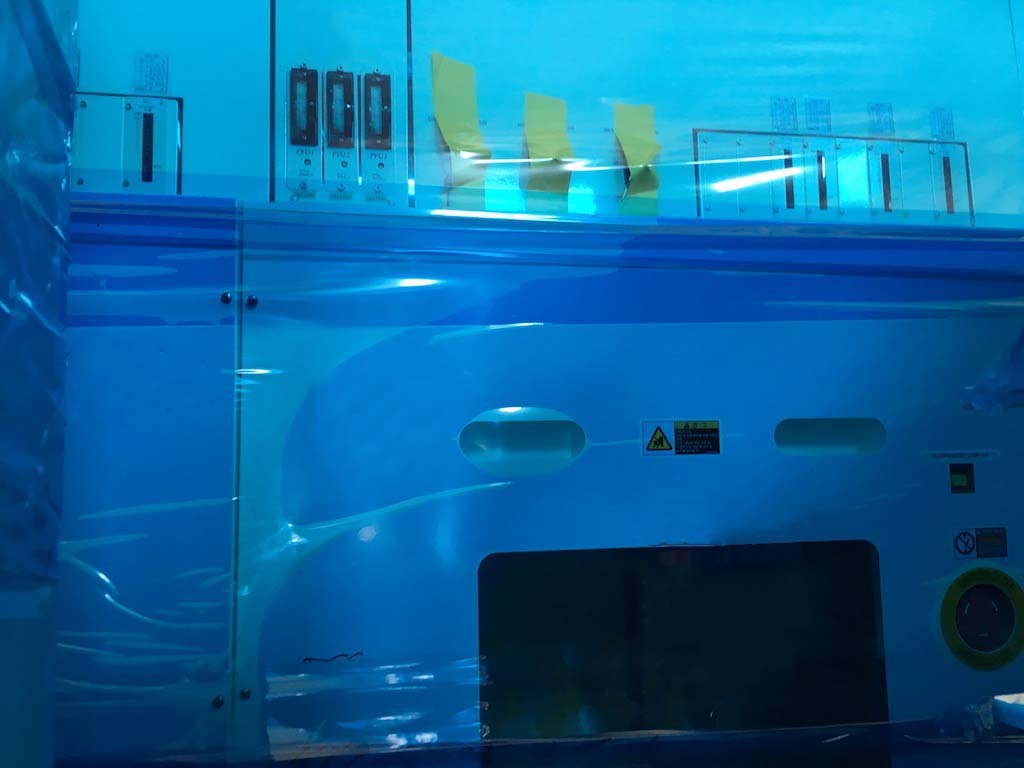

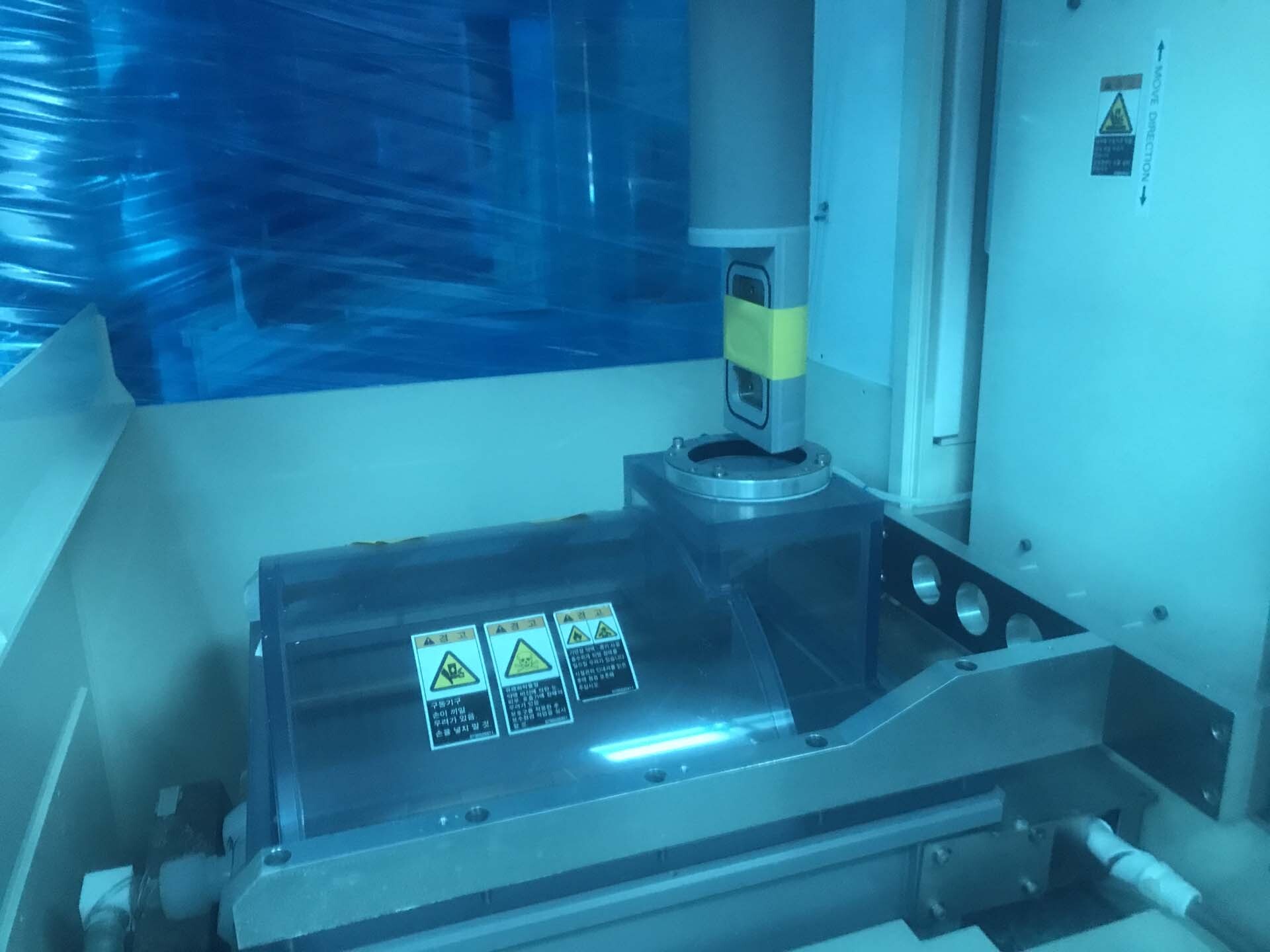

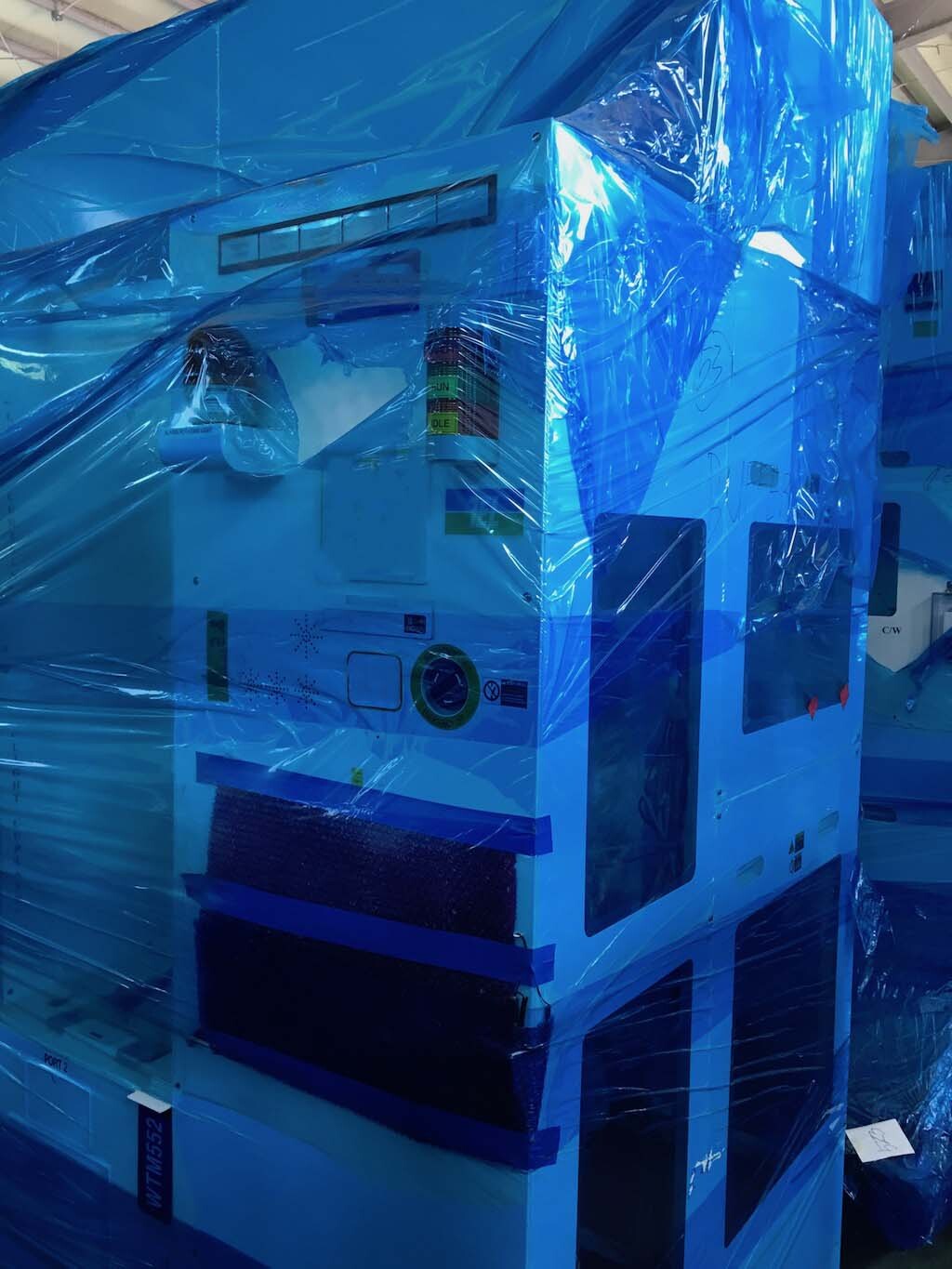

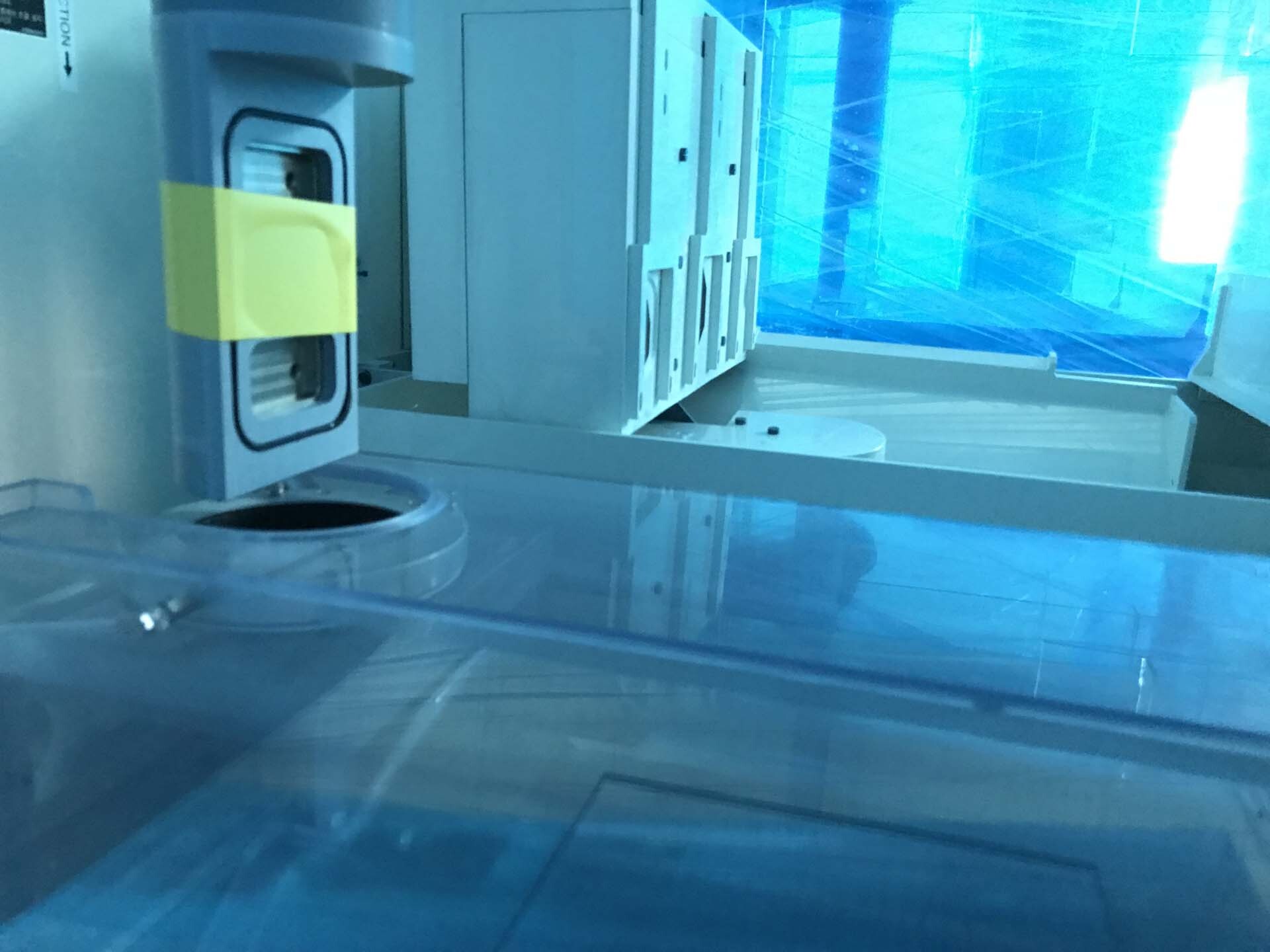

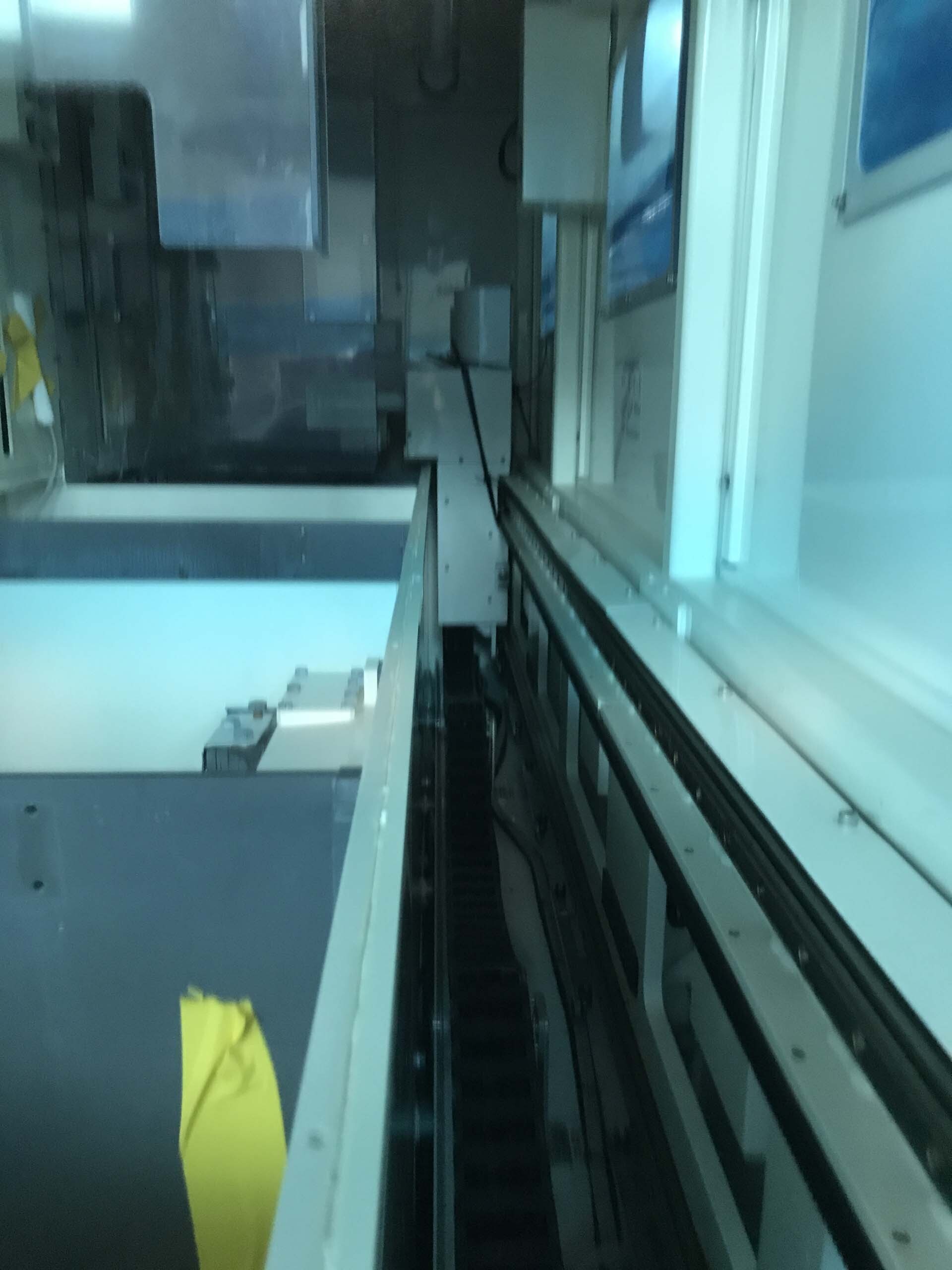

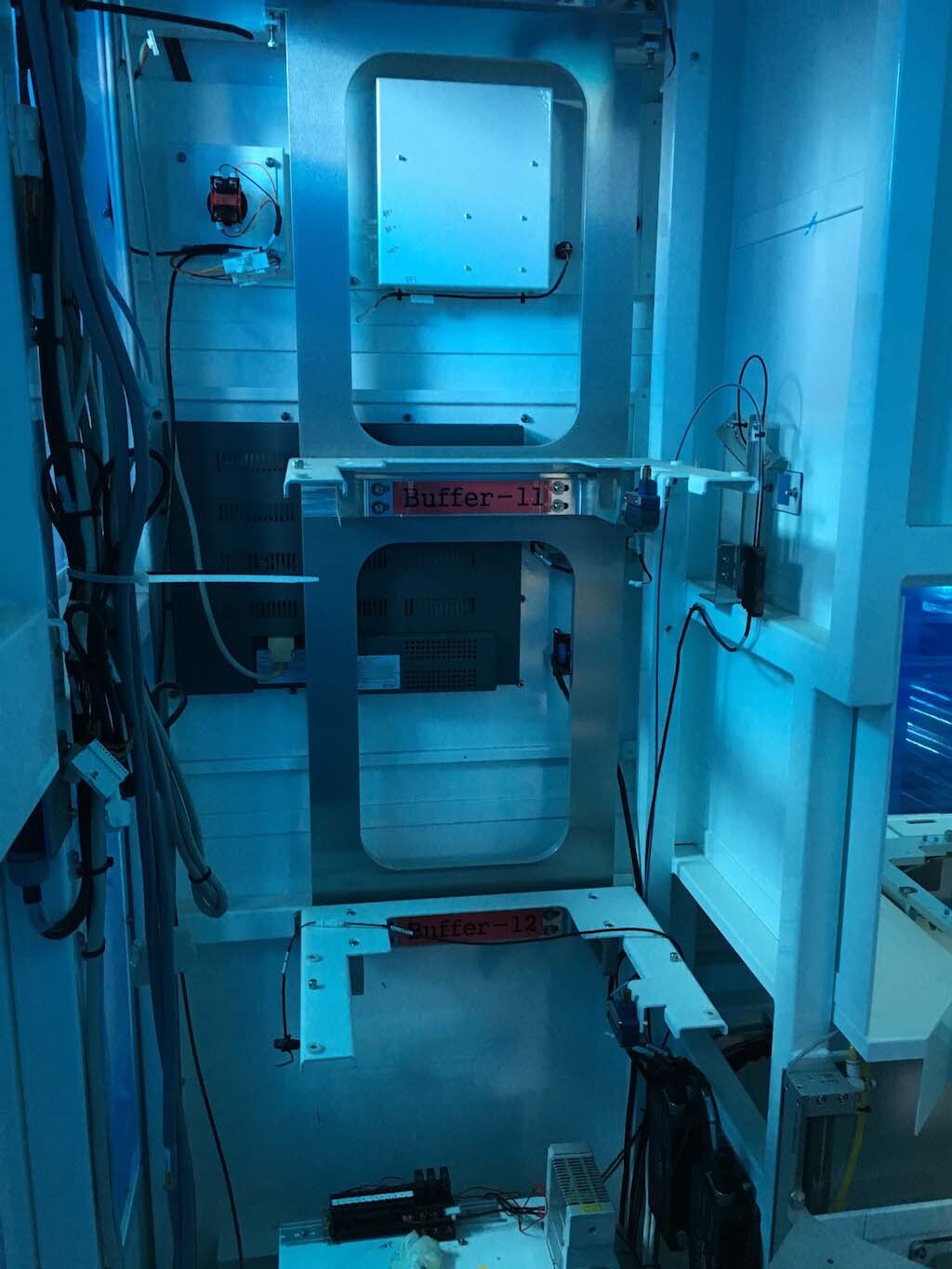

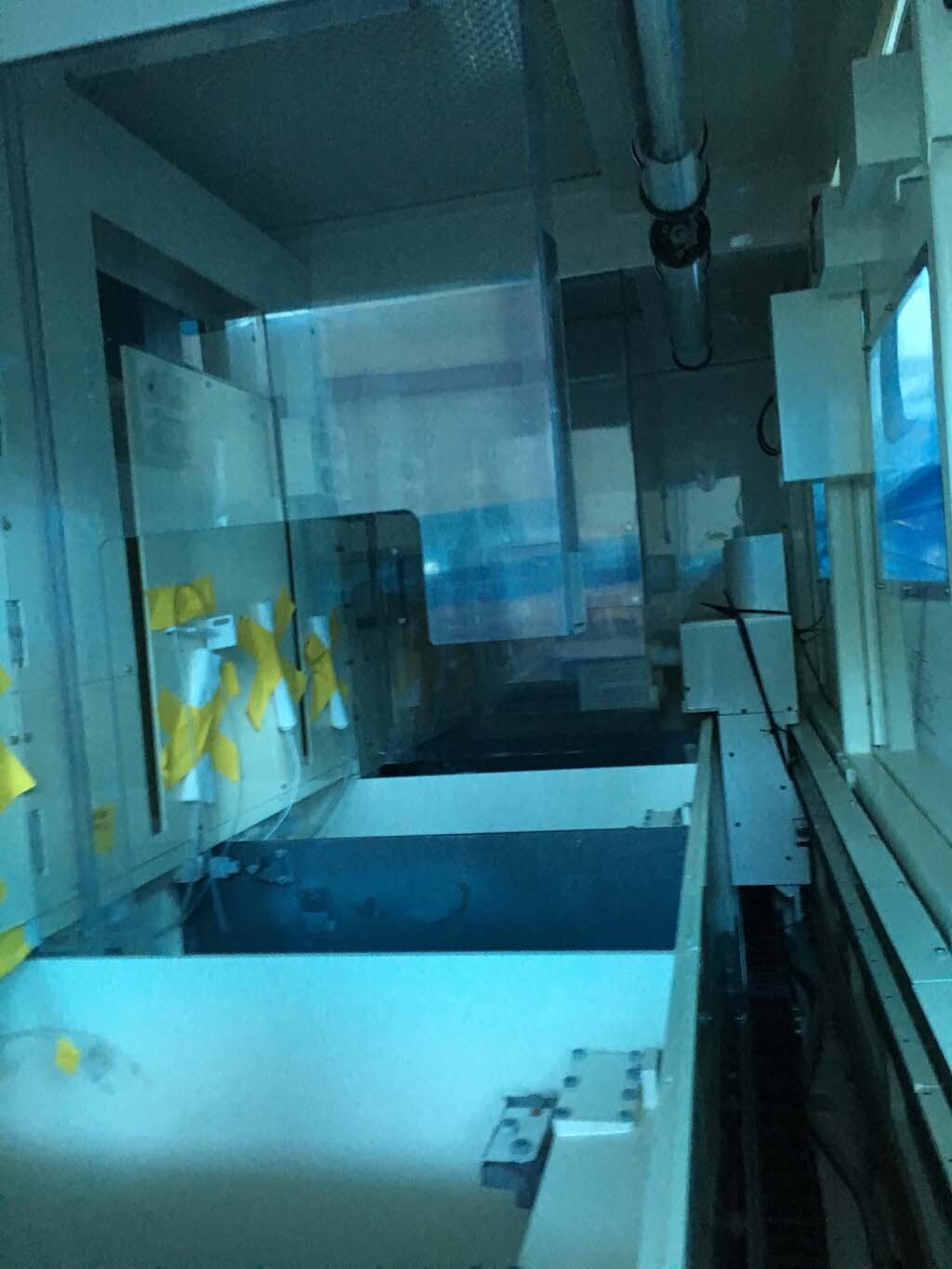

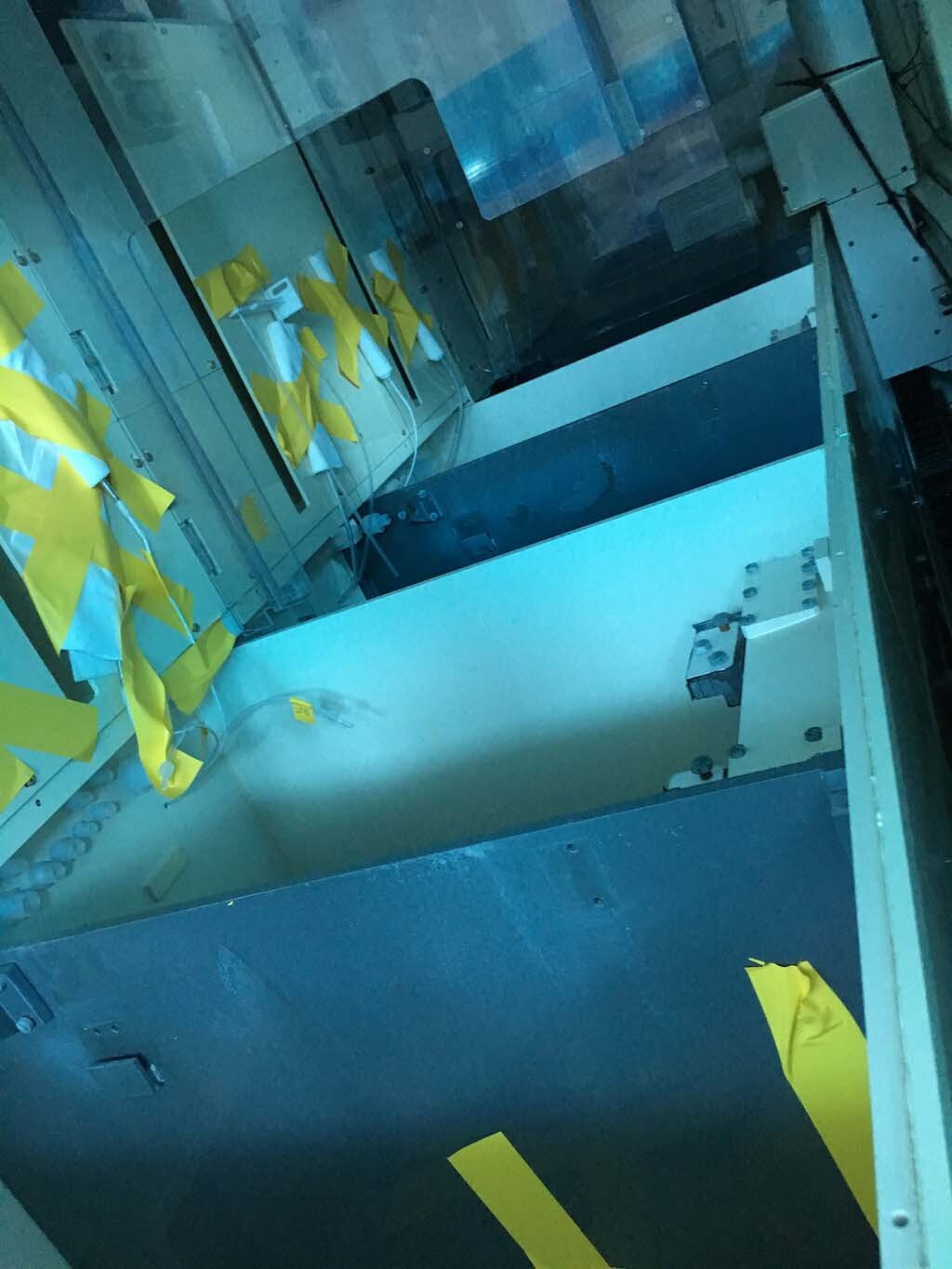

二手 TEL / TOKYO ELECTRON UW-300Z #9204046 待售

网址复制成功!

单击可缩放

ID: 9204046

晶圆大小: 12"

优质的: 2004

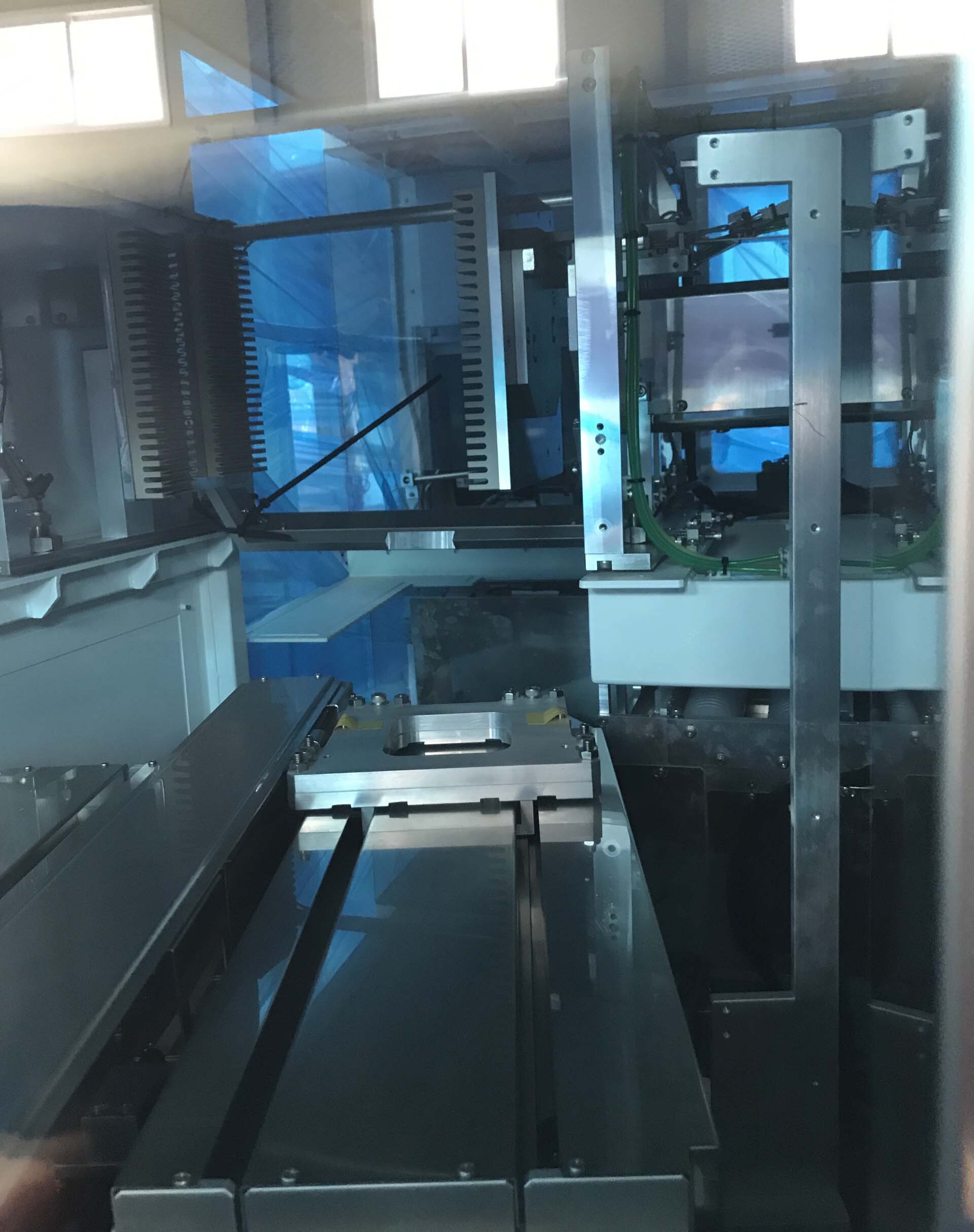

Wet station, 12"

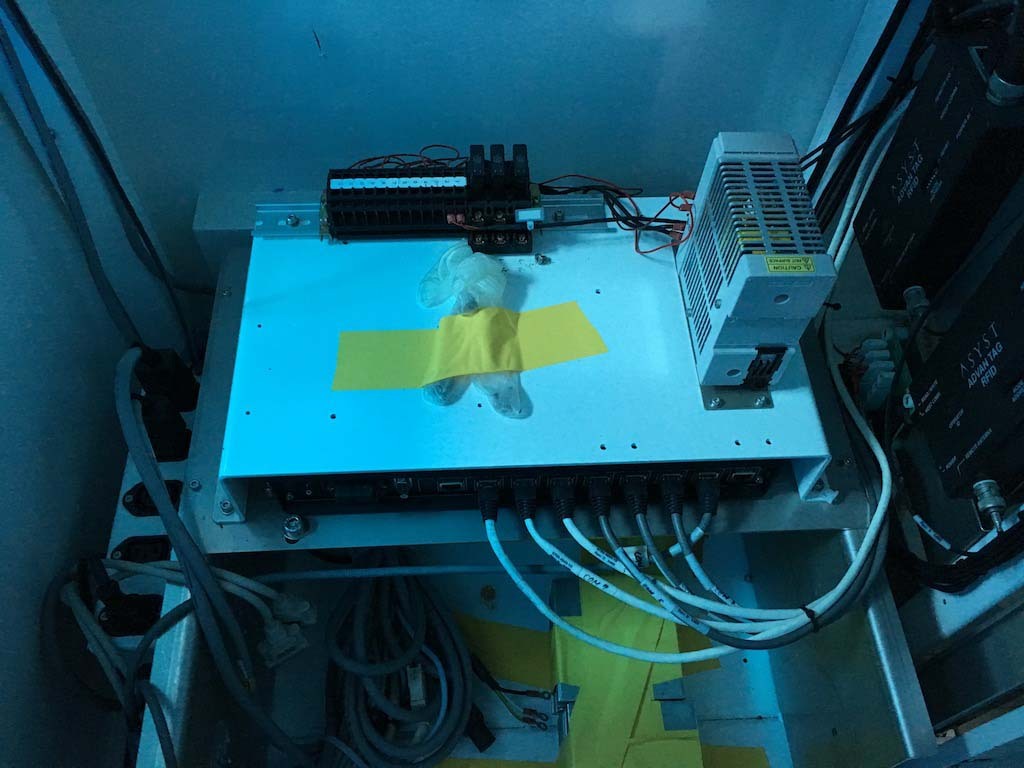

Main computer

Bath

SRM Tank

Temperature controller

Heater

Exhaust unit

FOUP Type 1: ENTEGRIS (AF3CWFAB20BUAFW)

FOUP Type 2: DAINICHI (SF300-02)

Wafer pitch: Half pitch

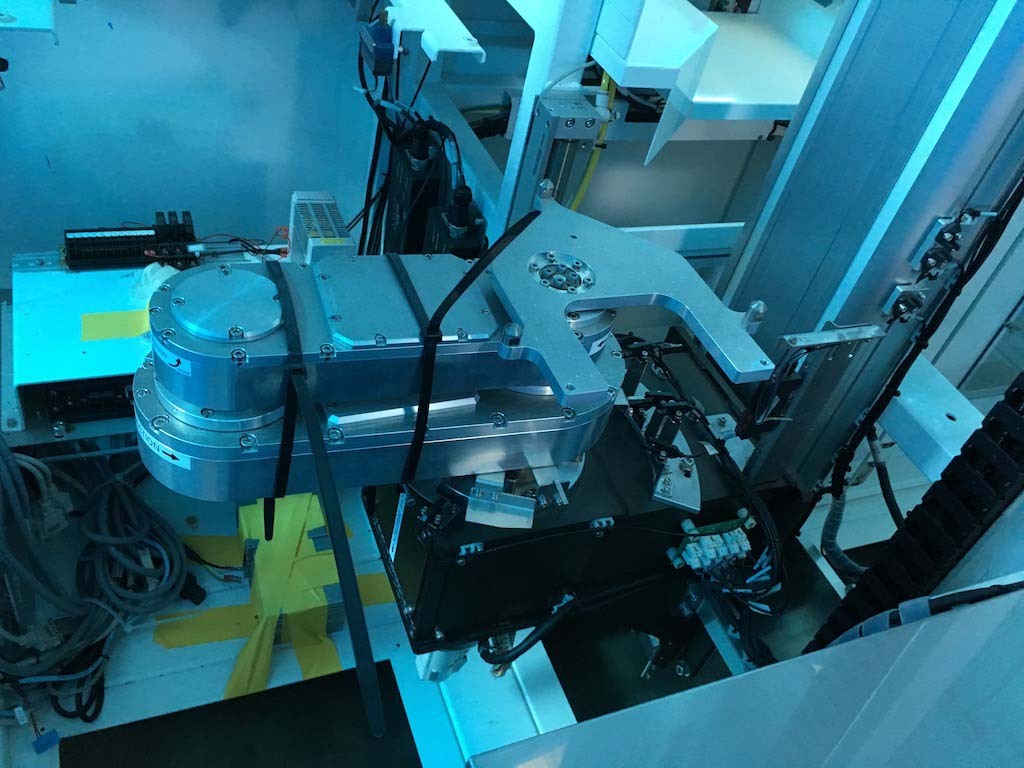

Arm

Wafer flow direction: Rear / Front

Number of wafers in process: (2) FOUP

(25) Slots FOUP

Chemical central supply

SD2 Dryer: Rinse and dry

Stocker: (12) FOUPs

Chemical:

HF

NH4OH

H2O2

HCL

IPA

O3W

Mainframe: Frame per and (2) Bath modules

Chemical bath: (4) Bath modules

Does not include CW and SD2

No factory mutual

External units:

Fire extinguisher

O3 Gas generator

No fluorescent lamp

Adjuster plate SS-304: 15 x 100 x 100 mm

Seismic bracing

Air operated valve

Display bath level sensor: Arm side and M/C

Outer panel material (C/S and SD2): SPCC

Chemical area panel material: Clear PVC

AMHS: OHT

No MMHS

FOUP ID Reader

On-line: GEM: SEMI E5 and E30

I/O Interface: HSMS to LAN (SEMI E37)

Signal tower: Front and maintenance area

CPU: PIII (600 MHz)

Operating system: Windows NT

Media: Floppy and zip

FOUP Station:

Load port:

(2) FOUP

FOUP Present sensor

Notch adjustment function

Shutter

Area sensor

KEYENCE BL601 FOUP ID Reader

FIMS Port (POD Opener):

Jump slot sensor

Wafer number and slot sensor

Carrier transfer: FOUP Check sensor

Stocker: (12) FOUPs

FFU

Location: Upper section LD / ULD (PTFE)

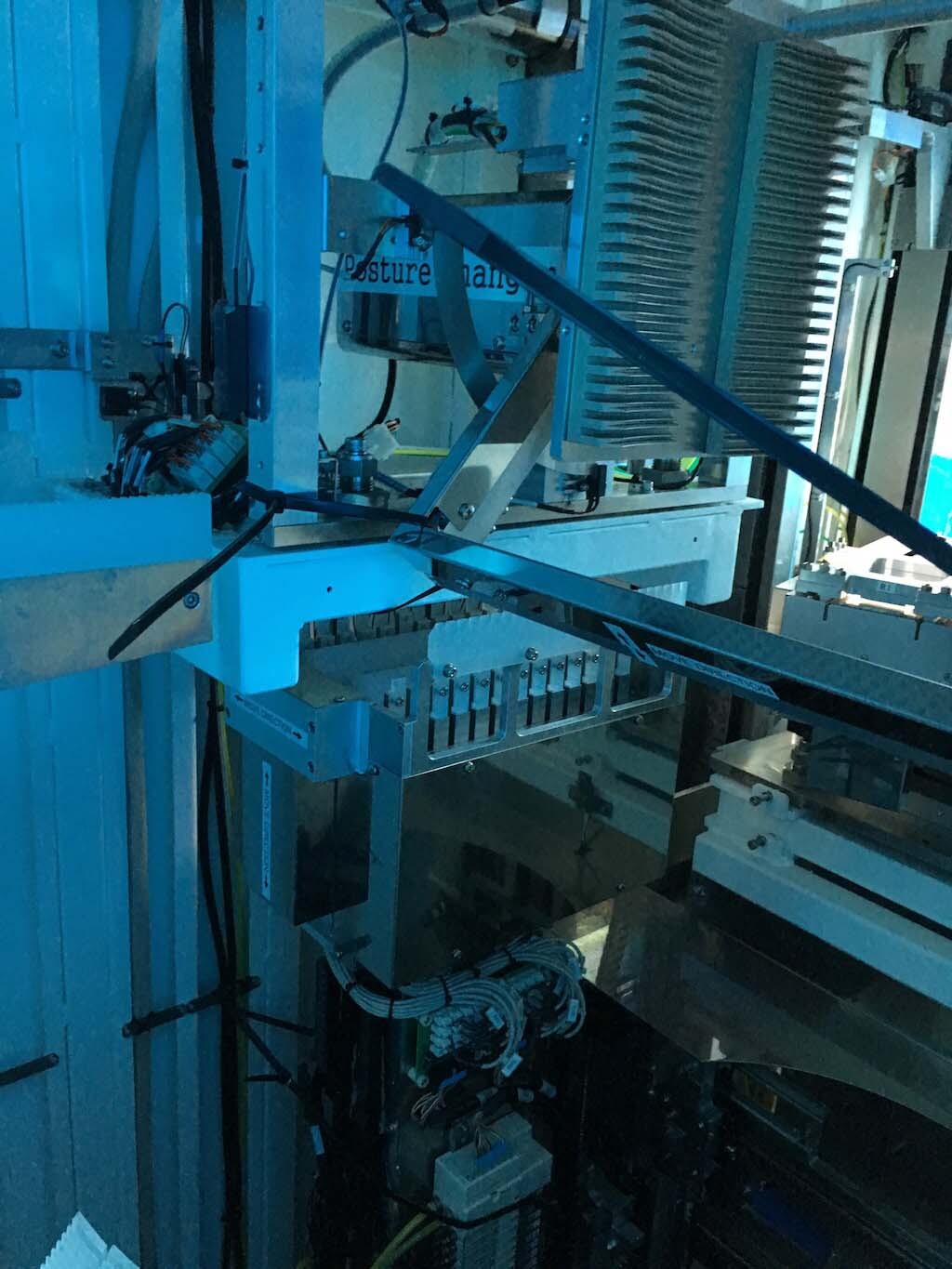

Course / Posture changer:

Pre-post changeover

Process number: 25 Wafers

LD / ULD:

Changes pre-post

Wafer hand turn function

Face to face function: (2) Carriers

Wafer hand material: PCTFE

Ionizer: 5024CE Controller

Other:

Direction access M/C media: Right side

Temporary wafer holder

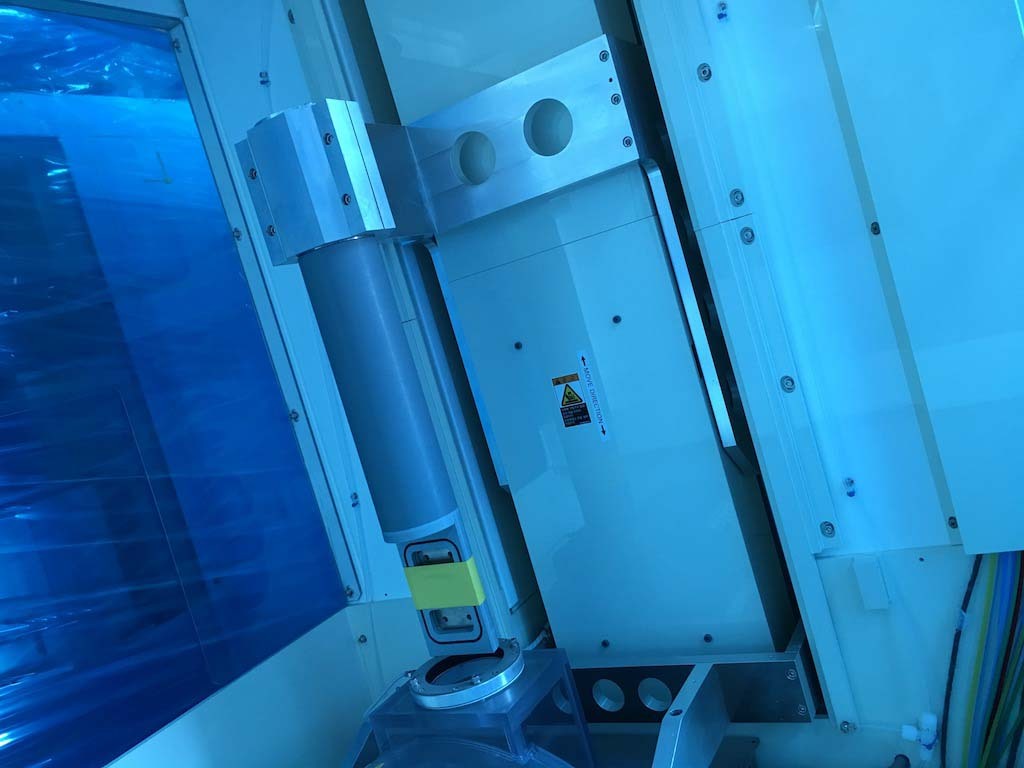

Process modules:

Module 1: SPOM

Process temperature: 80°C~140°C

Heating method: KOMATSU AIH-64QS CS Heater

Bath material: Quartz

Module 2: QDR (Hot)

Process temperature: 70°C/20°C

No hot DIW gen

Central supply

Bath material: Quartz

No MEGASONIC

DIW Shower (Hot)

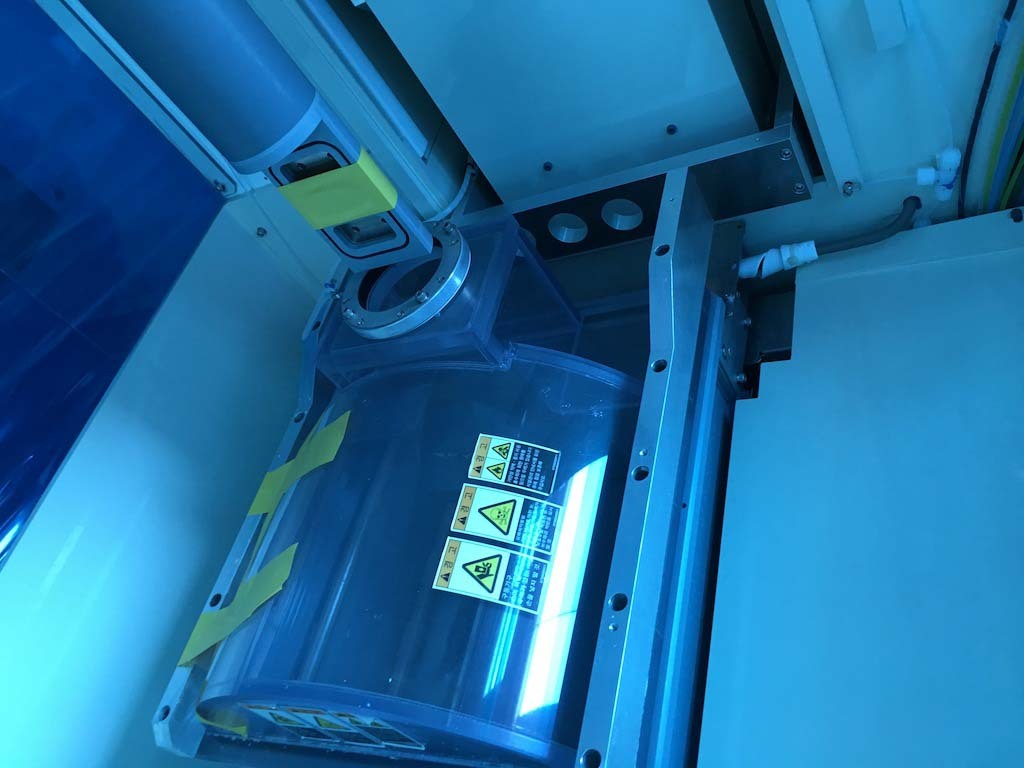

Module 3: SC1(M/S)

Process temperature: 30°C~70°C

Heating method: CS Heater with water jacket

Change mixing ration recipe

Bath material: PTFE

HORIBA CS-131 Concentration monitoring

KOKUSAI Alfa MEGASONIC, 2.4 kW

Module 4: POU

Process temperature: RT°C / Hot 70°C

No hot DIW Gen

Supplied

Bath material: Quartz

Chemical: HCL

SD2 (Rinse + dry)

Facilities:

CDA

N2

DIW

PCW

CM1: H2SO4

CM2: H2O2

CM3: NH4OH

CM4: HCL

CM5: IPA

Exhaust:

General

Solvent (SD2)

Acid (SD2, POU)

Alkali (POU, SC1)

Acid (SPOM, QDR)

Separate drains

AC Power:

EP1 (Normal): 208 VAC, 3 Phase, 125 A

EP2 (CVCF / UPS): 208 VAC, Single phase, 50 A

EP3 (CVCF): 120 VAC, 1 Phase, 5 A

2004 vintage.

TEL/TOKYO ELECTRON UW-300Z是一个用途广泛的湿式站,旨在为几乎任何类型的基材提供高端蚀刻、清洁和化学处理。TEL UW300Z采用加热的内部加热480升罐体,温度在10至75 ℃之间。这种强大的控制组合为用户提供了对湿站所有功能的精确控制,优化了化学过程。TOKYO ELECTRON UW 300Z的一个独特特征是上篮,可以用来容纳半导体晶片和其他基板,以防止它们互相接触或容器壁。这个篮子设计成可以倾斜和旋转,让使用者取得更好的处理结果。UW-300Z还可以配备多种尺寸的石英或EPDMS喷嘴,使用户能够以最高精度使用化学品。多个喷嘴可以安装在每个储罐中,允许用户在不同区域创建多个并发进程。加上循环泵,油箱保持恒温,化学应用均匀。TOKYO ELECTRON UW 300 Z还具有独特的安全系统,包括自动紧急关机开关,设计用于在紧急情况下立即关闭电源。此外,所有管道和阀门都是用不锈钢建造的,提供了一个耐腐蚀和持久的系统。总体而言,UW 300Z在广泛的化学过程中提供了卓越的性能。其高温和对化学品的严密控制为用户提供了高效可靠的系统,而其坚固的构造和安全特点则保证了长期的可靠性和安全性。使用TEL UW 300 Z,任何人都可以轻松创建精确和最佳的化学过程。

还没有评论