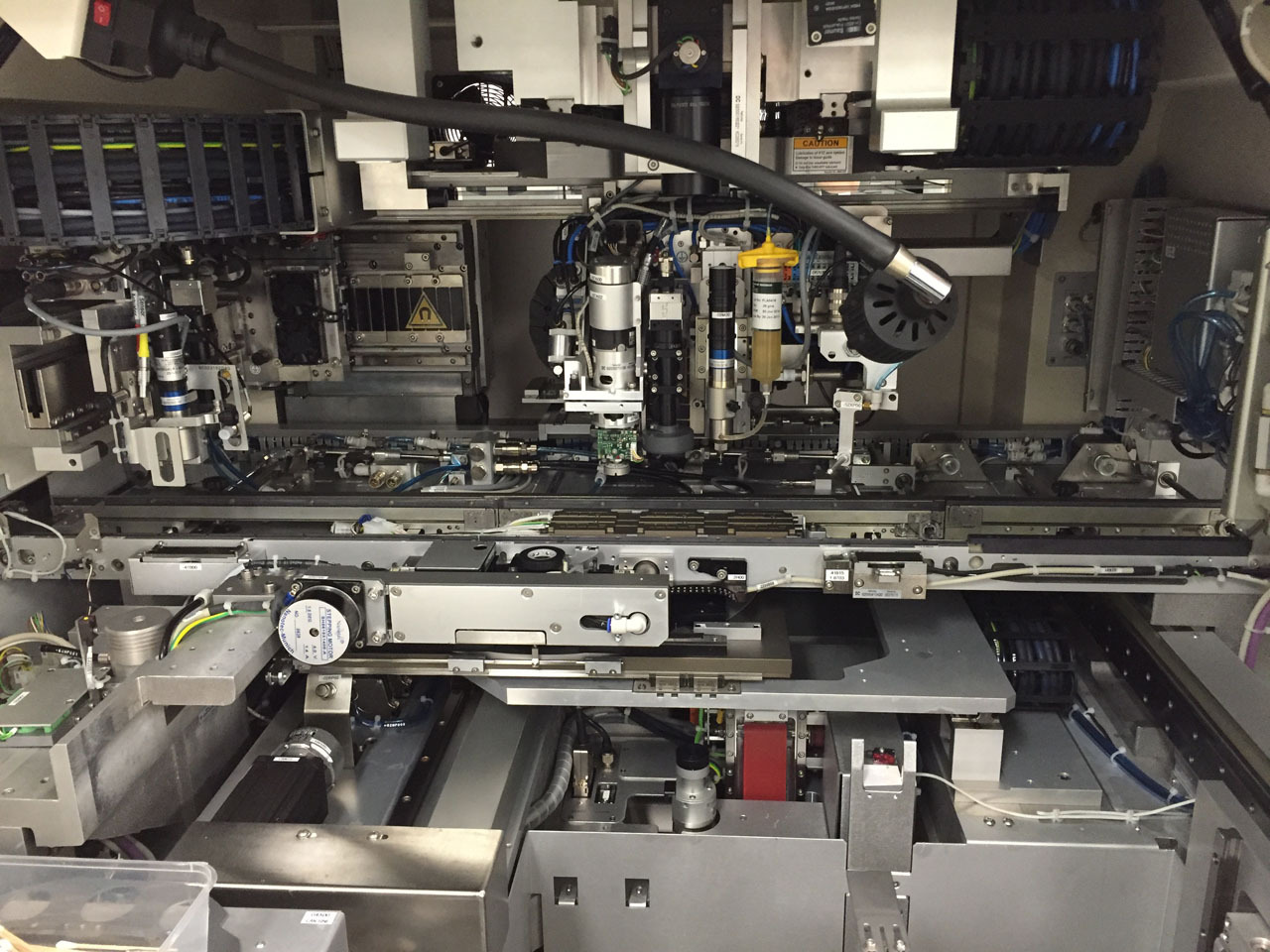

二手 DATACON / BESI 2200 Evo #9115929 待售

看起来这件物品已经卖了。检查下面的类似产品或与我们联系,我们经验丰富的团队将为您找到它。

单击可缩放

已售出

ID: 9115929

晶圆大小: 8"

优质的: 2008

Die attacher, 8"

In-line SMEMA configuration

Hard disk upgraded to SSD

Spare parts included

Equipment module:

Dynamic XYZ theta servo motors: yes

Theta axis rotary bond-head: yes

Programmable lighting systems with RGB light: yes

Datacon pattern recognition system with edge, pattern, and ink-dot recognition:

Programmable

IPU

CMOS Substrate camera/optics/illumination: Yes

Upward looking camera: Yes

Downward looking camera: Yes

Wafer camera: Yes

Programmable bond force (up to 7000 grams): Yes

Bond force sensor and mini-BMC kit: Yes

Ionizer:

Main axis: Yes

Substrate transport system:

Current transport system configuration:

Heated stage of up to 150 DC temperature

Flatboat configuration

BETS (Belt Elevation TS)

Belt classic transport system:

BETS

Component presentation system:

Wafer lifter and changer: Yes

Wafer table with stretcher: Yes

Additional frame down-holding application for 8" and 12" wafer:

Adaptor for 8"

Wafer frame adapter for automatic change: Yes

Wafer ring adapter for automatic change: Hoop ring adaptor

Waffle pack (Gel pack) holder 2":

Waffle pack adaptor

Separate gel-pack adaptor

Waffle pack (Gel pack) holder 4":

Waffle pack adaptor

Separate gel-pack adaptor

Tape and reel presentation: No

SEMS / GEMS Compliant: Capable but not activated

Input / Output system:

Magazine handler:

SMEMA Ready

I/O equipment: No

Die handling system:

Automatic tool changer unit 7-slot: Yes

Tool holders and tools:

Standard tool holder (shank and tip): Yes

Ejector system:

Single-chip ejector unit: Yes

Upgrade to multi-chip ejection carousel: Yes

Eject tool base: Yes

Needle kit: No

Epoxy application system:

Dispenser-pressure/time:

Time / Pressure

Volumetric pump

Epoxy stamping system:

Time / Pressure

Volumetric pump

Auger or positive displacement:

Configured based on solar product

Flip chip station

Automatic tool changer:

(7) Slots

Die attach

Flip chip capability

ID Axis

Jetter system: Yes

Built-in vacuum pump: Disconnected, but available

Heated stage (150°C): Yes

Vision system with up and down looking cameras

Placement accuracy: 10 µm (3 sigma)

Programmable bond force (7000 grams)

Die pick from wafer, waffle pack, gel pack - Wafer up to 12” with 8" adapter

Waffle pack / Gel-Pak® 2” x 2” and 4” x 4”

Substrate working range: 8"

ID Integrated dispenser for classic transport system

Dispenser volumetric screw pump (ID Axis)

P-Part for automatic transport system (for ID axis)

Calibration tool kit: No

208V/220V Power compatibility: 3Phase - 400V

Machine software installation disk: No

Integrated dispenser

Vision alignment

Pick & place head

X / Y Placement accuracy: ± 7 μm @ 3s

Theta placement accuracy: ± 0.15° @ 3s

Die attach: Disconnected

Heated bond head and plate

Standard bond head: 0° - 360° Rotation

Equipment operating and maintenance manual or CD-ROM: Yes

CE Marked

Currently crated

2008 vintage.

DATACON/BESI 2200 Evo是一款模具附件,设计用于在制造过程中精确放置零件。该设备采用先进的激光制导视觉系统和几台伺服电动机驱动的电动机来精确放置各部件,其高吞吐量和速度使其能够在保持最高质量的同时快速组装大量部件。BESI 2200 Evo是一款自动化模具附件,设计用于处理所有类型的组件,包括裸模、MEM设备、翻转芯片以及各种封装类型的各种其他产品。该单元由几个主要组件组成,包括控制单元、运动机器、机械拾取位置单元、视觉工具和拾取系统。控制资产负责控制电机和其他执行器,还提供与主机的通信。运动模型由两台伺服电机组成,可实现精细的运动和精度.机械拾取装置通过五个电动机轴的精度提供了很高的精度。选卡机构可确保元件从标准的13英寸全网格精确放置到各个元件。视觉设备使用机器视觉相机检测元件的存在,确定位置,并进行精确对准。最后,拾取系统由电磁体组成,允许拾取具有力场或真空杯的元件。集成微教模块大大提高了DATACON 2200 Evo的高吞吐量。操作员可以利用激光制导视觉机的坐标单元和教学装置,快速传授机器的精确路径和位置坐标。当机器被赋予基于协调工具的移动信号时,这些路径可以在极其严格的公差范围内再现。为了确保最高质量标准,2200 Evo配备了多个传感器,可跟踪装配过程中所采取的每个步骤。这包括诸如温度和振动之类的东西,允许对资产进行完整的监控。质量控制系统还会在装配完成时检查产品的一致性。总体而言,DATACON/BESI 2200 Evo是一款高效高效的模具连接器,旨在提供最高的零件放置精度和速度。通过利用先进的激光引导视觉系统和各种自动化组件,BESI 2200 Evo能够以最大的细心和一致性快速准确地生产出大量零件。

还没有评论