPMASTER AC 2000-P2是一种用于半导体晶片的晶片研磨、研磨和抛光设备。它是一种精密仪器,具有计算机化控制器、模块化无错误主轴传动装置以及多种优质磨料和快速更换安装在工业级花岗岩基座上。该系统设计处理200-300毫米晶圆研磨,精度和重复性最高。交流2000-P2采用两阶段研磨和抛光工艺。每个阶段分为两个部分:第一阶段由一个安装站、一个晶圆夹板和一个坚固的研磨轮组成。第二阶段采用不同的研磨轮,具有抛光垫支架和粗细的研磨剂。这两个阶段都包括变速调整,允许操作员根据需要增加或降低速度。交流2000-P2还设有计算机化控制器,为操作员提供详细数据,包括运行时间、进程设置、自动关闭和机器状态指示灯。控制器极具弹性,可以接受广泛的输入选择选项,例如手动、半自动和全自动模式。该单元还提供压力、滑移和振动极限调节等可调节参数,以确保最高的工艺精度。该机还有一个集成的除尘工具。空气叶片清除产生的磨料灰尘,同时将其放置在机器外部。尘埃收集网也有可调的设置,以满足最严格的颗粒要求。PETER WOLTERS AC 2000-P2配备了可提供高精度操作的模块化无错误主轴驱动器。这种精密的设计结合了人体工程学和交流电机技术的原理,提供了可靠和安全的操作。资产还包括各种可选模块,例如用于晶圆夹紧和超压控制的空气单元,以及高精度的振动保护模型。这些特性使得PETER WOLTERS/LAPMASTER AC 2000-P2一种高精度晶片量产的理想机器。其精密的工程设计和灵活性提供了真正的"一体"设备,能够研磨、抛光、吹风以及生产过程中所需的任何其他改进。系统的控制器使操作员能够完全控制过程,从而实现卓越的过程质量。交流2000-P2是寻找制造半导体晶片的可靠装置的生产商的理想选择。

还没有评论