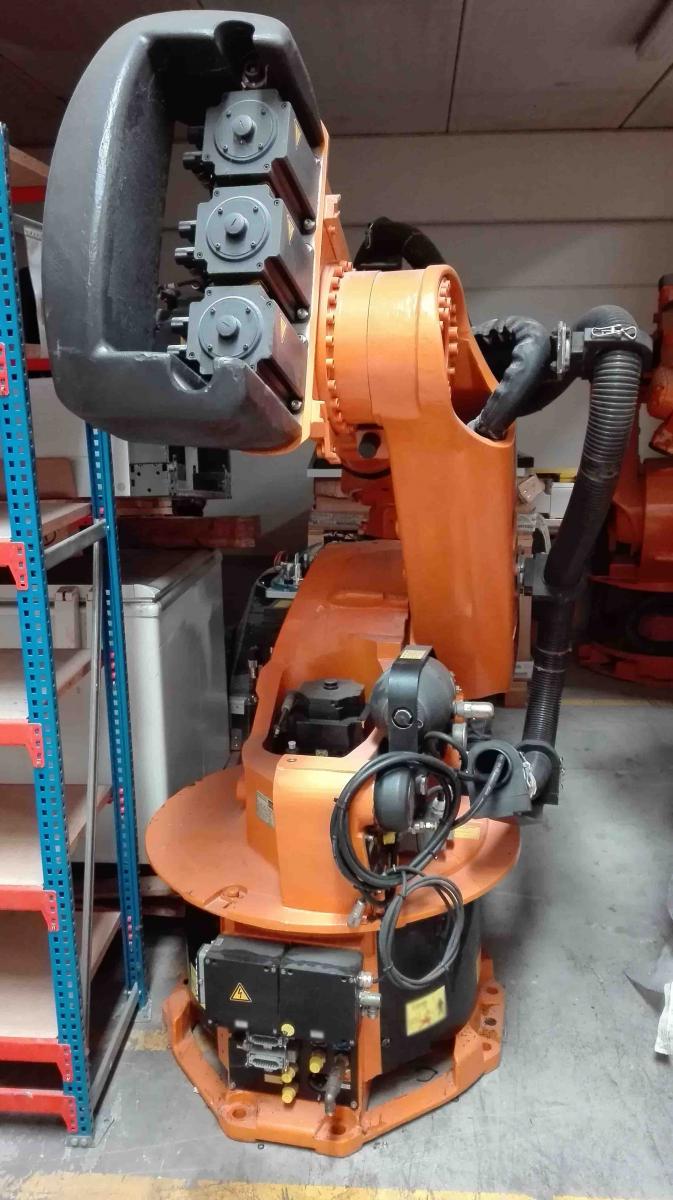

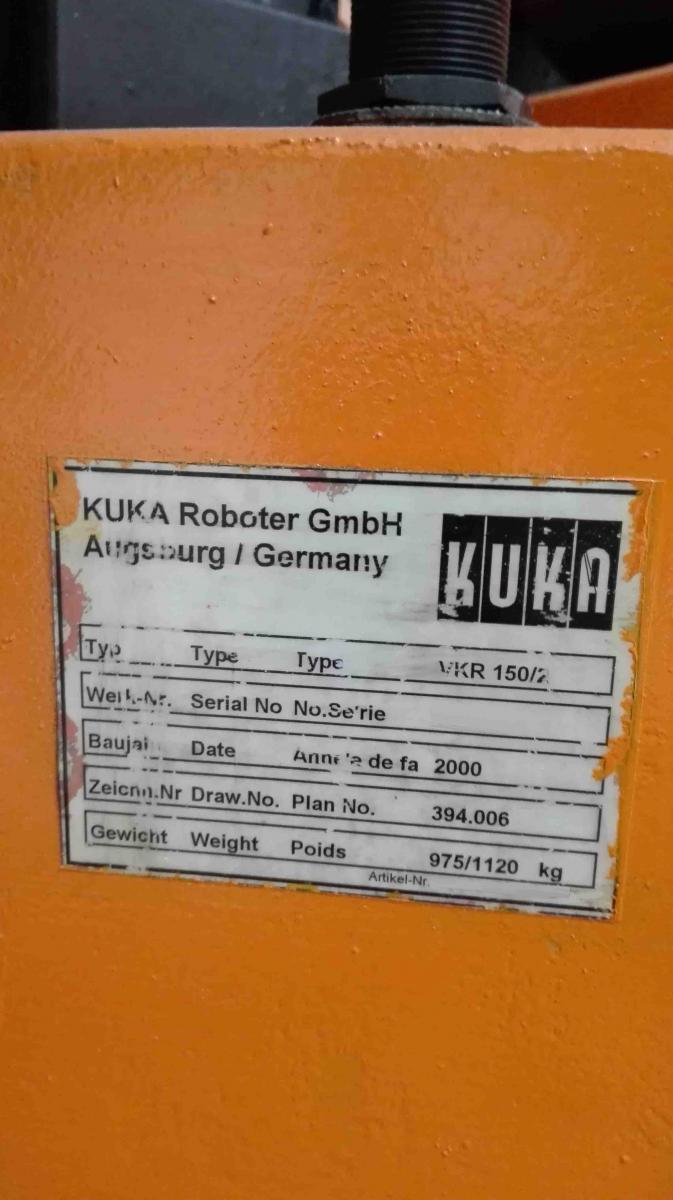

二手 KUKA Series 2000 #9180904 待售

网址复制成功!

单击可缩放

ID: 9180904

优质的: 2000

Robot

(5) Rating classes

Payloads: 150 to 270 kg

Different arm extensions

Mounting variants for the ceiling / floor

Repeatability: ±0.06 mm

Type: KR 150-2:

Maximum reach: 2,700 mm

Rated payload: 150 kg

Suppliment load, arm/link arm/rotating column: 50 / 100 / 300 kg

Suppliment load, arm + link arm, maximum: 100 kg

Maximum total load: 550 kg

(6) Axes

Mounting position: Floor, ceiling

Variant: Cleanroom, foundry

Positioning repeatability: ±0.06 mm

Controller: KR C2 edition2005

Temperature during operation: +10°C to +55°C

Protection classification: IP 65

Robot footprint: 1,006 mm x 1,006 mm

Connection: 7.3 kVA

Noise level: < 75 dB

Type: KR 150 L130-2:

Maximum reach: 2,900 mm

Rated payload: 130 kg

Suppliment load, arm/link arm/rotating column: 50 / 100 / 300 kg

Suppliment load, arm + link arm, maximum: 100 kg

Maximum total load: 530 kg

(6) Axes

Mounting position: Floor, ceiling

Variant: Cleanroom, foundry

Positioning repeatability: ±0.06 mm

Controller: KR C2 edition2005

Temperature during operation: +10°C to +55°C

Protection classification: IP 65

Robot footprint: 1,006 mm x 1,006 mm

Connection: 7.3 kVA

Noise level: < 75 dB

Type: KR 150 L110-2

Maximum reach: 3,100 mm

Rated payload: 110 kg

Suppliment load, arm/link arm/rotating column: 50 / 100 / 300 kg

Suppliment load, arm + link arm, maximum: 100 kg

Maximum total load: 510 kg

(6) Axes

Mounting position: Floor, ceiling

Variant: Cleanroom, foundry

Positioning repeatability: ±0.06 mm

Controller: KR C2 edition2005

Temperature during operation: +10°C to +55°C

Protection classification: IP 65

Robot footprint: 1,006 mm x 1,006 mm

Connection: 7.3 kVA

Noise level: < 75 dB

Speed with rated payload: 150 kg

Axis data Range (s/w) Speed with rated payload

Axis 1 (A1) ±185° 110°/s

Axis 2 (A2) 0°/–146° 110°/s

Axis 3 (A3) +155°/–119° 100°/s

Axis 4 (A4) ±350° 170°/s

Axis 5 (A5) ±125° 170°/s

Axis 6 (A6) ±350° 238°/s

Speed with rated payload: 130 kg

Axis data Range (s/w) Speed with rated payload

Axis 1 (A1) ±185° 105°/s

Axis 2 (A2) 0°/–146° 110°/s

Axis 3 (A3) +155°/–119° 95°/s

Axis 4 (A4) ±350° 170°/s

Axis 5 (A5) ±125° 170°/s

Axis 6 (A6) ±350° 238°/s

Speed with rated payload: 110 kg

Axis data Range (s/w) Speed with rated payload

Axis 1 (A1) ±185° 105°/s

Axis 2 (A2) 0°/–146° 110°/s

Axis 3 (A3) +155°/–119° 93°/s

Axis 4 (A4) ±350° 170°/s

Axis 5 (A5) ±125° 170°/s

Axis 6 (A6) ±350° 238°/s

2000 vintage.

KUKA Series 2000自动化晶圆处理器是一种集成到通用工业机器人系统中的机械臂。它能够处理直径达18英寸的晶片,以及精细的光电元件。手臂配有确保精确运动的高分辨率编码器和用于晶圆处理的真空吸盘工具,以保护易碎部件。真空吸盘工具具有很高的柔韧性,可以配置为接受不同形状和大小的晶片。Series 2000的可伸展臂最大可达8英寸,重复精度高达0.015毫米。它配备了先进的晶圆边缘精确识别视觉系统,以及晶圆闭塞检测的图像处理程序。使用KUKA KUKA Studio软件的工业级PC运行机器人手臂并确保可靠的操作。KUKA Series 2000能够执行广泛的晶圆处理任务。它能够从不同来源拾取晶片,转移到各个阶段,进行精确定位操作。它还可以以互补的方式对齐晶片,如完美的精细对齐和预对齐。再者,它配备了一个快速的下降和选择机制,允许一次快速操纵多个晶片。Series 2000广泛应用于半导体和光子学行业。它为恶劣工业环境中的精确晶圆处理操作提供了可靠、准确的解决方桉。它用途广泛、可靠,由轻巧但坚固的组件组成,并且需要最少的维护。由于体积小巧,KUKA Series 2000可以轻松地集成到现有生产线中,并用于新工艺和现有工艺。

还没有评论