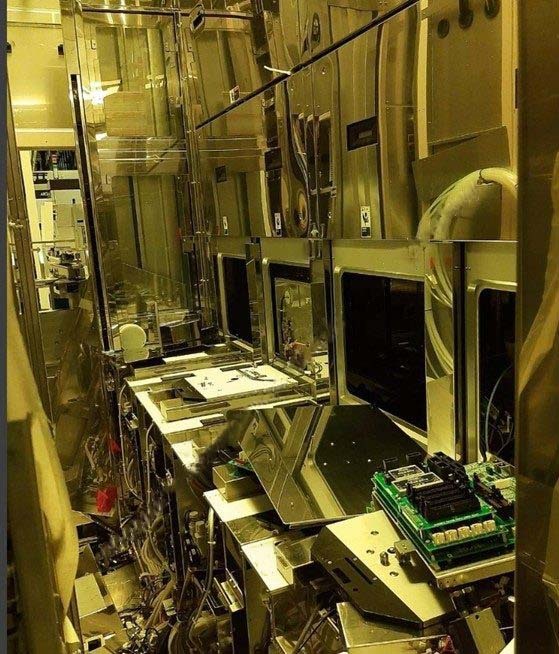

二手 TEL / TOKYO ELECTRON Clean Track ACT 12 #293604842 待售

看起来这件物品已经卖了。检查下面的类似产品或与我们联系,我们经验丰富的团队将为您找到它。

单击可缩放

已售出

ID: 293604842

晶圆大小: 12"

优质的: 2008

Coater / Developer system, 12"

AC Power box

AC Power cable: 3 Phase

SHINWA T & H

Chemical cabinet: COT + DEV

(4) Coater units

(4) Develop units

(12) LHP Units

(2) HHP Units

(9) PHP Units

(9) CPL Units

(3) ADH Units

WEE Unit

(5) PEB Units

IRA Block

CSB

TCU

Coater unit:

Unit 1:

HPT Resist pump

EBR / RRC / BSR: EBR + RRC + Back rinse

Temperature / Humidity sensor

Photo resist temperature controller

Motor flange temperature controller

Unit 2:

(5) Resist nozzles

Resist pump: HPT

EBR / RRC / BSR: EBR + RRC + Back rinse

Temp / Humidity sensor

PR Auto exchange system

Photo resist temperature controller

Motor flange temperature controller

FOC Center photo resist drain

Unit 3:

(5) Resist nozzles

Resist pump: HPT

EBR / RRC / BSR: EBR + RRC + Back rinse

Temp / Humidity sensor

PR Auto exchange system

Photo resist temperature controller

Motor flange temperature controller

FOC Center photo resist drain

Unit 4:

(5) Resist nozzles

HPT Resist pump

EBR / RRC / BSR: EBR + RRC + Back rinse

Temperature / Humidity sensor

PR Auto exchange system

Photo resist temperature controller

Motor flange temperature controller

FOC center photo resist drain

Develop unit:

Unit 1:

Spray H develop nozzle

Rinse left to right develop nozzle move

Developer temperature control

Auto damper

Auto dummy rinse

Cup type: STD DEV

Unit 2:

Spray H nozzle develop nozzle

Left to right develop nozzle

(2) Top rinses

Developer temperature control

Auto damper

Cup type: STD DEV

Unit 3:

Spray H nozzle develop nozzle

Left to right develop nozzle

(2) Top rinses

Developer temperature control

Auto damper

Auto dummy rinse

Cup type: STD DEV

Unit 4:

Spray H develop nozzle type

Left to right develop nozzle move type

(2) Top rinses

Developer temperature control

Auto damper

Auto dummy rainse

Cup type: STD DEV

Hard Disk Drive (HDD) not included

2008 vintage.

TEL/TOKYO ELECTRON Clean Track ACT 12是利用超高压清洁技术的光刻剥离设备。该系统能够去除光致抗蚀剂,而不会损坏基板,也不会产生微粒。Clean Track单元由于其超高压清洁技术,能够以最小的损坏从基板上去除光刻胶。这样可以确保基板不会因清洁过程而受损。除了超高压清洁技术外,机器还利用多种清洁机制从基板上清洗光刻胶。其中包括强大的CO2激光器、用于化学去除的雾化器、用于去除颗粒的晶圆清洁器以及用于机械作用的搅拌站。CO2激光器能够有选择地切除和去除基板上的光致抗蚀剂,而不会对底层造成损害。雾化器用于在基材上添加适当的化学溶液,溶解光刻胶并确保其被完全去除。晶圆清洁器设计用于清除清洁过程中基板上残留的任何颗粒。最后,搅拌站允许机械作用,进一步方便清洗过程。Clean Track工具还设计为提供自动化,从而实现高效和一致的结果。集成的控制资产和自动晶片处理可确保快速、准确地执行清洁过程。此外,真空泵技术还提供了较高的空气去除能力和快速干燥时间,确保从基板表面完全去除光致抗蚀剂。TEL Clean Track ACT 12模型是一种可靠高效的光敏剥离设备。它结合超高压清洁技术和其他清洁机制,为从基板上去除光刻胶提供了一个干净、准确、一致的系统。通过提供自动化、一致的结果,Clean Track单元可以帮助提高光刻工艺的效率,并使制造商能够生产更高质量的基板。

还没有评论